ASTM D2847-07

(Practice)Standard Practice for Testing Engine Coolants in Car and Light Truck Service

Standard Practice for Testing Engine Coolants in Car and Light Truck Service

SIGNIFICANCE AND USE

The data obtained from the use of this practice will provide a basis for the evaluation of coolant performance in passenger car and light truck service. The data obtained may also be used to provide added significance to the data obtained from simulated service and engine dynamometer tests.

SCOPE

1.1 This practice covers the procedure for evaluating corrosion protection and performance of an engine coolant in passenger car and light truck service.

Note 1—Coolant evaluation in vehicle service may require considerable time and expense; therefore, the product should be pretested in the laboratory for general acceptability. Tests may vary from small, closely controlled tests, to large tests where close control is not always practical.

1.2 The units quoted in this practice are to be regarded as standard. The values given in parentheses are approximate equivalents for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7 and Note A1.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2847 − 07

StandardPractice for

1

Testing Engine Coolants in Car and Light Truck Service

This standard is issued under the fixed designation D2847; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Practice

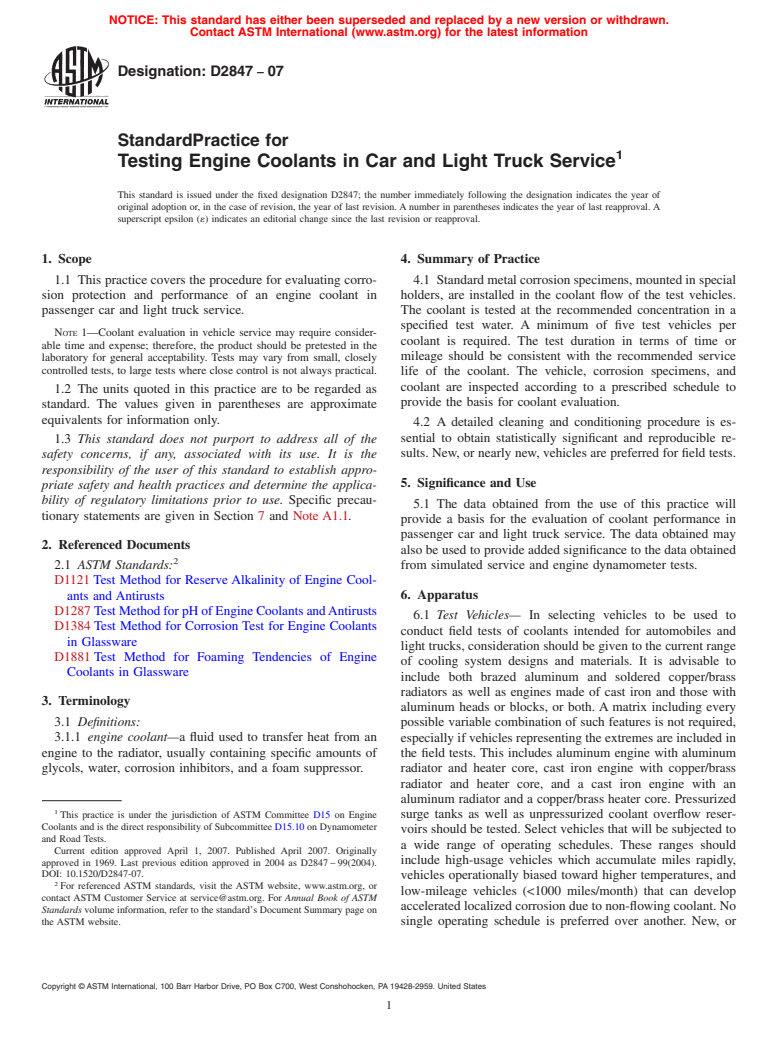

1.1 This practice covers the procedure for evaluating corro- 4.1 Standardmetalcorrosionspecimens,mountedinspecial

sion protection and performance of an engine coolant in holders, are installed in the coolant flow of the test vehicles.

passenger car and light truck service. The coolant is tested at the recommended concentration in a

specified test water. A minimum of five test vehicles per

NOTE 1—Coolant evaluation in vehicle service may require consider-

coolant is required. The test duration in terms of time or

able time and expense; therefore, the product should be pretested in the

mileage should be consistent with the recommended service

laboratory for general acceptability. Tests may vary from small, closely

controlled tests, to large tests where close control is not always practical.

life of the coolant. The vehicle, corrosion specimens, and

coolant are inspected according to a prescribed schedule to

1.2 The units quoted in this practice are to be regarded as

provide the basis for coolant evaluation.

standard. The values given in parentheses are approximate

equivalents for information only.

4.2 A detailed cleaning and conditioning procedure is es-

sential to obtain statistically significant and reproducible re-

1.3 This standard does not purport to address all of the

sults. New, or nearly new, vehicles are preferred for field tests.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific precau-

5.1 The data obtained from the use of this practice will

tionary statements are given in Section 7 and Note A1.1.

provide a basis for the evaluation of coolant performance in

passenger car and light truck service. The data obtained may

2. Referenced Documents

also be used to provide added significance to the data obtained

2

2.1 ASTM Standards: from simulated service and engine dynamometer tests.

D1121Test Method for Reserve Alkalinity of Engine Cool-

6. Apparatus

ants and Antirusts

D1287TestMethodforpHofEngineCoolantsandAntirusts

6.1 Test Vehicles— In selecting vehicles to be used to

D1384Test Method for Corrosion Test for Engine Coolants

conduct field tests of coolants intended for automobiles and

in Glassware

light trucks, consideration should be given to the current range

D1881Test Method for Foaming Tendencies of Engine

of cooling system designs and materials. It is advisable to

Coolants in Glassware

include both brazed aluminum and soldered copper/brass

radiators as well as engines made of cast iron and those with

3. Terminology

aluminum heads or blocks, or both. A matrix including every

3.1 Definitions: possible variable combination of such features is not required,

3.1.1 engine coolant—a fluid used to transfer heat from an especially if vehicles representing the extremes are included in

engine to the radiator, usually containing specific amounts of the field tests. This includes aluminum engine with aluminum

glycols, water, corrosion inhibitors, and a foam suppressor. radiator and heater core, cast iron engine with copper/brass

radiator and heater core, and a cast iron engine with an

aluminum radiator and a copper/brass heater core. Pressurized

1

This practice is under the jurisdiction of ASTM Committee D15 on Engine

surge tanks as well as unpressurized coolant overflow reser-

Coolants and is the direct responsibility of Subcommittee D15.10 on Dynamometer

voirs should be tested. Select vehicles that will be subjected to

and Road Tests.

a wide range of operating schedules. These ranges should

Current edition approved April 1, 2007. Published April 2007. Originally

include high-usage vehicles which accumulate miles rapidly,

approved in 1969. Last previous edition approved in 2004 as D2847–99(2004).

DOI: 10.1520/D2847-07.

vehicles operationally biased toward higher temperatures, and

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

low-mileage vehicles (<1000 miles/month) that can develop

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

acceleratedlocalizedcorrosionduetonon-flowingcoolant.No

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. single operating schedule is preferred

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.