ASTM D2710-99

(Test Method)Standard Test Method for Bromine Index of Petroleum Hydrocarbons by Electrometric Titration

Standard Test Method for Bromine Index of Petroleum Hydrocarbons by Electrometric Titration

SCOPE

1.1 This test method covers the determination of the amount of bromine-reactive material in petroleum hydrocarbons and is thus a measure of trace amounts of unsaturates in these materials. It is applicable to materials having bromine indexes below 1000.

1.2 This test method is applicable only to essentially olefin-free hydrocarbons or mixtures that are substantially free from material lighter than isobutane and have a distillation end point under 288°C (550°F).

1.3 The values stated in SI units are to be regarded as standard. The values stated in inch-pound units are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Sections 7, 8, and Annex A3. Note 1-This procedure has been cooperatively tested on materials with bromine indexes in the range from 100 to 1000. These materials include petroleum distillates such as straight-run and hydrocracked naphtha, reformer feed, kerosine, and aviation turbine fuel. Note 2-Materials with bromine index greater than 1000 should be tested for bromine number using Test Method D1159/IP 130. Note 3-Industrial aromatic hydrocarbons should be tested using Test Method D1492. 2. Referenced Documents ASTM Standards:

D 1159* Test Method for Bromine Number of Petroleum Distillates and Commercial Aliphatic Olefins by Electrometric Titration

D 1492* Test Method for Bromine Index of Aromatic Hydrocarbons by Coulometric Titration

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 2710 – 99

Designation: 299/92 (98)

Standard Test Method for

Bromine Index of Petroleum Hydrocarbons by Electrometric

Titration

This standard is issued under the fixed designation D 2710; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1492 Test Method for Bromine Index of Aromatic Hy-

drocarbons by Coulometric Titration

1.1 This test method covers the determination of the amount

D 5776 Test Method for Bromine Index of Aromatic Hy-

of bromine-reactive material in petroleum hydrocarbons and is

drocarbons by Electrometric Titration

thus a measure of trace amounts of unsaturates in these

materials. It is applicable to materials having bromine indexes

3. Terminology

below 1000.

3.1 Definition:

1.2 This test method is applicable only to essentially olefin-

3.1.1 bromine index—the number of milligrams of bromine

free hydrocarbons or mixtures that are substantially free from

that will react with 100 g of sample under the conditions of the

material lighter than isobutane and have a distillation end point

test.

under 288°C (550°F).

1.3 The values stated in SI units are to be regarded as

4. Summary of Test Method

standard. The values stated in inch-pound units are for infor-

4.1 A known mass of the sample dissolved in a specified

mation only.

solvent is titrated with standard bromide-bromate solution. The

1.4 This standard does not purport to address all of the

end point is indicated by a dead stop electrometric titration

safety concerns, if any, associated with its use. It is the

apparatus when the presence of free bromine causes a sudden

responsibility of the user of this standard to establish appro-

change in the electrical conductivity of the system.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific hazard

5. Significance and Use

statements, see Sections 7 and 8.

5.1 This test method provides a measure of trace amounts of

NOTE 1—This procedure has been cooperatively tested on materials

unsaturated hydrocarbons in petroleum distillates boiling up to

with bromine indexes in the range from 100 to 1000. These materials

288°C (550°F). An estimate of the quantity of these materials

include petroleum distillates such as straight-run and hydrocracked

is useful in assessing the suitability of the lighter fractions for

naphtha, reformer feed, kerosine, and aviation turbine fuel.

use as reaction solvents.

NOTE 2—Materials with bromine index greater than 1000 should be

tested for bromine number using Test Method D 1159/IP 130.

6. Apparatus

NOTE 3—Bromine index of industrial aromatic hydrocarbons should be

determined using Test Method D 1492 or D 5776. 6.1 Electrometric End Point Titration Apparatus—Any ap-

paratus designed to perform titrations to pre-set end points (see

2. Referenced Documents

Note 4) may be used in conjuction with a high-resistance

2.1 ASTM Standards:

polarizing current supply capable of maintaining approxi-

D 1159 Test Method for Bromine Number of Petroleum

mately 0.8 V across two platinum electrodes and with a

Distillates and Commercial Aliphatic Olefins by Electro-

sensitivity such that a voltage change of approximately 50 mV

metric Titration

at these electrodes is sufficient to indicate the end point. Other

types of commercially available electric titrimeters, including

certain pH meters, have also been found to be suitable.

This test method is under the jurisdiction of ASTM Committee D-2 on

NOTE 4—Pre-set end point indicated with polarized electrodes provides

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

a detection technique similar to the dead stop technique specified in

D02.04.OD on Physical Methods.

Current edition approved June 10, 1999. Published August 1999. Originally previous versions of this test method.

published as D 2710 – 68. Last previous edition D 2710 – 94.

In the IP, this test method is under the jurisdiction of the Standardization

Committee.

2 3

Annual Book of ASTM Standards, Vol 05.01. Annual Book of ASTM Standards, Vol 06.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

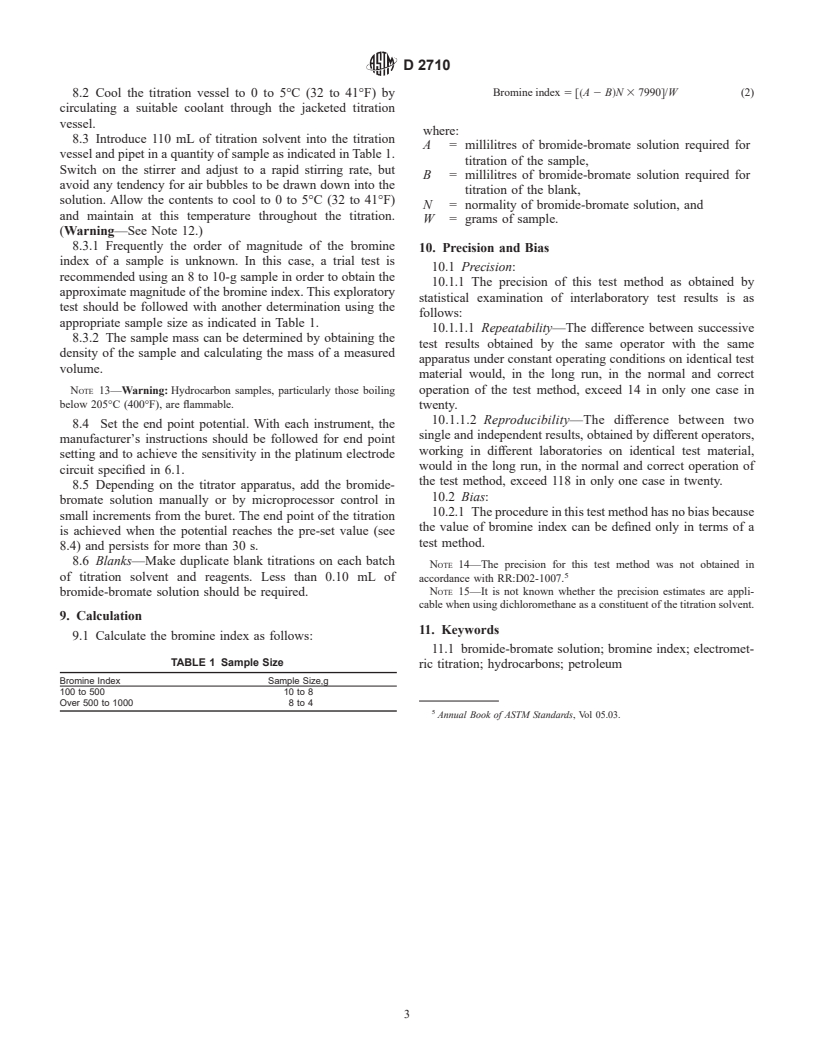

D 2710

6.2 Titration Vessel—A jacketed glass vessel of approxi-

A = millilitres of the Na S O solution required fortitra-

2 2 2 3

mately 150-mL capacity of such a form that can be conve-

tion of the bromide-bromate solution.

niently maintained at 0 to 5°C (32 to 41°F). A pair of platinum

NOTE 5—Warning: Poison. Combustible. May be fatal if swallowed.

electrodes spaced not more than 5 mm apart shall be mounted

Causes severe burns. Harmful if inhaled.

to extend well below the liquid level. Stirring shall be by a

NOTE 6—Warning: Poison. Corrosive. May be fatal if swallowed.

mechanical or electromagnetic stirrer and shall be rapid, but

Liquid and vapor cause severe burns. Harmful if inhaled.

not so vigorous as to draw air bubbles down to the electrodes.

7.3.2 Potassium Iodide Solution (150 g/L)—Dissolve 150 g

6.3 Burets, 10 and 50-mL capacity.

of KI in water and dilute to 1 L.

6.4 Iodine Number Flasks, glass-stoppered, 500-mL capac-

7.3.3 Sodium Thiosulfate, Standard Solution (0.05 N)—

ity.

Dissolve 12.5 g of sodium thiosulfate pentahydrate (Na S O ·

2 2 3

5H O) in water and add 0.01 g of sodium carbonate (Na CO )

7. Reagents

2 2 3

to stabilize the solution. Dilute to 1 L and mix thoroughly by

7.1 Purity of Reagents—Reagent grade chemicals shall be

shaking. Standardize by any accepted procedure that deter-

used in all tests. Unless otherwise indicated, it is intended that

mines the normality with an error not greater than 60.0002.

all reagents shall conform to the specifications of the American

Restandardize at intervals frequent enough to detect changes of

Chemical Society where such specifications are available.

0.0005 in normality.

Other grades may be used, providing it is first ascertained that

7.3.4 Starch Indicator Solution—Mix5gof soluble starch

the reagent is of sufficiently high purity to permit its use

with approximately 3 to 5 mL of water. If desired, add about

without lessening the accuracy of the determination.

0.65 g salicylic acid as preservative. Add the slurry to 500 mL

7.2 Purity of Water—Unless otherwise indicated, references

of boiling water and continue boiling for 5 to 10 min. Allow to

to water shall be understood to mean distilled water, or water

cool and decant the supernatant liquid into glass bottles and

of equivalent purity.

seal well. Starch solutions (some preserved with salicylic acid)

7.3 Preparation and Standardization:

are also commercially available and may be substituted.

7.3.1 Bromide-Bromate Standard Solution (0.05 N)—

7.3.5 Sulfuric Acid (1+5)—Carefully add 1 volume of

Dissolve 5.1 g of potassium bromide (KBr) and 1.4 g potas-

concentrated sulfuric acid (H SO , sp gr 1.84) to 5 volumes of

2 4

sium bromate (KBrO ) in water and dilute to 1 L. Standardize

water and thoroughly mix. (Warning—See Note 7.)

to four significant figures as follows: Place 50 mL of glacial

acetic acid (Warning—See Note 5.) and 1 mL of concentrated

NOTE 7—Warning: Poison. Corrosive. Strong Oxidizer. Contact with

organic material may cause fire. May be fatal if swallowed.

hydrochloric acid (HCl, sp gr 1.19) (Warning—See Note 6.) in

a 500-mL iodine number flask. Chill the solution in an ice bath

7.3.6 Titration Solvent—Prepare 1 L of titration solvent by

for approximately 10 min, and with constant swirling of the

mixing the following volumes of materials: 714 mL of glacial

flask, add from a 50-mL buret 40 to 45 mL of bromide-bromate

acetic acid, 134 mL of 1,1,1-trichloroethane or dichlo-

solution, estimated to the nearest 0.01 mL, at a rate such that

romethane, 134 mL of methanol, and 18 mL of H SO (1+5)

2 4

the addition takes between 90 and 120 s. Stopper the flask

(see 7.3.5).

immediately, shake the contents, place it again in the ice bath,

7.4 Solvents:

and add 5 mL of potassium iodide (KI) solution in the lip of the

7.4.1 Acetic Acid, glacial. (Warning—See Note

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.