ASTM D7548-22

(Test Method)Standard Test Method for Determination of Accelerated Iron Corrosion in Petroleum Products

Standard Test Method for Determination of Accelerated Iron Corrosion in Petroleum Products

SIGNIFICANCE AND USE

5.1 In general, wherever the possibility exists of water getting mixed with products/material (covered under 1.1) the results obtained by this test method will indicate the degree to which corrosion of iron components can be expected.

5.2 Test also determines the antirust properties of products/material (covered under 1.1) in preparation for the various stages through which the tested product may pass prior to or during its transport through a pipeline.

5.3 Test results are also meant to show whether or not the dosage levels and type of iron corrosion inhibitor added to a product/material (covered under 1.1) is sufficient for achieving the desired protection of affected assets such as storage tanks, process lines, and shipment systems.

SCOPE

1.1 This test method covers an accelerated laboratory and field procedure for the determination of corrosion of iron, in the presence of water, on samples such as gasoline and gasoline blended with 10 % ethanol, E10 (Specification D4814); gasoline-blend components (except butane); diesel fuel and biodiesel B5, except Grade No. 4-D (Specification D975); biodiesel B6 to B20 (Specification D7467); diesel-blend component such as light cycle-oil; No. 1 fuel oil, No. 2 fuel oil (Specification D396); aviation turbine fuel (Specification D1655).

1.2 The values stated in SI units are to be regarded as the standard.

1.2.1 Exception—Values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7548 − 22

Standard Test Method for

Determination of Accelerated Iron Corrosion in Petroleum

1

Products

This standard is issued under the fixed designation D7548; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D396Specification for Fuel Oils

D665Test Method for Rust-Preventing Characteristics of

1.1 This test method covers an accelerated laboratory and

Inhibited Mineral Oil in the Presence of Water

field procedure for the determination of corrosion of iron, in

D975Specification for Diesel Fuel

thepresenceofwater,onsamplessuchasgasolineandgasoline

D1193Specification for Reagent Water

blended with 10 % ethanol, E10 (Specification D4814);

D1655Specification for Aviation Turbine Fuels

gasoline-blend components (except butane); diesel fuel and

D4175Terminology Relating to Petroleum Products, Liquid

biodiesel B5, except Grade No. 4-D (Specification D975);

Fuels, and Lubricants

biodiesel B6 to B20 (Specification D7467); diesel-blend com-

D4814Specification for Automotive Spark-Ignition Engine

ponent such as light cycle-oil; No. 1 fuel oil, No. 2 fuel oil

Fuel

(Specification D396); aviation turbine fuel (Specification

D7467Specification for Diesel Fuel Oil, Biodiesel Blend

D1655).

(B6 to B20)

1.2 The values stated in SI units are to be regarded as the

G15TerminologyRelatingtoCorrosionandCorrosionTest-

3

standard.

ing (Withdrawn 2010)

1.2.1 Exception—Values in parentheses are for information

2.2 Other Standards:

only. 4

British Standard BS970–1:070M20 or European Steel

1.3 This standard does not purport to address all of the

C22E Number 1.1151—Carbon and Carbon Manganese

safety concerns, if any, associated with its use. It is the

Steels including Free Cutting Steels

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3.1 Definitions:

1.4 This international standard was developed in accor-

3.1.1 For definitions of terms used in this test method, refer

dance with internationally recognized principles on standard-

to Terminology D4175.

ization established in the Decision on Principles for the

3.1.2 corrosion, n—chemical or electrochemical reaction

Development of International Standards, Guides and Recom-

between a material, usually a metal, and its environment that

mendations issued by the World Trade Organization Technical

producesadeteriorationofthematerialanditsproperties. G15

Barriers to Trade (TBT) Committee.

3.1.3 rust, n—corrosion product consisting primarily of

hydrated iron oxide.

2. Referenced Documents

3.1.3.1 Discussion—Rust is a term properly applied only to

2

2.1 ASTM Standards:

ferrous alloys. G15

A108Specification for Steel Bar, Carbon and Alloy, Cold-

3.2 Acronyms:

Finished

3.2.1 TP—temperature probe.

D97Test Method for Pour Point of Petroleum Products

4. Summary of Test Method

1

This test method is under the jurisdiction of ASTM Committee D02 on

4.1 Apolishedironcorrosiontest-rodisimmersedin50mL

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

of the sample being tested and heated to 37.8°C (100°F), at

Subcommittee D02.14 on Stability, Cleanliness and Compatibility of Liquid Fuels.

Current edition approved May 1, 2022. Published May 2022. Originally

ɛ1

approvedin2009.Lastpreviouseditionapprovedin2022asD7548–16a(2022) .

3

DOI: 10.1520/D7548-22 The last approved version of this historical standard is referenced on

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.astm.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Annual Book of IP Standard Methods for Analysis and Testing of Petroleum and

Standards volume information, refer to the standard’s Document Summary page on Related Products, Vol 2. Available from Energy Institute, 61 New Cavendish St.,

the ASTM website. London, W1G 7AR, U.K., http://www.energyinst.org.

*A Summary of Changes section appears at the end of this standard

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7548 − 22

7,6

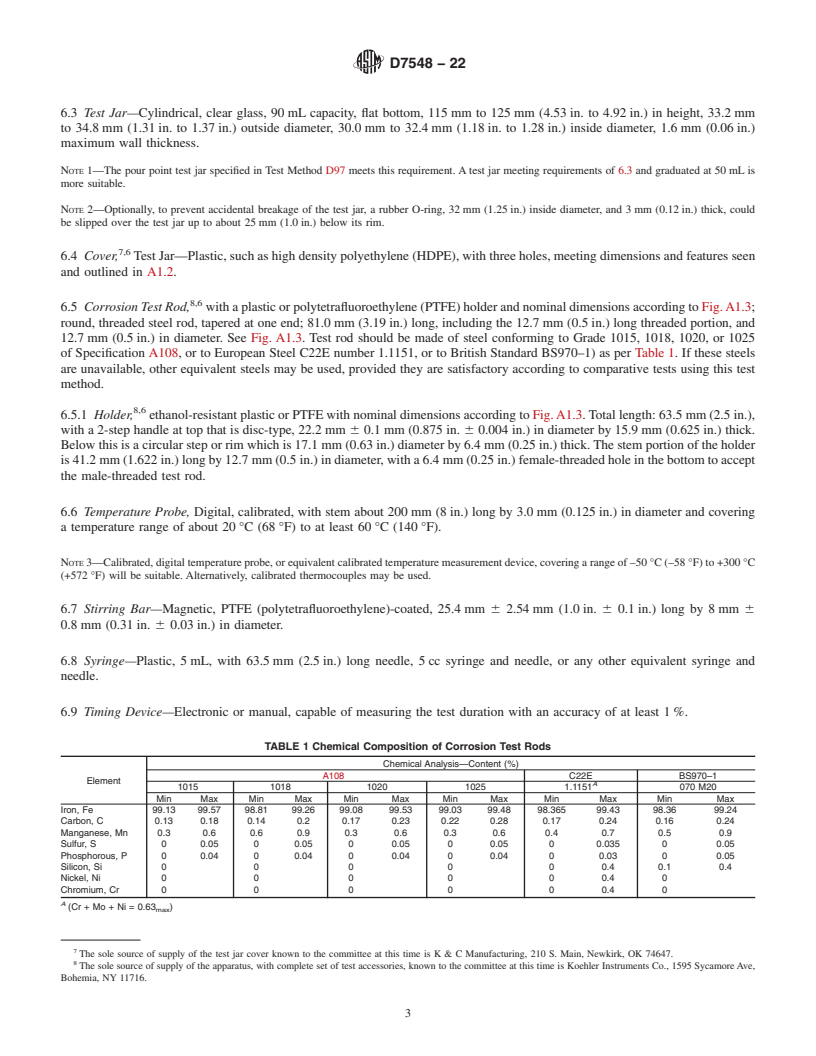

which point 5mLof reagent water,Type III or better, is added 6.4 Cover, Test Jar—Plastic, such as high density poly-

to the sample. Sample temperature is maintained between ethylene (HDPE), with three holes, meeting dimensions and

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D7548 − 16a (Reapproved 2022) D7548 − 22

Standard Test Method for

Determination of Accelerated Iron Corrosion in Petroleum

1

Products

This standard is issued under the fixed designation D7548; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorially corrected 13.1 in April 2022.

1. Scope Scope*

1.1 This test method covers an accelerated laboratory and field procedure for the determination of corrosion of iron, in the

presence of water, on samples such as gasoline and gasoline blended with 10 % ethanol, E10 (Specification D4814); gasoline-blend

components (except butane); diesel fuel and biodiesel B5, except Grade No. 4-D (Specification D975); biodiesel B6 to B20

(Specification D7467); diesel-blend component such as light cycle-oil; No.1 No. 1 fuel oil, No.2 No. 2 fuel oil (Specification

D396); aviation turbine fuel (Specification D1655).

1.2 The values stated in SI units are to be regarded as the standard.

1.2.1 Exception—Values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A108 Specification for Steel Bar, Carbon and Alloy, Cold-Finished

D97 Test Method for Pour Point of Petroleum Products

D396 Specification for Fuel Oils

D665 Test Method for Rust-Preventing Characteristics of Inhibited Mineral Oil in the Presence of Water

D975 Specification for Diesel Fuel

D1193 Specification for Reagent Water

D1655 Specification for Aviation Turbine Fuels

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

D4814 Specification for Automotive Spark-Ignition Engine Fuel

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.14 on Stability, Cleanliness and Compatibility of Liquid Fuels.

Current edition approved April 1, 2022May 1, 2022. Published April 2022May 2022. Originally approved in 2009. Last previous edition approved in 20162022 as

ɛ1

D7548 – 16a.D7548 – 16a (2022) . DOI: 10.1520/D7548-16AR22E01.10.1520/D7548-22

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7548 − 22

D7467 Specification for Diesel Fuel Oil, Biodiesel Blend (B6 to B20)

3

G15 Terminology Relating to Corrosion and Corrosion Testing (Withdrawn 2010)

2.2 Other Standards:

4

British Standard BS970–1:070M20 or European Steel C22E Number 1.1151—Carbon and Carbon Manganese Steels including

Free Cutting Steels

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer to Terminology D4175.

3.1.2 corrosion, n—chemical or electrochemical reaction between a material, usually a metal, and its environment that produces

a deterioration of the material and its properties. G15

3.1.3 rust, n—corrosion product consisting primarily of hydrated iron oxide.

3.1.3.1 Discussion—

Rust is a term properly applied only to ferrous alloys. G15

3.2 Acronyms:

3.2.1 TP—temperature probe.

4. Summary of Test Method

4.1 A polished iron corrosion test-rod is immersed in 50 mL of the sample being tested and heated to 37.8 °C (100 °F), at which

point 5 mL of reagent water, Type III or better, is added to the sample. Sample temperature is maintained between 37 °C to 39 °C

(98 °F to 102 °F), with the target being 37.8 °C (100 °F), f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.