EN 927-10:2019

(Main)Paints and varnishes - Coating materials and coating systems for exterior wood - Part 10: Resistance to blocking of paints and varnishes on wood

Paints and varnishes - Coating materials and coating systems for exterior wood - Part 10: Resistance to blocking of paints and varnishes on wood

This document specifies a test method for determining, under specified optional conditions, whether a single-coat film or a multi-coat system of paints and varnishes on wood after a specified drying period is sufficiently dry to avoid damage when two painted surfaces or one painted surface and another surface are placed in contact under pressure and subsequently separated. The method is intended to simulate the conditions when painted articles come into contact which each other. In comparison to EN ISO 9117-2, the conditioning and parameters which influence the behaviour of wood coatings are more specific.

NOTE In some countries, the test is called a "block or blocking resistance" test.

Beschichtungsstoffe - Beschichtungsstoffe und Beschichtungssysteme für Holz im Außenbereich - Teil 10: Bestimmung der Blockfestigkeit von Beschichtungsstoffen und Beschichtungssystemen für Holz

Diese Europäische Norm legt ein Prüfverfahren, unter Normbedingungen, zur Bestimmung, ob ein Ein- oder Mehrschichtsystem von Beschichtungsstoffen auf Holz nach einer festgelegten Trocknungsdauer ausreichend trocken ist, um Beschädigungen zu vermeiden, wenn zwei beschichtete Flächen oder eine beschichtete Fläche und eine andere Fläche unter Druck Kontakt miteinander haben und danach getrennt werden, fest. Das Verfahren ist dafür vorgesehen, die Bedingungen, wenn beschichtete Gegenstände miteinander Kontakt haben, zu simulieren. Im Vergleich zu EN ISO 9117 2 sind die Konditionierung und die Parameter, die das Leistungsverhalten von Holzbeschichtungen beeinflussen, spezifischer.

ANMERKUNG In einigen Ländern wird die Prüfung "Blockfestigkeitsprüfung" genannt.

Peintures et vernis - Produits de peinture et systèmes de peinture pour le bois en extérieur - Partie 10 : Résistance au blocage des peintures et vernis sur bois

La présente Norme européenne spécifie une méthode d’essai permettant de déterminer, dans les conditions normales, si un feuil monocouche ou un système multi-couches de peintures et vernis sur bois, après une durée spécifiée de séchage, est suffisamment sec pour ne pas être endommagé lorsque deux surfaces peintes ou une surface peinte et une autre surface sont placées en contact sous pression avant d’être séparées. La méthode est destinée à simuler les conditions auxquelles sont soumis des articles peints lorsqu’ils entrent en contact les uns avec les autres. Comparé à l’EN ISO 9117 2, le conditionnement et les paramètres qui influencent le comportement des revêtements pour bois sont plus spécifiques.

NOTE Dans certains pays, l’essai est appelé « essai de résistance au blocage » ou « essai de résistance à l’adhérence ».

Barve in laki - Premazi in premazni sistemi za zaščito lesa za zunanjo uporabo - 10. del: Odpornost filmov premazov proti medsebojnemu zlepljanju

Ta evropski standard določa metodo preskusa za določanje, pri standardnih pogojih, ali se enojni film ali večplastni sistem barv in lakov za les po določenem času sušenja dovolj posušijo, da se lahko izognemo škodi, ko sta dve pobarvani ploskvi ali ena pobarvana ploskev in druga ploskev v stiku pod tlakom in naknadno ločeni. Ta metoda je namenjena simulaciji pogojev, ko so pobarvani izdelki v stiku drug z drugim. V primerjavi s standardom EN ISO 9117 2 sta priprava in podatki, ki vplivajo na vedenje premazov za les, bolj specifični.

OPOMBA: V nekaterih državah se preskus imenuje preskus »odpornosti proti zlepljenju«.

General Information

- Status

- Published

- Publication Date

- 30-Apr-2019

- Withdrawal Date

- 29-Nov-2019

- Technical Committee

- CEN/TC 139 - Paints and varnishes

- Drafting Committee

- CEN/TC 139/WG 2 - Coating systems for wood

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 30-May-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 08-May-2019

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 927-10:2019 - Paints and varnishes: Coating materials and coating systems for exterior wood - Part 10: Resistance to blocking of paints and varnishes on wood is a CEN test standard that defines a reproducible laboratory method to determine whether a single-coat film or multi‑coat system on wood is sufficiently dry to avoid damage when two painted surfaces (or one painted and another substrate) are pressed together and then separated. Often called a blocking or block resistance test, the method simulates real-world contact conditions (e.g., stacked panels, windows and doors in contact) and is more specific for wood coatings than EN ISO 9117-2.

Key topics and requirements

- Scope and principle: Apply coating(s) to test panels, allow specified drying, press coated faces together under defined load, conditioning and climate, then separate and assess damage.

- Substrates: Defined substrate options include:

- s1 - Spruce (Picea abies) with controlled growth‑ring orientation and density (example: 3–8 rings/10 mm; density range given in the standard).

- s2 - Other wood species or pre-coated specimens for customer‑specific needs.

- s3 - Inert substrate (PVC film free of migrating plasticizers) for non‑absorbing comparisons.

- s4 - Other plane substrates (e.g., plywood).

- Apparatus and climatic control: Weights to produce specified pressure; oven or climatic chamber for conditioning (standard examples in the text include ovens controlled at 50 ±2 °C or 60 ±2 °C).

- Application and film thickness: Application methods (brush, roller, spray) per manufacturer specs; dry film thickness measured per referenced methods.

- Drying, conditioning and loading regimes: Specified drying intervals and climate conditions before, during and after loading to reflect realistic exposure.

- Evaluation and reporting: Post‑test inspection for damage, criteria for pass/fail, and required information for a complete test report. Precision data and annexes provide supplementary guidance.

Practical applications and users

- Who uses EN 927-10:2019: Paint and varnish manufacturers, wood‑coating formulators, independent test laboratories, quality control teams, specifiers, and manufacturers of exterior wood products (windows, doors, joinery, cladding).

- Why use it: To verify blocking resistance of exterior wood coatings, set performance specifications, support product development (formulation, overcoating intervals), and reduce field failures caused by stuck surfaces during storage, transport or installation.

Related standards

- EN 927-1 (classification and selection for exterior wood coatings)

- EN ISO 1513 (sample examination and preparation)

- EN ISO 2808 (film thickness determination)

- EN ISO 15528 (sampling)

- ISO 554 (standard atmospheres for conditioning/testing)

Keywords: EN 927-10:2019, resistance to blocking, blocking resistance test, paints and varnishes, exterior wood coatings, wood coating testing, block test.

Frequently Asked Questions

EN 927-10:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Paints and varnishes - Coating materials and coating systems for exterior wood - Part 10: Resistance to blocking of paints and varnishes on wood". This standard covers: This document specifies a test method for determining, under specified optional conditions, whether a single-coat film or a multi-coat system of paints and varnishes on wood after a specified drying period is sufficiently dry to avoid damage when two painted surfaces or one painted surface and another surface are placed in contact under pressure and subsequently separated. The method is intended to simulate the conditions when painted articles come into contact which each other. In comparison to EN ISO 9117-2, the conditioning and parameters which influence the behaviour of wood coatings are more specific. NOTE In some countries, the test is called a "block or blocking resistance" test.

This document specifies a test method for determining, under specified optional conditions, whether a single-coat film or a multi-coat system of paints and varnishes on wood after a specified drying period is sufficiently dry to avoid damage when two painted surfaces or one painted surface and another surface are placed in contact under pressure and subsequently separated. The method is intended to simulate the conditions when painted articles come into contact which each other. In comparison to EN ISO 9117-2, the conditioning and parameters which influence the behaviour of wood coatings are more specific. NOTE In some countries, the test is called a "block or blocking resistance" test.

EN 927-10:2019 is classified under the following ICS (International Classification for Standards) categories: 87.040 - Paints and varnishes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 927-10:2019 has the following relationships with other standards: It is inter standard links to CEN/TS 16499:2013, EN ISO 1513:2010, EN ISO 2808:2019, EN 927-1:2013, EN 915:1996, EN ISO 15528:2020, EN 927-2:2022, EN 927-2:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 927-10:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2019

Nadomešča:

SIST-TS CEN/TS 16499:2014

Barve in laki - Premazi in premazni sistemi za zaščito lesa za zunanjo uporabo - 10.

del: Odpornost filmov premazov proti medsebojnemu zlepljanju

Paints and varnishes - Coating materials and coating systems for exterior wood - Part

10: Resistance to blocking of paints and varnishes on wood

Beschichtungsstoffe - Beschichtungsstoffe und Beschichtungssysteme für Holz im

Außenbereich - Bestimmung der Blockfestigkeit

Peintures et vernis - Produits de peinture et systèmes de peinture pour le bois en

extérieur - Résistance au blocage des peintures et vernis sur bois

Ta slovenski standard je istoveten z: EN 927-10:2019

ICS:

71.100.50 Kemikalije za zaščito lesa Wood-protecting chemicals

87.040 Barve in laki Paints and varnishes

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 927-10

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2019

EUROPÄISCHE NORM

ICS 87.040 Supersedes CEN/TS 16499:2013

English Version

Paints and varnishes - Coating materials and coating

systems for exterior wood - Part 10: Resistance to blocking

of paints and varnishes on wood

Peintures et vernis - Produits de peinture et systèmes Beschichtungsstoffe - Beschichtungsstoffe und

de peinture pour le bois en extérieur - Partie 10 : Beschichtungssysteme für Holz im Außenbereich - Teil

Résistance au blocage des peintures et vernis sur bois 10: Bestimmung der Blockfestigkeit von

Beschichtungsstoffen und Beschichtungssystemen für

Holz

This European Standard was approved by CEN on 16 December 2018.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 927-10:2019 E

worldwide for CEN national Members.

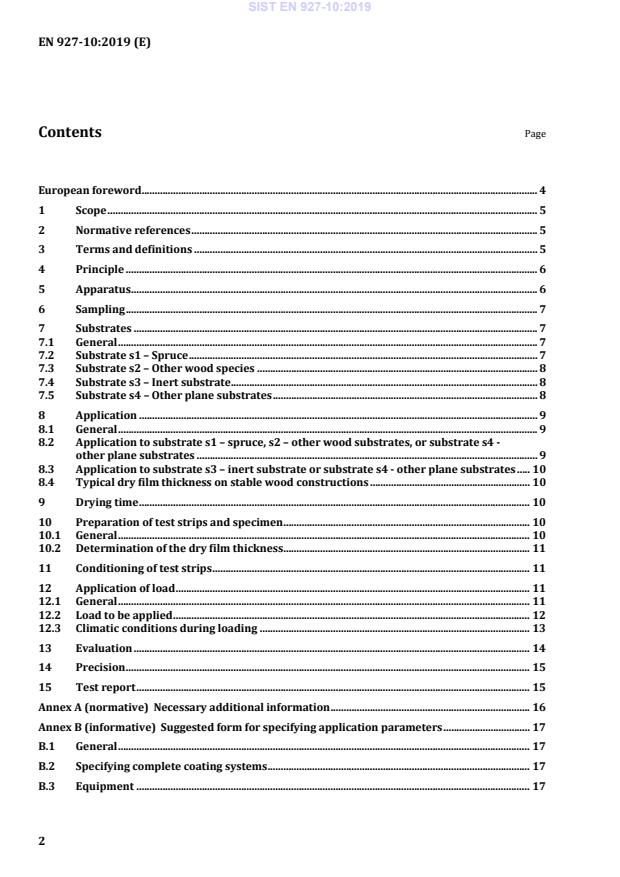

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Principle . 6

5 Apparatus . 6

6 Sampling . 7

7 Substrates . 7

7.1 General . 7

7.2 Substrate s1 – Spruce . 7

7.3 Substrate s2 – Other wood species . 8

7.4 Substrate s3 – Inert substrate . 8

7.5 Substrate s4 – Other plane substrates . 8

8 Application . 9

8.1 General . 9

8.2 Application to substrate s1 – spruce, s2 – other wood substrates, or substrate s4 -

other plane substrates . 9

8.3 Application to substrate s3 – inert substrate or substrate s4 - other plane substrates . 10

8.4 Typical dry film thickness on stable wood constructions . 10

9 Drying time . 10

10 Preparation of test strips and specimen . 10

10.1 General . 10

10.2 Determination of the dry film thickness . 11

11 Conditioning of test strips . 11

12 Application of load . 11

12.1 General . 11

12.2 Load to be applied . 12

12.3 Climatic conditions during loading . 13

13 Evaluation . 14

14 Precision . 15

15 Test report . 15

Annex A (normative) Necessary additional information . 16

Annex B (informative) Suggested form for specifying application parameters . 17

B.1 General . 17

B.2 Specifying complete coating systems . 17

B.3 Equipment . 17

B.4 Process . 17

B.5 Spreading rate. 17

B.6 Flash-off . 17

B.7 Drying and curing . 18

B.8 Overcoating intervals . 18

B.9 Sanding . 18

B.10 Examples for specifying application parameters. 18

Bibliography . 22

European foreword

This document (EN 927-10:2019) has been prepared by Technical Committee CEN/TC 139 “Paints and

varnishes”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by November 2019, and conflicting national standards

shall be withdrawn at the latest by November 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes CEN/TS 16499:2013.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

1 Scope

This document specifies a test method for determining, under specified optional conditions, whether a

single-coat film or a multi-coat system of paints and varnishes on wood after a specified drying period is

sufficiently dry to avoid damage when two painted surfaces or one painted surface and another surface

are placed in contact under pressure and subsequently separated. The method is intended to simulate

the conditions when painted articles come into contact which each other. In comparison to

EN ISO 9117-2, the conditioning and parameters which influence the behaviour of wood coatings are

more specific.

NOTE In some countries, the test is called a “block or blocking resistance” test.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 927-1, Paints and varnishes - Coating materials and coating systems for exterior wood - Part 1:

Classification and selection

EN ISO 1513, Paints and varnishes - Examination and preparation of test samples (ISO 1513)

EN ISO 2808, Paints and varnishes - Determination of film thickness (ISO 2808)

EN ISO 15528, Paints, varnishes and raw materials for paints and varnishes - Sampling (ISO 15528)

ISO 554, Standard atmospheres for conditioning and/or testing - Specifications

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1

blocking

unwanted adhesion between two surfaces, at least one of which has been coated, when they are left in

contact under load after a given drying period

Note 1 to entry: Blocking does not apply to bonding of coated surfaces after insufficient drying.

Note 2 to entry: In practice, blocking can occur if coated wood panels are stacked on each other or on windows

and doors if the frames are in direct contact with the faces. Blocking depends on temperature and load (pressure).

Note 3 to entry: The term blocking is also sometimes used to describe agglomerated caked powder.

Note 4 to entry: Unwanted adhesion can lead to damage upon separation.

[SOURCE: EN ISO 4618:2014, 2.30, modified – added Notes to entry.]

3.2

load

mass needed to achieve a suitable test pressure

Note 1 to entry: High temperature and humidity increase the stress at a given load. The application method, film

thickness, drying conditions and climatic conditions should also be taken into account.

3.3

after tack

property of a film to remain sticky after normal drying or curing

Note 1 to entry: The term after tack can also mean a subjectively stickiness of the surface (“finger tack” or

“surface tack”). This effect however might not necessarily be related to blocking.

[SOURCE: EN ISO 4618:2014, 2.10, modified – added Note 1 to entry.]

3.4

stable mass

mass achieved when the difference between two subsequent weighings within 24 h does not exceed

0,2 %

[SOURCE: EN 927-5:2006, 3.3]

3.5

stackability

resistance to damage due to unwanted adhesion between adjacent surfaces of articles that develops

when these articles are left in contact

[SOURCE: EN ISO 9117-2:2010, 3.1]

4 Principle

The coating material or the coating system under test is applied on test panels or cut strips under

specified conditions. After specified drying time and under specified climatic conditions, the two test

panels or cut stripes are placed crosswise in contact with each other. This assembly is subsequently

placed in a test apparatus to be subjected to a specified load under specified climatic conditions. After a

specified period of time, the load is removed and the test panels manually separated under specific

climatic conditions and the contact areas examined for any damage to the coating in the area of contact.

5 Apparatus

5.1 Weights, of a mass which correspond to the requirements of 12.2.

5.2 Oven or conditioning chamber, depending on the selected climatic conditions during load (see

Clause 11 or 12.3):

— oven of appropriate size, controlled at a temperature of (50 ± 2) °C or (60 ± 2) °C;

— climatic conditioning chamber where the selected climatic conditions can be achieved.

5.3 Tools for application on test specimen s1, s2, s4, (e.g. roller, brush, spray equipment)

depending on the paint manufacturer's specification.

6 Sampling

Take a representative sample of the product to be tested (or of each product in the case of a multi-coat

system), in accordance with EN ISO 15528. Examine and prepare each sample for testing in accordance

with EN ISO 1513.

7 Substrates

7.1 General

Depending on the specimens provided for use, different application methods can be required (see

Table 1).

Table 1 — Substrate

Substrate (s) Type Description Recommended use

Standard test method

Spruce (Picea abies) to check a coating

s1 Wood

(see 7.2) system or an individual

top coat

Individual wood

species on customer-

Any wood species specific requirement

s2 Other wood substrates

(see 7.3) (e.g. a coated test

specimen from which

test panels can be cut)

Lab test method to

compare different top

coats (simulation of the

s3 Inert substrate PVC-foil (see 5.3)

blocking behaviour on

not absorbing

substrates)

Lab test method to

E.g. plywood according compare different

s4 Other plane substrates

to EN 636 coating materials or

coating systems

7.2 Substrate s1 – Spruce

The wood shall be spruce (Picea abies) that has been selected to be free from knots and cracks, to be

straight-grained and of normal growth rate (i.e. between 3 and 8 annual rings per 10 mm).

The panels shall be planed all round to a smooth and uniform finish. The inclination of the growth rings

to the test face shall be (45 ± 10)°. See Figure 1. The wood shall be free from blue stain and evidence of

surface or bulk infection. Abnormal porosity shall be avoided. Condition the wood prior to conversion

into test panels in accordance with ISO 554 at (20 ± 2) °C and a relative humidity of (65 ± 5) %. The

density of the wood shall be between 0,4 g/cm3 and 0,5 g/cm3 when measured at an equilibrium

moisture content at standard climate in accordance with ISO 554 at (20 ± 2) °C and a relative humidity

of (65 ± 5) %.

Key

1 front of panel (test face)

a min. 3, max. 8 growth rings per 10 mm (applies for the whole panel)

α angle of growth rings to test face min. 35°, max. 55°

Figure 1 — Selection of wood

7.3 Substrate s2 – Other wood species

In case of customer-specific requirements or if it might be assumed that other types of wood might give

a different result an alternative wood species should be used as substrate. It is also an option for

manufacturers to provide an already coated test specimen from which test panels can be cut. The

chosen panel shall be precisely described in the test report. The surface of the specimens provided shall

be plane. The test substrate shall be conditioned until constant mass at standard conditions according

to ISO 554 [(20 ± 2) °C and (65 ± 5) % relative humidity].

7.4 Substrate s3 – Inert substrate

7.4.1 Test panels (“strips”) made of polyvinyl chloride (PVC) film free of migrating plasticizers, of

sufficient rigidity to ensure a flat surface, impervious to and unaffected by water or aliphatic organic

solvents and of nominal thickness 0,25 mm. Other types of plastics film might be used where the coating

material contains solvents which can adversely affect the PVC film. If the coating delaminates from the

substrate before or during the test, another, more suitable substrate should be used.

NOTE PVC foils can have different properties on the two sides, only one of the sides being intended for

coating.

7.4.2 Film applicator, preferably automatic, used at an application speed of 10 mm/s to 15 mm/s and

fitted with a doctor blade (see 8.3) with an appropriate gap clearance and a gap width of at least 60 mm.

7.4.3 Use cutting knife, metal template or straight-edge ruler to cut the foils.

7.5 Substrate s4 – Other plane substrates

The selected substrate should be precisely described in the test report. Alternatives that may be used

include absorbing substrates (e.g. plywood) as well as non absorbing substrates (e.g. glass, aluminium,

coated paper, polymer panels). Absorbing substrates should be conditioned until achieving constant

mass at standard conditions according to EN 23270 [(23 ± 2) °C and (50 ± 5) % relative humidity].

8 Application

8.1 General

Depending on the specimens provided for use, a different type of application might be required (see

Table 2).

Table 2 — Type of application

Substrate (s) Type Description Recommended

application

s1 Wood Spruce (Picea abies) According to

(see 7.2) manufacturer's

specification

s2 Other wood species Any wood species According to

(see 7.3) manufacturer's

specification or

customer's

specification

Optional use of already

coated test specimen

from which test panels

can be cut

s3 Inert substrate PVC-foil (see 5.3) Application of the top

coat to be investigated

in a dry film thickness

related to practice, by

means of a film

applicator

s4 Other plane substrates E.g. plywood according According to

to EN 636 manufacturer's

specification,

customer's

specification or by

application of the top

coat to be investigated

in a dry film thickness

related to practice, by

means of a film

applicator

8.2 Application to substrate s1 – spruce, s2 – other wood substrates, or substrate s4 -

other plane substrates

If nothing else is specified by the manufacturer of the coating system, the conditioned, planed wood

specimens (test panels), shall be manually sanded with abrasive paper (180 grade) just before

application. Dust shall be removed completely. The test panels are coated with the coating system to be

tested, closely following manufacturer's instructions or specification. Examples of possible suitable

application methods and their specification are given in Annex B.

8.3 Application to substrate s3 – inert substrate or substrate s4 - other plane substrates

Use an automatic film applicator fitted with a d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...