ASTM D7651-10

(Test Method)Standard Test Method for Gravimetric Measurement of Particulate Concentration of Hydrogen Fuel

Standard Test Method for Gravimetric Measurement of Particulate Concentration of Hydrogen Fuel

SIGNIFICANCE AND USE

Low operating temperature fuel cells such as proton exchange membrane fuel cells (PEMFCs) require high purity hydrogen for maximum material performance and lifetime. Measurement of particulates in hydrogen is necessary for assuring a feed gas of sufficient purity to satisfy fuel cell and internal combustion system needs as defined in SAE J2719. The particulates in hydrogen fuel for FCVs and gaseous hydrogen powered internal combustion engine vehicles may adversely affect pneumatic control components, such as valves, or other critical system components. Therefore, the concentration of particulates in the hydrogen fuel should be limited as specified by ISO 14687, SAE J2719, or other hydrogen fuel quality specifications.

Although not intended for application to gases other than hydrogen fuel, techniques within this test method can be applied to gas samples requiring determination of particulate matter.

SCOPE

1.1 This test method is primarily intended for gravimetric determination of particulates in hydrogen intended as a fuel for fuel cell or internal combustion engine powered vehicles. This test method describes operating and quality control procedures required to obtain data of known quality satisfying the requirements of SAE J2719 and the California Code of Regulations, Title 4, Division 9, Chapter 6, Article 8, Sections 4180 – 4181. The levels of precision and accuracy stated. This test method can be applied to other gaseous samples requiring determination of particulates provided the user’s data quality objectives are satisfied.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7651 − 10

Standard Test Method for

Gravimetric Measurement of Particulate Concentration of

Hydrogen Fuel

This standard is issued under the fixed designation D7651; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 Other Standards:

California Code of Regulations ,Title 4, Division 9, Chapter

1.1 This test method is primarily intended for gravimetric

6, Article 8, Sections 4180 – 4181

determination of particulates in hydrogen intended as a fuel for

ISO 14687 Hydrogen fuel -- Product specification -- Part 1:

fuel cell or internal combustion engine powered vehicles. This

All applications except proton exchange membrane

test method describes operating and quality control procedures

(PEM) fuel cell for road vehicles

required to obtain data of known quality satisfying the require-

ments of SAE J2719 and the California Code of Regulations,

Title 4, Division 9, Chapter 6,Article 8, Sections 4180 – 4181. 3. Terminology

The levels of precision and accuracy stated. This test method

3.1 Acronyms:

can be applied to other gaseous samples requiring determina-

3.1.1 FCV—Hydrogen Fuel Cell Vehicle

tion of particulates provided the user’s data quality objectives

are satisfied.

3.1.2 PSA—Particulate sampling adapter for sampling par-

ticulate in hydrogen fuel.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3.1.3 PEM—Polymer Electrolyte Membrane, also called

standard.

Proton Exchange Membrane

1.3 This standard does not purport to address all of the

3.1.4 SAE—Society of Automotive Engineering

safety concerns, if any, associated with its use. It is the

3.2 Definitions:

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3.2.1 contaminant—impuritythatadverselyaffectsthecom-

bility of regulatory limitations prior to use.

ponents within the fuel cell system or the hydrogen storage

system

2. Referenced Documents

3.2.2 density—Massperunitofvolumeofthefuelgasorair

2.1 ASTM Standards:

being considered.

D7650 Test Method for Test Method for Sampling of Par-

ticulate Matter in High Pressure Hydrogen used as a

3.2.3 fuel cell hydrogen—hydrogen satisfying the specifica-

Gaseous Fuel with an In-Stream Filter

tions in SAE J2719.

2.2 SAE Standards:

3.2.4 weight monitoring filter, WMF—This filter is put

SAE J2719 Hydrogen Quality Guideline for Fuel Cell

inside the glove box (7.3) with balance (7.1) and not removed

Vehicles, April 2008

from the glove box (7.3). The weight of this filter is always

SAE J2600 Compressed Hydrogen Surface Vehicle Refuel-

measured before and after each measurement event.

ing Connection Devices

3.3 SAE J2719—Informational Report on the development

of a hydrogen quality guideline for fuel cell vehicles. This

ThistestmethodisunderthejurisdictionofASTMCommitteeD03onGaseous

report specifies PEM FCV hydrogen fuel quality from the

Fuels and is the direct responsibility of Subcommittee D03.14 on Hydrogen and

fueling nozzle.

Fuel Cells.

Current edition approved July 1, 2010. Published August 2010. DOI: 10.1520/

D7651–10.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Office of Administrative Law 300 Capitol Mall, Suite 1250

Standards volume information, refer to the standard’s Document Summary page on Sacramento, CA 95814-4339

the ASTM website. Available from International Organization for Standardization (ISO), 1, ch. de

Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale, la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

PA 15096-0001, http://www.sae.org. www.iso.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7651 − 10

3.4 SAE J2600 Compressed Hydrogen Surface Vehicle Re- 7. Apparatus

fueling Connection Devices—This document specifies the de-

7.1 Balance—The balance must measure to 10-5 g. The

sign requirements for nozzles and receptacles used in high

balance should have the capability to download the weight

pressure hydrogen applications such as delivery from a fueling

6,7

measurement into Microsoft Excel , or a similar program, for

station to a FCV

weight recording and calibration. In order to prevent contami-

nation of particulates from ambient air, the balance must be

4. Summary of Test Method

placed inside a glove box in a small confined room with a

8,7

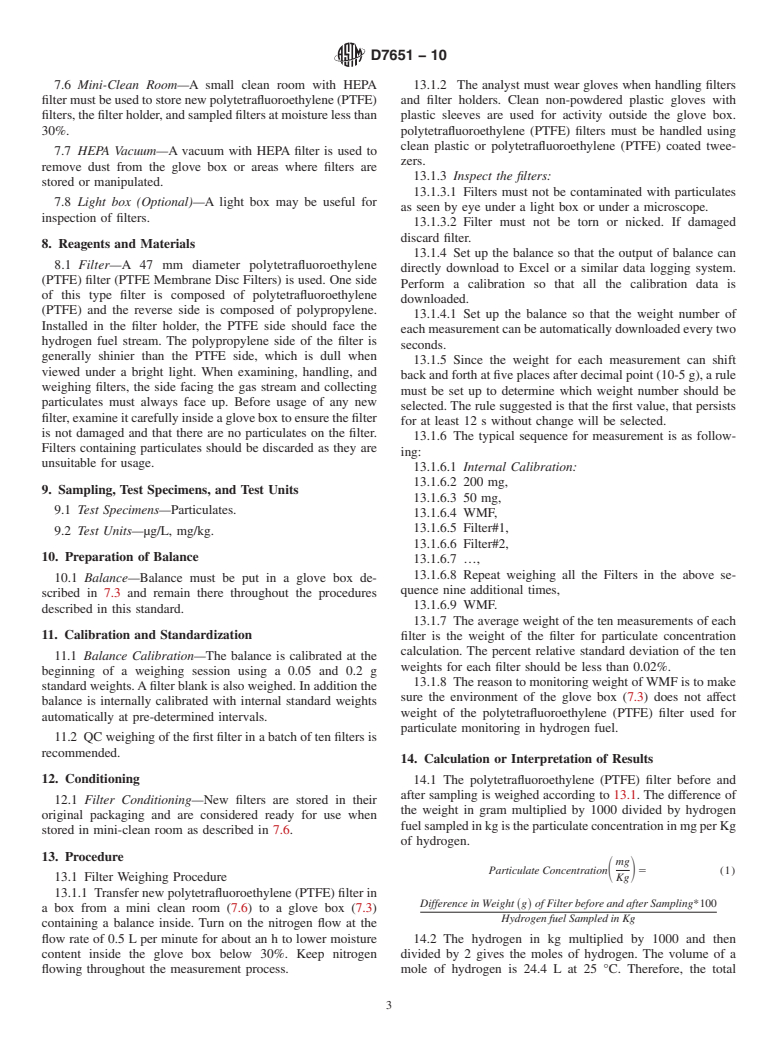

4.1 This procedure is for the weight determination of filters

HEPA air cleaner.

before and after collection of particulates contained within

7.2 Calibration weight–Class 1 (Class S)—categorycalibra-

hydrogen fuel or other gaseous streams at fueling station

tionweightswithatoleranceof 60.1mg.certifiedastraceable

dispenser nozzles (Test Method D7650, SAE J2600) or other

to NIST mass standards. The weights used for calibration are a

gaseous fuel delivery system dispenser interfaces. The particu-

0.05 g and 0.2 g weight, of corrosion-resistant construction.

late concentration is determined by dividing the particulate

Calibration weight is to be certified on an annual basis. The

weight,whichisthedifferenceoffilterweightsbeforeandafter

weight of the particular 0.2µm polytetrafluoroethylene (PTFE)

sampling, by the total volume of hydrogen or other gaseous

filter used in this method test was around 0.1g.

fuel passing through a filter. Every precaution should be taken

to avoid contamination of particulates 10 µm or larger onto the

7.3 Glove box—A glove box is a sealed container that, in

filter coming from the PSA, the analytical system, ambient air,

this application, is designed to allow weight measurement by

filter handling or other environmental sources.

balance without particulate contamination from ambient air.

Two gloves are generally built into the front sides of the glove

5. Significance and Use

box with entry arranged in such a way that the user can place

5.1 Low operating temperature fuel cells such as proton

their hands into the gloves and perform weight measurement,

exchange membrane fuel cells (PEMFCs) require high purity

install filters and assemble the filter holder inside the box. The

hydrogen for maximum material performance and lifetime.

glove box must be maintained clean at all times and any visual

Measurement of particulates in hydrogen is necessary for

particulate matter must be removed immediately. A HEPA

assuring a feed gas of sufficient purity to satisfy fuel cell and

vacuum can be used for cleaning purposes. A side evacuation

internal combustion system needs as defined in SAE J2719.

port or anti-chamber should also be used to minimize contami-

The particulates in hydrogen fuel for FCVs and gaseous

nating the glove box environment. The glove box should be

hydrogen powered internal combustion engine vehicles may

flushedatalltimeswithcleandryN2maintainingaRHof30%

adverselyaffectpneumaticcontrolcomponents,suchasvalves,

or less inside the glove box as determined by a data logger or

or other critical system components. Therefore, the concentra-

other device installed in the glove box.

tion of particulates in the hydrogen fuel should be limited as

7.4 Static Charge Removal Device—Astaticchargeremoval

specified by ISO 14687, SAE J2719, or other hydrogen fuel

device, such as an ionization bar, must be placed inside the

quality specifications.

glovebox(7.3)nexttothebalance.Beforemeasurementofany

5.2 Although not intended for application to gases other

material,suchasstandardweightsandfilters,thestaticcharges

than hydrogen fuel, techniques within this test method can be

on the material must be removed using a static charge removal

applied to gas samples requiring determination of particulate

device. Alternatively, anti-static strips which consist of radio-

matter.

active (α - particle) Polonium-210 strips can be used to

discharge static from weights and filters. Polonium strips

6. Interferences

should be replaced every 6 months (conservatively) or accord-

6.1 Particulate matter 10 µm or larger originating in the

ing to the useful life quoted by the manufacturer.

environmentorequipmentwillinterferewiththedetermination

7.5 Moisture/Temperature Data Logger—A data logger is

of total particulate matter collected on the filter. Every precau-

placed inside the glove box to measure both moisture and

tion should be taken to avoid contamination of particulates 10

temperature of atmosphere inside the glove box either continu-

µmorlargerontothefiltercomingfromthePSA,theanalytical

ouslyora

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.