ASTM D4423-00(2006)

(Test Method)Standard Test Method for Determination of Carbonyls In C4 Hydrocarbons

Standard Test Method for Determination of Carbonyls In C<inf>4</inf> Hydrocarbons

SIGNIFICANCE AND USE

The determination of the carbonyl content of polymerization-grade 1,3-butadiene is necessary, since in some polymerization reactions, the presence of carbonyls in excess over some specified amount can have a deleterious effect upon the polymer properties or the reaction itself, or both.

SCOPE

1.1 This test method covers the determination of carbonyls (ketones and aldehydes) in C4 hydrocarbons. This test method was tested on polymerization-grade 1,3-butadiene.

1.2 The applicable range for this test method is 0 to 50 mg/kg carbonyls calculated as acetaldehyde.

1.3 Other C4 hydrocarbons and their mixtures besides polymerization-grade 1,3-butadiene could be tested using this same test method. However, the precision section of this test method covers only carbonyls in applicable range as listed in , as found in polymerization-grade 1,3-butadiene.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D4423–00 (Reapproved 2006)

Standard Test Method for

Determination of Carbonyls In C Hydrocarbons

This standard is issued under the fixed designation D4423; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope releasing an equivalent amount of hydrochloric acid which is

thenback-titratedtotheoriginalcoloration.Ablankcontaining

1.1 This test method covers the determination of carbonyls

only methanol and sample is titrated and the sample’s results

(ketones and aldehydes) in C hydrocarbons. This test method

are calculated using the blank adjustment. Results are reported

was tested on polymerization-grade 1,3-butadiene.

as milligrams per kilogram carbonyls as acetaldehyde.

1.2 The applicable range for this test method is 0 to

50mg/kg carbonyls calculated as acetaldehyde.

4. Significance and Use

1.3 Other C hydrocarbons and their mixtures besides

4.1 The determination of the carbonyl content of

polymerization-grade 1,3-butadiene could be tested using this

polymerization-grade1,3-butadieneisnecessary,sinceinsome

same test method. However, the precision section of this test

polymerization reactions, the presence of carbonyls in excess

method covers only carbonyls in applicable range as listed in

over some specified amount can have a deleterious effect upon

1.2, as found in polymerization-grade 1,3-butadiene.

the polymer properties or the reaction itself, or both.

1.4 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

5. Apparatus

standard.

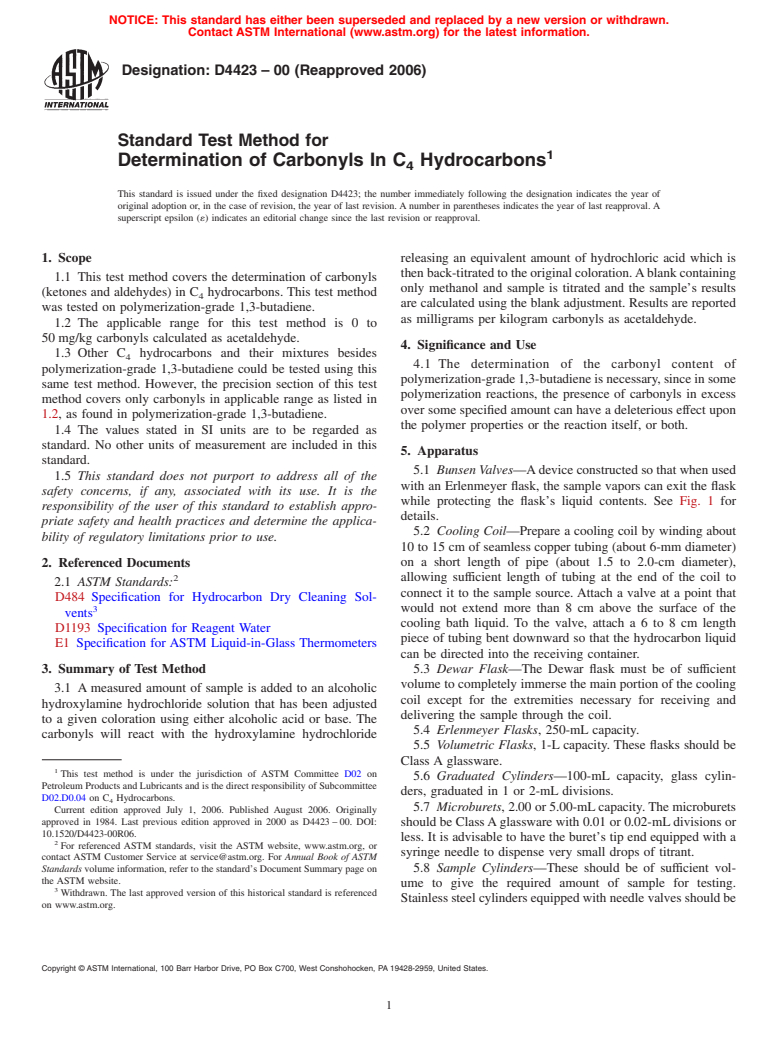

5.1 Bunsen Valves—Adeviceconstructedsothatwhenused

1.5 This standard does not purport to address all of the

with an Erlenmeyer flask, the sample vapors can exit the flask

safety concerns, if any, associated with its use. It is the

while protecting the flask’s liquid contents. See Fig. 1 for

responsibility of the user of this standard to establish appro-

details.

priate safety and health practices and determine the applica-

5.2 Cooling Coil—Prepare a cooling coil by winding about

bility of regulatory limitations prior to use.

10 to 15 cm of seamless copper tubing (about 6-mm diameter)

2. Referenced Documents on a short length of pipe (about 1.5 to 2.0-cm diameter),

2 allowing sufficient length of tubing at the end of the coil to

2.1 ASTM Standards:

connect it to the sample source. Attach a valve at a point that

D484 Specification for Hydrocarbon Dry Cleaning Sol-

3 would not extend more than 8 cm above the surface of the

vents

cooling bath liquid. To the valve, attacha6to8cm length

D1193 Specification for Reagent Water

piece of tubing bent downward so that the hydrocarbon liquid

E1 Specification for ASTM Liquid-in-Glass Thermometers

can be directed into the receiving container.

3. Summary of Test Method 5.3 Dewar Flask—The Dewar flask must be of sufficient

volume to completely immerse the main portion of the cooling

3.1 A measured amount of sample is added to an alcoholic

coil except for the extremities necessary for receiving and

hydroxylamine hydrochloride solution that has been adjusted

delivering the sample through the coil.

to a given coloration using either alcoholic acid or base. The

5.4 Erlenmeyer Flasks, 250-mL capacity.

carbonyls will react with the hydroxylamine hydrochloride

5.5 Volumetric Flasks, 1-L capacity. These flasks should be

Class A glassware.

This test method is under the jurisdiction of ASTM Committee D02 on

5.6 Graduated Cylinders—100-mL capacity, glass cylin-

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

ders, graduated in 1 or 2-mL divisions.

D02.D0.04 on C Hydrocarbons.

5.7 Microburets,2.00or5.00-mLcapacity.Themicroburets

Current edition approved July 1, 2006. Published August 2006. Originally

approved in 1984. Last previous edition approved in 2000 as D4423–00. DOI:

shouldbeClassAglasswarewith0.01or0.02-mLdivisionsor

10.1520/D4423-00R06.

less. It is advisable to have the buret’s tip end equipped with a

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

syringe needle to dispense very small drops of titrant.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.8 Sample Cylinders—These should be of sufficient vol-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

ume to give the required amount of sample for testing.

Withdrawn. The last approved version of this historical standard is referenced

Stainlesssteelcylindersequippedwithneedlevalvesshouldbe

on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

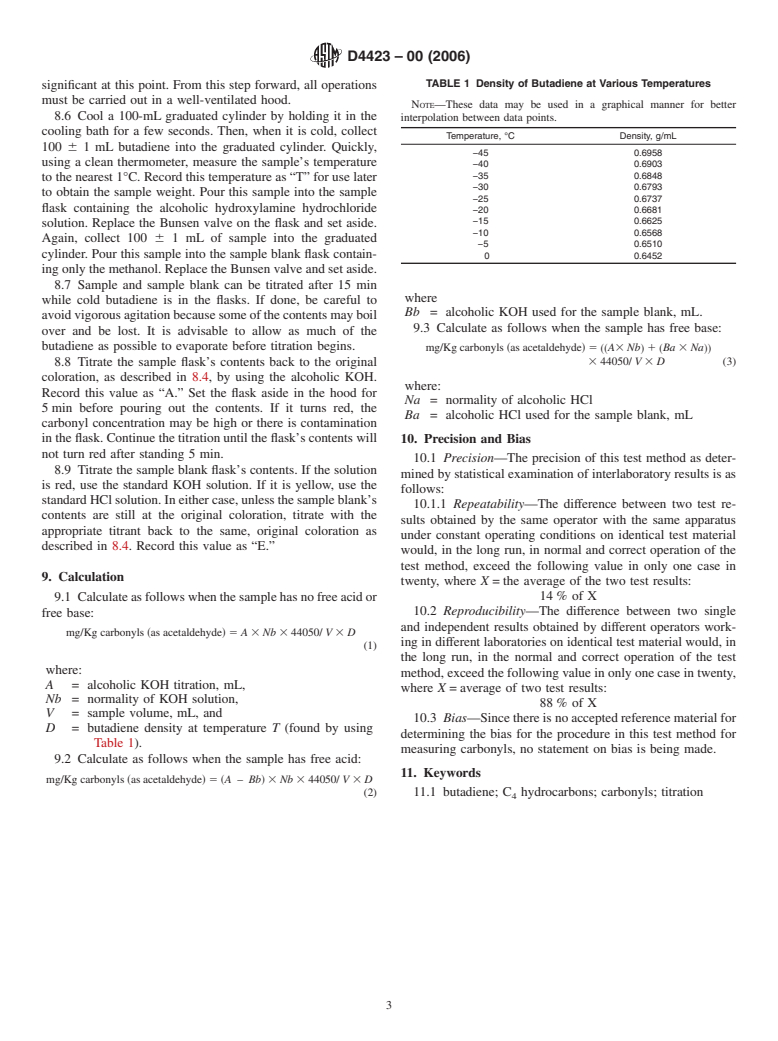

D4423–00 (2006)

(Warning—Corrosive. Can cause severe burns or blindness.

Evolution of heat produces a violent reaction or eruption upon

too rapid mixture with water.) Make to volume with methanol

in a 1-L volumetric flask. Standardize against a primary

standard, potassium acid phthalate.

6.6 Dry Ice (Carbon Dioxide Solid)—(Warning—

Extremely cold (−78.5°C). Liberates heavy gas which may

cause suffocation. Contact with skin causes burns or freezing,

or both. Vapors may react violently with hot magnesium or

aluminum alloys.)

6.7 Stoddard Solvent—Conforming to the specification

listed in Specification D484.(Warning—Combustible. Vapor

harmful.)

6.8 Thymol Blue Indicator—Dissolve0.04gofthymolblue

in 100 mL of anhydrous methanol. (Warning—Flammable.

Vaporharmful.Maybefatalorcauseblindnessifswallowedor

FIG. 1 Apparatus

inhaled. Cannot be made nonpoisonous.)

7. Preparation of Apparatus

used. It is suggested that a 500-mL-capacity cylinder be the

minumum size to be used for butadiene.

7.1 Dry Ice-Stoddard Solvent Bath—Add a sufficient quan-

5.9 Thermometer—For observing temperatures below

tity of Stoddard solvent into the Dewar flask to ensure that the

−45°C. The Low Cloud and Pour Point Thermometer, con-

cooling coil will be submerged in the liquid plus dry ice (solid

forming to the requirements for ASTM Thermometer 6C, as

CO ). (Warning—See 6.6 and 6.7.) Carefully add sufficient

prescribedinSpecificationE1,issatisfactory.Thermometer6C

dry ice to the Stoddard solvent to obtain a temperature of at

has a range from −80 to +20°C.

least −50°C. (Warning—Great care must be taken during this

step. Do not add the dry ice all at once, but in small pieces,

6. Reagents and Materials

especially at the beginning. Wear protective gloves and ad-

6.1 Purity of Reagents—Reagentgradechemicalsshouldbe

equateeyeprotectiontopreventanycontactwiththeextremely

used in all tests. Unless otherwise indicated, it is intended that

cold materials.) Attach the sample cylinder containing the

all reagents conform to the specifications of the Committee on

butadiene (Warning—Extremely flammable gas under pres-

Analytical Reagents of theAmerican Chemical Society where

sure. May form explosive peroxides upon exposure to air.

such specifications are available. Other grades may be used,

Harmful if inhaled. Irritating to eyes, skin, and mucous

provided it is first ascertained that the reagent is of sufficiently

membranes.) to the cooling coil and immerse the coil into the

high purity to permit its use without lessening the accuracy of

liquid. Support the sample cylinder in a cylinder rack or using

the determination.

a ring stand and appropriate clamps. Be sure the coil is

6.2 Purity of Water—Unlessotherwiseindicated,references

positioned so that the delive

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.