ASTM D4423-10

(Test Method)Standard Test Method for Determination of Carbonyls In C4 Hydrocarbons

Standard Test Method for Determination of Carbonyls In C<inf>4</inf> Hydrocarbons

SIGNIFICANCE AND USE

The determination of the carbonyl content of polymerization-grade 1,3-butadiene is necessary, since in some polymerization reactions, the presence of carbonyls in excess over some specified amount can have a deleterious effect upon the polymer properties or the reaction itself, or both.

SCOPE

1.1 This test method covers the determination of carbonyls (ketones and aldehydes) in C4 hydrocarbons. This test method was tested on polymerization-grade 1,3-butadiene.

1.2 The applicable range for this test method is 0 to 50 mg/kg carbonyls calculated as acetaldehyde.

1.3 Other C4 hydrocarbons and their mixtures besides polymerization-grade 1,3-butadiene could be tested using this same test method. However, the precision section of this test method covers only carbonyls in applicable range as listed in 1.2, as found in polymerization-grade 1,3-butadiene.

1.4 WARNINGMercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s websitehttp://www.epa.gov/mercury/faq.htmfor additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4423 − 10

StandardTest Method for

1

Determination of Carbonyls in C Hydrocarbons

4

This standard is issued under the fixed designation D4423; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method covers the determination of carbonyls

D484Specification for Hydrocarbon Dry Cleaning Solvents

(ketones and aldehydes) in C hydrocarbons. This test method

4

3

(Withdrawn 1982)

was tested on polymerization-grade 1,3-butadiene.

D1193Specification for Reagent Water

1.2 The applicable range for this test method is 0 to

E1Specification for ASTM Liquid-in-Glass Thermometers

50mg/kg carbonyls calculated as acetaldehyde.

3. Summary of Test Method

1.3 Other C hydrocarbons and their mixtures besides

4

3.1 A measured amount of sample is added to an alcoholic

polymerization-grade 1,3-butadiene could be tested using this

hydroxylamine hydrochloride solution that has been adjusted

same test method. However, the precision section of this test

to a given coloration using either alcoholic acid or base. The

method covers only carbonyls in applicable range as listed in

carbonyls will react with the hydroxylamine hydrochloride

1.2, as found in polymerization-grade 1,3-butadiene.

releasing an equivalent amount of hydrochloric acid which is

thenback-titratedtotheoriginalcoloration.Ablankcontaining

1.4 WARNING—Mercury has been designated by many

regulatory agencies as a hazardous material that can cause only methanol and sample is titrated and the sample’s results

are calculated using the blank adjustment. Results are reported

central nervous system, kidney and liver damage. Mercury, or

as milligrams per kilogram carbonyls as acetaldehyde.

its vapor, may be hazardous to health and corrosive to

materials.Cautionshouldbetakenwhenhandlingmercuryand

4. Significance and Use

mercury containing products. See the applicable product Ma-

4.1 The determination of the carbonyl content of

terial Safety Data Sheet (MSDS) for details and EPA’s

polymerization-grade1,3-butadieneisnecessary,sinceinsome

website—http://www.epa.gov/mercury/faq.htm—for addi-

polymerization reactions, the presence of carbonyls in excess

tional information. Users should be aware that selling mercury

over some specified amount can have a deleterious effect upon

and/or mercury containing products into your state or country

the polymer properties or the reaction itself, or both.

may be prohibited by law.

1.5 The values stated in SI units are to be regarded as 5. Apparatus

standard. No other units of measurement are included in this

5.1 Bunsen Valves—Adeviceconstructedsothatwhenused

standard.

with an Erlenmeyer flask, the sample vapors can exit the flask

while protecting the flask’s liquid contents. See Fig. 1 for

1.6 This standard does not purport to address all of the

details.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

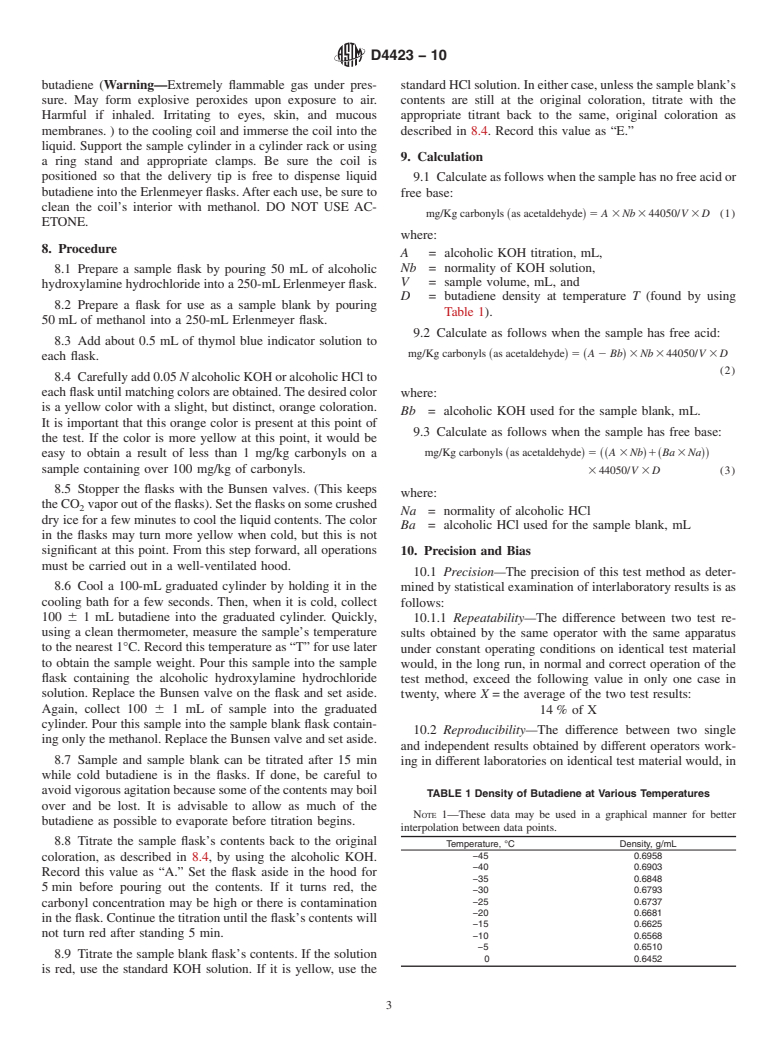

5.2 Cooling Coil—Prepare a cooling coil by winding about

priate safety and health practices and determine the applica- 10 to 15 cm of seamless copper tubing (about 6-mm diameter)

bility of regulatory limitations prior to use.

on a short length of pipe (about 1.5 to 2.0-cm diameter),

allowing sufficient length of tubing at the end of the coil to

connect it to the sample source. Attach a valve at a point that

would not extend more than 8 cm above the surface of the

cooling bath liquid. To the valve, attacha6to8cm length

1 2

This test method is under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

D02.D0.04 on C4 Hydrocarbons. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 1, 2010. Published June 2010. Originally the ASTM website.

3

approved in 1984. Last previous edition approved in 2006 as D4423–00(2006). The last approved version of this historical standard is referenced on

DOI: 10.1520/D4423-10. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4423 − 10

4

such specifications are available. Other grades may be used,

provided it is first ascertained that the reagent is of sufficiently

high purity to permit its use without lessening the accuracy of

the determination.

6.2 Purity of Water—Unless otherwi

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4423–00 (Reapproved 2006) Designation:D4423–10

Standard Test Method for

1

Determination of Carbonyls Inin C Hydrocarbons

4

This standard is issued under the fixed designation D4423; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of carbonyls (ketones and aldehydes) in C hydrocarbons. This test method was

4

tested on polymerization-grade 1,3-butadiene.

1.2 The applicable range for this test method is 0 to 50mg/kg carbonyls calculated as acetaldehyde.

1.3 Other C hydrocarbons and their mixtures besides polymerization-grade 1,3-butadiene could be tested using this same test

4

method. However, the precision section of this test method covers only carbonyls in applicable range as listed in 1.2, as found in

polymerization-grade 1,3-butadiene.

1.4The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5

1.4 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central

nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware

that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

3

D484 Specification for Hydrocarbon Dry Cleaning Solvents

D1193 Specification for Reagent Water

E1 Specification for ASTM Liquid-in-Glass Thermometers

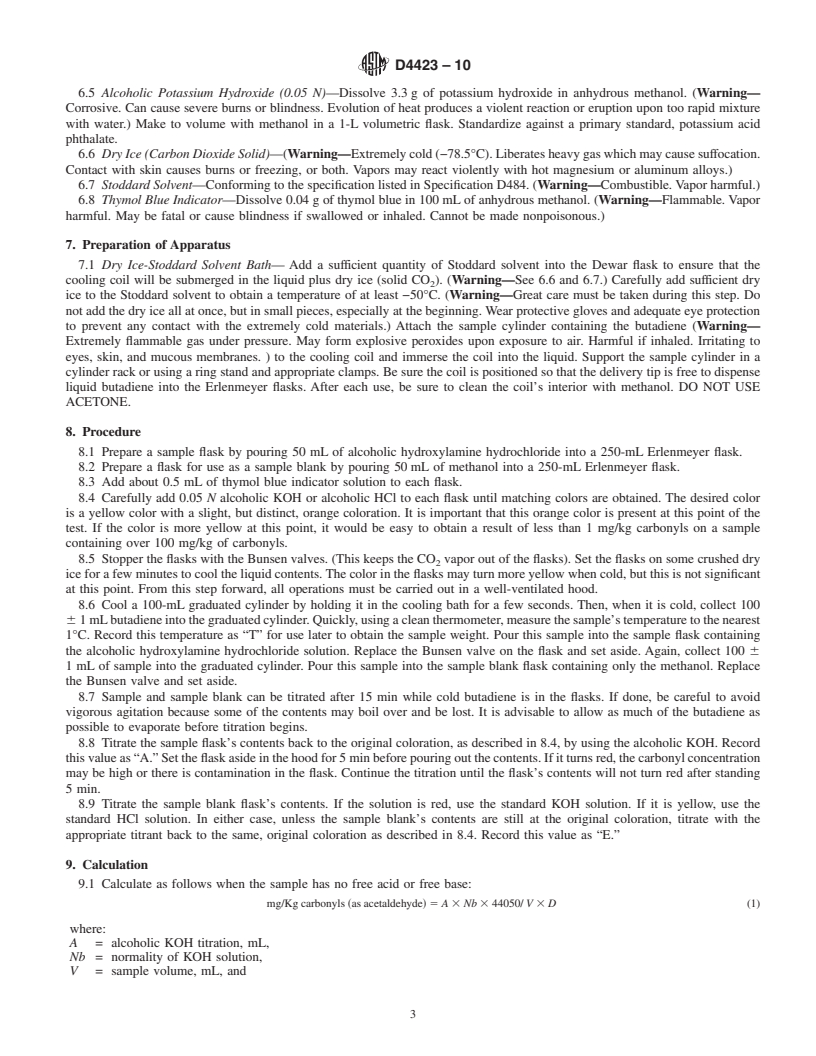

3. Summary of Test Method

3.1 A measured amount of sample is added to an alcoholic hydroxylamine hydrochloride solution that has been adjusted to a

given coloration using either alcoholic acid or base. The carbonyls will react with the hydroxylamine hydrochloride releasing an

equivalent amount of hydrochloric acid which is then back-titrated to the original coloration. A blank containing only methanol

and sample is titrated and the sample’s results are calculated using the blank adjustment. Results are reported as milligrams per

kilogram carbonyls as acetaldehyde.

4. Significance and Use

4.1 Thedeterminationofthecarbonylcontentofpolymerization-grade1,3-butadieneisnecessary,sinceinsomepolymerization

reactions,thepresenceofcarbonylsinexcessoversomespecifiedamountcanhaveadeleteriouseffectuponthepolymerproperties

or the reaction itself, or both.

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.D0.04

on C Hydrocarbons.

4

Current edition approved July 1, 2006. Published August 2006. Originally approved in 1984. Last previous edition approved in 2000 as D4423–00. DOI:

10.1520/D4423-00R06.on C4 Hydrocarbons.

Current edition approved May 1, 2010. Published June 2010. Originally approved in 1984. Last previous edition approved in 2006 as D4423–00(2006). DOI:

10.1520/D4423-10.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Withdrawn. The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4423–10

5. Apparatus

5.1 BunsenValves—AdeviceconstructedsothatwhenusedwithanErlenmeyerflask,thesamplevaporscanexittheflaskwhile

protecting the flask’s liquid contents. See Fig. 1 for details.

5.2 Cooling Coil—Prepare a cooling coil by winding about 10 to 15 cm o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.