ASTM F2619/F2619M-07

(Specification)Standard Specification for High-Density Polyethylene (PE) Line Pipe

Standard Specification for High-Density Polyethylene (PE) Line Pipe

ABSTRACT

This specification covers the requirements and test methods for high-density polyethylene (PE) materials, line pipes, and fittings used in pressure or non-pressure oil and gas producing applications to convey fluids such as oil, dry or wet gas, multiphase fluids, and non-potable oilfield water. This specification does not apply to pipes for gas distribution applications. PE material compounds suitable for use in the manufacture of pipes and fittings under this specification shall adhere to values of the following properties: density (natural base resin), melt index, flexural modulus, tensile strength at yield, SCG resistance, hydrostatic strength, color and UV stabilization, hydrostatic design stress, and hydrostatic design basis. The line pipes shall meet specific requirements as to workmanship, dimensions (outside diameter, toe-in, outside surface irregularity, ovality, wall thickness, and special sizes), inside surface ductility, tensile elongation, bendback resistance, elevated temperature sustained pressure, short-term strength and pressurization, apparent tensile strength at yield, and carbon black content. And conversely, PE fittings shall be manufactured in accordance with their intended use with correspondingly sized PE line pipes, as follows: socket fusion fittings, butt fusion fittings, electrofusion fittings, fabricated fittings, and transition fittings.

SCOPE

1.1 This specification covers requirements and test methods for high-density polyethylene (PE) materials, pipe and fittings for pressure or non-pressure oil and gas producing applications to convey fluids such as oil, dry or wet gas, multiphase fluids, and non-potable oilfield water. This specification does not cover pipe for gas distribution applications.

1.1.1 For the purposes of this specification, high-density polyethylene material is Specification D 3350 density cell classification 3 or higher. This specification does not cover materials having Specification D 3350 density cell classification less than 3 such as medium or low density polyethylene materials.

1.2 Units—The values stated in either SI or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of each other. Combining values from the two systems may result in non-compliance with the standard. Values in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F2619/F2619M – 07

Standard Specification for

High-Density Polyethylene (PE) Line Pipe

ThisstandardisissuedunderthefixeddesignationF2619/F2619M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1603 Test Method for Carbon Black Content in Olefin

Plastics

1.1 This specification covers requirements and test methods

D2122 Test Method for Determining Dimensions of Ther-

for high-density polyethylene (PE) materials, pipe and fittings

moplastic Pipe and Fittings

for pressure or non-pressure oil and gas producing applications

D2290 Test Method for Apparent Hoop Tensile Strength of

to convey fluids such as oil, dry or wet gas, multiphase fluids,

Plastic or Reinforced Plastic Pipe by Split Disk Method

and non-potable oilfield water. This specification does not

D2683 Specification for Socket-Type Polyethylene Fittings

cover pipe for gas distribution applications.

for Outside Diameter-Controlled Polyethylene Pipe and

1.1.1 For the purposes of this specification, high-density

Tubing

polyethylene material is Specification D3350 density cell

D2837 TestMethodforObtainingHydrostaticDesignBasis

classification 3 or higher. This specification does not cover

forThermoplastic Pipe Materials or Pressure Design Basis

materialshavingSpecificationD3350densitycellclassification

for Thermoplastic Pipe Products

less than 3 such as medium or low density polyethylene

D3261 Specification for Butt Heat Fusion Polyethylene

materials.

(PE)PlasticFittingsforPolyethylene(PE)PlasticPipeand

1.2 Units—The values stated in either SI or inch-pound

Tubing

units are to be regarded separately as standard. The values

D3350 Specification for Polyethylene Plastics Pipe and

stated in each system may not be exact equivalents; therefore,

Fittings Materials

each system shall be used independently of each other. Com-

D4218 Test Method for Determination of Carbon Black

bining values from the two systems may result in non-

Content in Polyethylene Compounds By the Muffle-

compliance with the standard. Values in parentheses are

Furnace Technique

provided for information only.

F412 Terminology Relating to Plastic Piping Systems

1.3 This standard does not purport to address all of the

F1055 Specification for Electrofusion Type Polyethylene

safety concerns, if any, associated with its use. It is the

Fittings for Outside Diameter Controlled Polyethylene

responsibility of the user of this standard to establish appro-

Pipe and Tubing

priate safety and health practices and determine the applica-

F1473 Test Method for Notch Tensile Test to Measure the

bility of regulatory limitations prior to use.

Resistance to Slow Crack Growth of Polyethylene Pipes

2. Referenced Documents and Resins

F1973 Specification for Factory Assembled Anodeless Ris-

2.1 ASTM Standards:

ers and Transition Fittings in Polyethylene (PE) and

D638 Test Method for Tensile Properties of Plastics

Polyamide 11 (PA11) and Polyamide 12 (PA12) Fuel Gas

D1598 Test Method for Time-to-Failure of Plastic Pipe

Distribution Systems

Under Constant Internal Pressure

F2206 Specification for Fabricated Fittings of Butt-Fused

D1599 TestMethodforResistancetoShort-TimeHydraulic

Polyethylene (PE) Plastic Pipe, Fittings, Sheet Stock, Plate

Pressure of Plastic Pipe, Tubing, and Fittings

Stock, or Block Stock

D1600 Terminology for Abbreviated Terms Relating to

2.2 Other Documents:

Plastics

CFR 49 Part 192 Transportation of Natural and Other Gas

by Pipeline: Minimum Federal Safety Standards

Federal Register Vol. 71, No. 50, March 15, 2006

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas.

CSA Z662 Oil and Gas Pipeline Systems

Current edition approved Nov. 15, 2007. Published December 2007. DOI:

10.1520/F2619_F2619M-07.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from U.S. Department of Transportation, Transportation Safety

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Institute,PipelineSafetyDivision,POBox25082,OklahomaCity,OK73125-5050.

Standards volume information, refer to the standard’s Document Summary page on Available from Canadian Standards Association (CSA), 5060 Spectrum Way,

the ASTM website. Mississauga, ON L4W 5N6, Canada, http://www.csa.ca.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2619/F2619M – 07

TABLE 1 Specification D3350 Cell Classification and Property Values for Materials

A

Cell Classification and Property Values—Material Designation Code

Property

PE3608 PE3708 PE3710 PE4608 PE4708 PE4710

Density (natural base resin) 3 3 3 4 4 4

Melt Index 4 4 4 4 4 4

Flexural Modulus $4 $4 $4 $4 $4 $5

Tensile Strength at Yield $4 $4 $4 $4 $4 $4

SCG Resistance 6 7 7 6 7 7

Hydrostatic Strength Classification 4 4 4 4 4 4

Color and UV Stabilizer See 4.1.1 See 4.1.1 See 4.1.1 See 4.1.1 See 4.1.1 See 4.1.1

B

HDS at 73°F [23°C] , psi [MPa] 800 [5.5] 800 [5.5] 1000 [6.9] 800 [5.5] 800 [5.5] 1000 [6.9]

B CC C C C C

HDB at 140°F [60°C] , psi [MPa]

A

Specification D3350 cell classification values reflect typical property values for numerous lots of the material and do not include testing bias or manufacturing

tolerances. Values for individual material lots can vary from typical values. Contact the manufacturer for information about testing bias and material manufacturing

tolerances.

B

HDS and HDB determined in accordance with Test Method D2837 and PPI TR-3. HDB and HDS listed ratings are published in PPI TR-4.

C

Rating required; consult manufacturer for rated value.

FED-STD-123G Federal Standard Marking for Shipment 3.2.5 specimen, n—pipe or an element of pipe that is

(Civil Agencies) subjected to test.

Military Standard 129P Standard Practice—Military Mark-

4. Materials

ing for Shipment and Storage

PPI TR-3 Policies and Procedures for Developing Hydro-

4.1 Classification and Properties—Polyethylene material

static Design Basis (HDB), Pressure Design Basis (PDB), compounds suitable for use in the manufacture of pipe and

Strength Design Basis (SDB), and Minimum Required fittingsunderthisspecificationshallmeetSpecificationD3350,

Strength (MRS) Ratings for Thermoplastic Piping Mate- and shall meet the Specification D3350 classification and

rials or Pipe property requirements in Table 1, and shall have HDB and

PPI TR-4 Listing of Hydrostatic Design Basis (HDB), HDS ratings at 73°F [23°C] and HDB ratings at 140°F [60°C]

Strength Design Basis (SDB), Pressure Design Basis in accordance with PPITR-3,Test Method D2837 andTable 1.

(PDB) and Minimum Required Strength (MRS) Ratings When tested in accordance withTest Method D1598, virgin PE

for Thermoplastic Piping Materials or Pipe material compound shall meet Table 5 requirements applicable

to the material designation code.

3. Terminology

4.1.1 Color and Ultraviolet (UV) Stabilization—

3.1 Definitions—Unless otherwise specified, definitions are

Polyethylene material compounds in the pipe shall meet

inaccordancewithTerminologyF412,andabbreviationsarein Specification D3350 color and UV stabilizer Code C or Code

accordance with Terminology D1600.

E.CodeCcompoundsshallcontain2to3percentcarbonblack

3.2 Definitions of Terms Specific to This Standard: whentestedper5.6.CodeEcolorcompoundsareusedonlyfor

3.2.1 multiphase fluid, n—oil, gas, and water in any com-

coextruded color stripes and shall be colored with UV stabi-

bination produced from one or more oil or gas wells, or lizer. Code E compounds shall contain sufficient UV stabilizer

recombined oil or gas well fluids that may have been separated

for at least 24 months of unprotected outdoor storage.

in passing through surface facilities.

4.1.2 The manufacturer shall have procedures for ensuring

3.2.2 oilfield water, n—fresh or salt water transported by

that materials meeting 4.1 are received in a condition that is

pipeline, regardless of purity or quality, from wells or surface

suitable for processing, including receiving inspection to dis-

locations for the purpose of providing water injection to cover damage or contamination from shipping and verification

underground reservoirs; or disposing of waste water from

of appropriate material properties.

hydrocarbon or gas production, processing, or storage facili-

NOTE 1—Changes to Specification D3350 and PPI TR-3 resulted in

ties.

changes to thermoplastic material designation codes for polyethylene

3.2.3 productionrun,n—thecontinuousextrusionofpipeof

materials. (See Terminology F412 for the thermoplastic material designa-

a specific diameter, wall thickness and material compound (see

tion code definition.) A Specification D3350 requirement to usea4for

SCG resistance values of 4 or 6 was deleted, density cell 3 was split into

4.1).

cells 3 and 4, and a SCG resistance value of 7 (>500 h per Test Method

3.2.3.1 Discussion—Continuous production may be tempo-

F1473 (PENT)) was added. Changes to PPITR-3 provide for an increased

rarily interrupted by loss of power or circumstances such as

HDS for water at 73°F for materials that demonstrate >500 h SCG

breakdowns or screen changes, etc.; however, a change of

resistance per Test Method F1473 (PENT), and a LCL/LTHS ratio of at

diameter or wall thickness (dimension ratio) or material

least 90 percent per Test Method D2837, and substantiation per PPI TR-3

compound constitutes a new production run.

to show that extrapolation of the 73°F stress regression curve is linear to

3.2.4 sample, n—pipe or an element of pipe that represents the 438 000-h (50-year) intercept.

a quantity of pipe and provides a specimen or specimens for

4.2 Rework Material—Rework material is acceptable to

testing.

manufacture pipe and fittings in accordance with this specifi-

cation as part of a blend with virgin material compound

meeting 4.1 and 4.1.1. Rework material shall be polyethylene

Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825,

Irving, TX 75062, http://www.plasticpipe.org. materialcompoundfromthemanufacturer’sownpipeorfitting

F2619/F2619M – 07

production that met 4.1 and 4.1.1 as virgin material compound. 5.1.3 The interior of the pipe shall be free of cuttings,

Rework material shall be traceable per 4.2.1 and shall have the shavings and debris when produced.

sameSpecificationD3350cellclassificationandpropertyvalue

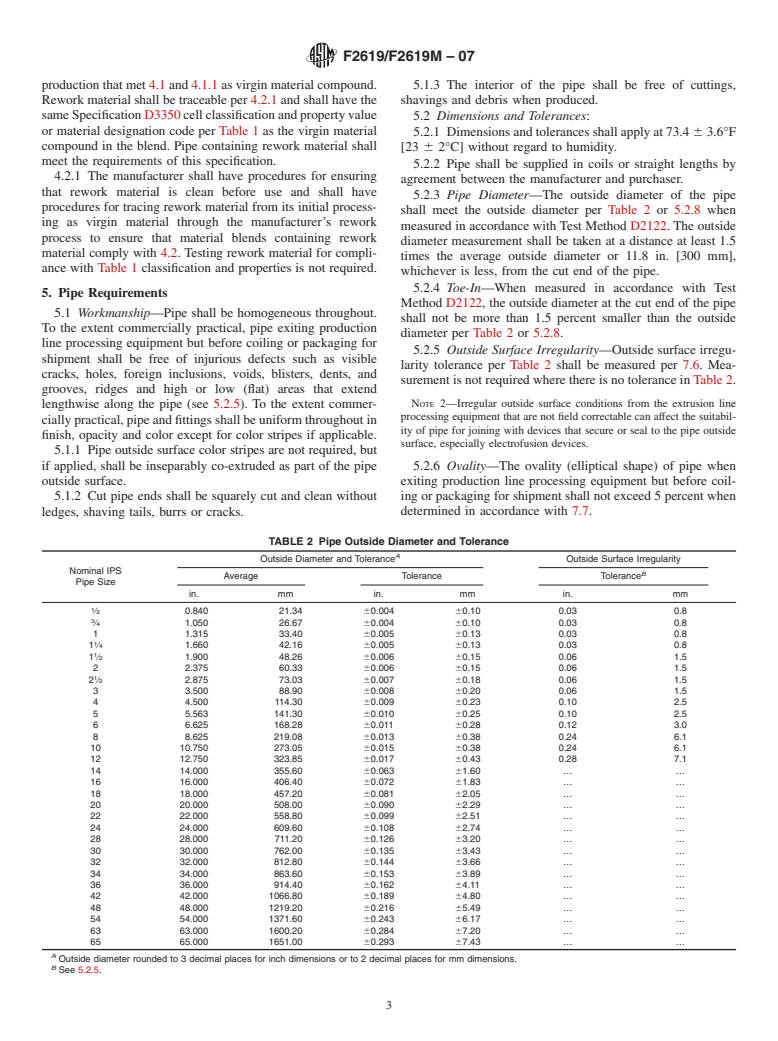

5.2 Dimensions and Tolerances:

or material designation code per Table 1 as the virgin material

5.2.1 Dimensionsandtolerancesshallapplyat73.4 63.6°F

compound in the blend. Pipe containing rework material shall

[23 6 2°C] without regard to humidity.

meet the requirements of this specification.

5.2.2 Pipe shall be supplied in coils or straight lengths by

4.2.1 The manufacturer shall have procedures for ensuring

agreement between the manufacturer and purchaser.

that rework material is clean before use and shall have

5.2.3 Pipe Diameter—The outside diameter of the pipe

procedures for tracing rework material from its initial process-

shall meet the outside diameter per Table 2 or 5.2.8 when

ing as virgin material through the manufacturer’s rework

measured in accordance with Test Method D2122. The outside

process to ensure that material blends containing rework

diameter measurement shall be taken at a distance at least 1.5

material comply with 4.2. Testing rework material for compli-

times the average outside diameter or 11.8 in. [300 mm],

ance with Table 1 classification and properties is not required.

whichever is less, from the cut end of the pipe.

5.2.4 Toe-In—When measured in accordance with Test

5. Pipe Requirements

Method D2122, the outside diameter at the cut end of the pipe

5.1 Workmanship—Pipe shall be homogeneous throughout.

shall not be more than 1.5 percent smaller than the outside

To the extent commercially practical, pipe exiting production

diameter per Table 2 or 5.2.8.

line processing equipment but before coiling or packaging for

5.2.5 Outside Surface Irregularity—Outside surface irregu-

shipment shall be free of injurious defects such as visible

larity tolerance per Table 2 shall be measured per 7.6. Mea-

cracks, holes, foreign inclusions, voids, blisters, dents, and

surement is not required where there is no tolerance inTable 2.

grooves, ridges and high or low (flat) areas that extend

NOTE 2—Irregular outside surface conditions from the extrusion line

lengthwise along the pipe (see 5.2.5). To the extent commer-

processing equipment that are not field correctable can affect the suitabil-

ciallypractical,pipeandfittingsshallbeuniformthroughoutin

ity of pipe for joining with devices that secure or seal to the pipe outside

finish, opacity and color except for color stripes if applicable.

surface, especially electrofusion devices.

5.1.1 Pipe outside surface color stripes are not required, but

if applied, shall be inseparably co-extruded as part of the pipe 5.2.6 Ovality—The ovality (elliptical shape) of pipe when

outside surface. exiting production line processing equipment but before coil-

5.1.2 Cut pipe ends shall be squarely cut and clean without ing or packaging for shipment shall not exceed 5 percent when

ledges, shaving tails, burrs or cracks. determined in accordance with 7.7.

TABLE 2 Pipe Outside Diameter and Tolerance

A

Outside Diameter and Tolerance Outside Surface Irregularity

Nominal IPS

B

Average Tolerance Tolerance

Pipe Size

in. mm in. mm in. mm

⁄2 0.840 21.34 60.004 60.10 0.03 0.8

⁄4 1.050 26.67 60.004 60.10 0.03 0.8

1 1.315 33.40 60.005 60.13 0.03 0.8

1 ⁄4 1.660 42.16 60.005 60.13 0.03 0.8

1 ⁄2 1.900 48.26 60.006 60.15 0.06 1.5

2 2.375 60.33 60.006 60.15 0.06 1.5

2 ⁄2 2.875 73.03 60.007 60.18 0.06 1.5

3 3.500 88.90 60.008 60.20 0.06 1.5

4 4.500 114.30 60.009 60.23 0.10 2.5

5 5.563 141.30 60.010 60.25 0.10 2.5

6 6.625 168.28 60.011 60.28 0.12 3.0

8 8.625 219.08 60.013 60.38 0.24 6.1

10 10.750 273.05 60.015 60.38 0.24 6.1

12 12.750 323.85 60.017 60.43 0.28 7.1

14 14.000 355.60 60.063 61.60 … …

16 16.000 406.40 60.072 61.83 … …

18 18.000 457.20 60.081 62.05 … …

20 20.000 508.00 60.090 62.29 … …

22 22.000 558.80 60.099 62.51 … …

24 24.000 609.60 60.108 62.74 … …

28 28.000 711.20 60.126 63.20 … …

30 30.000 762.00 60.135 63.43 … …

32 32.000 812.80 60.144 63.66 … …

34 34.000 863.60 60.153 63.89 … …

36 36.000 914.40 60.162 64.11 … …

42 42.000 1066.80 60.189 64.80 … …

48 48.000 1219.20 60.216 65.49 … …

54 54.000 1371.60 60.243 66.17 … …

63 63.000 1600.20 60.284 67.20 … …

65 65.000 1651.00 60.293 67.43 … …

A

Outside diameter rounded to 3 decimal place

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.