ASTM C1373-98

(Practice)Standard Practice for Determination of Thermal Resistance of Attic Insulation Systems Under Simulated Winter Conditions

Standard Practice for Determination of Thermal Resistance of Attic Insulation Systems Under Simulated Winter Conditions

SCOPE

1.1 This practice presents a laboratory procedure to determine the thermal resistance of attic insulation systems under simulated steady-state winter conditions. The practice applies only to attic insulation systems that face an open attic air space.

1.2 The thermal resistance of the insulation is inferred from calculations based on measurements on a ceiling system consisting of components consistent with the system being studied. For example, such a system might consist of a gypsum board or plywood ceiling, wood ceiling joists, and attic insulation with its top exposed to an open air space. The temperature applied to the gypsum board or plywood shall be in the range of 18 to 24°C (64 to 75°F). The air temperature above the insulation shall correspond to winter conditions and may range from -46°C to 10°C (-51 to 50°F). The gypsum board or plywood ceiling shall be sealed to prevent direct airflow between the warm an cold sides of the system.

1.3 This practice applies to a wide variety of loose-fill or blanket thermal insulation products including fibrous glass, rock/slag wool, or cellulosic fiber materials; granular types including vermiculite and perlite; pelletized products; and any other insulation material that may be installed pneumatically or poured in place. The practice considers the effects on heat for example, gypsum board, air films, and possible facings, films, or other materials that may abe used in conjunction with the insulation.

1.4 This practice measures the thermal resistance of the attic/ceiling system in which the insulation material has been preconditioned according to the material Specifications C549, C665, C739, and C764.

1.5 The specimen preparation techniques outlined in this standard do not cover the characterization of loose-fill materials intended for enclosed applications.

1.6 This practice may be used to characterize material behavior under controlled steady-state laboratory conditions intended to simulate actual temperature conditions of use. The practice does not simulate forced air flow conditions.

1.7 All values shall be reported in both SI units and inch-pound units unless specified otherwise by the client.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1373 – 98

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Determination of Thermal Resistance of Attic Insulation

Systems Under Simulated Winter Conditions

This standard is issued under the fixed designation C 1373; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope units unless specified otherwise by the client.

1.8 This standard does not purport to address all of the

1.1 This practice presents a laboratory procedure to deter-

safety concerns, if any, associated with its use. It is the

mine the thermal resistance of attic insulation systems under

responsibility of the user of this standard to establish appro-

simulated steady-state winter conditions. The practice applies

priate safety and health practices and determine the applica-

only to attic insulation systems that face an open attic air space.

bility of regulatory limitations prior to use.

1.2 The thermal resistance of the insulation is inferred from

calculations based on measurements on a ceiling system

2. Referenced Documents

consisting of components consistent with the system being

2.1 ASTM Standards:

studied. For example, such a system might consist of a gypsum

C 167 Test Methods for Thickness and Density of Blanket

board or plywood ceiling, wood ceiling joists, and attic

or Batt Thermal Insulations

insulation with its top exposed to an open air space. The

C 168 Terminology Relating to Thermal Insulating Materi-

temperature applied to the gypsum board or plywood shall be

als

in the range of 18 to 24°C (64 to 75°F). The air temperature

C 177 Test Method for Steady-State Heat Flux Measure-

above the insulation shall correspond to winter conditions and

ments and Thermal Transmission Properties by Means of

may range from –46°C to 10°C (–51 to 50°F). The gypsum

the Guarded Hot Plate Apparatus

board or plywood ceiling shall be sealed to prevent direct

C 236 Test Method for Steady-State Thermal Performance

airflow between the warm and cold sides of the system.

of Building Assemblies by Means of a Guarded Hot Box

1.3 This practice applies to a wide variety of loose-fill or

C 518 Test Method for Steady-State Heat Flux Measure-

blanket thermal insulation products including fibrous glass,

ments and Thermal Transmission Properties by Means of

rock/slag wool, or cellulosic fiber materials; granular types

the Heat Flow Meter Apparatus

including vermiculite and perlite; pelletized products; and any

C 520 Test Methods for Density of Granular Loose-Fill

other insulation material that may be installed pneumatically or

Insulations

poured in place. The practice considers the effects on heat

C 549 Specification for Perlite Loose Fill Insulation

transfer of structures, specifically the ceiling joists, substrate,

C 665 Specification for Mineral-Fiber Blanket Thermal In-

for example, gypsum board, air films, and possible facings,

sulation for Light Frame Construction and Manufactured

films, or other materials that may be used in conjunction with

Housing

the insulation.

C 687 Practice for Determination of Thermal Resistance of

1.4 This practice measures the thermal resistance of the

Loose-Fill Building Insulation

attic/ceiling system in which the insulation material has been

C 739 Specification for Cellulosic Fiber (Wood Base)

preconditioned according to the material Specifications C 549,

Loose-Fill Thermal Insulation

C 665, C 739, and C 764.

C 764 Specification for Mineral Fiber Loose-Fill Thermal

1.5 The specimen preparation techniques outlined in this

Insulation

standard do not cover the characterization of loose-fill materi-

C 976 Test Method for Thermal Performance of Building

als intended for enclosed applications.

Assemblies by Means of a Calibrated Hot Box

1.6 This practice may be used to characterize material

C 1045 Practice for Calculating Thermal Transmission

behavior under controlled steady-state laboratory conditions

Properties from Steady-State Heat Flux Measurements

intended to simulate actual temperature conditions of use. The

C 1058 Practice for Selecting Temperatures for Evaluating

practice does not simulate forced air flow conditions.

and Reporting Thermal Properties of Thermal Insulation

1.7 All values shall be reported in both SI and inch-pound

C 1114 Test Method for Steady-State Thermal Transmission

Properties by Means of the Thin-Heater Apparatus

This practice is under the jurisdiction of ASTM Committee C-16 on Thermal

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

Measurements.

Current edition approved Nov. 10, 1998. Published May 1999. Annual Book of ASTM Standards, Vol 04.06.

C 1373

densities will depend upon the product type, the installed

thickness, the installation equipment used, the installation

technique, and the geometry of the insulated space.

4.5 The onset of natural convection under winter conditions

may be a function of specimen thickness. For purposes of this

practice, the tests shall be carried out at thicknesses at which

the product is used.

4.6 Since this practice simulates winter conditions, the heat

flow direction shall be vertically upwards.

4.7 Specimens shall be prepared in a manner consistent with

the intended installation procedure. Products for pneumatic

installation shall be pneumatically-applied (blown), and prod-

ucts for pour-in-place installation shall be poured into place.

See 5.2.

5. Equipment

NOTE 1—A constant hot-side temperature (T, hot) is used for both tests

5.1 Thermal test apparatus used for this practice shall meet

and the temperature difference increases as the cold side temperature (T,

the following requirements:

cold) is decreased. See 5.1.6 for requirements on size of air space.

FIG. 1 Schematic of Thermal Resistance for a Permeable Attic 5.1.1 Conformance to Standards—The apparatus shall con-

Insulation Under Simulated Winter Conditions (Heat Flow Up)

form to all requirements of the ASTM thermal test method

used, except as required by 5.1.2-5.1.6.

C 1363 Test Method for the Thermal Performance of Build-

5.1.2 Size—The apparatus shall be capable of testing speci-

ing Assemblies by Means of a Hot Box Apparatus

mens at the thickness intended for product use. Length and

width of the metering area shall be at least twice the spacing of

3. Terminology

the wood joists or four times the specimen thickness, which-

3.1 Definitions— Unless otherwise stated, the definitions

ever is greater (see Fig. 2).

listed in Terminology C 168 are applicable herein.

5.1.3 Temperature— The apparatus shall be capable of

testing with the hot side surface maintained between 18 and

4. Significance and Use

24°C (64 and 75°F), and with the cold side air temperature

4.1 The thermal resistance of a ceiling system is used to

maintained near the winter condition for the particular climate

characterize its steady-state thermal performance.

being simulated, which may range from –46 to 10°C (–51 to

4.2 The thermal resistance of insulation is related to the

50°F). In the absence of specified temperatures, the ambient

density and thickness of the insulation. Test data on thermal

temperatures listed in Table 2 of C 1058 on Temperatures for

resistance are obtained at a thickness and density representative

Thermal Transmittance Evaluations may be used.

of the end use applications. In addition, the thermal resistance

NOTE 1—Only those with a hot ambient of 24°C (75°F) are applicable.

of the insulation system will be different from that of the

thermal insulation alone because of the system construction

5.1.4 Humidity—The absolute humidity on both sides of the

and materials.

test apparatus shall be maintained low enough to prevent

4.3 This practice is needed because the in-service thermal

condensation within the specimen. See 6.9.6 of Test Method

resistance of some permeable attic insulations under winter

C 1363 for humidity requirements for the hot box methods, 6.6

conditions may be different, lower or higher R, than that

of Test Method C 177 for the guarded hot plate method, and

measured at or close to simulated room temperature conditions

7.10 of Test Method C 518 for the heat flow meter apparatus.

utilizing small-scale tests in which the insulation is sandwiched

5.1.5 Orientation and Direction of Heat Flow—The thermal

between two isothermal impermeable plates that have a tem-

test specimen shall be oriented horizontally with heat flow up.

perature difference (DT) of 20 to 30°C (36 to 54°F). When such

insulation is installed in an attic, on top of a ceiling composed

of normal building materials such as gypsum board or ply-

wood, with an open top surface exposed to the attic air space,

the thermal resistance under winter conditions with heat flow

up and large temperature differences may be significantly less

because of additional heat transfer by natural convection. Fig.

1 illustrates the difference between results from small scale

tests and tests under the conditions of this practice. See Ref

(1-12) for discussions of this phenomenon.

4.4 In normal use, the thickness of insulation products may

range from 75 mm (3 in.) to 500 mm (20 in.). Installed

The boldface numbers in parentheses refer to the list of references at the end of FIG. 2 Requirements on Dimensions of Test Specimen Metering

this standard. Area

C 1373

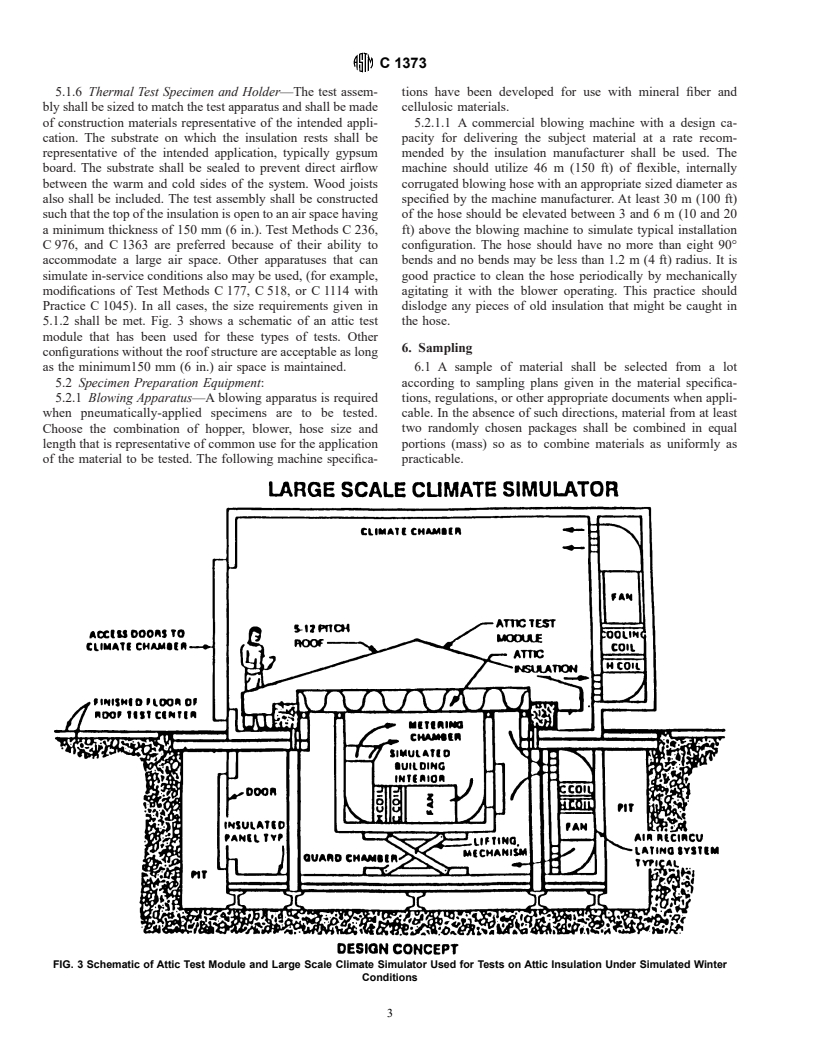

5.1.6 Thermal Test Specimen and Holder—The test assem- tions have been developed for use with mineral fiber and

bly shall be sized to match the test apparatus and shall be made cellulosic materials.

of construction materials representative of the intended appli- 5.2.1.1 A commercial blowing machine with a design ca-

cation. The substrate on which the insulation rests shall be pacity for delivering the subject material at a rate recom-

representative of the intended application, typically gypsum mended by the insulation manufacturer shall be used. The

board. The substrate shall be sealed to prevent direct airflow machine should utilize 46 m (150 ft) of flexible, internally

between the warm and cold sides of the system. Wood joists corrugated blowing hose with an appropriate sized diameter as

also shall be included. The test assembly shall be constructed specified by the machine manufacturer. At least 30 m (100 ft)

such that the top of the insulation is open to an air space having of the hose should be elevated between 3 and 6 m (10 and 20

a minimum thickness of 150 mm (6 in.). Test Methods C 236, ft) above the blowing machine to simulate typical installation

C 976, and C 1363 are preferred because of their ability to configuration. The hose should have no more than eight 90°

accommodate a large air space. Other apparatuses that can bends and no bends may be less than 1.2 m (4 ft) radius. It is

simulate in-service conditions also may be used, (for example, good practice to clean the hose periodically by mechanically

modifications of Test Methods C 177, C 518, or C 1114 with agitating it with the blower operating. This practice should

Practice C 1045). In all cases, the size requirements given in dislodge any pieces of old insulation that might be caught in

5.1.2 shall be met. Fig. 3 shows a schematic of an attic test the hose.

module that has been used for these types of tests. Other

6. Sampling

configurations without the roof structure are acceptable as long

as the minimum150 mm (6 in.) air space is maintained. 6.1 A sample of material shall be selected from a lot

5.2 Specimen Preparation Equipment: according to sampling plans given in the material specifica-

5.2.1 Blowing Apparatus—A blowing apparatus is required tions, regulations, or other appropriate documents when appli-

when pneumatically-applied specimens are to be tested. cable. In the absence of such directions, material from at least

Choose the combination of hopper, blower, hose size and two randomly chosen packages shall be combined in equal

length that is representative of common use for the application portions (mass) so as to combine materials as uniformly as

of the material to be tested. The following machine specifica- practicable.

FIG. 3 Schematic of Attic Test Module and Large Scale Climate Simulator Used for Tests on Attic Insulation Under Simulated Winter

Conditions

C 1373

6.2 The insulation material should be preconditioned to a representative density. Some bag labels utilize multiple densi-

moisture content in equilibrium with the laboratory conditions ties to reflect the fact that greater thickness installations usually

prior to the specimen installation. Preconditioning of materials result in higher installed densities. The use of multiple densi-

not only ensures controlled installation conditions but may ties can be detected from the bag label by calculating the label

reduce the time required to condition the prepared specimen density for several different R-value levels. Label densities for

prior to thermal testing. For conditioning requirements, see the a given R-value can be calculated from the bag label by

applicable materials Specifications C 520, C 549, C 665, dividing the minimum mass/unit area by the minimum thick-

C 739, and C 764. ness. If the calculated densities are significantly different, the

multiple density label has been used. When applicable speci-

7. Specimen Preparation

fications or codes do not specify the density to be used for

7.1 General Instructions:

comparison purposes, the recommended practice is to use the

7.1.1 All specimens shall be prepared to a thickness and unit 2

R-30 label density ( R(SI) – 5.3 m · K/W). If the density is not

area mass that are given for the label R-value specification of

available from the bag label, a density for test purposes can be

interest for the material under test.

established by the procedures outlined in Test Method C 520 or

7.1.2 Specimens shall be prepared in a manner consistent

Specification C 739.

with the intended installation procedure. All materials shall be

7.2.3 Calculate the target mass of insulation required to fill

installed carefully using the manufacturer’s recommended

the sample frame to the target thickness and density from the

installation practice. Batts shall be cut, as required, to fit the

equation:

available specimen holder. Products for pneumatic installation

m5r@~L 3 A ! – V # (1)

ins joist

shall be pneumatically-applied (blown), and products for

pour-in-place installation shall be poured into the specimen

where:

h

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.