ASTM A908-03

(Specification)Standard Specification for Stainless Steel Needle Tubing

Standard Specification for Stainless Steel Needle Tubing

ABSTRACT

The specification covers austenitic, stainless steel, needle tubing in hard-drawn tempers for industrial application. An electric furnace or other similar primary melting process with or without degassing or refining may be used. Needle tubing shall be made by the seamless or welded and drawn process and shall be furnished in the hard-drawn temper condition. Tension tests shall be made to meet the required tensile requirements.

SCOPE

1.1 This specification covers austenitic, stainless steel, needle tubing in hard-drawn tempers for industrial applications.

1.2 In general, needle tubing describes small-diameter tubing with outside diameters (ODs) in the range of 0.008 to 0.203 in. (0.2 to 5.2 mm) with nominal wall thicknesses in the range of 0.002 to 0.015 in. (0.05 to 0.4 mm). Needle tubing gages are normally 6 through 33.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 908 – 03

Standard Specification for

1

Stainless Steel Needle Tubing

This standard is issued under the fixed designation A 908; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

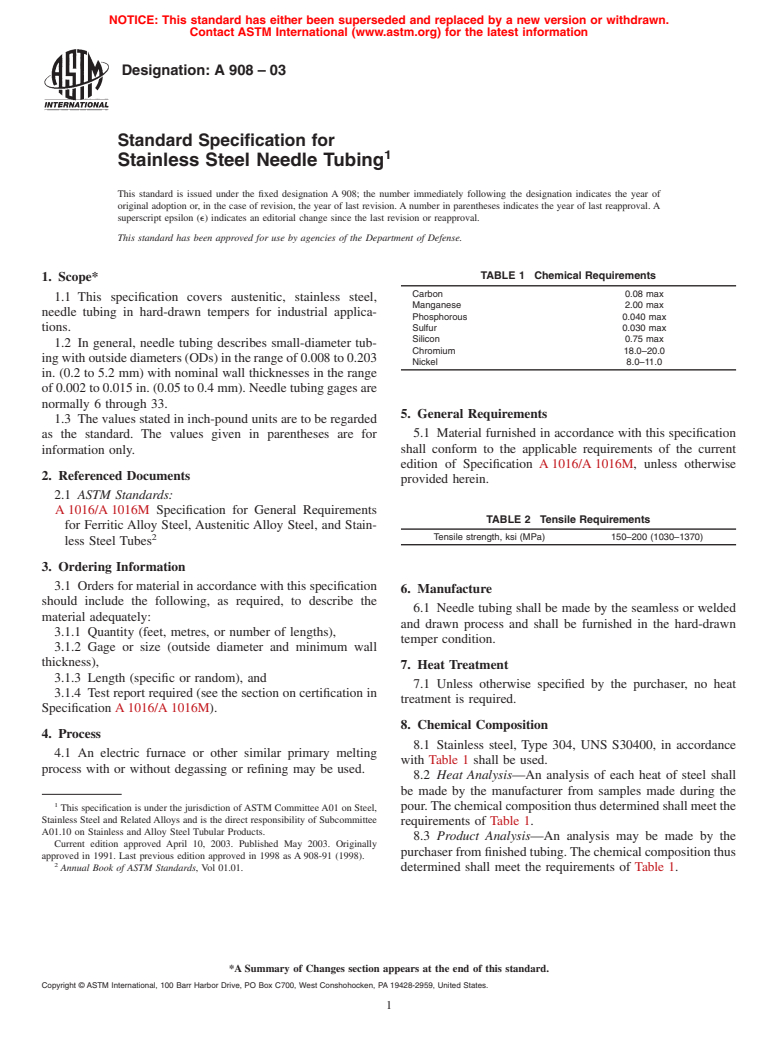

TABLE 1 Chemical Requirements

1. Scope*

Carbon 0.08 max

1.1 This specification covers austenitic, stainless steel,

Manganese 2.00 max

needle tubing in hard-drawn tempers for industrial applica-

Phosphorous 0.040 max

tions. Sulfur 0.030 max

Silicon 0.75 max

1.2 In general, needle tubing describes small-diameter tub-

Chromium 18.0–20.0

ing with outside diameters (ODs) in the range of 0.008 to 0.203

Nickel 8.0–11.0

in. (0.2 to 5.2 mm) with nominal wall thicknesses in the range

of 0.002 to 0.015 in. (0.05 to 0.4 mm). Needle tubing gages are

normally 6 through 33.

5. General Requirements

1.3 The values stated in inch-pound units are to be regarded

5.1 Material furnished in accordance with this specification

as the standard. The values given in parentheses are for

information only. shall conform to the applicable requirements of the current

edition of Specification A 1016/A 1016M, unless otherwise

2. Referenced Documents

provided herein.

2.1 ASTM Standards:

A 1016/A 1016M Specification for General Requirements

TABLE 2 Tensile Requirements

for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stain-

2 Tensile strength, ksi (MPa) 150–200 (1030–1370)

less Steel Tubes

3. Ordering Information

3.1 Orders for material in accordance with this specification

6. Manufacture

should include the following, as required, to describe the

6.1 Needle tubing shall be made by the seamless or welded

material adequately:

and drawn process and shall be furnished in the hard-drawn

3.1.1 Quantity (feet, metres, or number of lengths),

temper condition.

3.1.2 Gage or size (outside diameter and minimum wall

thickness),

7. Heat Treatment

3.1.3 Length (specific or random), and

7.1 Unless otherwise specified by the purchaser, no heat

3.1.4 Test report required (see the section on certification in

treatment is required.

Specification A 1016/A 1016M).

8. Chemical Composition

4. Process

8.1 Stainless steel, Type 304, UNS S30400, in accordance

4.1 An electric furnace or other similar primary melting

with Table 1 shall be used.

process with or without degassing or refining may be used.

8.2 Heat Analysis—An analysis of each heat of steel shall

be made by the manufacturer from samples made during the

1

pour.The chemical composition thus determined shall meet the

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

requirements of Table 1.

A01.10 on Stainless and Alloy Steel Tubular Products.

8.3 Product Analysis—An analysis may be made by the

Current edition approved April 10, 2003. Published May 2003. Originally

purchaser from finished tubing.The chemical composition thus

approved in 1991. Last previous edition approved in 1998 as A 908-91 (1998).

2

determined shall meet the requirements of Table 1.

Annua

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.