ASTM D4807-88(1999)

(Test Method)Standard Test Method for Sediment in Crude Oil by Membrane Filtration

Standard Test Method for Sediment in Crude Oil by Membrane Filtration

SCOPE

1.1 This test method covers the determination of sediment in crude oils by membrane filtration. This test method has been validated for crude oils with sediments up to about 0.15 mass %.

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The accepted unit of measure for this test method is mass %.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D4807–88(Reapproved 1999)

Designation: MPMS Chapter 10.8

Standard Test Method for

Sediment in Crude Oil by Membrane Filtration

This standard is issued under the fixed designation D4807; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This test method has been approved by the sponsoring committee and accepted by the Cooperating Societies in accordance with

established procedures.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of sediment 4.1 A knowledge of the sediment content of crude oil is

incrudeoilsbymembranefiltration.Thistestmethodhasbeen important both in the operation of the refinery and in the

validated for crude oils with sediments up to about 0.15 mass buying and selling of crude oils.

%.

5. Apparatus

1.2 This standard does not purport to address all of the

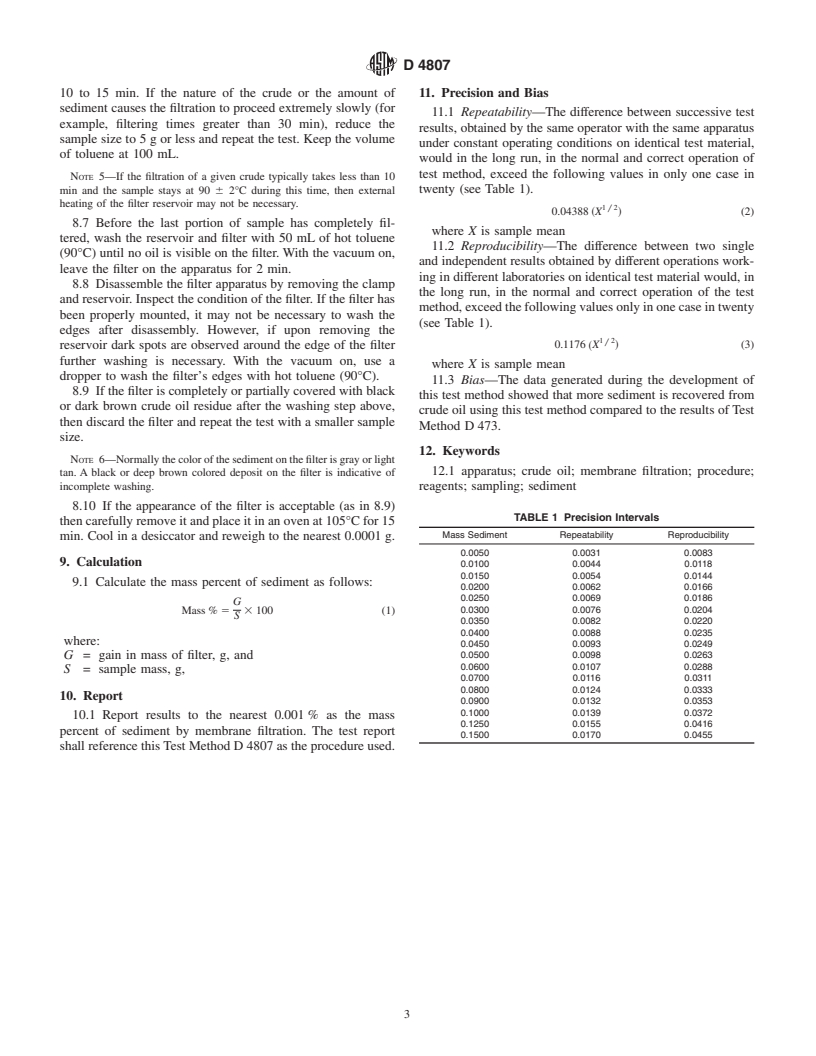

5.1 Reservoir and Filter Support Assembly—an assembly

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- designed to hold 47-mm diameter filters was used in the

development of this test method (see Fig. 1).

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 5.1.1 Filter Reservoir—capable of holding from about 250

mL of solvent. The lower part of the reservoir has a 40-mm

1.3 The accepted unit of measure for this test method is

mass %. inside diameter and is designed to secure the 47-mm diameter

filter against the filter support.The reservoir can be jacketed to

2. Referenced Documents

facilitate heating the reservoir and sample during filtering.

2.1 ASTM Standards:

NOTE 1—Use of a glass reservoir should minimize the effect of static

D473 Test Method for Sediment in Crude Oils and Fuel

electricity when filtering.

Oils by the Extraction Method

5.1.2 Filter Support/Funnel—support base for the filter has

D2892 Test Method for Distillation of Crude Petroleum

a porous scintered glass center section about 40 to 43 mm in

(15-Theoretical Plate Column)

diameter. The support base is designed to fit securely against

D4057 Practice for Manual Sampling of Petroleum and

thereservoirholdingthefilterinplaceovertheporoussection.

Petroleum Products

Thestemofthefunnelportionshouldbelongenoughtoextend

D4177 Practice for Automatic Sampling of Petroleum and

down into the filter flask such that the end is below the outlet

Petroleum Products

for the vacuum.

D4377 Test Method for Water in Crude Oils by Pontentio-

5.1.3 Clamp Assembly—spring or screw type clamp to

metric Karl Fischer Titration

secure the reservoir to the filter support. The clamp should be

tight enough to prevent the solvent from leaking through at the

3. Summary of Test Method

junction between the glass and filter membrane. The exterior

3.1 A portion of a representative crude oil sample is

dimensions of the reservoir and support/funnel are designed to

dissolved in hot toluene and filtered under vacuum through a

facilitate clamping the two pieces together.

0.45-µm porosity membrane filter. The filter with residue is

5.1.4 Rubber Stopper—asingle-hole,capableofholdingthe

washed, dried, and weighed to give the final result.

lower stem of the filter support/funnel securely onto the

filtering flask.

This test method is under the jurisdiction of ASTM Committee D-2 on

5.1.5 Vacuum Filtering Flask, 500 mL or larger.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.02 on Static Petroleum Measurement.

Current edition approved March 25, 1988. Published May 1988.

2 4

Annual Book of ASTM Standards, Vol 05.01. Afiltration assembly as supplied by Millipore Corp.,Ashly Rd., Bedford, MA

Annual Book of ASTM Standards, Vol 05.02. 01730, was found acceptable.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4807

to place the sample into the laboratory test container. The

laboratory test container and sample volume shall be of

sufficientdimensionsandvolumetoallowmixingasdescribed

in 7.3.1. Mixing is required to properly disperse sediment as

well as any water present in the sample.

7.2 Laboratory Sample—Use only representative samples

obtained as specified in Practice D4057 or D4177 for this test

method. Analyze samples within two weeks after taking the

sample. Retaining samples longer may affect the results.

FIG. 1 Membrane Filtration Assembly

7.3 Test Samples—The following sample handling proce-

dure shall apply.

5.2 Membrane Filter, nylon membrane filter, 47 mm in

7.3.1 Mix the test sample of crude oil at room temperature

diameter with 0.45-µm pore size.

in the original container immediately (within 15 min) before

5.3 Oven, capable of maintaining a temperature of 105 6

analysis to ensure complete homogeneity.Atest sample drawn

2°C.

directly from a large volume dynamic mixing system analyze

5.4 Vacuum Pump, capable of reducing and maintaining the

within 15 min or else remix as follows:

pressure at 200 mm Hg (−80 KPA) during the filtering.

5.5 Analytical Balance, capable of measuring to the nearest NOTE 3—Analysis should follow mixing as soon as possible. The

15-min interval mentioned above is a general guideline which may not

0.0001 g.

1 apply to all crudes, especially some light crudes which do not hold water

5.6 Heating Coil for Filter Assembly— copper tubing ( ⁄8-

in suspension for even this short a time.

in.diameter)woundaroundthereservoironthefilterapparatus

7.3.2 Mixingofthesampleshouldnotincreasethetempera-

and connected to a circulating bath to maintain the oil in the

ture of the sample more than 10°C, or a loss of water may

reservoir at 90 6 2°C (see Fig. 1). Alternative methods of

occur and this affects sample composition. The type of mixer

heating the reservoir such as heating tape or glass thermal

depends on the quantity of crude. Before any unknown mixer

jacket could also be used.

is used, the specifications for the homogenization test, Annex

5.7 Mixer —a nonaerating, high-speed mixer capable of

A,mustbemet.Themixermustbere-evaluatedfollowingany

meetingthehomogenizationefficiencytestinAnnexA1.Large

changes in the type of crude, quantity of crude, or shape of the

volume dynamic mixing systems such as those used with

sample container.

automatic crude oil sampling receptacles are also acceptable

7.3.3 For small test sample volumes, 50 to 300 mL, a

providing they comply with Annex A1.

nonaerating, high-speed, shear mixer is required. Use the

6. Reagents

mixingtime,mixingspeed,andheightabovethebottomofthe

container found to be satisfactory inAnnexA1. Clean and dry

6.1 Purity of Reagents—Reagent grade chemicals shall be

the mixer between samples.

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit-

8. Procedure

tee onAnalytical Reagents of theAmerican Chemical Society,

8.1 Prepare nylon filters by heating in an oven at 105°C for

where such specifications are available. Other grades may be

15 min. Cool and store the dried filters in a desiccator (without

used, provided it is first ascertained that the reagent is of

desiccant) until needed. Use only new filters.

sufficiently high purity to permit its use without lessening the

8.2 Weigh the filter immediately before use to the nearest

accuracy of the determination.

0.0001 g.

6.2 Toluene (Warning, Flammable).

8.3 Using tweezers, place the membrane filter on the center

NOTE 2—Warning:Flammable.

of the filter support, which is mounted on the filtering flask

with a rubber stopper.Attach the reservoir to the filter support

7. Sampling, Test Specimens

and clamp it securely.

7.1 Sampling,isdefinedasallthestepsrequiredtoobtainan

8.4 Connect the heating coil to the circulating bath and

aliquot of the contents of any pipe, tank, or other system, and

place the coil around the lower part of the reservoir. Set the

temperature of the circulating bath so as to maintain the oil in

the reservoir at 90 6 2°C.

The following filter was used in generating the precision: MSI Nylon 60

Membrane Filter from Fisher Scientific, Catalog Number NO-4-SP047-00. Other

NOTE 4—Care sho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.