ASTM D2847-99(2004)

(Practice)Standard Practice for Testing Engine Coolants in Car and Light Truck Service

Standard Practice for Testing Engine Coolants in Car and Light Truck Service

SCOPE

1.1 This practice covers the procedure for evaluating corrosion protection and performance of an engine coolant in passenger car and light truck service. Note 1Coolant evaluation in vehicle service may require considerable time and expense; therefore, the product should be pretested in the laboratory for general acceptability. Tests may vary from small, closely controlled tests, to large tests where close control is not always practical.

1.2 The units quoted in this practice are to be regarded as standard. The values given in parentheses are approximate equivalents for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section and Note 0.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2847–99 (Reapproved2004)

Standard Practice for

Testing Engine Coolants in Car and Light Truck Service

This standard is issued under the fixed designation D2847; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope engine to the radiator, usually containing specific amounts of

glycols, water, corrosion inhibitors, and a foam suppressor.

1.1 This practice covers the procedure for evaluating corro-

sion protection and performance of an engine coolant in

4. Summary of Practice

passenger car and light truck service.

4.1 Standardmetalcorrosionspecimens,mountedinspecial

NOTE 1—Coolant evaluation in vehicle service may require consider-

holders, are installed in the coolant flow of the test vehicles.

able time and expense; therefore, the product should be pretested in the

The coolant is tested at the recommended concentration in a

laboratory for general acceptability. Tests may vary from small, closely

specified test water. A minimum of five test vehicles per

controlled tests, to large tests where close control is not always practical.

coolant is required. The test duration in terms of time or

1.2 The units quoted in this practice are to be regarded as

mileage should be consistent with the recommended service

standard. The values given in parentheses are approximate

life of the coolant. The vehicle, corrosion specimens, and

equivalents for information only.

coolant are inspected according to a prescribed schedule to

1.3 This standard does not purport to address all of the

provide the basis for coolant evaluation.

safety concerns, if any, associated with its use. It is the

4.2 A detailed cleaning and conditioning procedure is es-

responsibility of the user of this standard to establish appro-

sential to obtain statistically significant and reproducible re-

priate safety and health practices and determine the applica-

sults. New, or nearly new, vehicles are preferred for field tests.

bility of regulatory limitations prior to use. Specific precau-

tionary statements are given in Section 7 and Note A1.1. 5. Significance and Use

5.1 The data obtained from the use of this practice will

2. Referenced Documents

provide a basis for the evaluation of coolant performance in

2.1 ASTM Standards:

passenger car and light truck service. The data obtained may

D1121 Test Method for Reserve Alkalinity of Engine

also be used to provide added significance to the data obtained

Coolants and Antirusts

from simulated service and engine dynamometer tests.

D1287 Test Method for pH of Engine Coolants and Anti-

rusts

6. Apparatus

D1384 TestMethodforCorrosionTestforEngineCoolants

6.1 Test Vehicles— In selecting vehicles to be used to

in Glassware

conduct field tests of coolants intended for automobiles and

D1881 Test Method for Foaming Tendencies of Engine

light trucks, consideration should be given to the current range

Coolants in Glassware

of cooling system designs and materials. It is advisable to

include both brazed aluminum and soldered copper/brass

3. Terminology

radiators as well as engines made of cast iron and those with

3.1 Definitions:

aluminum heads or blocks, or both. A matrix including every

3.1.1 engine coolant—a heat exchange fluid with good

possible variable combination of such features is not required,

low-temperature properties used to transfer heat from an

especially if vehicles representing the extremes are included in

the field tests. This includes aluminum engine with aluminum

radiator and heater core, cast iron engine with copper/brass

This practice is under the jurisdiction of ASTM Committee D15 on Engine

radiator and heater core, and a cast iron engine with an

Coolants and is the direct responsibility of Subcommittee D15.10 on Dynamometer

aluminum radiator and a copper/brass heater core. Pressurized

and Road Tests.

surge tanks as well as unpressurized coolant overflow reser-

Current edition approved Oct. 1, 2004. Published November 2004. Originally

approved in 1969. Last previous edition approved in 1999 as D2847–99.

voirs should be tested. Select vehicles that will be subjected to

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

a wide range of operating schedules. These ranges should

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

include high-usage vehicles which accumulate miles rapidly,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. vehicles operationally biased toward higher temperatures, and

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2847–99 (2004)

low-mileage vehicles (<1000 miles/month) that can develop

acceleratedlocalizedcorrosionduetonon-flowingcoolant.No

single operating schedule is preferred over another. New, or

nearly new, vehicles are preferred because of possible difficul-

ties,explainedin9.2.1,incleaningoldercoolingsystemsprior

to test.

6.2 Metal Corrosion Specimens—The description, specifi-

cation, preparation, cleaning, and weighing of the metal

corrosion specimens used in this practice are given in detail in

FIG. 2 Specimen Bundle Sleeve

Test Method D1384. The metal specimens are assembled for

test as shown in Fig. 1. Each set of specimens is mounted in a

canvas reinforced phenolic tube illustrated in Fig. 2. The

specimen and tube assembly are placed in a capsule which is

mountedinthevehiclecoolingsystem.Twotypesofspecimen

capsules may be used; the by-pass (partial-flow) heater circuit

type (Fig. 3) is the standard capsule, and the full-flow type

(Fig. 4) is optional. The partial-flow heater circuit capsule is

located between the heater supply and the heater-return line

and shall contain two or more sets of specimens.The full-flow

capsule is installed in the upper radiator hose and contains one

or more sets of specimens.

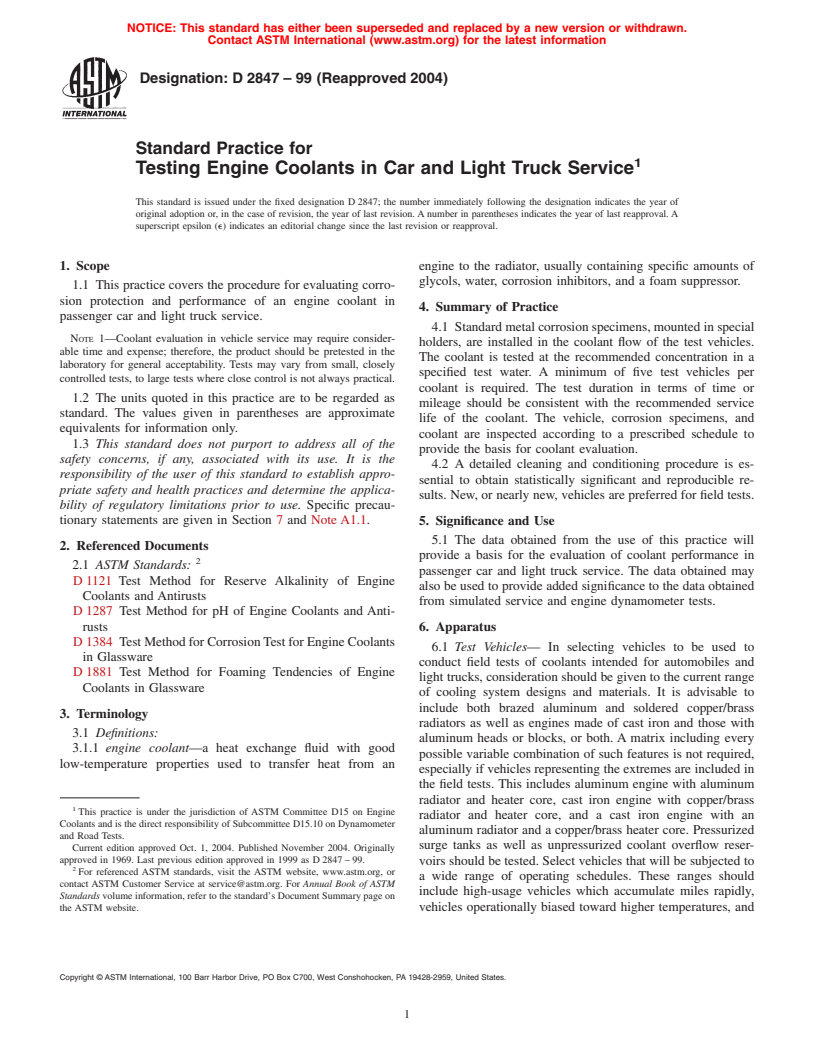

6.2.1 The schematic of the specimen holder installation is

shown in Fig. 5. Fig. 6 is a photograph of a typical installation

of test capsules. The optional full-flow capsule should be

mountedaslowaspossibleintheupperradiatorhosetoensure

coolant coverage of the metal specimens when the vehicle is

FIG. 3 By-Pass (Heater Circuit) Specimen Capsule

FIG. 4 Full-Flow Specimen Capsule

notinuse.Thepartial-flowcapsulemustbemountedvertically

to avoid trapped air.Apair of fabricated copper tees with ⁄8-in

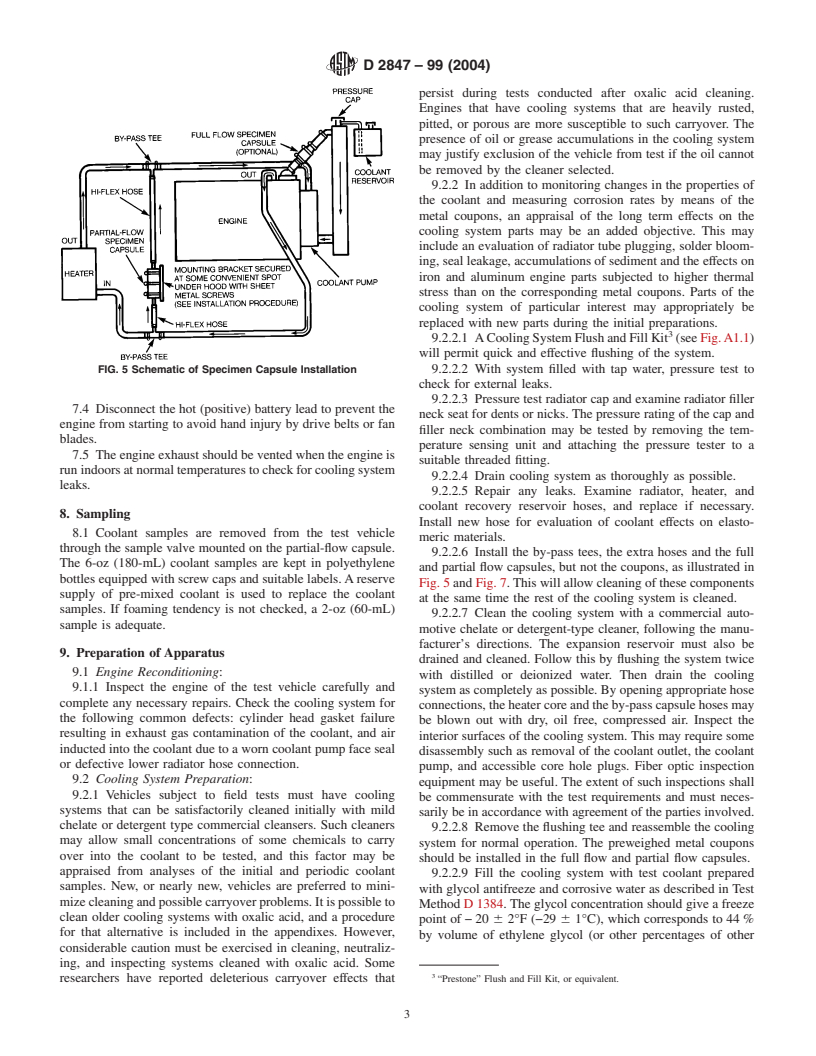

(9.5-mm) outside diameter copper tubing side taps (Fig. 7) are

spliced into the heater hose lines to provide a constant bypass

flow through the specimen capsule. The circuit must be so

arranged that coolant flows through the capsule whenever the

vehicle is in operation. On air-conditioned vehicles with a

vacuum-operated heater flow control valve, the by-pass tee

must be installed ahead of the flow control valve to insure

constant flow.

7. Safety Precautions

7.1 All coolant concentrates and their solutions should be

considered harmful or fatal if swallowed.

7.2 Caution should be used when removing the radiator cap

from a hot cooling system.

7.3 Allinstallationsshallbemadewiththeenginecooledto

FIG. 1 Corrosion Specimen Bundle ambient air temperature to avoid burns.

D2847–99 (2004)

persist during tests conducted after oxalic acid cleaning.

Engines that have cooling systems that are heavily rusted,

pitted, or porous are more susceptible to such carryover. The

presence of oil or grease accumulations in the cooling system

may justify exclusion of the vehicle from test if the oil cannot

be removed by the cleaner selected.

9.2.2 In addition to monitoring changes in the properties of

the coolant and measuring corrosion rates by means of the

metal coupons, an appraisal of the long term effects on the

cooling system parts may be an added objective. This may

include an evaluation of radiator tube plugging, solder bloom-

ing,sealleakage,accumulationsofsedimentandtheeffectson

iron and aluminum engine parts subjected to higher thermal

stress than on the corresponding metal coupons. Parts of the

cooling system of particular interest may appropriately be

replaced with new parts during the initial preparations.

9.2.2.1 ACoolingSystemFlushandFillKit (seeFig.A1.1)

will permit quick and effective flushing of the system.

FIG. 5 Schematic of Specimen Capsule Installation 9.2.2.2 With system filled with tap water, pressure test to

check for external leaks.

9.2.2.3 Pressure test radiator cap and examine radiator filler

7.4 Disconnect the hot (positive) battery lead to prevent the

neck seat for dents or nicks.The pressure rating of the cap and

engine from starting to avoid hand injury by drive belts or fan

filler neck combination may be tested by removing the tem-

blades.

perature sensing unit and attaching the pressure tester to a

7.5 Theengineexhaustshouldbeventedwhentheengineis

suitable threaded fitting.

runindoorsatnormaltemperaturestocheckforcoolingsystem

9.2.2.4 Drain cooling system as thoroughly as possible.

leaks.

9.2.2.5 Repair any leaks. Examine radiator, heater, and

coolant recovery reservoir hoses, and replace if necessary.

8. Sampling

Install new hose for evaluation of coolant effects on elasto-

8.1 Coolant samples are removed from the test vehicle

meric materials.

through the sample valve mounted on the partial-flow capsule.

9.2.2.6 Install the by-pass tees, the extra hoses and the full

The 6-oz (180-mL) coolant samples are kept in polyethylene

and partial flow capsules, but not the coupons, as illustrated in

bottlesequippedwithscrewcapsandsuitablelabels.Areserve

Fig.5andFig.7.Thiswillallowcleaningofthesecomponents

supply of pre-mixed coolant is used to replace the coolant

at the same time the rest of the cooling system is cleaned.

samples. If foaming tendency is not checked, a 2-oz (60-mL)

9.2.2.7 Clean the cooling system with a commercial auto-

sample is adequate.

motive chelate or detergent-type cleaner, following the manu-

facturer’s directions. The expansion reservoir must also be

9. Preparation of Apparatus

drained and cleaned. Follow this by flushing the system twice

9.1 Engine Reconditioning:

with distilled or deionized water. Then drain the cooling

9.1.1 Inspect the engine of the test vehicle carefully and

systemascompletelyaspossible.Byopeningappropriatehose

complete any necessary repairs. Check the cooling system for

connections,theheatercoreandtheby-passcapsulehosesmay

the following common defects: cylinder head gasket failure

be blown out with dry, oil free, compressed air. Inspect the

resulting in exhaust gas contamination of the coolant, and air

interior surfaces of the cooling system.This may require some

inductedintothecoolantduetoaworncoolantpumpfaceseal

disassembly such as removal of the coolant outlet, the coolant

or defective lower radiator hose connection.

pump, and accessible core hole plugs. Fiber optic inspection

9.2 Cooling System Preparation:

equipment may be useful. The extent of such inspections shall

9.2.1 Vehicles subject to field tests must have cooling

be commensurate with the test requirements and must neces-

systems that can be satisfactorily cleaned initially with mild

sarilybeinaccordancewithagreementofthepartiesinvolved.

chelate or detergent type commercial cleansers. Such cleaners

9.2.2.8 Remove the flushing tee and reassemble the cooling

may allow small concentrations of some chemicals to carry

system for normal operation. The preweighed metal coupons

over into the coolant to be tested, and this factor may be

should be installed in the full flow and partial flow capsules.

appraised from analyses of the initial and periodic coolant

9.2.2.9 Fill the cooling system with test coolant prepared

samples. New, or nearly new, vehicles are preferred to mini-

with glycol antifreeze and corrosive water as described in Test

mizecleaningandpossiblecarryoverproblems.Itispossibleto

Method D1384.The glycol concentration should give a freeze

clean older cooling systems with oxalic acid, and a procedure

point of−20 6 2°F (−29 6 1°C), which corresponds to 44%

for that alternative is included in the appendixes. However,

by volume of ethylene glycol (or other percentages of other

considerable caution must be exercised in cleaning, neutraliz-

ing, and inspecting systems cleaned with oxalic acid. Some

researchers have reported deleterious carryover effects that “Prestone” Flush and Fill Kit, or equivalent.

D2847–99 (2004)

FIG. 6 Full-Flow and Partial-Flow Specimen Capsules

10. Procedure

10.1 Test the coolant being evaluated in a minimum of five

vehicles at the recommended concentration.

10.2 Vehicle operating conditions may vary considerably in

any test fleet; therefore, record the type of service for each

vehicle. Mileage accumulation rates may vary considerably;

therefore, the recommended inspections in 10.5 may be diffi-

culttoschedule.Alternativeinspectionandsamplingschedules

may be developed to suit the needs and circumstances of the

test.

10.3 The recommended concentration for coolant is listed

below. Weather conditions in Northern areas may require

testingatahigherconcentration.Evaluateothercoolingsystem

3 5

NOTE 1—Dimension A is 19.1 or 16.0 mm ( ⁄4 or ⁄8 in.) diameter

products at the recommended or implied concentration, in the

depending on size of heater hose.

product use directions. Coolant concentrations and normal

FIG. 7 By-Pass Tee

coolant operating temperature ranges are as follows:

Concentration, volume %, or 44

glycols) unless climatic extremes require lower freeze points.

Freezing point, °F (°C) −20 (−29)

Range for normal operating temperature of engine 180 to 235 (82 to 113)

Theexpansionreservoirshallbefilledtothemarkedlevelwith

coolant, °F (°C)

the same coolant solution. Run the engine long enough to

ensurethatanyairtrappedinthesystemisexpelled,andcheck 10.4 Use a synthetic corrosive water as described inAnnex

the system for leaks. Upon cool down, the coolant level in the

A2todilutethecoolant.Additionstothecoolingsystemduring

expansionreservoirwillneedtobecheckedandbroughttothe the test should be the prescribed mixture of coolant and

proper level. corrosive water.

9.2.2.10 Label the radiator and expansion reservoir fill caps

10.5 Perform periodic inspections throughout the test as

conspicuously to show a coolant test is being conducted, and given in Table 1.

include instructions with whom to contact in case coolant

11. Calculation

additionsareneededorotherproblemsoccur.Obtaintheinitial

coolant sample and record the start-of-test date, odometer 11.1 Record the corrosion data in milligrams per specimen.

reading, and engine hour rea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.