ASTM D7718-11

(Practice)Standard Practice for Obtaining In-Service Samples of Lubricating Grease

Standard Practice for Obtaining In-Service Samples of Lubricating Grease

SIGNIFICANCE AND USE

This practice is typically used to obtain in-service lubricating grease samples from machinery.

In this practice, a consistent and repeatable method is outlined for obtaining trendable samples from the following applications including motor-operated valves, gearboxes, pillow-block bearings, electric motors, exposed bearings, open gears, or failed grease-lubricated components. This allows for analysis and inspection of in-service lubricating grease that aids in predicting the life and condition of the grease-lubricated component. This information can be combined with other technologies such as infrared imaging, vibration analysis, and ultrasonic vibration analysis to predict when a machine may fail. The knowledge gained by the aforementioned analyses, in addition to the knowledge gained from the in-service lubricating grease analysis and inspection, may allow for more overall uptime by aiding in the prediction of grease-lubricated component failures as part of a predictive maintenance schedule. The prediction of a failing grease-lubricated component will also improve the level of safety of all who work around the component.

SCOPE

1.1 This practice covers the method to obtain a trendable in-service lubricating grease sample from the following configurations including motor-operated valves, gearboxes, pillow-block bearings, electric motors, exposed bearings, open gears, or failed grease-lubricated components.

1.2 In some cases, it may be necessary to take more than one sample from a piece of equipment to obtain more trendable results. Examples of this could be a large bearing that does not fully rotate, such as a slew bearing, or one in which sufficient mixing does not otherwise occur.

1.3 Samples taken in the above manner may need to be mixed to form a more homogeneous sample. This may also be true of other samples such as those taken from open face bearings.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. The exception to this is a standard English units thread for which there is no metric equivalent.

Note 1—The standard pipe thread referred to is the national pipe thread tapered thread.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7718 − 11

Standard Practice for

1

Obtaining In-Service Samples of Lubricating Grease

This standard is issued under the fixed designation D7718; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope 2.2 ANSI/ASME Standard:

B1.20.1 Pipe Threads, General Purpose (Inch)

1.1 This practice covers the method to obtain a trendable

in-service lubricating grease sample from the following con-

3. Terminology

figurations including motor-operated valves, gearboxes,

pillow-block bearings, electric motors, exposed bearings, open 3.1 Definitions:

gears, or failed grease-lubricated components.

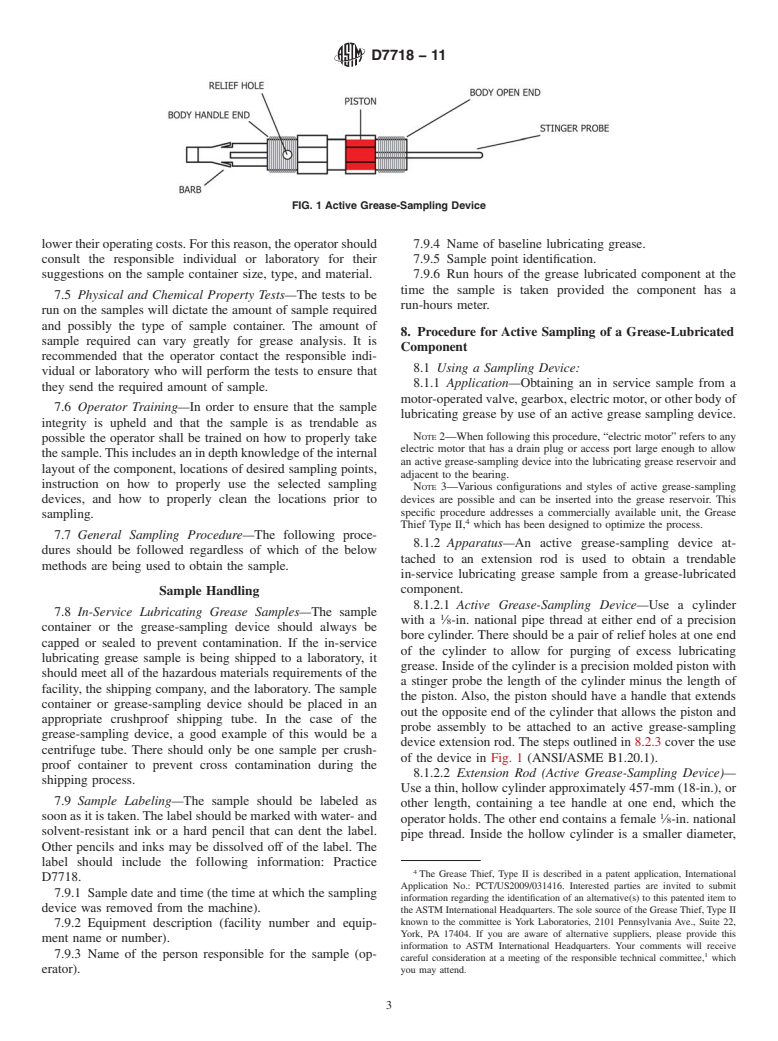

3.1.1 active grease-sampling device, n—device designed to

take an active sample of a lubricating grease from a bearing,

1.2 Insomecases,itmaybenecessarytotakemorethanone

gear, or drive shaft located in a grease-lubricated component.

sample from a piece of equipment to obtain more trendable

results. Examples of this could be a large bearing that does not

3.1.2 active sampling, v—to use a sampling device to

fully rotate, such as a slew bearing, or one in which sufficient

actively gather an in-service lubricating grease sample from a

mixing does not otherwise occur.

grease-lubricated component.

1.3 Samples taken in the above manner may need to be

3.1.3 actuate, v—to hold the interior cylinder of the active

mixed to form a more homogeneous sample. This may also be

grease-sampling device while pushing the exterior cylinder

true of other samples such as those taken from open face

forward toward the grease-lubricated component that is being

bearings.

sampledallowinglubricatinggreasetofillthesamplingdevice.

1.4 The values stated in SI units are to be regarded as the

3.1.4 extension rod, n—tool used to extend the depth at

standard. The values given in parentheses are for information

which a sample is taken with an active grease-sampling device.

only.TheexceptiontothisisastandardEnglishunitsthreadfor

3.1.4.1 Discussion—The extension rod may also be used to

which there is no metric equivalent.

remotely actuate an active grease-sampling device.

NOTE1—Thestandardpipethreadreferredtoisthenationalpipethread

3.1.5 in-service lubricating grease, n—lubricating grease

tapered thread.

that has been applied as a lubricant to a gear, bearing, or drive

1.5 This standard does not purport to address all of the

screw for any period of time.

safety concerns, if any, associated with its use. It is the

3.1.6 lubricating grease, n—semi-fluid to solid product of a

responsibility of the user of this standard to establish appro-

dispersion of a thickener in a liquid lubricant.

priate safety and health practices and determine the applica-

3.1.6.1 Discussion—The dispersion of the thickener forms a

bility of regulatory limitations prior to use.

two-phase system and immobilizes the liquid lubricant by

surface tension and other physical forces. Other ingredients are

2. Referenced Documents

commonly included to impart special properties. D217

2

2.1 ASTM Standards:

3.1.7 passive grease-sampling device, n—device designed

D217 Test Methods for Cone Penetration of Lubricating

to gather a sample from the equipment by being attached to the

Grease

grease reservoir at the purge point.

D4057 Practice for Manual Sampling of Petroleum and

3.1.7.1 Discussion—This device has also been designed to

Petroleum Products

contain a lubricating grease sample that has been gathered with

other methods.

1

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum

3.1.8 passive sampling, v—to use a passive grease-sampling

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

device to collect a purged sample of in-service lubricating

mittee D02.96.04 on Guidelines for In-Services Lubricants Analysis.

grease from a purge path.

Current edition approved May 1, 2011. Published May 2011. DOI:10.1520/

D7718-11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7718 − 11

3.1.9 trendable, adj—sample of in-service lubricating 5.2 Sampling Devices—The sampling devices for each pro-

grease used to trend the physical properties, wear levels, and c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.