ASTM B476-21

(Specification)Standard Specification for General Requirements for Wrought Precious Metal Electrical Contact Materials

Standard Specification for General Requirements for Wrought Precious Metal Electrical Contact Materials

ABSTRACT

This specification covers general requirements common to wrought precious metal electrical contact alloy products in the form of sheet, strip, wire, and rod. The raw material shall be of such quality and purity that the finished product shall have the properties and characteristics prescribed in the applicable product specification. The product shall be produced by a combination of hot or cold working operations, it shall be finished, unless otherwise specified, by cold working, annealing, or heat treatment as may be necessary to meet the specified properties. Surfaces of all material furnished to this specification shall be smooth, clean, and free from scratches, stains, rough spots, slivers, laps, scale, pits, and any other injurious defects. Test methods such as chemical analysis and physical tests shall be performed accordingly.

SIGNIFICANCE AND USE

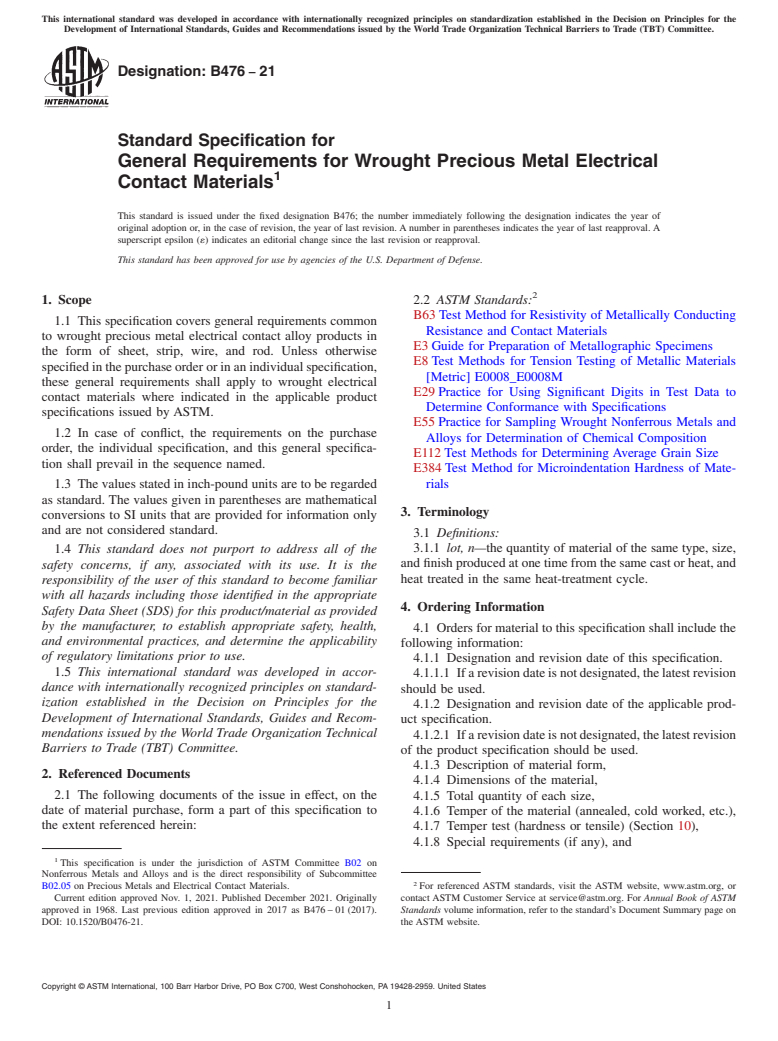

11.1 For purpose of determining compliance with the specified limits for requirements of the properties listed in the following table, an observed value or a calculated value shall be rounded as indicated in accordance with Practice E29.

Property

Unit

Rounded Unit

for Observed or

Calculated Value

Chemical composition

percent

Hardness

Knoop (100-g load unless other-

wise specified)

Vicker (specify load)

Rockwell (all scales, specify which)

Rockwell superficial (all scales,

specify which)

nearest unit on the last right

hand place of figure of

specified limit

Resistivity

μΩ·cm

Tensile strength

psi (MPa)

nearest 1000 psi (nearest 10

MPa)

Yield Strength

psi (MPa)

nearest 1000 psi (nearest

10 MPa)

Elongation

Below 5 %

percent

nearest multiple of 0.5 %

5 % and over

percent

nearest 1 %

Grain size

Up to 0.055 mm incl.

mm

nearest multiple of 0.005

mm

Over 0.055 to 0.160, mm, incl.

mm

nearest 0.01 mm

SCOPE

1.1 This specification covers general requirements common to wrought precious metal electrical contact alloy products in the form of sheet, strip, wire, and rod. Unless otherwise specified in the purchase order or in an individual specification, these general requirements shall apply to wrought electrical contact materials where indicated in the applicable product specifications issued by ASTM.

1.2 In case of conflict, the requirements on the purchase order, the individual specification, and this general specification shall prevail in the sequence named.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet (SDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental practices, and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B476 −21

Standard Specification for

General Requirements for Wrought Precious Metal Electrical

1

Contact Materials

This standard is issued under the fixed designation B476; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

2

1. Scope 2.2 ASTM Standards:

B63Test Method for Resistivity of Metallically Conducting

1.1 This specification covers general requirements common

Resistance and Contact Materials

to wrought precious metal electrical contact alloy products in

E3Guide for Preparation of Metallographic Specimens

the form of sheet, strip, wire, and rod. Unless otherwise

E8Test Methods for Tension Testing of Metallic Materials

specifiedinthepurchaseorderorinanindividualspecification,

[Metric] E0008_E0008M

these general requirements shall apply to wrought electrical

E29Practice for Using Significant Digits in Test Data to

contact materials where indicated in the applicable product

Determine Conformance with Specifications

specifications issued by ASTM.

E55Practice for Sampling Wrought Nonferrous Metals and

1.2 In case of conflict, the requirements on the purchase

Alloys for Determination of Chemical Composition

order, the individual specification, and this general specifica-

E112Test Methods for Determining Average Grain Size

tion shall prevail in the sequence named.

E384Test Method for Microindentation Hardness of Mate-

1.3 The values stated in inch-pound units are to be regarded rials

as standard. The values given in parentheses are mathematical

3. Terminology

conversions to SI units that are provided for information only

and are not considered standard.

3.1 Definitions:

3.1.1 lot, n—the quantity of material of the same type, size,

1.4 This standard does not purport to address all of the

andfinishproducedatonetimefromthesamecastorheat,and

safety concerns, if any, associated with its use. It is the

heat treated in the same heat-treatment cycle.

responsibility of the user of this standard to become familiar

with all hazards including those identified in the appropriate

4. Ordering Information

Safety Data Sheet (SDS) for this product/material as provided

by the manufacturer, to establish appropriate safety, health,

4.1 Ordersformaterialtothisspecificationshallincludethe

and environmental practices, and determine the applicability

following information:

of regulatory limitations prior to use.

4.1.1 Designation and revision date of this specification.

1.5 This international standard was developed in accor-

4.1.1.1 Ifarevisiondateisnotdesignated,thelatestrevision

dance with internationally recognized principles on standard-

should be used.

ization established in the Decision on Principles for the

4.1.2 Designation and revision date of the applicable prod-

Development of International Standards, Guides and Recom-

uct specification.

mendations issued by the World Trade Organization Technical

4.1.2.1 Ifarevisiondateisnotdesignated,thelatestrevision

Barriers to Trade (TBT) Committee.

of the product specification should be used.

4.1.3 Description of material form,

2. Referenced Documents

4.1.4 Dimensions of the material,

2.1 The following documents of the issue in effect, on the

4.1.5 Total quantity of each size,

date of material purchase, form a part of this specification to 4.1.6 Temper of the material (annealed, cold worked, etc.),

the extent referenced herein:

4.1.7 Temper test (hardness or tensile) (Section 10),

4.1.8 Special requirements (if any), and

1

This specification is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

2

B02.05 on Precious Metals and Electrical Contact Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2021. Published December 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1968. Last previous edition approved in 2017 as B476–01(2017). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/B0476-21. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B476−21

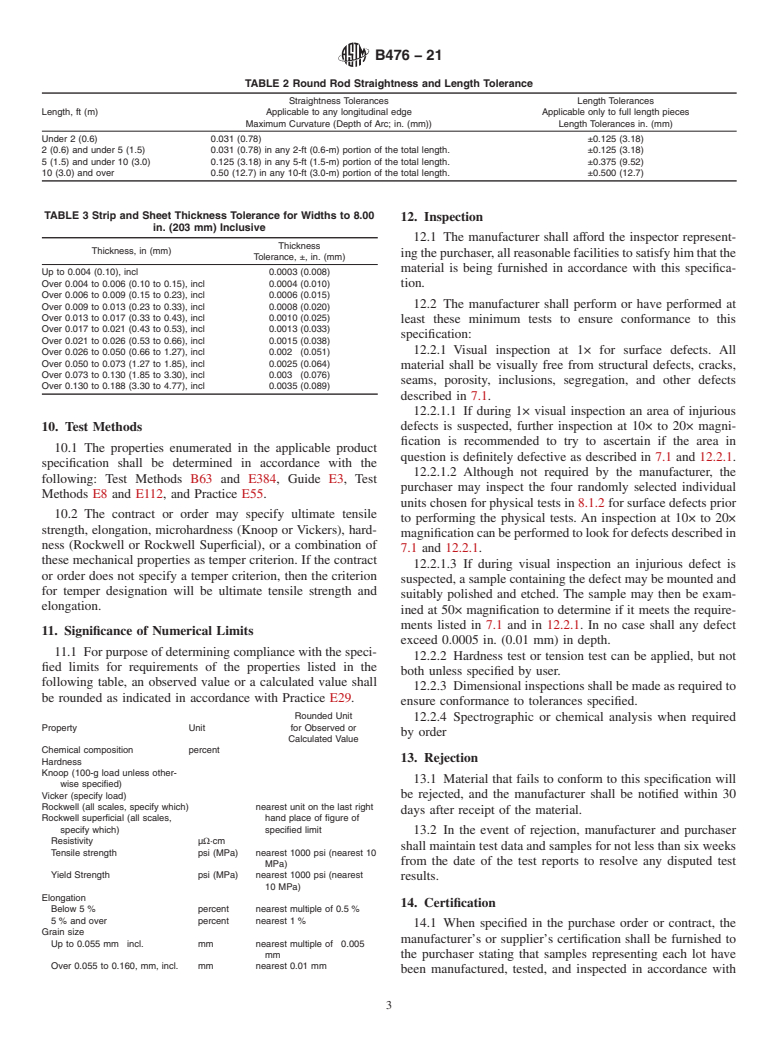

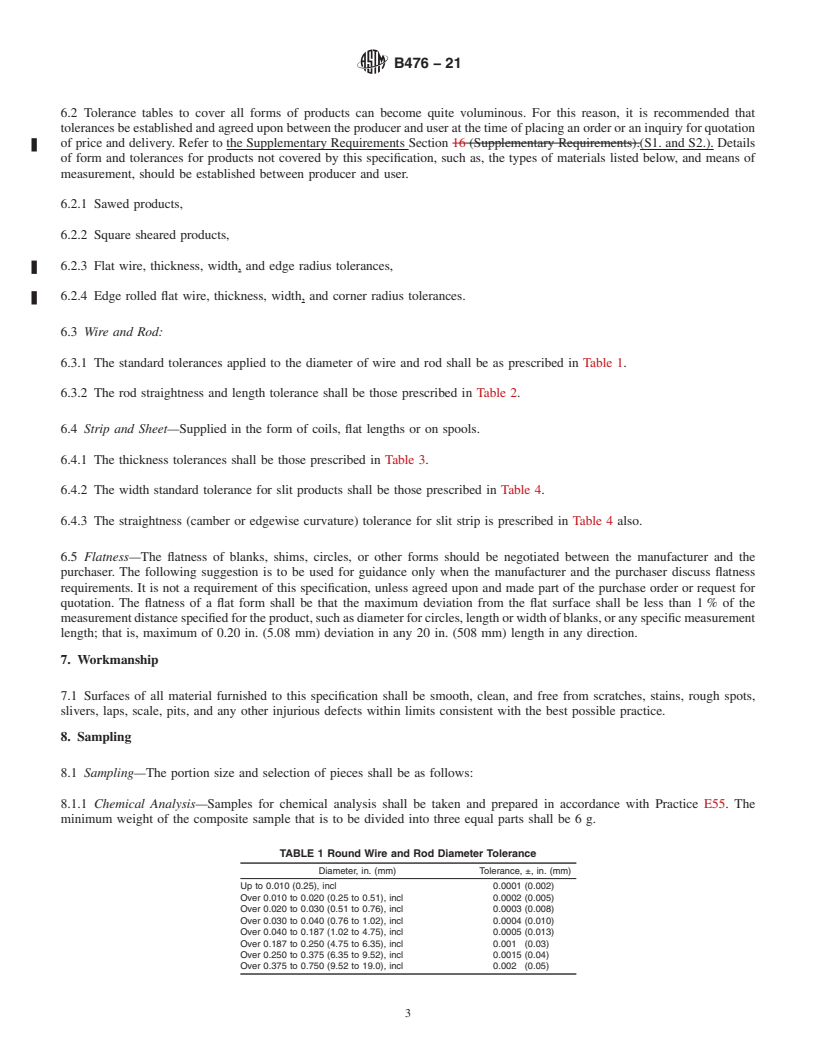

4.1.9 Certification (Section 14). 6.4.1 The thickness tolerances shall be those prescribed in

Table 3.

4.2 Specify the following, i

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B476 − 01 (Reapproved 2017) B476 − 21

Standard Specification for

General Requirements for Wrought Precious Metal Electrical

1

Contact Materials

This standard is issued under the fixed designation B476; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers general requirements common to wrought precious metal electrical contact alloy products in the form

of sheet, strip, wire, and rod. Unless otherwise specified in the purchase order or in an individual specification, these general

requirements shall apply to wrought electrical contact materials where indicated in the applicable product specifications issued by

ASTM.

1.2 In case of conflict, the requirements on the purchase order, the individual specification, and this general specification shall

prevail in the sequence named.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet

(SDS) for this product/material as provided by the manufacturer, to establish appropriate safety safety, health, and healthenvi-

ronmental practices, and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect, on the date of material purchase, form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

B63 Test Method for Resistivity of Metallically Conducting Resistance and Contact Materials

B772 Guide for Specifying the Chemical Compositions for Electrical Contact Materials (Arcing and Nonarcing) (Withdrawn

3

2021)

E3 Guide for Preparation of Metallographic Specimens

1

This specification is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.05 on

Precious Metals and Electrical Contact Materials.

Current edition approved April 1, 2017Nov. 1, 2021. Published April 2017December 2021. Originally approved in 1968. Last previous edition approved in 20122017 as

B476 – 01 (2012).(2017). DOI: 10.1520/B0476-01R17.10.1520/B0476-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B476 − 21

E8 Test Methods for Tension Testing of Metallic Materials [Metric] E0008_E0008M

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E55 Practice for Sampling Wrought Nonferrous Metals and Alloys for Determination of Chemical Composition

E112 Test Methods for Determining Average Grain Size

E384 Test Method for Microindentation Hardness of Materials

3. Terminology

3.1 Definitions:

3.1.1 lot, n—the quantity of material of the same type, size, and finish produced at one time from the same cast or heat, and heat

treated in the same heat-treatment cycle.

4. Ordering Information

4.1 Orders for material to this specification shall include the following information:

4.1.1 Designation and revision date of this specification.

4.1.1.1 If a revision date is not designated, the latest revision should be used.

4.1.2 Designation and revision date of the applicable product specification.

4.1.2.1 If a revision date is not designated, the latest revision of the product specification should b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.