ASTM D2883-95(2009)

(Test Method)Standard Test Method for Reaction Threshold Temperature of Liquid and Solid Materials (Withdrawn 2016)

Standard Test Method for Reaction Threshold Temperature of Liquid and Solid Materials (Withdrawn 2016)

SIGNIFICANCE AND USE

The reaction thresholds of a material are a measure of the tendency of the material or its decomposition products to undergo gas phase reactions of various types. Hot-flame and cool-flame thresholds relate directly to reactions which are involved in autoignition phenomena. Pre-flame, catalytic and thermal polymerization thresholds also relate to autoignition in that they represent reactions which can be under some conditions the precursors of ignition reactions.

SCOPE

1.1 This test method covers determination of the pre-flame, cool-flame, and hot-flame reaction threshold temperatures and the incipient reaction temperature of liquids and solids. Data may be obtained at pressures from low vacuum to 0.8 MPa (115 psia) for temperatures within the range from room temperature to 925 K (1200°F).

1.2 This test method may be applied to any substance that is a liquid or a solid at room temperature and atmospheric pressure and that, at room temperature, is compatible with glass and stainless steel. Air is the intended oxidizing medium; however, other media may be substituted provided appropriate precautions are taken for their safe use.

1.3 The values stated in SI units are to be regarded as the standard. In cases where materials, products, or equipment are available in inch-pound units only, SI units are omitted.

1.4 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 6.8, Sections 7 and 9.

WITHDRAWN RATIONALE

This test method covers determination of the pre-flame, cool-flame, and hot-flame reaction threshold temperatures and the incipient reaction temperature of liquids and solids. Data may be obtained at pressures from low vacuum to 0.8 MPa (115 psia) for temperatures within the range from room temperature to 925 K (1200°F).

Formerly under the jurisdiction of Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants, this test method was withdrawn in July 2016 due to lack of interest in maintaining the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2883 −95(Reapproved 2009)

Standard Test Method for

Reaction Threshold Temperature of Liquid and Solid

Materials

This standard is issued under the fixed designation D2883; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2021SpecificationforNeutralDetergent,40PercentAlky-

lbenzene Sulfonate Type (Withdrawn 2000)

1.1 This test method covers determination of the pre-flame,

E659Test Method for Autoignition Temperature of Liquid

cool-flame, and hot-flame reaction threshold temperatures and

Chemicals

the incipient reaction temperature of liquids and solids. Data

2.2 Military Standards:

may be obtained at pressures from low vacuum to 0.8 MPa

MIL-C-81302Trichlorotrifluoroethane

(115 psia) for temperatures within the range from room

MIL-T-7003Trichloroethylene

temperature to 925 K (1200°F).

1.2 Thistestmethodmaybeappliedtoanysubstancethatis

3. Terminology

a liquid or a solid at room temperature and atmospheric

3.1 Definitions of Terms Specific to This Standard:

pressure and that, at room temperature, is compatible with

3.1.1 catalytic reaction, n—afast,self-sustaining,energetic,

glass and stainless steel.Air is the intended oxidizing medium;

sometimesluminous,sometimesaudiblereactionthatoccursas

however, other media may be substituted provided appropriate

a result of catalytic action on the surface of the thermocouple

precautions are taken for their safe use.

or other solid surface within the combustion chamber.

1.3 The values stated in SI units are to be regarded as the

3.1.2 cool-flame reaction, n—a relatively slow, self-

standard. In cases where materials, products, or equipment are

sustaining, barely luminous reaction of the sample or its

available in inch-pound units only, SI units are omitted.

decompositionproductswiththeatmosphereinthecombustion

1.4 This standard is used to measure and describe the

chamber.

response of materials, products, or assemblies to heat and

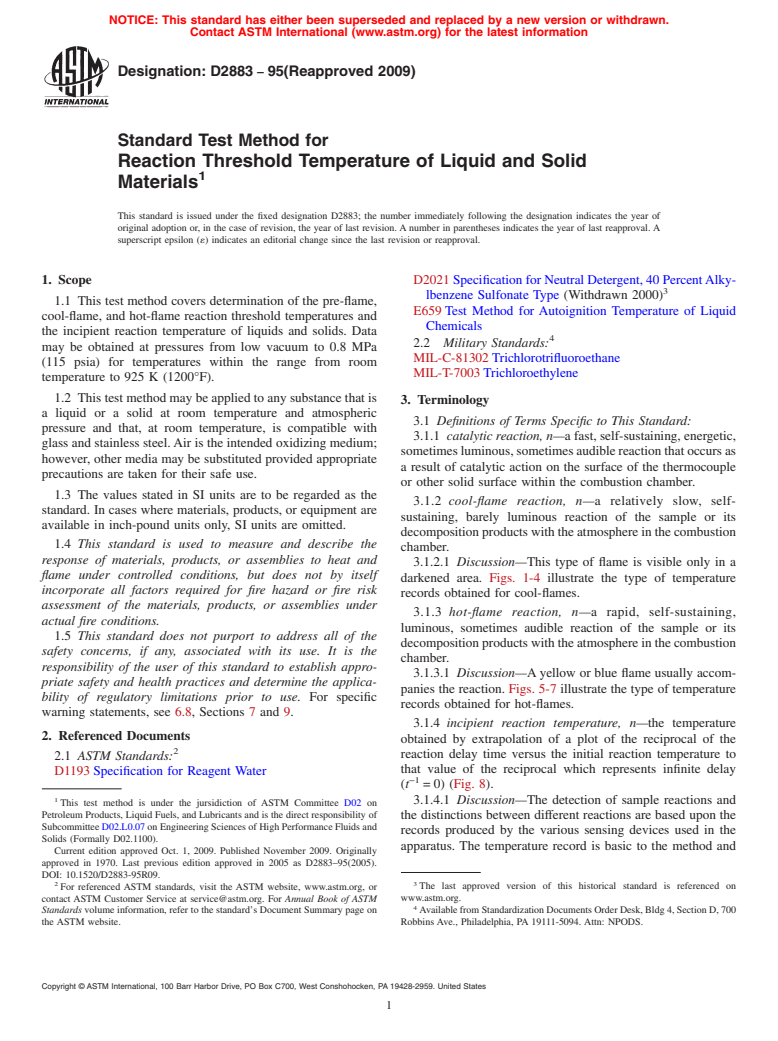

3.1.2.1 Discussion—This type of flame is visible only in a

flame under controlled conditions, but does not by itself

darkened area. Figs. 1-4 illustrate the type of temperature

incorporate all factors required for fire hazard or fire risk

records obtained for cool-flames.

assessment of the materials, products, or assemblies under

3.1.3 hot-flame reaction, n—a rapid, self-sustaining,

actual fire conditions.

luminous, sometimes audible reaction of the sample or its

1.5 This standard does not purport to address all of the

decompositionproductswiththeatmosphereinthecombustion

safety concerns, if any, associated with its use. It is the

chamber.

responsibility of the user of this standard to establish appro-

3.1.3.1 Discussion—Ayellow or blue flame usually accom-

priate safety and health practices and determine the applica-

panies the reaction. Figs. 5-7 illustrate the type of temperature

bility of regulatory limitations prior to use. For specific

records obtained for hot-flames.

warning statements, see 6.8, Sections 7 and 9.

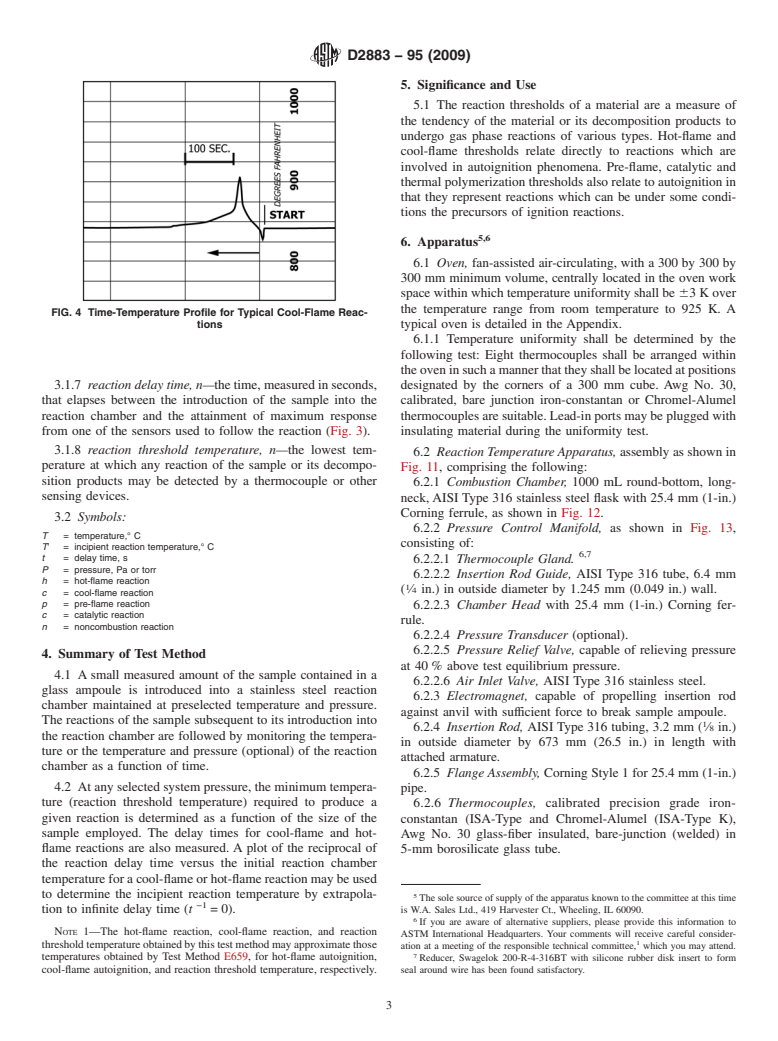

3.1.4 incipient reaction temperature, n—the temperature

2. Referenced Documents

obtained by extrapolation of a plot of the reciprocal of the

reaction delay time versus the initial reaction temperature to

2.1 ASTM Standards:

that value of the reciprocal which represents infinite delay

D1193Specification for Reagent Water

−1

(t =0)(Fig. 8).

3.1.4.1 Discussion—The detection of sample reactions and

This test method is under the jursidiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

the distinctions between different reactions are based upon the

SubcommitteeD02.L0.07onEngineeringSciencesofHighPerformanceFluidsand

records produced by the various sensing devices used in the

Solids (Formally D02.1100).

apparatus. The temperature record is basic to the method and

Current edition approved Oct. 1, 2009. Published November 2009. Originally

approved in 1970. Last previous edition approved in 2005 as D2883–95(2005).

DOI: 10.1520/D2883-95R09.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg4,SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094. Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2883−95 (2009)

FIG. 1Time-Temperature Profile for Typical Cool-Flame Reactions

FIG. 2Time-Temperature Profile for Typical Cool-Flame Reactions

FIG. 3Time-Temperature Profile for Typical Cool-Flame Reactions

shall be regarded as the primary source of such data. The use of the type of reaction that may occur when dealing with

ofapressurerecordandtherecordsofothersensingdevicesto potentially reactive substances.

obtain additional data is optional.

3.1.6 pre-flame reaction, n—a slow, nonluminous reaction

3.1.5 noncombustivereaction,n—areactionotherthancom- of the sample or its decomposition products with the atmo-

bustion or thermal degradation undergone by certain materials sphere in the combustion chamber.

upon exposure to elevated temperatures. 3.1.6.1 Discussion—Fig. 9 and Fig. 10 illustrate the type of

3.1.5.1 Discussion—Thermal polymerization is an example temperature records obtained for preflame reactions.

D2883−95 (2009)

5. Significance and Use

5.1 The reaction thresholds of a material are a measure of

the tendency of the material or its decomposition products to

undergo gas phase reactions of various types. Hot-flame and

cool-flame thresholds relate directly to reactions which are

involved in autoignition phenomena. Pre-flame, catalytic and

thermalpolymerizationthresholdsalsorelatetoautoignitionin

that they represent reactions which can be under some condi-

tions the precursors of ignition reactions.

5,6

6. Apparatus

6.1 Oven, fan-assisted air-circulating, with a 300 by 300 by

300 mm minimum volume, centrally located in the oven work

spacewithinwhichtemperatureuniformityshallbe 63Kover

the temperature range from room temperature to 925 K. A

FIG. 4 Time-Temperature Profile for Typical Cool-Flame Reac-

tions typical oven is detailed in the Appendix.

6.1.1 Temperature uniformity shall be determined by the

following test: Eight thermocouples shall be arranged within

theoveninsuchamannerthattheyshallbelocatedatpositions

3.1.7 reaction delay time, n—thetime,measuredinseconds, designated by the corners of a 300 mm cube. Awg No. 30,

that elapses between the introduction of the sample into the calibrated, bare junction iron-constantan or Chromel-Alumel

reaction chamber and the attainment of maximum response thermocouplesaresuitable.Lead-inportsmaybepluggedwith

from one of the sensors used to follow the reaction (Fig. 3). insulating material during the uniformity test.

3.1.8 reaction threshold temperature, n—the lowest tem-

6.2 Reaction Temperature Apparatus, assembly as shown in

perature at which any reaction of the sample or its decompo-

Fig. 11, comprising the following:

sition products may be detected by a thermocouple or other

6.2.1 Combustion Chamber, 1000 mL round-bottom, long-

sensing devices.

neck,AISI Type 316 stainless steel flask with 25.4 mm (1-in.)

Corning ferrule, as shown in Fig. 12.

3.2 Symbols:

6.2.2 Pressure Control Manifold, as shown in Fig. 13,

T = temperature,° C

consisting of:

T' = incipient reaction temperature,° C

6,7

t = delay time, s

6.2.2.1 Thermocouple Gland.

P = pressure, Pa or torr

6.2.2.2 Insertion Rod Guide, AISI Type 316 tube, 6.4 mm

h = hot-flame reaction

( ⁄4 in.) in outside diameter by 1.245 mm (0.049 in.) wall.

c = cool-flame reaction

p = pre-flame reaction

6.2.2.3 Chamber Head with 25.4 mm (1-in.) Corning fer-

c = catalytic reaction

rule.

n = noncombustion reaction

6.2.2.4 Pressure Transducer (optional).

6.2.2.5 Pressure Relief Valve, capable of relieving pressure

4. Summary of Test Method

at 40% above test equilibrium pressure.

4.1 A small measured amount of the sample contained in a

6.2.2.6 Air Inlet Valve, AISI Type 316 stainless steel.

glass ampoule is introduced into a stainless steel reaction

6.2.3 Electromagnet, capable of propelling insertion rod

chamber maintained at preselected temperature and pressure.

against anvil with sufficient force to break sample ampoule.

The reactions of the sample subsequent to its introduction into

6.2.4 Insertion Rod, AISI Type 316 tubing, 3.2 mm ( ⁄8 in.)

the reaction chamber are followed by monitoring the tempera-

in outside diameter by 673 mm (26.5 in.) in length with

ture or the temperature and pressure (optional) of the reaction

attached armature.

chamber as a function of time.

6.2.5 Flange Assembly, Corning Style 1 for 25.4 mm (1-in.)

4.2 At any selected system pressure, the minimum tempera-

pipe.

ture (reaction threshold temperature) required to produce a

6.2.6 Thermocouples, calibrated precision grade iron-

given reaction is determined as a function of the size of the

constantan (ISA-Type and Chromel-Alumel (ISA-Type K),

sample employed. The delay times for cool-flame and hot-

Awg No. 30 glass-fiber insulated, bare-junction (welded) in

flame reactions are also measured. A plot of the reciprocal of

5-mm borosilicate glass tube.

the reaction delay time versus the initial reaction chamber

temperatureforacool-flameorhot-flamereactionmaybeused

to determine the incipient reaction temperature by extrapola-

The sole source of supply of the apparatus known to the committee at this time

−1

tion to infinite delay time (t =0). is W.A. Sales Ltd., 419 Harvester Ct., Wheeling, IL 60090.

If you are aware of alternative suppliers, please provide this information to

NOTE 1—The hot-flame reaction, cool-flame reaction, and reaction

ASTM International Headquarters. Your comments will receive careful consider-

thresholdtemperatureobtainedbythistestmethodmayapproximatethose

ation at a meeting of the responsible technical committee, which you may attend.

temperatures obtained by Test Method E659, for hot-flame autoignition, Reducer, Swagelok 200-R-4-316BT with silicone rubber disk insert to form

cool-flame autoignition, and reaction threshold temperature, respectively. seal around wire has been found satisfactory.

D2883−95 (2009)

FIG. 5Time-Temperature Profile and Delay Time for Typical Hot-Flame Reactions

FIG. 6Time-Temperature Profile and Delay Time for Typical Hot-Flame Reactions

FIG. 7Time-Temperature Profile and Delay Time for Typical Hot-Flame Reactions

6.3 Sample Ampoule, illustrated for solids and liquids in

Fig. 14.

D2883−95 (2009)

7.3 Chloroform,technicalgrade.(Warning—Canbefatalif

swallowed. Harmful if inhaled. Can produce toxic vapors if

burned. See A2.5.)

7.4 Detergent, free-rinsing, conforming to Specification

D2021.

7.5 Reagent Water, conforming to Specification D1193,

either grade.

7.6 Acetic Acid, ACS reagent grade.

7.7 Hydroiodic Acid, 57% reagent grade.

8. Test Specimen

8.1 Liquid Sample—200 mL is sufficient for the determina-

tion of the various reaction threshold temperatures at a single

FIG. 8 Effect of the Reaction Temperature on the Delay Time to

pressure.

Determine Incipient Reaction Temperature

8.2 Solid Sample—150 g is sufficient for the determination

of the various reaction threshold temperatures at a single

6,8

6.4 Temperature Recorder, 475 to 1025 K, (400 to

pressure.

1400°F) range, ⁄4 s full-scale deflection, thermocouple actua-

tion with range changes for iron-constantan and Chromel-

9. Procedure

Alumel elements.

9.1 Method A for Liquids:

6,9

6.5 HypodermicSyringe, fluorocarbon-tipped0.5mLand

9.1.1 Clean a combustion chamber as follows: rinse with

2.5 mLwith hypodermic needles suitable for introduction into

trichloroethylene (Warning—Harmful if inhaled. High con-

sample ampoules.

centrations may cause unconsciousness or death. Contact can

6.6 Pressure Gauges, capable of determining the appropri-

cause skin irritation and dermatitis. See A2.2.), immerse in

ate pressure with an accuracy of 61%.

cleaning compound for a minimum of 15 min at 293 to 308 K,

wash with detergent, and rinse thoroughly with reagent water.

6.7 Vacuum System, capable of attaining and maintaining

6,10

Dryinanovenat393to423K.Discardthechamberifnotfree

the required pressure with mechanical vacuum pump and

of deposits. Clean the thermocouple internal supports, anvil,

cold trap inserted in the line between the reaction temperature

and insertion rod in the same manner.

apparatus and the pump.

6,11

6.8 Gas Supply System, capable of supplying the appro- NOTE2—Achloroform(see7.3)rinsepriortowashingcanproveuseful

in some cases. Difficult deposits may be removed by walnut shell

priate gas, dewpoint 215 K (−70°F) maximum and essentially

abrasion. Discard the chamber if deposits can not be removed or if

free of contaminants at pressures up to 0.8 MPa. (Warning—

inspection reveals that the interior of the chamber has been damaged or

Compressed gas under high pressure. Gas reduces oxygen

corroded.

available for breathing. See A2.1.)

NOTE 3—Stainless steel, Type 316 combustion chambers and an air

atmospherehavebeenspecifiedwiththistestmethod.However,chambers

6.9 Exhaust Hood, capable of disposing of fumes vented

of other materials and of different sizes, and atmospheres of other gases

from the reaction temperature apparatus.

may be used when required.

NOTE 4—Chambers may be tested for the presence of peroxide or free

7. Reagents and Materials

radical residues by purging them with nitrogen and rinsing with a freshly

prepared mixture of 3 mL each of chloroform, glacial acetic acid,

7.1 Trichloroethylene, conforming to MIL-T-7003. Trichlo-

(Warning—Poison. Corrosive. Combustible. Can be fatal if swallowed.

rotrifluoroethane conforming to MIL-C-81302 or high flash

Causes severe burns. Harmful if inhaled. See A2.6) and hydroiodic acid

point naphtha may be used as alternatives. (Warning—

(57%analyticalgrade,notstabilized)(Warning—Poison.Corrosive.Can

Harmful if inhaled. High concentrations may cause uncon-

be fatal if swallowed. Liquid and vapor cause severe burns. Harmful if

inhaled. SeeA2.7). When this mixture is poured into a clean glass vessel

sciousness or death. Contact can cause skin irritation and

and 10 drops of stabilized starch solution added, a trace of the starch-

dermatitis. See A2.2.)

iodine color

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.