ASTM A470/A470M-05e1

(Specification)Standard Specification for Vacuum-Treated Carbon and Alloy Steel Forgings for Turbine Rotors and Shafts

Standard Specification for Vacuum-Treated Carbon and Alloy Steel Forgings for Turbine Rotors and Shafts

ABSTRACT

This specification covers vacuum-treated carbon and alloy steel forgings for turbine rotors and shafts. Materials shall be manufactured and treated by: melting process via basic electric-furnace; secondary melting process via electrode-electroslag or vacuum-arc remelting; vacuum degassing; forging process via hot mechanical working; heat treatment via double-normalizing and tempering, or normalizing, quenching and tempering; and rough machining and axial boring. Tension and impact tests shall be done to evaluate the conformance of steel forgings with the following mechanical properties: tensile strength and toughness, notch toughness, yield strength, elongation, and reduction of area. Chemical composition conformances shall also be assessed by heat and product analyses. Nondestructive tests, such as ultrasonic and internal examination, and stability tests shall also be performed. Retreatments may be executed one or more times, but not more than three additional times, if results of the mechanical tests do not conform to specified requirements.

SCOPE

1.1 This specification covers vacuum-treated carbon and alloy steel forgings for turbine rotors and shafts.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

´1

Designation: A470/A470M – 05

Standard Specification for

Vacuum-Treated Carbon and Alloy Steel Forgings for

1

Turbine Rotors and Shafts

This standard is issued under the fixed designationA470/A470M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Step-cooling temperatures in S4.1.2 editorially corrected in September 2006.

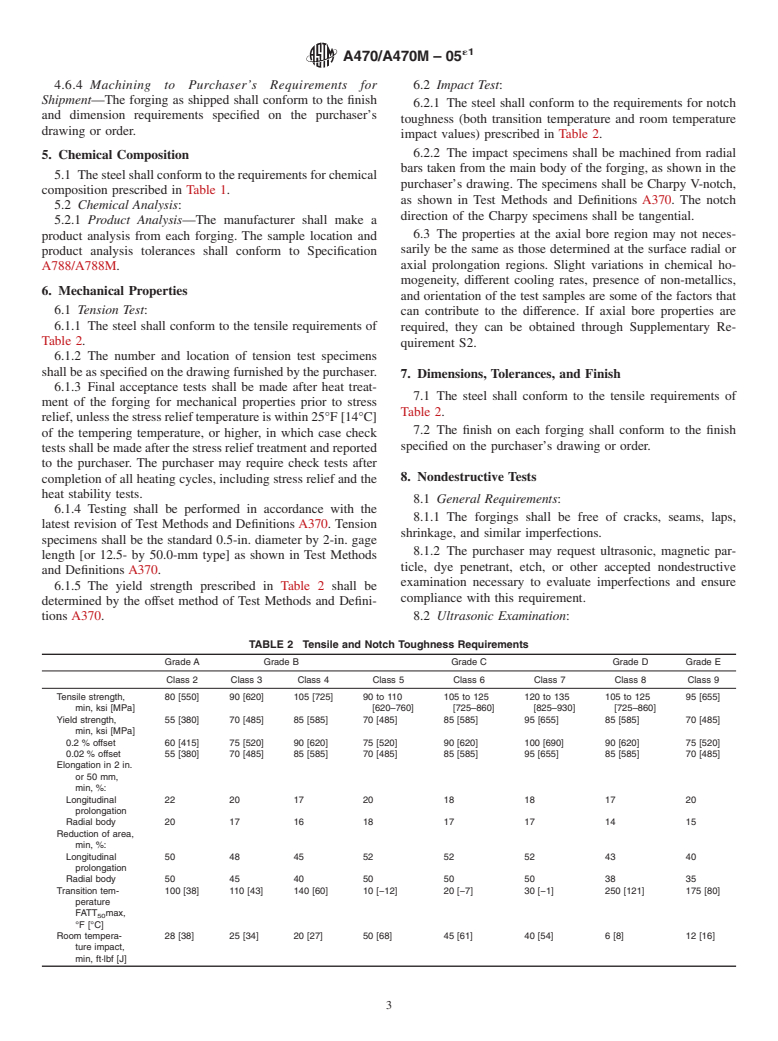

1. Scope* A751 Test Methods, Practices, andTerminology for Chemi-

cal Analysis of Steel Products

1.1 This specification covers vacuum-treated carbon and

A788/A788M Specification for Steel Forgings, General Re-

alloy steel forgings for turbine rotors and shafts.

quirements

1.2 The values stated in either SI units or inch-pound units

E139 Test Methods for Conducting Creep, Creep-Rupture,

are to be regarded separately as standard. The values stated in

and Stress-Rupture Tests of Metallic Materials

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

3. Ordering Information and General Requirements

values from the two systems may result in non-conformance

3.1 Material supplied to this specification shall conform to

with the standard.

the requirements of Specification A788/A788M, which out-

1.3 This standard does not purport to address all of the

lines additional ordering information, manufacturing methods

safety concerns, if any, associated with its use. It is the

and procedures, marking, certification, production analysis

responsibility of the user of this standard to establish appro-

variations, and additional supplementary requirements.

priate safety and health practices and determine the applica-

3.2 In addition to the ordering information required by

bility of regulatory limitations prior to use.

Specification A788/A788M, the purchaser shall include with

2. Referenced Documents the inquiry and order, the grade and class of steel, alternative

2

maximum for silicon content (see Table 1), the choice of yield

2.1 ASTM Standards:

strength offset (0.2 or 0.02 %), and any tests, supplementary

A275/A275M Practice for Magnetic Particle Examination

requirements, and purchase options desired.

of Steel Forgings

3.3 Forging Drawing—Each forging shall be manufactured

A293 Specification for Steel Forgings, Carbon and Alloy,

3

in accordance with a drawing furnished by the purchaser

for Turbine Generator Rotors and Shafts

showing the dimensions of the forging and bore hole, if any,

A370 Test Methods and Definitions for Mechanical Testing

and the location of mechanical test specimens.

of Steel Products

3.4 Supplementary Requirements—Supplementary require-

A418/A418M Practice for Ultrasonic Examination of Tur-

ments are provided. These requirements shall apply only when

bine and Generator Steel Rotor Forgings

specified in the purchase order.

A472/A472M Specification for Heat Stability of Steam

3.5 If the requirements of this specification are in conflict

Turbine Shafts and Rotor Forgings

with the requirements of Specification A788/A788M, the

requirements of this specification shall prevail.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

4. Manufacture

A01.06 on Steel Forgings and Billets.

4.1 Melting Process:

Current edition approved Sept. 22, 2006. Published September 2005. Originally

approved in 1962. Last previous edition approved in 2003 as A470 – 03. DOI: 4.1.1 The steel shall be made by the basic electric-furnace

10.1520/A0470_A0470M-05E01.

process.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1.2 Provisions for subsequent secondary melting of the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

steel by the consumable electrode-electroslag or vacuum-arc

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

remelting processes are included in Supplementary Require-

3

Withdrawn. The last approved version of this historical standard is referenced

ment S7.

on www.astm.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

A470/A470M – 05

A

TABLE 1 Chemical Requirements

Grade A Grade B Grade C Grade D Grade E

Ni-Mo-V Ni-Mo-V Ni-Cr-Mo-V Cr-Mo-V Ni-Mo-V

Carbon 0.22–0.30 0.22–0.30 0.28 0.25–0.35 0.30

Manganese 0.20–0.60 0.20–0.60 0.20–0.60 1.00 0.70

Phosp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.