ASTM D6158-99

(Specification)Standard Specification for Mineral Hydraulic Oils

Standard Specification for Mineral Hydraulic Oils

SCOPE

1.1 This specification covers mineral oils used in hydraulic systems, where the performance requirements demand fluids with one of the following characteristics:

1.1.1 A refined base oil (Class HH).

1.1.2 A refined mineral base oil with rust and oxidation inhibitors (Class HL), and

1.1.3 A refined mineral base oil with rust and oxidation inhibitors plus antiwear characteristics (Class HM).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 6158 – 99

Standard Specification for

Mineral Hydraulic Oils

This standard is issued under the fixed designation D 6158; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope and Opaque Liquids (the Calculation of Dynamic Viscos-

ity)

1.1 This specification covers mineral oils used in hydraulic

D 471 Test Method for Rubber Property—Effect of Liq-

systems, where the performance requirements demand fluids

uids

with one of the following characteristics:

D 664 Test Method forAcid Number of Petroleum Products

1.1.1 A refined base oil (Class HH),

by Potentiometric Titration

1.1.2 A refined mineral base oil with rust and oxidation

D 665 Test Method for Rust-Preventing Characteristics of

inhibitors (Class HL), and

Inhibited Mineral Oil in the Presence of Water

1.1.3 A refined mineral base oil with rust and oxidation

D 892 Test Method for Foaming Characteristics of Lubri-

inhibitors plus antiwear characteristics (Class HM).

cating Oils

1.2 This specification defines the requirements of mineral

D 943 Test Method for Oxidation Characteristics of Inhib-

oil-based hydraulic fluids that are compatible with most

ited Mineral Oils

existing machinery components when there is adequate main-

D 974 Test Method for Acid and Base Number by Color-

tenance.

Indicator Titration

1.3 This specification defines only new lubricating oils

D 1298 Practice for Density, Relative Density (Specific

before they are installed in the hydraulic system.

Gravity), or API Gravity of Crude Petroleum and Liquid

1.4 This specification defines specific types of hydraulic

Petroleum Products by Hydrometer Method

oils.Itdoesnotincludeallhydraulicoils.Someoilsthatarenot

D 1401 Test Method for Water Separability of Petroleum

included may be satisfactory for certain hydraulic applications.

Oils and Synthetic Fluids

Certain equipment or conditions of use may permit or require

D 2070 Test Method for Thermal Stability of Hydraulic

a wider or narrower range of characteristics than those de-

Oils

scribed herein.

D 2270 Practice for Calculating Viscosity Index from Kine-

1.5 The following safety hazard caveat pertains to the test

matic Viscosity at 40 and 100°C

methods referenced in this specification. This standard does

D 2422 Classification of Industrial Fluid Lubricants by

not purport to address all of the safety concerns, if any,

Viscosity System

associated with its use. It is the responsibility of the user of this

D 2619 Test Method for Hydrolytic Stability of Hydraulic

standard to establish appropriate safety and health practices

Fluids (Beverage Bottle Method)

and determine the applicability of regulatory limitation prior

D 2882 Test Method for Indicating theWear Characteristics

to use.

of Petroleum and Non-Petroleum Hydraulic Fluids on a

2. Referenced Documents

Constant Volume Vane Pump

D 2983 Test Method for Low-Temperature Viscosity of

2.1 ASTM Standards:

Automotive Fluid Lubricants Measured by Brookfield

D 92 Test Method for Flash and Fire Points by Cleveland

Viscometer

Open Cup

D 3427 Test Method for Air Release Properties of Petro-

D 97 Test Method for Pour Point of Petroleum Oils

leum Oils

D 130 Test Method for Detection of Copper Corrosion from

D 4052 Test Method for Density and Relative Density of

Petroleum Products by the Copper Strip Tarnish Test

Liquids by Digital Density Meter

D 445 Test Method for Kinematic Viscosity of Transparent

D 4310 Test Method for Determination of the Sludging and

Corrosion Tendencies of Inhibited Mineral Oils

This specification is under the jurisdiction of ASTM Committee D-2 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.N on Hydraulic Fluids.

Current edition approved Dec. 10, 1999. Published February 2000. Originally

published as D 6158 – 97. Last previous edition D 6158 – 97. Annual Book of ASTM Standards, Vol 09.01.

2 4

Annual Book of ASTM Standards, Vol 05.01. Annual Book of ASTM Standards, Vol 05.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6158–99

D 6080 Practice for Defining the Viscosity Characteristics systems where equipment is intended to operate over a wide

of Hydraulic Fluids range of ambient temperatures.

3. Classification

4. Classification Requirements

3.1 Type HH Hydraulic Oils—Non-inhibited refined min-

4.1 Type HH—The requirements for this type of oil are

eral oils for hydraulic systems that do not have specific

presented in Table 1 and include Viscosity Grades ISO VG

requirementsofoxidationstability,rustprotection,oranti-wear

from 10 to 150, in accordance with Classification D 2422.

properties. Type HH oils are usually intended for total loss

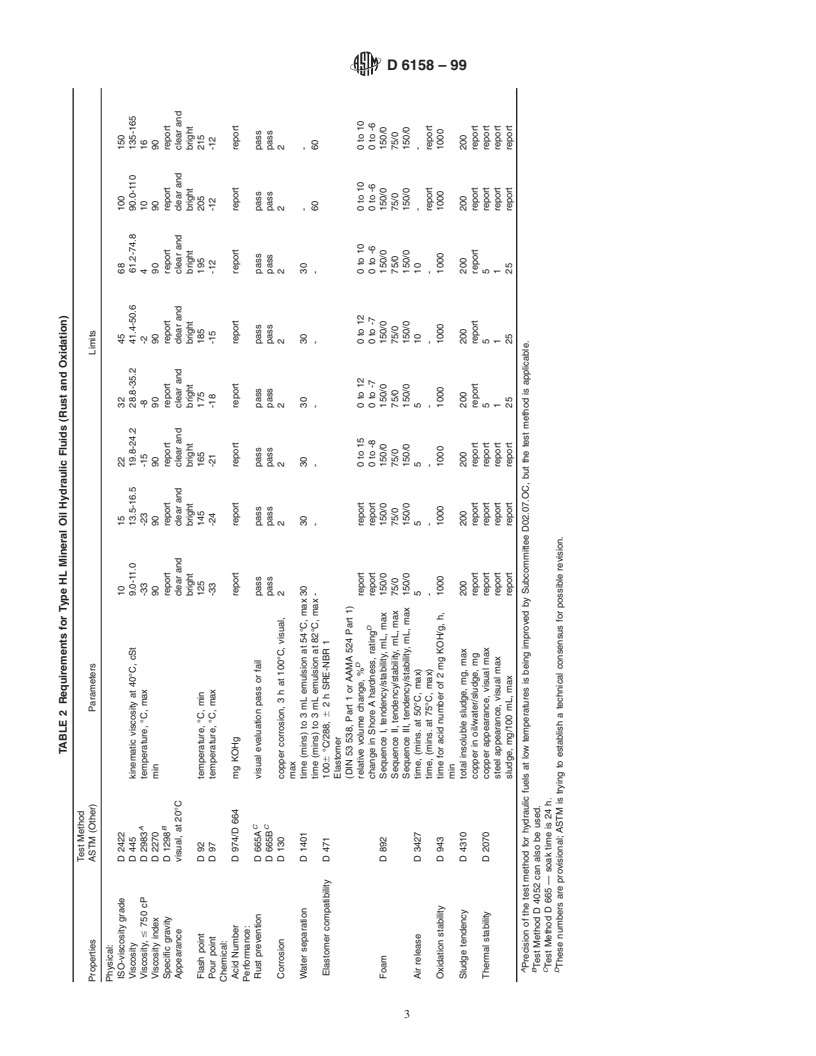

4.2 Type HL—The requirements for this type of oil are

systems or very light-duty equipment.

presented in Table 2 and include Viscosity Grades ISO VG

3.2 Type HL Hydraulic Oils—Refined mineral oils with

from 10 to 150, in accordance with Classification D 2422.

improved rust protection and oxidation stability for hydraulic

4.3 Type HM—The requirements for this type of oil are

systemswhererelativelyhightemperaturesandlongperiodsof

presented in Table 3 and include Viscosity Grades ISO VG

operation time are expected, and where there is the possibility

from 10 to 150, in accordance with Classification D 2422.

of water or humidity that could rust metal parts of the

4.4 Type HV—The requirements for this type of oil are

machinery.These oils are intended for use in systems where no

presented in Table 4 and include Viscosity Grades ISO VG

metal to metal contact is expected between the moving parts.

from 10 to 150, in accordance with Classification D 2422.

Usually systems working at low pressures specify HL oils.

Some high-pressure piston pumps can operate satisfactorily on

5. Inspection

these oils.

5.1 Inspection of the material shall be agreed upon between

3.3 Type HM Hydraulic Oils—Oils of HL type with im-

the purchaser and the supplier.

proved anti-wear properties, for general hydraulic systems,

especially for those working at high pressures and where the

6. Packaging and Package Marking

possibility of metal to metal contact between the moving parts

6.1 The material shall be suitably packaged to permit

exists. Type HM oils are usually specified for hydraulic

acceptance by the carrier and to afford adequate protection

systems with vane pumps, or when the system is intended to

fromnormalhazardsofhandlingandshipping.Packagingshall

work at maximum pump capacity for long periods of time.

conform to applicable carrier rules and regulations.

3.4 Type HV Hydraulic Oils—Oils of HM type with im-

6.2 Packaging and labeling shall comply with state or

proved viscosity/temperature properties, for general hydraulic

federal regulations.

6.3 Each container shall be plainly marked with the manu-

facturer’snameandbrand,productioncodeorlotnumber,type

Annual Book of ASTM Standards, Vol 05.03.

TABLE 1 Requirements for Type HH Mineral Oil Hydraulic Fluids

Test Method

Properties ASTM (Other) Parameters Limits

Physical

ISO viscosity grade D 2422 10 15 22 32 46 68 100 150

Viscosity D 445 kinematic viscosity at 9.0-11.0 13.5-16.5 19.8-24.2 28.8-35.2 41.4-50.6 61.2-74.8 90.0-110 135-165

40°C, cSt

A

Viscosity,# 750 cP D 2983 temperature, °/C report report report report report report report report

Viscosity index D 2270 report report report report report report report report

B

Specific gravity D 1298 report report report report report report report report

Appearance Visual clear and clear and clear and clear and clear and clear and clear and clear and

bright bright bright bright bright bright bright bright

Flash point D 92 temperature, °C, min 125 145 165 175 185 195 205 215

Pour point D 97 temperature, °C, max -15 -12 -9 -6 -6 -6 -6 -6

Chemical

Acid number D 974/D 664 mg KOH/g, max 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05

Performance

Elastomer D 471 100 6 1°C/288 6 2h report report report report report report report report

compatibility 6 2h SRE-NBR 1

Elastomer (DIN53 538,

Part 1 or

AMA 524, Part 1)

relative volume change, report report 0 to 15 0 to 12 0 to 12 0 to 10 0 to 10 0 to 10

%C

change in Shore A report report 0 to –8 0 to –7 0 to –7 0 to –6 0 to –6 0 to –6

hardness, rating C

A

Precision of the test method for hydraulic oils at low temperatures is being improved by Subcommittee D02.07.OC, but the test method is applicable.

B

Test Method D 4052 can also be used.

D6158–99

TABLE 2 Requirements for Type HL Mineral Oil Hydraulic Fluids (Rust and Oxidation)

Test Method

Properties ASTM (Other) Parameters Limits

Physical:

ISO-viscosity grade D 2422 10 15 22 32 45 68 100 150

Viscosity D 445 kinematic viscosity at 40°C, cSt 9.0-11.0 13.5-16.5 19.8-24.2 28.8-35.2 41.4-50.6 61.2-74.8 90.0-110 135-165

A

Viscosity,# 750 cP D 2983 temperature, °C, max -33 -23 -15 -8 -2 4 10 16

Viscosity index D 2270 min 90 90 90 90 90 90 90 90

B

Specific gravity D 1298 report report report report report report report report

Appearance visual, at 20°C clear and clear and clear and clear and clear and clear and clear and clear and

bright bright bright bright bright bright bright bright

Flash point D 92 temperature, °C, min 125 145 165 175 185 195 205 215

Pour point D 97 temperature, °C, max -33 -24 -21 -18 -15 -12 -12 -12

Chemical:

Acid Number D 974/D 664 mg KOHg report report report report report report report report

Performance:

C

Rust prevention D 665A visual evaluation pass or fail pass pass pass pass pass pass pass pass

C

D 665B pass pass pass pass pass pass pass pass

Corrosion D 130 copper corrosion, 3 h at 100°C, visual,2 222 2 2 2 2

max

Water separation D 1401 time (mins) to 3 mL emulsion at 54°C, max 30 30 30 30 30 30 - -

time (mins) to 3 mL emulsion at 82°C, max - - - - - - 60 60

Elastomer compatibility D 471 1006 °C/288, 6 2 h SRE-NBR 1

Elastomer

(DIN 53 538, Part 1 or AAMA 524 Part 1)

D

relative volume change, % report report 0 to 15 0 to 12 0 to 12 0 to 10 0 to 10 0 to 10

D

change in Shore A hardness, rating report report 0 to -8 0 to -7 0 to -7 0 to -6 0 to -6 0 to -6

Foam D 892 Sequence I, tendency/stability, mL, max 150/0 150/0 150/0 150/0 150/0 150/0 150/0 150/0

Sequence II, tendency/stability, mL, max 75/0 75/0 75/0 75/0 75/0 75/0 75/0 75/0

Sequence III, tendency/stability, mL, max 150/0 150/0 150/0 150/0 150/0 150/0 150/0 150/0

Air release D 3427 time, (mins. at 50°C, max) 5 5 5 5 10 10 - -

time, (mins. at 75°C, max) - - - - - - report report

Oxidation stability D 943 time for acid number of 2 mg KOH/g, h, 1000 1000 1000 1000 1000 1000 1000 1000

min

Sludge tendency D 4310 total insoluble sludge, mg, max 200 200 200 200 200 200 200 200

copper in oil/water/sludge, mg report report report report report report report report

Thermal stability D 2070 copper appearance, visual max report report report 5 5 5 report report

steel appearance, visual max report report report 1 1 1 report report

sludge, mg/100 mL, max report report report 25 25 25 report report

A

Precision of the test method for hydraulic fuels at low temperatures is being improved by Subcommittee D02.07.OC, but the test method is applicable.

B

Test Method D 4052 can also be used.

C

Test Method D 665 — soak time is 24 h.

D

These numbers are provisional; ASTM is trying to establish a technical consensus for possible revision.

D6158–99

TABLE 3 Requirements for Type HM Mineral Oil Hydraulic Fluids (Anti-wear)

Test Method

Properties ASTM (Other) Parameters Limits

Physical:

ISO-viscosity grade D 2422 10 15 22 32 46 68 100 150

Viscosity D 445 kinematic viscosity at 40°C, cSt 9.0-11.0 13.5-16.5 19.8-24.2 28.8-35.2 41.4-50.6 61.2-74.8 90.0-110 135-165

A

Viscosity# 750 cP D 2983 temperature, °C, max -33 -23 -15 (-8) -2 4 10 16

Viscosity index D 2270 *min 90 90 90 90 90 90 90 90

B

Specific gravity D 1298 report report report report report report report report

Appearance Visual, at 20°C clear and clear and clear and clear and clear and clear and clear and clear and

bright bright bright bright bright bright bright bright

Flash point D 92 temperature, °C, min 125 145 165 175 185 195 205 215

Pour point D 97 temperature, °C, max -33 -24 -21 -18 -15 -12 -12 -12

Chemical:

Acid number D 974/D 664 mg KOH/g, max report report report report report report report report

Performance

C

Rust prevention D 665A visual evaluation, pass or fail pass pass pass pass pass pass pass pass

C

D 665B visual evaluation, pass or fail pass pass pass pass pass pass pass pass

Corrosion D 130 copper corrosion, 3 h at 100°C, visual, 2 2 2 2 2 2 2 2

max

Water separability D 1401 time (mins) to 3 mL emulsion 30 30 30 30 30 30 - -

max at 54°C

time (mins) to 3 mL emulsion - - - - - - 60 60

max at 82°C

Elastomer compatibility D 471 100 6 1°C/288 6 2h

SRE-NBR 1 Elastomer

(DIN53 538, Part 2 or AAMA 524,

Part 2)

D

relative volume change, % report report 0 to 15 0 to 12 0 to 12 0 to 10 0 to 10 0 to 10

D

change in Shore A hardness, rating report report 0 to -8 0 to -7 0 to -7 0 to -6 0 to -6 0 to -6

Foam D 892 Sequence I tendency/stability mL max 150/0 150/0 150/0 150/0 150/0 150/0 150/0 150/0

Sequence II tendency/stability mL max 75/0 75/0 75/0 75/0 75/0 75/0 75/0 75/0

Sequence III tendency/stability mL max 150/0 150/0 150/0 150/0 150/0 150/0 150/0 150/0

Air release D 3427 time (mins) at 50°C, max 5 5 5 5 10 13 - -

time (mins) at 75°C max - - - - - - report report

Oxidation stability D 943 time for acid number of 2 mg 1000 1000 1000 1000 1000 1000 1000 1000

KOH/g, h, min

Sludge tendency D 4310 total insoluble sludge, mg, max 200 200 200 200 200 200 200 200

copper oil/water/sludge, mg report report report report report report report report

Thermal stability D 2070 copper appearance, visual report report report 5 5 5 report report

steel appearance, visual report report report 1 1 1 report report

sludge, mg/100 mL report report report 25 25 25 report report

Wear protection D 2882 weight loss vanes + ring, mg, - - 50 50 50 - - -

max at 65 6°C/100H

weight loss vanes + ring, mg, - - - - - 50 50 50

max at 79 4°C/100H

A

Precision of the test method for hydraulic oils at low temperatures is being improved by Subcommittee D02.07.OC, but the test method is applicable.

B

Test Method D 4052 can also be used.

C

Test Method D 665 — soak time is 24 h.

D

These numbers are provisional; ASTM is trying to establish a technical consensus for possible revision.

D6158–99

TABLE 4 Requirements for Type HV M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.