ASTM E488-96(2003)

(Test Method)Standard Test Methods for Strength of Anchors in Concrete and Masonry Elements

Standard Test Methods for Strength of Anchors in Concrete and Masonry Elements

SIGNIFICANCE AND USE

These test methods are intended to provide data from which applicable design data and specifications are derivable for a given anchorage device used in a structural member of concrete, masonry and related products and for qualifying anchors or anchorage systems.

The test methods shall be followed to ensure reproducibility of the test data.

SCOPE

1.1 These test methods cover procedures for determining the static, seismic, fatigue and shock, tensile and shear strengths of post-installed and cast-in-place anchorage systems in structural members made of concrete or structural members made of masonry. Only those tests required by the specifying authority need to be performed.

1.2 These test methods are intended for use with such anchorage devices designed to be installed perpendicular to a plane surface of the structural member.

1.3 Whereas combined tension and shear as well as torsion tests are performed under special conditions, such tests are not covered in the methods described herein.

1.4 While individual procedures are given for static, seismic, fatigue and shock testing, nothing herein shall preclude the use of combined testing conditions which incorporate two or more of these types of tests, (such as seismic, fatigue and shock tests in series), since the same equipment is used for each of these tests.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E488–96 (Reapproved 2003)

Standard Test Methods for

Strength of Anchors in Concrete and Masonry Elements

This standard is issued under the fixed designation E488; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E575 Practice for Reporting Data from Structural Tests of

Building Constructions, Elements, Connections, and As-

1.1 These test methods cover procedures for determining

semblies

the static, seismic, fatigue and shock, tensile and shear

strengths of post-installed and cast-in-place anchorage systems

3. Terminology

in structural members made of concrete or structural members

3.1 Definitions of Terms Specific to This Standard:

made of masonry. Only those tests required by the specifying

3.1.1 adhesive anchor—a post-installed anchor that derives

authority need to be performed.

its holding strength from the chemical compound between the

1.2 These test methods are intended for use with such

wall of the hole and the anchor rods. The materials used

anchorage devices designed to be installed perpendicular to a

includeepoxy,cementitiousmaterial,polyesterresin,andother

plane surface of the structural member.

similar types.

1.3 Whereas combined tension and shear as well as torsion

3.1.2 anchor spacing—the distance between anchors mea-

tests are performed under special conditions, such tests are not

sured centerline to centerline, in mm (in.); also, the minimum

covered in the methods described herein.

distance between reaction points of the test frame.

1.4 While individual procedures are given for static, seis-

3.1.3 cast-in-place anchor—ananchorthatisinstalledprior

mic, fatigue and shock testing, nothing herein shall preclude

to the placement of concrete and derives its holding strength

the use of combined testing conditions which incorporate two

from plates, lugs, or other protrusions that are cast into the

or more of these types of tests, (such as seismic, fatigue and

concrete.

shock tests in series), since the same equipment is used for

3.1.4 displacement—movement of an anchor relative to the

each of these tests.

structural member. For tension tests, displacement is measured

1.5 This standard does not purport to address all of the

along the axis of the anchor, and for shear tests, displacement

safety concerns, if any, associated with its use. It is the

is measured perpendicular to the axis of the anchor, in mm

responsibility of the user of this standard to establish appro-

(in.).

priate safety and health practices and determine the applica-

3.1.5 edge distance—side cover distance or the distance

bility of regulatory limitations prior to use.

from the centerline of an anchor to the nearest edge of a

2. Referenced Documents structural member, in mm (in.); also, minimum distance from

the centerline to the test frame.

2.1 ASTM Standards:

3.1.6 embedment depth—distance from the test member

E4 Practices for Force Verification of Testing Machines

surface to the installed end of the anchor, in mm (in.), prior to

E171 Specification for Atmospheres for Conditioning and

the setting of the anchor.

Testing Flexible Barrier Materials

3.1.7 expansion anchor—a post-installed anchor that de-

E468 Practice for Presentation of Constant Amplitude Fa-

rives its holding strength through a mechanically expanded

tigue Test Results for Metallic Materials

systemwhichexertsforcesagainstthesidesofthedrilledhole.

3.1.8 fatigue test—a laboratory test that applies repeated

These test methods are under the jurisdiction of ASTM Committee E06 on

load cycles to an anchorage system for the purpose of

Performance of Buildings and are the direct responsibility of Subcommittee E06.13

determining the fatigue life or fatigue strength of that system.

on Structural Performance of Connections in Building Construction.

3.1.9 LVDT—a linear variable differential transformer used

Current edition approved May 10, 2003. Published June 2003. Originally

approved in 1976. Last previous edition approved in 1996 as E488–96. DOI:

for measuring the displacement or movement of an anchor or

10.1520/E0488-96R03.

anchor system.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.10 post-installed anchor—an anchor that is installed

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

after the placement and hardening of concrete.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E488–96 (2003)

3.1.11 run-out—a condition where failure did not occur at a ¯

N = average number of load cycles in tension

T

specified number of load cycles in a fatigue test.

fatigue test.

¯

3.1.12 safe working loads—the allowable or design load

N = average number of load cycles in shear

S

obtained by applying factors of safety to the ultimate load of fatigue test.

the anchorage device, kN (lbf). D = displacement of anchor occurring at maxi-

FT

mum load for tension fatigue test mm (in.).

3.1.13 seismic test—a laboratory test that applies load

D = displacement of anchor occurring at maxi-

cycles of varying magnitude and frequency to an anchorage FS

mum load for shear fatigue test mm (in.).

system for the purpose of simulating a seismic event (earth-

A and B = maximum displacement instrument read-

fu fu

quake).

ings for fatigue tests mm (in.).

3.1.14 shear test—a test in which an anchor is loaded

A and B = initialdisplacementinstrumentreadingsfor

fi fi

perpendicular to the axis of the anchor and parallel to the

fatigue tests mm (in.).

surface of the structural member.

D = averagemaximumdisplacementfortension

FT

3.1.15 shock test—a laboratory test that simulates shock

fatigue tests mm (in.).

loads on an anchorage system by the application of a short

D = average maximum displacement for shear

FS

duration external load.

fatigue tests mm (in.).

3.1.16 static test—atestinwhichaloadisslowlyappliedto

an anchor according to a specified rate such that the anchor

4. Significance and Use

receives one loading cycle.

4.1 These test methods are intended to provide data from

3.1.17 structural member—thematerialinwhichtheanchor

which applicable design data and specifications are derivable

is installed and which resists forces from the anchor.

for a given anchorage device used in a structural member of

3.1.18 tensile test—a test in which an anchor is loaded

concrete, masonry and related products and for qualifying

axially in tension.

anchors or anchorage systems.

3.1.19 undercut anchor—a post-installed anchor that de-

4.2 The test methods shall be followed to ensure reproduc-

rives its holding strength from an expansion of an embedded

ibility of the test data.

portion of the anchor into a portion of the hole that is larger in

5. Apparatus

diameter than the portion of the hole between the enlarged

section and the surface of the structural member. The enlarged

5.1 Equipment:

diameter section of the hole is predrilled or enlarged by an

5.1.1 Laboratory—Suitable equipment shall be used to

expansion process during setting of the anchor.

performteststogeneratedatarequiredtopublishloadtablesor

3.2 Symbols:

to obtain listings from approval agencies, building officials,

etc. Calibrated electronic load and displacement measuring

devices which meet the sampling rate of loading specified

h = effective depth of embedment of an anchor

ef

herein shall be used. The equipment shall be capable of

in mm (in.).

measuring the forces to an accuracy within 6 1% of the

F = safe working load in kN (lbf).

s

anticipated ultimate load, when calibrated in accordance with

h = thickness of the structural member in mm

Practices E4. The load and displacement measuring devices

(in.).

shall be capable of providing data points at least once per

h = anchor embedment depth in mm (in.).

v

second in order to produce continuous load versus displace-

s = anchor spacing in mm (in.) measured cen-

ment curves. A minimum of 120 data points per instrument

terline to centerline.

shall be obtained and recorded for each individual test. The

c = edge distance in mm (in.) measured from

readings shall be obtained prior to reaching peak load. The

centerline of anchor to edge.

instruments shall be positioned to measure the vertical move-

d = nominal anchor diameter in mm (in.).

ment of the anchor with respect to points on the structural

D = uncorrected displacement for tension tests

T

member in such a way that the instrument is not influenced

in mm (in.).

D = uncorrected displacement for shear tests in during the test by deflection or failure of the anchor or

S

structural member. The testing device shall be of sufficient

mm (in.).

A and B = instrument readings at a given load in mm

capacity to prevent yielding of its various components and

N N

(in.). shallensurethattheappliedtensionloadsremainparalleltothe

A and B = initial instrument readings in mm (in.).

axes of the anchors and that the applied shear loads remain

I I

D = average displacement at maximum load for

parallel to the surface of the structural member during testing.

T

tension tests in mm (in.).

5.1.2 Field Tests—Suitable equipment shall be used to

D = average displacement at maximum load for

S perform tests required to verify correct installation or provide

shear tests in mm (in.).

proof loads on anchors installed at a specific job site. Cali-

n = number of test samples.

bratedloadcellswhichmeetthespecifiedrateofloadinggiven

N = total number of load cycles in tension

T

herein shall be used. The equipment shall be capable of

fatigue test.

measuring the forces to an accuracy within 6 2% of the

N = total number of load cycles in shear fatigue

S

applied load, when calibrated in accordance with Practices E4.

test.

For field tests which require displacement measurements, use

E488–96 (2003)

eithermanuallyreaddialgagesorelectronicloadanddisplace-

ment measuring devices, provided they are capable of gener-

ating a minimum of 50 data points prior to reaching peak load.

For field tests requiring displacement measurements, the in-

strument(s) shall be positioned to measure the vertical move-

ment of the anchor with respect to points on the structural

member in such a way that the instrument is not influenced

during the test by deflection or failure of the anchor or

structural member. The testing device shall be of sufficient

capacity to prevent yielding of its various components and

shallensurethattheappliedtensionloadsremainparalleltothe

axes of the anchors and that the applied shear loads remain

parallel to the surface of the structural member during testing.

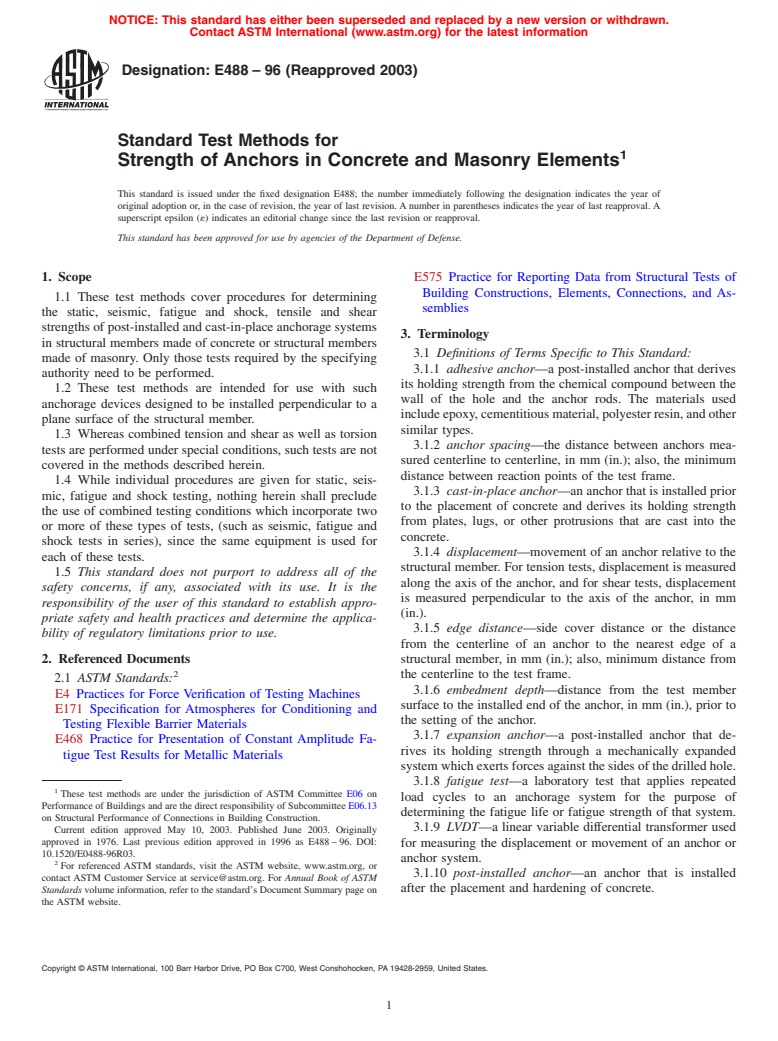

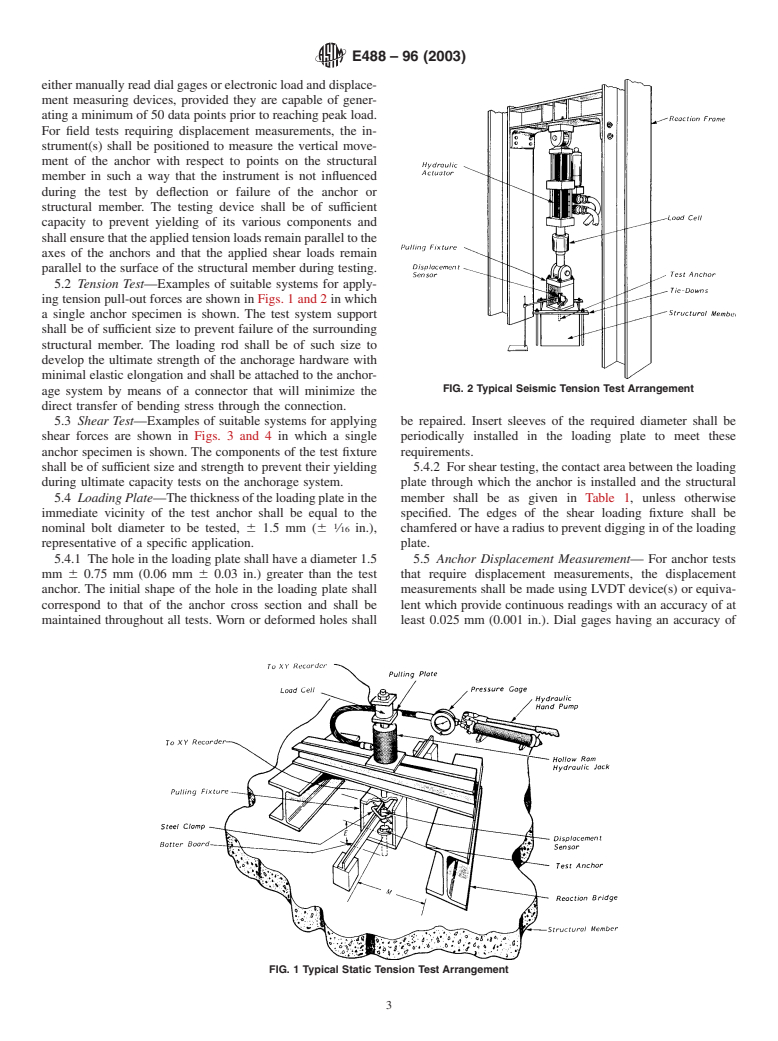

5.2 Tension Test—Examples of suitable systems for apply-

ing tension pull-out forces are shown in Figs. 1 and 2 in which

a single anchor specimen is shown. The test system support

shall be of sufficient size to prevent failure of the surrounding

structural member. The loading rod shall be of such size to

develop the ultimate strength of the anchorage hardware with

minimal elastic elongation and shall be attached to the anchor-

FIG. 2 Typical Seismic Tension Test Arrangement

age system by means of a connector that will minimize the

direct transfer of bending stress through the connection.

5.3 Shear Test—Examples of suitable systems for applying be repaired. Insert sleeves of the required diameter shall be

shear forces are shown in Figs. 3 and 4 in which a single periodically installed in the loading plate to meet these

anchor specimen is shown. The components of the test fixture requirements.

shall be of sufficient size and strength to prevent their yielding 5.4.2 Forsheartesting,thecontactareabetweentheloading

during ultimate capacity tests on the anchorage system. plate through which the anchor is installed and the structural

5.4 Loading Plate—Thethicknessoftheloadingplateinthe member shall be as given in Table 1, unless otherwise

immediate vicinity of the test anchor shall be equal to the specified. The edges of the shear loading fixture shall be

nominal bolt diameter to be tested, 6 1.5 mm (6 ⁄16 in.), chamferedorhavearadiustopreventdigginginoftheloading

representative of a specific application. plate.

5.4.1 Theholeintheloadingplateshallhaveadiameter1.5 5.5 Anchor Displacement Measurement— For anchor tests

mm 6 0.75 mm (0.06 mm 6 0.03 in.) greater than the test that require displacement measurements, the displacement

anchor. The initial shape of the hole in the loading plate shall measurements shall be made using LVDT device(s) or equiva-

correspond to that of the anchor cross section and shall be lent which provide continuous readings with an accuracy of at

maintained throughout all tests. Worn or deformed holes shall least 0.025 mm (0.001 in.). Dial gages having an accuracy of

FIG. 1 Typical Static Tension Test Arrangement

E488–96 (2003)

FIG. 3 Typical Method of Applying Shear Loads to Anchors Attached to Structural Members—Direct Loading Method

FIG. 4 Typical Seismic Shear Test Arrangement—Indirect Loading Method

TABLE 1 Shear Loading Plate Bearing Area as a Function of

be used for a group of anchors tested as a closely spaced

Anchor Diameter

cluster. Displacement measurements as described in 5.5 in-

Anchor Diameter, Shear Loading Plate Contact Area,

clude components of deformation not directly associated with

2 2

mm (in.) cm (in. )

displacement of the anchor relative to the structural member.

<10 (< ⁄8) 50–80 (8.00–12.40)

Include components of deformation such as elastic elongation

3 5

10–<16 ( ⁄8 –< ⁄8) 80.01–120 (12.41–18.60)

5 7

16–<22 ( ⁄8 –< ⁄8) 120.01–160 (18.61–24.80) of the loading rod anchor stem, deformation of the loading

22–<51 ( ⁄8 –<2) 160.01–260 (24.81–40.30)

plate,sleeves,shims,attachmenthardware,andlocalstructural

>51 (>2) 260.1–400 (40.31–62.00)

member material. Deduct all of the elongations from these

sources from the total displacement measurements by using

supplementary measuring devices or calibration test data for

0.025 mm (0.001 in.) are permitted in field testing or for

the installed test set-up with rigid specimen replacing the

generaltestswhereprecisedisplacementmeasurementsarenot

anchor to be tested. The displacement to be used for the

required.

evaluationofthefindingsistheaveragedisplacementindicated

5.5.1 Tension Test:

by both instruments mounted symmetrically equidistant from

5.5.1.1 Single Anchor—The displacement measuring de-

the centroid of the cl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.