FprEN 16881

(Main)Food processing machinery - Pasteurizers, vats and cream cookerss - Safety and hygiene requirements

Food processing machinery - Pasteurizers, vats and cream cookerss - Safety and hygiene requirements

This European Standard applies to discontinuous pasteurizers and cream cookers for ice cream mixes, pasty liquid products for gelato, pastry, chocolate and food processing, as described in 3.2.

This European Standard applies to fixed and movable artisan machinery (not designed to be moved during operation), with a capacity of not more than 600 l.

This European Standard deals with all significant hazards, hazardous situations and events relevant to the machinery, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4).

This European Standard deals with the hazards which can arise during transport, assembly, commissioning, operation, cleaning, use, maintenance, decommissioning, dismantling, disabling and scrapping of the machine.

This European Standard covers the following types of machines:

- pasteurizers;

- ageing vats;

- cream cookers.

This European Standard is not applicable for pasteurizers and cream cookers without cooling systems.

This European Standard does not give requirements for heating and cooling equipment.

This European Standard is not applicable to machines which are manufactured before the date of publication of this European Standard by CEN.

Nahrungsmittelmaschinen - Pasteurisiergeräte, Bottiche und Eismaschinen - Sicherheits- und Hygieneanforderungen

Diese Europäische Norm gilt für diskontinuierliche Pasteurisiergeräte und Eismaschinen zur Verarbeitung von Eiskremmix, dickflüssigen Produkten für Eis, Teig und Schokolade sowie zur Lebensmittelverarbeitung, wie in 3.2 beschrieben.

Diese Europäische Norm gilt für fest installierte und ortsveränderliche Handwerksmaschinen (die nicht dazu bestimmt sind, während des Betriebs bewegt zu werden), mit einem Fassungsvermögen von nicht mehr als 600 l.

Diese Europäische Norm behandelt alle signifikanten Gefährdungen, gefahrbringende Situationen und Ereignisse, die auf diese Maschinen zutreffen, wenn sie bestimmungsgemäß und unter Bedingungen von durch den Hersteller vernünftigerweise vorhersehbaren Fehlanwendungen verwendet werden.

Diese Europäische Norm behandelt die Gefährdungen, die während Transport, Montage, Inbetriebnahme, Betrieb, Reinigung, Verwendung, Instandhaltung, Außerbetriebnahme, Demontage, Außerbetriebsetzung und Verschrottung der Maschine auftreten können.

Diese Europäische Norm deckt die folgenden Arten von Maschinen ab:

- Pasteurisiergeräte;

- Reifebottiche;

- Eismaschinen (Cremekocher).

Diese Europäische Norm gilt nicht für Pasteurisiergeräte und Eismaschinen ohne Kühlsystem.

Diese Europäische Norm stellt keine Anforderungen an Heiz und Kühlgeräte.

Diese Europäische Norm gilt nicht für Maschinen, die vor deren Veröffentlichung durch CEN hergestellt wurden.

Machines pour les produits alimentaires - Pasteurisateurs, cuves et cuiseurs de crème - Prescriptions relatives à la sécurité et l'hygiène

La présente Norme européenne s'applique aux pasteurisateurs discontinus et cuiseurs de crème pour les mélanges de crème glacée, produits liquides pâteux destinés à la fabrication de glaces artisanales, pâtisseries, chocolats et autres produits alimentaires, telles que décrits en 3.2.

La présente Norme européenne s'applique aux machines artisanales fixes et mobiles (non conçues pour être déplacées en cours de fonctionnement) d'une capacité inférieure ou égale à 600 l.

La présente Norme européenne traite de tous les phénomènes dangereux, situations et événements dangereux significatifs applicables aux machines lorsqu'elles sont utilisées normalement et dans les conditions de mauvais usage raisonnablement prévisible par le fabricant (voir Article 4).

La présente Norme européenne traite des phénomènes dangereux qui peuvent survenir pendant le transport, l'assemblage, la mise en service, le fonctionnement, le nettoyage, l'utilisation, la maintenance, la mise hors service, le démontage et la mise au rebut de la machine.

La présente Norme européenne couvre les types de machines suivants :

- les pasteurisateurs ;

- les cuves de maturation ;

- les cuiseurs de crème.

La présente Norme européenne ne s'applique pas aux pasteurisateurs et cuiseurs de crème dépourvus de systèmes de refroidissement.

La présente Norme européenne ne donne aucune prescription relative aux équipements de chauffage et de refroidissement.

La présente Norme européenne ne s’applique pas aux machines fabriquées avant la date de publication de la présente Norme européenne par le CEN.

Stroji za predelavo hrane - Pasterizatorji, kadi in kuhalniki za pripravo kreme - Varnostne in higienske zahteve

General Information

- Status

- Not Published

- Technical Committee

- CEN/TC 153 - Food processing machinery - Safety and hygiene specifications

- Drafting Committee

- CEN/TC 153/WG 6 - Artisan ice cream machinery

- Current Stage

- 5098 - Decision to abandon - Formal Approval

- Start Date

- 29-Sep-2021

- Completion Date

- 11-Feb-2026

Overview

FprEN 16881 - published by CEN - specifies safety and hygiene requirements for discontinuous pasteurizers, ageing vats and cream cookers used in small-scale food production (ice‑cream mixes, gelato, pastry, chocolate and similar pasty liquid products). The standard applies to fixed and movable artisan machinery (not intended to be moved during operation) with a rated capacity of not more than 600 l. It addresses hazards throughout the machine lifecycle (transport, assembly, commissioning, operation, cleaning, maintenance, decommissioning, dismantling and scrapping).

Key scope limits:

- Covers: pasteurizers, ageing vats, cream cookers (with cooling systems).

- Excludes: machines without cooling systems, heating/cooling equipment specification, and machines manufactured before the date of publication.

Key Topics and Requirements

FprEN 16881 is a type C machine standard (per EN ISO 12100) and complements general hygiene standards for food machinery. Major technical areas include:

- Risk identification and hazardous zones: identification of mechanical, electrical, thermal, noise, ergonomic and hygiene hazards; zoned access considerations (e.g., lid-to-hopper trapping points, rotating device feed openings, draw‑off openings).

- Mechanical safety: guarding, prevention of crushing and entrapment, loss of stability/tipping prevention.

- Electrical safety: protection against electric shock, EMC considerations, emergency stop, prevention of unexpected start‑up, enclosure IP ratings.

- Thermal safety: safe handling of hot surfaces and fluids.

- Hygiene and cleanability: materials of construction, surface finishes, design principles to ensure effective cleaning, sanitation and disinfection; includes normative annexes on cleanability and testing disinfection/pasteurization processes.

- Noise and ergonomics: guidance on noise testing, ergonomic design to reduce operator risk and strain.

- Documentation and verification: required instruction handbook, service manual, cleaning instructions, marking and verification/validation of safety and hygiene measures.

Applications and Who Uses It

FprEN 16881 is intended for:

- Manufacturers and machine designers of small-capacity pasteurizers, vats and cream cookers (artisan equipment).

- Food safety and hygiene engineers responsible for cleanability and sanitation validation.

- Compliance officers, notified bodies and testing labs assessing conformity with EU Machinery Directive requirements.

- Artisan ice‑cream, gelato and pastry producers specifying or purchasing safe, hygienic processing equipment.

Benefits include clearer conformity routes, reduced biological and physical hazards in product processing, and alignment with EU safety and hygiene expectations.

Related Standards

- EN ISO 12100 (risk assessment)

- EN 1672-2 (food processing hygiene)

- EN 60204-1 (electrical equipment of machines)

- EN ISO 3744 / EN ISO 11201 / EN ISO 4871 (acoustics)

- EN 349, EN 953, EN ISO 13849-1 (mechanical safety / guards / control systems)

Keywords: FprEN 16881, pasteurizers, cream cookers, ageing vats, food processing machinery, safety requirements, hygiene requirements, cleanability, CEN, artisan machinery.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

FprEN 16881 is a draft published by the European Committee for Standardization (CEN). Its full title is "Food processing machinery - Pasteurizers, vats and cream cookerss - Safety and hygiene requirements". This standard covers: This European Standard applies to discontinuous pasteurizers and cream cookers for ice cream mixes, pasty liquid products for gelato, pastry, chocolate and food processing, as described in 3.2. This European Standard applies to fixed and movable artisan machinery (not designed to be moved during operation), with a capacity of not more than 600 l. This European Standard deals with all significant hazards, hazardous situations and events relevant to the machinery, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This European Standard deals with the hazards which can arise during transport, assembly, commissioning, operation, cleaning, use, maintenance, decommissioning, dismantling, disabling and scrapping of the machine. This European Standard covers the following types of machines: - pasteurizers; - ageing vats; - cream cookers. This European Standard is not applicable for pasteurizers and cream cookers without cooling systems. This European Standard does not give requirements for heating and cooling equipment. This European Standard is not applicable to machines which are manufactured before the date of publication of this European Standard by CEN.

This European Standard applies to discontinuous pasteurizers and cream cookers for ice cream mixes, pasty liquid products for gelato, pastry, chocolate and food processing, as described in 3.2. This European Standard applies to fixed and movable artisan machinery (not designed to be moved during operation), with a capacity of not more than 600 l. This European Standard deals with all significant hazards, hazardous situations and events relevant to the machinery, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This European Standard deals with the hazards which can arise during transport, assembly, commissioning, operation, cleaning, use, maintenance, decommissioning, dismantling, disabling and scrapping of the machine. This European Standard covers the following types of machines: - pasteurizers; - ageing vats; - cream cookers. This European Standard is not applicable for pasteurizers and cream cookers without cooling systems. This European Standard does not give requirements for heating and cooling equipment. This European Standard is not applicable to machines which are manufactured before the date of publication of this European Standard by CEN.

FprEN 16881 is classified under the following ICS (International Classification for Standards) categories: 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

FprEN 16881 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

FprEN 16881 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

oSIST prEN 16881:2015

01-september-2015

Stroji za predelavo hrane - Pasterizatorji, kadi in kuhalniki za pripravo kreme -

Varnostne in higienske zahteve

Food processing machinery - Pasteurizers, vats and cream cookers - Safety and hygiene

requirements

Nahrungsmittelmaschinen - Pasteurisiergeräte, Bottiche und Eismaschinen - Sicherheits-

und Hygieneanforderungen

Machines pour les produits alimentaires - Pasteurisateurs, cuves et cuiseurs de crème -

Prescriptions relatives à la sécurité et l'hygiène

Ta slovenski standard je istoveten z: prEN 16881

ICS:

67.260 Tovarne in oprema za Plants and equipment for the

živilsko industrijo food industry

oSIST prEN 16881:2015 en,fr,de

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

oSIST prEN 16881:2015

oSIST prEN 16881:2015

EUROPEAN STANDARD

DRAFT

prEN 16881

NORME EUROPÉENNE

EUROPÄISCHE NORM

June 2015

ICS 67.260

English Version

Food processing machinery - Pasteurizers, vats and cream

cookers - Safety and hygiene requirements

Machines pour les produits alimentaires - Pasteurisateurs, Nahrungsmittelmaschinen - Pasteurisiergeräte, Bottiche

cuves et cuiseurs de crème - Prescriptions relatives à la und Eismaschinen - Sicherheits- und

sécurité et l'hygiène Hygieneanforderungen

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 153.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other language

made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United

Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are aware and to

provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2015 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 16881:2015 E

worldwide for CEN national Members.

oSIST prEN 16881:2015

prEN 16881:2015 (E)

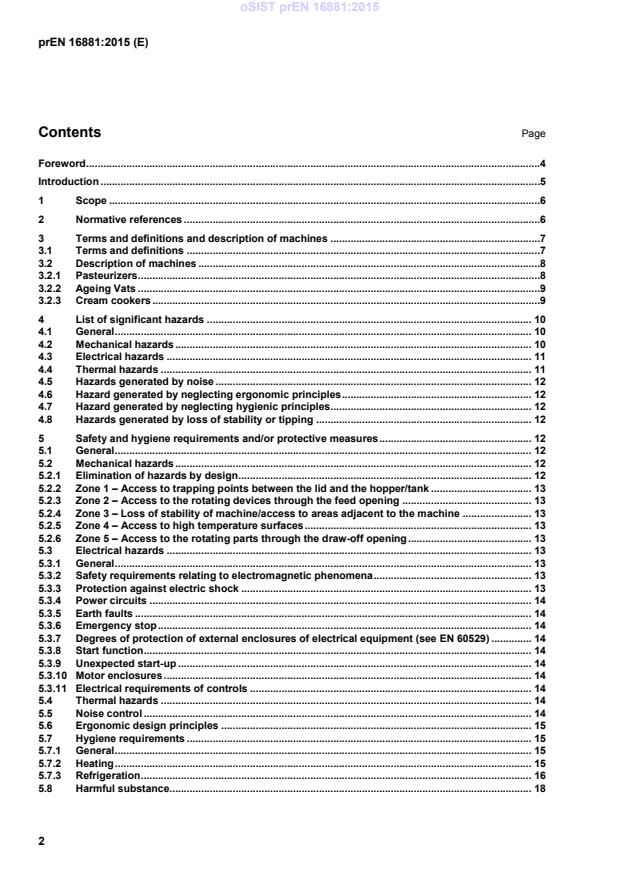

Contents Page

Foreword .4

Introduction .5

1 Scope .6

2 Normative references .6

3 Terms and definitions and description of machines .7

3.1 Terms and definitions .7

3.2 Description of machines .8

3.2.1 Pasteurizers .8

3.2.2 Ageing Vats .9

3.2.3 Cream cookers .9

4 List of significant hazards . 10

4.1 General . 10

4.2 Mechanical hazards . 10

4.3 Electrical hazards . 11

4.4 Thermal hazards . 11

4.5 Hazards generated by noise . 12

4.6 Hazard generated by neglecting ergonomic principles . 12

4.7 Hazard generated by neglecting hygienic principles . 12

4.8 Hazards generated by loss of stability or tipping . 12

5 Safety and hygiene requirements and/or protective measures . 12

5.1 General . 12

5.2 Mechanical hazards . 12

5.2.1 Elimination of hazards by design . 12

5.2.2 Zone 1 – Access to trapping points between the lid and the hopper/tank . 13

5.2.3 Zone 2 – Access to the rotating devices through the feed opening . 13

5.2.4 Zone 3 – Loss of stability of machine/access to areas adjacent to the machine . 13

5.2.5 Zone 4 – Access to high temperature surfaces . 13

5.2.6 Zone 5 – Access to the rotating parts through the draw-off opening . 13

5.3 Electrical hazards . 13

5.3.1 General . 13

5.3.2 Safety requirements relating to electromagnetic phenomena . 13

5.3.3 Protection against electric shock . 13

5.3.4 Power circuits . 14

5.3.5 Earth faults . 14

5.3.6 Emergency stop . 14

5.3.7 Degrees of protection of external enclosures of electrical equipment (see EN 60529) . 14

5.3.8 Start function . 14

5.3.9 Unexpected start-up . 14

5.3.10 Motor enclosures . 14

5.3.11 Electrical requirements of controls . 14

5.4 Thermal hazards . 14

5.5 Noise control . 14

5.6 Ergonomic design principles . 15

5.7 Hygiene requirements . 15

5.7.1 General . 15

5.7.2 Heating . 15

5.7.3 Refrigeration . 16

5.8 Harmful substance. 18

oSIST prEN 16881:2015

prEN 16881:2015 (E)

6 Verification of safety and hygiene requirements and/or protective measures . 18

7 Information of use . 18

7.1 General . 18

7.2 Instruction handbook . 18

7.3 Service manual . 20

7.4 Cleaning . 20

7.5 Marking . 20

Annex A (normative) Noise test code (Grade 2 of accuracy) . 21

A.1 Terms and definitions . 21

A.2 Installation and mounting conditions . 21

A.3 Operating conditions . 21

A.4 Emission sound pressure level determination . 21

A.5 Measurement uncertainties . 22

A.6 Information to be recorded . 22

A.7 Information to be reported . 22

A.8 Declaration and verification of noise emission values . 22

Annex B (normative) Principles of design to ensure the cleanability of the machinery . 23

B.1 Definitions . 23

B.2 Material of construction . 23

B.3 Design . 24

Annex C (normative) Testing Disinfection of Pasteurizers, Vats Machines . 41

C.1 Testing disinfection by cleaning . 41

C.2 Testing of the pasteurization process . 41

C.3 Testing during cream production . 42

Annex ZA (informative) Relationship between this European Standard and the Essential Requirements

of EU Directive 2006/42/EC . 43

Bibliography . 44

oSIST prEN 16881:2015

prEN 16881:2015 (E)

Foreword

This document (prEN 16881:2015) has been prepared by Technical Committee CEN/TC 153 “Machinery intended

for use with foodstuffs and feed”, the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

This document has been prepared under a mandate given to CEN by the European Commission and the European

Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document.

oSIST prEN 16881:2015

prEN 16881:2015 (E)

Introduction

This European Standard is a type C standard as stated in EN ISO 12100:2010.

The machinery concerned and the extent to which hazards, hazardous situations and hazardous events are covered

are indicated in the scope of this document.

When provisions of this type C standard are different from those which are stated in type A or B standards, the

provisions of this type C standard take precedence over the provisions of the other standards for machines that have

been designed and built according to the provisions of this type C standard.

Complementary to the hygiene requirements common to all food processing machines, specific requirements for

cleanability and sanitation of the machines in the scope are formulated.

oSIST prEN 16881:2015

prEN 16881:2015 (E)

1 Scope

This European Standard applies to machines of ice cream mixes, pasty liquid products for gelato, pastry, chocolate

and food processing, as described in Clause 3.

The European Standard applies to fixed and movable artisan machinery (not designed to be moved during

operation), with a rated capacity of not more than 600 l.

This European Standard deals with all significant hazards, hazardous situations and events relevant to the

machinery, when they are used as intended and under conditions of misuse which are reasonably foreseeable by

the manufacturer (see Clause 4).

This European Standard deals with the hazards which can arise during transport, assembly, commissioning,

operation, cleaning, use, maintenance, decommissioning, dismantling, disabling and scrapping of the machine.

This European Standard covers the following types of machines:

— pasteurizers;

— ageing vats;

— cream cookers.

This European Standard does not apply to equipment feeding and dosing, equipment, supply of inert gas and

heating and cooling equipment and any extraction (container, extraction belt etc.).

This European Standard is not applicable to cream cookers without cooling systems

This European Standard is not applicable to machines which are manufactured before the date of publication of this

European Standard by CEN.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for

its application. For dated references, only the edition cited applies. For undated references, the latest edition of the

referenced document (including any amendments) applies.

EN 349:1993+A1:2008, Safety of machinery - Minimum gaps to avoid crushing of parts of the human body

EN 574:1996+A1:2008, Safety of machinery - Two-hand control devices - Functional aspects - Principles for design

EN 614-1, Safety of machinery – Ergonomic design principles – Part 1: Terminology and general principles

EN 953, Safety of machinery – Guards – General requirements for the design and construction of fixed and movable

guards

EN 1672-2:2005+A1:2009, Food processing machinery - Basic concepts - Part 2: Hygiene requirements

EN 60204-1:2006, Safety of machinery - Electrical equipment of machines - Part 1: General requirements (IEC

60204:2005, modified)

EN 60529, Degrees of protection provided by enclosures (IP Code) (IEC 60529)

EN ISO 3744:2010, Acoustics - Determination of sound power levels and sound energy levels of noise sources

using sound pressure - Engineering methods for an essentially free field over a reflecting plane (ISO 3744:2010)

oSIST prEN 16881:2015

prEN 16881:2015 (E)

EN ISO 4287, Geometrical product specifications (GPS) - Surface texture: Profile method - Terms, definitions and

surface texture parameters (ISO 4287)

EN ISO 4871, Acoustics - Declaration and verification of noise emission values of machinery and equipment (ISO

4871)

EN ISO 11201, Acoustics - Noise emitted by machinery and equipment - Determination of emission sound pressure

levels at a work station and at other specified positions in an essentially free field over a reflecting plane with

negligible environmental corrections (ISO 11201)

EN ISO 11688-1, Acoustics - Recommended practice for the design of low-noise machinery and equipment - Part 1:

Planning (ISO/TR 11688-1)

EN ISO 12100:2010, Safety of machinery - General principles for design - Risk assessment and risk reduction (ISO

12100:2010)

EN ISO 13732-1, Ergonomics of the thermal environment - Methods for the assessment of human responses to

contact with surfaces - Part 1: Hot surfaces (ISO 13732-1)

EN ISO 13732-3, Ergonomics of the thermal environment - Methods for the assessment of human responses to

contact with surfaces - Part 3: Cold surfaces (ISO 13732-3)

EN ISO 13849-1:2008, Safety of machinery - Safety-related parts of control systems - Part 1: General principles for

design (ISO 13849-1:2006)

EN ISO 13850, Safety of machinery - Emergency stop - Principles for design (ISO 13850)

EN ISO 13857:2008, Safety of machinery - Safety distances to prevent hazard zones being reached by upper and

lower limbs (ISO 13857:2008)

EN ISO 14119:2013, Safety of machinery - Interlocking devices associated with guards - Principles for design and

selection (ISO 14119:2013)

3 Terms and definitions and description of machines

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the following apply.

3.1.1

hopper lid

mobile guard used to lock the hopper which contain the mixing device of the product

Note 1 to entry: The hopper lid is also used to restart the work cycle.

3.1.2

mixing device

suitable device to ensure mixing and circulation of the mixture

3.1.3

draw-off device

suitable device to allow the extraction of the finished product

3.1.4

hopper

part of the machinery suitable to store the mixture during the work cycle

oSIST prEN 16881:2015

prEN 16881:2015 (E)

3.1.5

compression type machines

machines where the cooling is performed by means of a refrigerant liquid at low pressure in a heat exchanger

(evaporator), the steam thus formed becomes a liquid by a mechanical compression higher pressure and cooling in

another heat exchanger (condenser)

3.1.6

condenser

heat exchanger in which after compression, the vaporized refrigerant is liquefied, giving off heat to external cooling

system

3.1.7

evaporator

heat exchanger in which, after the reduction of pressure, the refrigerant is vaporized by absorbing heat from the

medium which shall be cooled

3.2 Description of machines

3.2.1 Pasteurizers

Machine used for mixing, heating, cooling ingredients in order to produce and store the mix for artisan gelato (see

Figure 1), operated step by step or fully automatically, whose hopper can be heated or cooled by air or water

condensing unit, internal or remote.

Key

1 hopper

2 hopper lid (cover)

3 mixing device

4 draw-off device

5 heated or cooled device

6 compressor

7 condensing unit

8 castors/pins

Figure 1 — Typical layout of pasteurizers

oSIST prEN 16881:2015

prEN 16881:2015 (E)

3.2.2 Ageing Vats

Machine used for the storage and ageing the mix for artisan gelato (see Figure 2), operated step by step or fully

automatically, whose hopper can be heated or cooled by air or water condensing unit, internal or remote.

Key

1 hopper

2 hopper lid (cover)

3 mixing device

4 draw-off device

5 heated or cooled device

6 compressor

7 condensing unit

8 castors/pins

Figure 2 — Typical layout of vats

3.2.3 Cream cookers

Pasteurizer intended for use with liquid and thick mixes (see Figure 3), operated step by step or fully automatically,

whose hopper can be heated or cooled by air or water condensing unit, internal or remote.

oSIST prEN 16881:2015

prEN 16881:2015 (E)

Key

1 hopper

2 hopper lid (cover)

3 mixing device

4 draw-off device

5 heated or cooled device

6 compressor

7 condensing unit

8 castors/pins

Figure 3 — Typical layout of cream cookers

4 List of significant hazards

4.1 General

This clause contains all the significant hazards, hazardous situations and events, as far as they are dealt with in this

European Standard, identified by risk assessment as significant for this type of machinery and which require action

to eliminate or reduce the risk.

4.2 Mechanical hazards

The example shown in Figure 4 illustrates danger zones associated with these hazards:

oSIST prEN 16881:2015

prEN 16881:2015 (E)

Key

1 Zone 1

2 Zone 2

3 Zone 3

4 Zone 4

5 Zone 5

Figure 4 — Danger zones

Zone 1: Access to trapping points between the lid and the hopper/tank:

— crushing hazard of fingers and hands between the edge hopper and the lid;

Zone 2: Access to the rotating devices through the feed opening:

— hazards of trapping and shearing of arms between the blades of mixing device and the hopper/tank;

Zone 3: Loss of stability of machine - access to areas adjacent to the machine:

— hazard of trapping and crushing of whole or part of body if machine overturns;

Zone 4: Access to high temperature surfaces:

— hazard of scalds and burns, in case of accidental contact;

Zone 5: Access to the rotating parts through the draw-off opening:

— hazard of trapping and shearing of arms between the blades of rotating device.

4.3 Electrical hazards

Hazard of electric shock from direct or indirect contact with live components. Hazard of external influences on

electrical equipment (e.g. cleaning with water). If liquids such as spilled products or cleaning agents such as water

come into contact with the electrical conductors, there is a danger of electric shock.

4.4 Thermal hazards

High temperature of external parts and hand operated components creates a hazard of scalds and burns. This

hazard can be present also when the machinery is switched off.

oSIST prEN 16881:2015

prEN 16881:2015 (E)

4.5 Hazards generated by noise

Machinery can generate an airborne noise being able to involve a deterioration of hearing or accidents due to the

interferences with the oral communication and the perception of the acoustical signals. The noise can produce:

— ringing in the ears;

— tiredness, stress, etc.;

— other effects as loss of balance, loss of perception;

— interference with speech communication;

— inability to hear acoustic warning signals.

4.6 Hazard generated by neglecting ergonomic principles

During operation, cleaning and maintenance, there could be the risk for safety and health resulting from awkward

body postures or from an excessive effort. Movement or filling of the bowl especially at heights can create a risk of

injury to the body from lifting, pushing and pulling of heavy loads.

4.7 Hazard generated by neglecting hygienic principles

The neglect of hygienic principles can create unacceptable contamination of foodstuff and therefore a risk to human

health of the operator and consumer, i.e. through physical, chemical or microbial pollution.

4.8 Hazards generated by loss of stability or tipping

Risk of impact or crushing the body, in particular resulting from machinery with castors.

5 Safety and hygiene requirements and/or protective measures

5.1 General

Machinery shall be designed according to the principles of EN ISO 12100:2010 for hazard relevant but not

significant, which are not dealt with by this standard (e.g. sharp edges). This specific risk assessment shall be part of

the general risk assessment of the machine. When fixed guard, or parts of the machine acting as such, are not

permanently fixed, e.g. by welding, their fixing systems shall remain attached to the guards or to the machinery when

the guards are removed.

5.2 Mechanical hazards

5.2.1 Elimination of hazards by design

Unless otherwise specified, interlocking guards shall be at least interlocking without guard blocking as defined in

EN ISO 14119:2013, 4.2, and they shall comply with EN ISO 14119:2013, Clause 5, 7 and 8. Access to dangerous

zones of drive shafts, coupling between the motor and the reduction gear and transmission belts shall be prevented

by fixed guards or movable interlocking guards in accordance with EN 953. Any gaps between moving parts and

fixed parts of the machinery shall be so arranged that either it is not possible for a finger to enter the gap (i.e. a gap

of 6 mm or less) or the gap shall be sufficiently large to prevent trapping and crushing in accordance with

EN 349:1993+A1:2008, Table 1. The safety related parts of the control system shall meet at least a performance

level “c” defined in accordance with EN ISO 13849-1:2008. Openings in guards shall comply with

EN ISO 13857:2008, Table 4.

oSIST prEN 16881:2015

prEN 16881:2015 (E)

5.2.2 Zone 1 – Access to trapping points between the lid and the hopper/tank

Covers of hopper/tank when in opening position shall have a device keeping the covers in a stable position to

prevent unintentional closing (i.e. with balancing systems). The speed of closure of the lids, having a mass greater

than 2,8 kg, shall not be greater than 50 mm/s when the distance from the hopper/tank to the front edge of the lid is

less than 200 mm. Powered lid shall be operated by a hold-to-run control device in conformity to

EN 574:1996+A1:2008, 5.4.1, and shall remain in their position in case of power failure.

5.2.3 Zone 2 – Access to the rotating devices through the feed opening

Access to the zone in which it moves the rotary mixer shall be prevented by a lid/guard interlocked with guard

locking (see EN ISO 14119:2013, 4.3). Openings and/or slides in cover or in the hopper/tank shall be in accordance

with EN ISO 13857:2008, 4.5. For small openings shall be used EN ISO 13857:2008, Table 4. The interlocking

device of the lid shall operate at a maximum opening of the lid of 30 mm.

5.2.4 Zone 3 – Loss of stability of machine/access to areas adjacent to the machine

Machines shall be designed to be stable. For machines designed to be fixed to the floor, the instruction handbook

shall indicate the values of forces at the fixing points and the dimensions of the anchor points provided. Free

standing machines without castors shall not fall or tip over when tilted 10° from the horizontal plane in the most

unfavourable direction and containing the most unfavourable load. Free standing machines with castors shall have

at least two castors (or sets of castors) fitted with a locking device to prevent rolling or turning.

5.2.5 Zone 4 – Access to high temperature surfaces

Control knobs that have to be hand-gripped shall not exceed a 55 °C temperature. The parts of machinery surface

that can come into contact with the operator shall not exceed a 65 °C temperature. In all other cases guards shall be

provided.

5.2.6 Zone 5 – Access to the rotating parts through the draw-off opening

Access to rotating parts through the draw-off openings, e.g. mixing device shall be prevented by fixed or movable

guards. The guards shall be designed so that there is a good view of the area behind it (for example, grids) and the

size shall comply with the safety distances in EN ISO 13857:2008, Table 2. The guards shall be designed in

accordance with the requirements of EN 953. Openings in guards shall be in accordance with EN ISO 13857:2008,

Table 4. It shall not be possible to operate the mixing element when the guards are opened and the opening of a

guard shall stop the mixing element within 4 s when the machine is empty. If this is not possible, guards shall be

interlocked with guard locking which is released only when the mixing device has stopped.

5.3 Electrical hazards

5.3.1 General

The electrical equipment shall comply with EN 60204-1:2006, with the following precision.

5.3.2 Safety requirements relating to electromagnetic phenomena

The machines shall have sufficient immunity to electromagnetic disturbances to enable them to operate safely as

intended and not fail to danger when exposed to the levels and types of disturbances intended by the manufacturer.

The manufacturer of the machines shall design, install and wire the equipment and sub-assemblies taking into

account the recommendations of the suppliers of these sub-assemblies.

5.3.3 Protection against electric shock

The electrical equipment shall comply with EN 60204-1:2006, Clause 6. For movable machines the instruction

handbook shall contain recommended practice, such as, disconnecting the machine from the electrical supply before

moving it, and the need to avoid damaging the supply cable during movement.

oSIST prEN 16881:2015

prEN 16881:2015 (E)

5.3.4 Power circuits

Devices for detection and interruption of over-current shall be applied to each live conductor in compliance with

EN 60204-1:2006, 7.2.3. In case of single phase machines, no such device is required for earthed neutral conductor.

5.3.5 Earth faults

When equipment within the scope of this European Standard is supplied from a single phase conductor and an

earthed neutral conductor, there is no requirement for double pole interruption in the control circuit, according to

EN 60204-1:2006, 9.4.3.1.

5.3.6 Emergency stop

These machines do not require an emergency stop device. Nevertheless it is necessary an emergency stop, it shall

comply with EN ISO 13850:2008.

5.3.7 Degrees of protection of external enclosures of electrical equipment (see EN 60529)

Enclosures including control actuating devices, signals and display elements exposed motor shall be at least IP 54.

5.3.8 Start function

Start devices shall be designed to reduce the risk of inadvertent operation by conforming to EN 60204-1:2006, 10.6.

The start function can be actuated by closing the lid.

5.3.9 Unexpected start-up

The hazards from mechanical parts unexpectedly restarting by restoration of energy supply after an interruption shall

be provided by conforming to EN 60204-1:2006, 7.5.

5.3.10 Motor enclosures

Where a motor has a degree of protection lower than IP23 (see EN 60529), it shall be mounted inside an enclosure

(see EN 60204-1:2006, 14.2) that guarantees a minimum degree of protection of IP23 (see EN 60529). The whole

machine frame shall have a degree of protection IP24 (see EN 60529).

5.3.11 Electrical requirements of controls

Control actuating devices, signals and display elements shall have a degree of protection IP54 (see EN 60529).

5.4 Thermal hazards

Where hopper/tanks are heated and/or cooled, the temperatures of touchable surfaces in the working area shall

conform to EN ISO 13732-1. The contact period for surfaces intended to be touched during operation of the mixer

shall be assumed to be not less than 3 s. Where hopper/tanks are cooled, the requirements for the touchable

surfaces shall according to EN ISO 13732-3. The temperature of external condensing unit surfaces shall be in

conformity with EN ISO 13732-1.

5.5 Noise control

The machines shall be designed and constructed so that the risk due to the airborne noise emission is reduced to

the lowest levels, by applying in particular measures at source to control the noise (EN ISO 11688-1). The success

of the applied noise reduction measures is assessed on the basis of the actual noise emission values (see Annex A)

in relation to other machines of the same family.

oSIST prEN 16881:2015

prEN 16881:2015 (E)

5.6 Ergonomic design principles

The design of the machines shall take account of the principles given in EN 614-1. The force required to open

manually operated covers shall not exceed 150 N, e.g. by counterbalancing. Awkward body postures during

maintenances and cleaning as well as when filling and emptying the bowl shall be avoided. This can be achieved

through good ergonomic design and by using automatic loading and discharge equipment. Under best lifting

conditions the use of the machine shall not involve a person lifting more than 25 kg.

5.7 Hygiene requirements

5.7.1 General

5.7.1.1 Introduction

Machines shall be designed and manufactured in accordance with the requirements of EN 1672-2:2005+A1:2009

and Annex B of this European Standard give additional information. The instructions for use shall include

recommendations for cleaning procedures and advices on suitable (and, if appropriate) and unsuitable cleaning

materials, as well as any means necessary to protect the operator, such as personal protective equipment. The 3

zones defined in EN 1672-2:2005+A1:2009 are shown in Figure 5 and are in general at least as follows; the precise

boundary between the areas depends on the detailed design of the machine.

5.7.1.2 Food area

The food area is as follows:

— inside of the hopper/tank and hopper lid;

— mixer;

— draw-off device.

5.7.1.3 Splash area

The food area is as follows:

— outer part of the hopper/tank and lid;

— parts of the frame which face the draw-off device.

5.7.1.4 Non-food area

The rest of the machine.

5.7.2 Heating

The pasteurizer shall be designed and manufactured in such a way that they meet the following requirements:

a) Pasteurizer shall be fitted with a temperature gauge or temperature range gauge to control the temperature of

the mix in the tank. The measuring point shall be selected in such a way that the displayed temperature

corresponds to the product temperature of the mix in the tank

b) There are two options for the pasteurization process:

— reach the product temperature of the whole mix in the tank ≥ 65 °C and hold for 30 min or

— reach the product temperature of the whole mix in the tank ≥ 85 °C

oSIST prEN 16881:2015

prEN 16881:2015 (E)

5.7.3 Refrigeration

The pasteurizer shall be designed and manufactured in such a way that they meet the following requirements:

a) Pasteurizer shall be fitted with a temperature gauge or temperature range gauge to control the temperature of

the mix in the tank. The measuring point shall be selected in such a way that the displayed temperature

corresponds to the product temperature of the mix in the tank.

b) It shall be possible to hold the product temperature of the mix in the tank at 5 °C or colder.

c) If the mix in a tank is being heated or the mix is added to the tank at a higher product temperature, then it shall

be possible to cool the mix to at least 5 °C or lower at an ambient temperature of 25 °C in no longer than

120 min when heated to 65 °C. The successful pasteurization shall be documented in such a way that it can be

verified.

key

food zone

splash zone

non-food zone

Figure 5a) — Hygiene areas of cream cookers

oSIST prEN 16881:2015

prEN 16881:2015 (E)

key

food zone

splash zone

non-food zone

Figure 5b) — Hygiene areas of vats

key

food zone

splash zone

non-food zone

Figure 5c) — Hygiene areas of pasteurizers

Figure 5 — Hygiene areas of pasteurizers, vats and cream cookers

oSIST prEN 16881:2015

prEN 16881:2015 (E)

5.8 Harmful substance

Because the precaution requested will depend on the actual cleaning agent used, it is not possible to give any

technical requirement in this standard. The manufacturer shall give in the instruction handbook details on cleaning

products and the personal protective equipment to be used (gloves and aprons).

6 Verification of safety and hygiene requirements and/or protective measures

This clause contains the methods of the verification of the compliance with the safety requirements of this European

Standard. As far as the criteria for acceptance and the conditions during verification are self-evident, they can also

be found in the Table 1. Verification of the requirements can be made by means of inspection, calculation or testing.

These shall be applied to a machine in a fully commissioned condition but partial dismantling may be necessary for

the purpose of some checks. Such partial dismantling shall not invalidate the result of verification.

Table 1 — Methods of the verification of the compliance with the safety requirements

Relevant clause Method of verification

5.2.2 By verification of the function of the interlocking guard with guard

locking and the electrical circuit diagram

By measurement of the dimension

5.2.3 By visual inspection and verification of the function of the interlocking

guard with guard locking and the electrical circuit diagram

By functional test

5.2.4 By tilting test at 10° and verification of the instruction handbook

5.2.5 By measurement of the temperature and functional test

5.2.6 By verification of the function of the interlocking guard with guard

locking and the electrical circuit diagram

By measurement of the dimension

5.3 Verification shall be in accordance with EN 60204–1:2006, Clause 18

5.4 By measurement of the temperature

5.5 In accordance with Annex A

5.6 By visual inspection and verification of the instruction handbook

5.7 In accordance with EN 1672–2: 2005+A1:2009, Clause 6, and visual

examination and Annex C

7 Information of use

7.1 General

Information for use shall meet the requirements of EN ISO 12100:2010, Clause 6. An instruction handbook shall be

provided.

7.2 Instruction handbook

The manufacturer shall provide an instruction handbook in accordance with EN ISO 12100:2010, 6.5.

The instruction handbook shall include a training program for the operator.

The program shall include the instruction that the operators shall not:

oSIST prEN 16881:2015

prEN 16881:2015 (E)

a) access at any time to the pasteurizers, vats and cream cookers without having first isolated the main power

supply;

b) attempt to carry out electrical or mechanical repairs on the pasteurizer, vat and cream cooker, unless properly

authorized;

c) remove guards from the pasteurizer, vat and cream cooker unless properly authorized;

d) interfere with the interlocking devices on the pasteurizer, vat and cream cooker;

e) handle the scrapers / blades without using protective devices;

f) allow an untrained person to take charge of a pasteurizer, vat and cream cooker without supervision;

g) use any unauthorized or improvised means of gaining access to parts of the machines which are not normally

inaccessible;

h) move the machine, except for applying precautions described in the handbook to avoid electrical risks and

tipping over risks.

The instruction handbook shall recommend that the user arranges a program of inspections to be carried out

regularly by a responsible person to verify that all guards and cover are secure and properly in position and that all

protective devices are functioning correctly.

The manufacturer should give the periods between inspections.

The instruction handbook shall provide:

— minimum specifications for extraction equipment, if required;

— values of forces at the fixing points and their dimensions, where the machine is fixed on the floor;

— warning to the operator during maintenance on the hazard of residual voltage especially on capacitors;

— information about prevention measures which have to be taken by the user including warning to use suitable

flooring to prevent slipping;

— instructions to isolating the machine in a safe condition in the event of repair or maintenance;

— cleaning shall be only be performed when the power supply is turned off;

— method of cleaning food areas, splash areas and non-food areas and the recommended cleaning products (see

7.4);

— the limits that shall be respected and the measures to be taken for ensuring stability during use, transportation,

assembly, dismantling when out of service, testing or foreseeable breakdown;

— the operating method to be followed in the event of accident or breakdown; if a blockage is likely to occur, the

operating method to be followed so as to enable the equipment to be safely unblocked;

— the specifications of the spare parts to be used, when these affect the health and safety of operators;

— if need be: the description of the adjustment and maintenance operations to be carried out by the user and the

preventive maintenance measures to be observed;

— if need be: instructions designed to enable adjustments and maintenance to be carried out safely, including the

protective measures to be taken during these operations;

oSIST prEN 16881:2015

prEN 16881:2015 (E)

— in the case of machinery capable of being plugged into an electricity supply: information warning the user that

he shall be able to check that the plug remains visible from any of the points to which he has access;

— the instruction handbook (and any sales literature describing the performances of the machine) shall contain the

following information on airborne noise emissions, determined and declared in accordance with Annex A:

— the A-weighted emission sound pressure level at workstations, where this exceeds 70 dB(A); where this

level does not exceed 70 dB(A), this fact shall be indicated;

— the peak C-weighted instantaneous sound pressure value at workstations, where this exceeds 63 Pa

(130 dB in relation to 20 μPa);

— the A-weighted sound power level emitted by the machinery, where the A-weighted emission sound

pressu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...