ASTM D8093-19

(Guide)Standard Guide for Nondestructive Evaluation of Nuclear Grade Graphite

Standard Guide for Nondestructive Evaluation of Nuclear Grade Graphite

SIGNIFICANCE AND USE

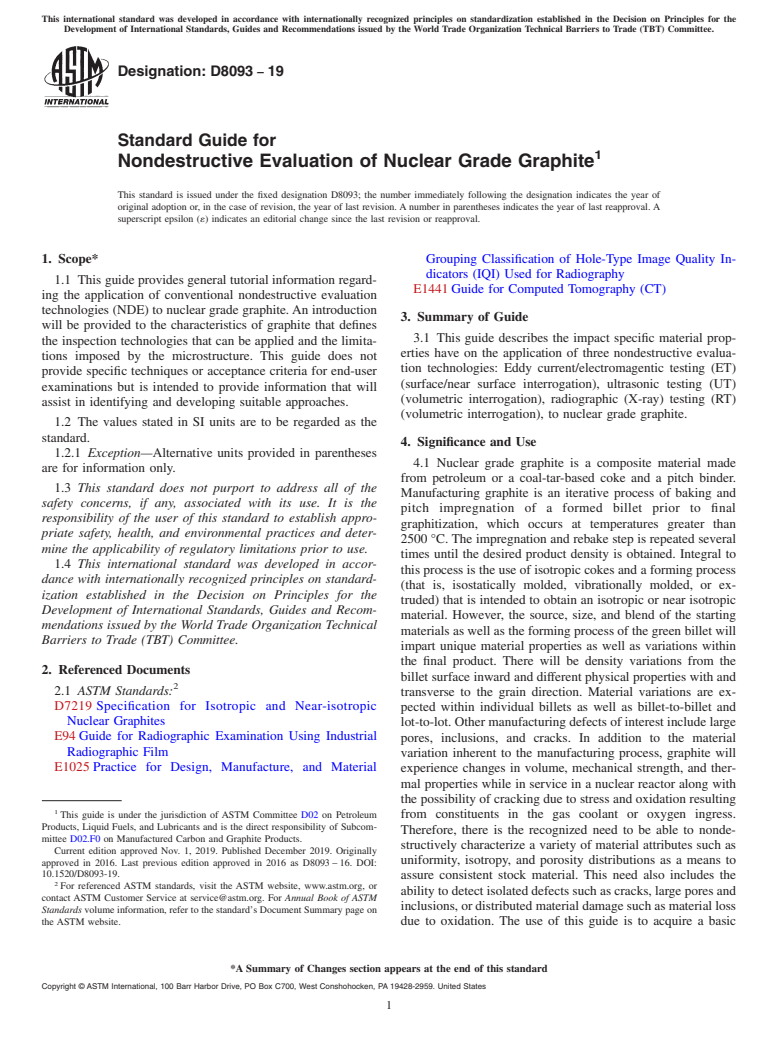

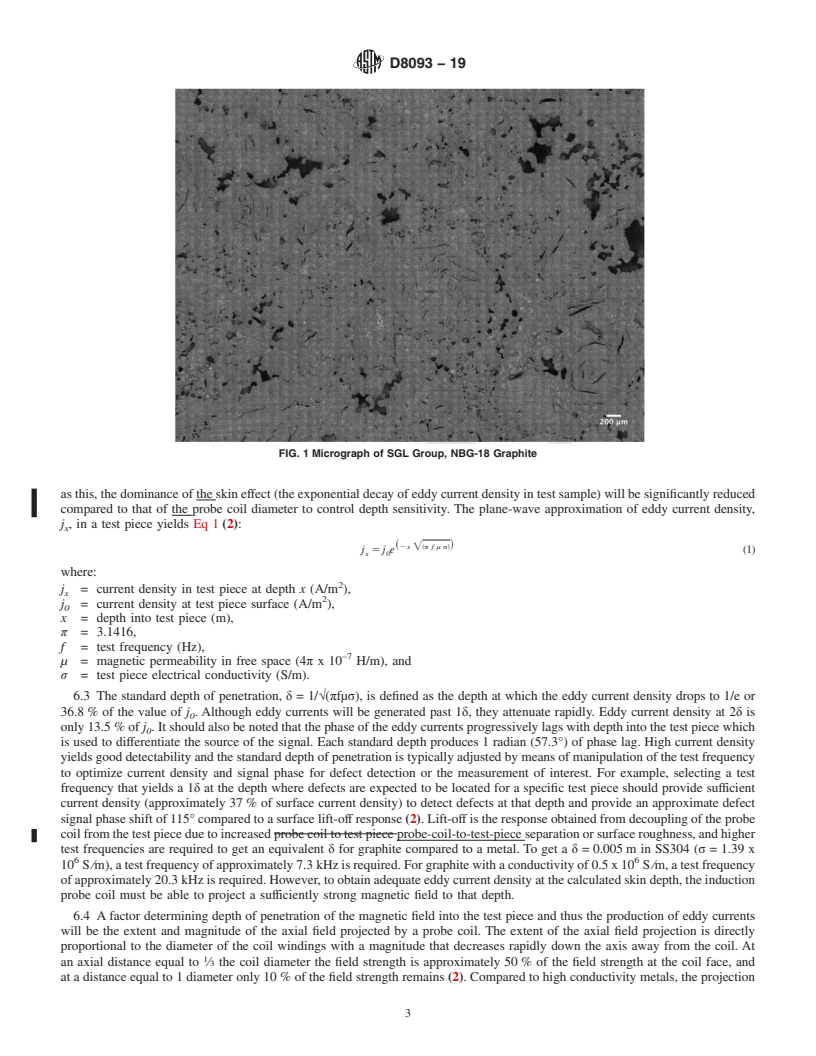

4.1 Nuclear grade graphite is a composite material made from petroleum or a coal-tar-based coke and a pitch binder. Manufacturing graphite is an iterative process of baking and pitch impregnation of a formed billet prior to final graphitization, which occurs at temperatures greater than 2500 °C. The impregnation and rebake step is repeated several times until the desired product density is obtained. Integral to this process is the use of isotropic cokes and a forming process (that is, isostatically molded, vibrationally molded, or extruded) that is intended to obtain an isotropic or near isotropic material. However, the source, size, and blend of the starting materials as well as the forming process of the green billet will impart unique material properties as well as variations within the final product. There will be density variations from the billet surface inward and different physical properties with and transverse to the grain direction. Material variations are expected within individual billets as well as billet-to-billet and lot-to-lot. Other manufacturing defects of interest include large pores, inclusions, and cracks. In addition to the material variation inherent to the manufacturing process, graphite will experience changes in volume, mechanical strength, and thermal properties while in service in a nuclear reactor along with the possibility of cracking due to stress and oxidation resulting from constituents in the gas coolant or oxygen ingress. Therefore, there is the recognized need to be able to nondestructively characterize a variety of material attributes such as uniformity, isotropy, and porosity distributions as a means to assure consistent stock material. This need also includes the ability to detect isolated defects such as cracks, large pores and inclusions, or distributed material damage such as material loss due to oxidation. The use of this guide is to acquire a basic understanding of the unique attributes of nuclear grade graphite and its a...

SCOPE

1.1 This guide provides general tutorial information regarding the application of conventional nondestructive evaluation technologies (NDE) to nuclear grade graphite. An introduction will be provided to the characteristics of graphite that defines the inspection technologies that can be applied and the limitations imposed by the microstructure. This guide does not provide specific techniques or acceptance criteria for end-user examinations but is intended to provide information that will assist in identifying and developing suitable approaches.

1.2 The values stated in SI units are to be regarded as the standard.

1.2.1 Exception—Alternative units provided in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8093 − 19

Standard Guide for

1

Nondestructive Evaluation of Nuclear Grade Graphite

This standard is issued under the fixed designation D8093; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Grouping Classification of Hole-Type Image Quality In-

dicators (IQI) Used for Radiography

1.1 This guide provides general tutorial information regard-

E1441Guide for Computed Tomography (CT)

ing the application of conventional nondestructive evaluation

technologies (NDE) to nuclear grade graphite.An introduction

3. Summary of Guide

will be provided to the characteristics of graphite that defines

3.1 This guide describes the impact specific material prop-

the inspection technologies that can be applied and the limita-

erties have on the application of three nondestructive evalua-

tions imposed by the microstructure. This guide does not

tion technologies: Eddy current/electromagentic testing (ET)

provide specific techniques or acceptance criteria for end-user

(surface/near surface interrogation), ultrasonic testing (UT)

examinations but is intended to provide information that will

(volumetric interrogation), radiographic (X-ray) testing (RT)

assist in identifying and developing suitable approaches.

(volumetric interrogation), to nuclear grade graphite.

1.2 The values stated in SI units are to be regarded as the

standard.

4. Significance and Use

1.2.1 Exception—Alternative units provided in parentheses

4.1 Nuclear grade graphite is a composite material made

are for information only.

from petroleum or a coal-tar-based coke and a pitch binder.

1.3 This standard does not purport to address all of the

Manufacturing graphite is an iterative process of baking and

safety concerns, if any, associated with its use. It is the

pitch impregnation of a formed billet prior to final

responsibility of the user of this standard to establish appro-

graphitization, which occurs at temperatures greater than

priate safety, health, and environmental practices and deter-

2500°C.The impregnation and rebake step is repeated several

mine the applicability of regulatory limitations prior to use.

times until the desired product density is obtained. Integral to

1.4 This international standard was developed in accor-

thisprocessistheuseofisotropiccokesandaformingprocess

dance with internationally recognized principles on standard-

(that is, isostatically molded, vibrationally molded, or ex-

ization established in the Decision on Principles for the

truded) that is intended to obtain an isotropic or near isotropic

Development of International Standards, Guides and Recom-

material. However, the source, size, and blend of the starting

mendations issued by the World Trade Organization Technical

materialsaswellastheformingprocessofthegreenbilletwill

Barriers to Trade (TBT) Committee.

impart unique material properties as well as variations within

the final product. There will be density variations from the

2. Referenced Documents

billet surface inward and different physical properties with and

2

2.1 ASTM Standards:

transverse to the grain direction. Material variations are ex-

D7219 Specification for Isotropic and Near-isotropic

pected within individual billets as well as billet-to-billet and

Nuclear Graphites

lot-to-lot.Othermanufacturingdefectsofinterestincludelarge

E94Guide for Radiographic Examination Using Industrial

pores, inclusions, and cracks. In addition to the material

Radiographic Film

variation inherent to the manufacturing process, graphite will

E1025 Practice for Design, Manufacture, and Material

experience changes in volume, mechanical strength, and ther-

mal properties while in service in a nuclear reactor along with

the possibility of cracking due to stress and oxidation resulting

1

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum

from constituents in the gas coolant or oxygen ingress.

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

Therefore, there is the recognized need to be able to nonde-

mittee D02.F0 on Manufactured Carbon and Graphite Products.

structively characterize a variety of material attributes such as

Current edition approved Nov. 1, 2019. Published December 2019. Originally

uniformity, isotropy, and porosity distributions as a means to

approved in 2016. Last previous edition approved in 2016 as D8093–16. DOI:

10.1520/D8093-19.

assure consistent stock material. This need also includes the

2

For

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D8093 − 16 D8093 − 19 An American National Standard

Standard Guide for

1

Nondestructive Evaluation of Nuclear Grade Graphite

This standard is issued under the fixed designation D8093; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This guide provides general tutorial information regarding the application of conventional nondestructive evaluation

technologies (NDE) to nuclear grade graphite. An introduction will be provided to the characteristics of graphite that defines the

inspection technologies that can be applied and the limitations imposed by the microstructure. This guide does not provide specific

techniques or acceptance criteria for end-user examinations but is intended to provide information that will assist in identifying

and developing suitable approaches.

1.2 The values stated in SI units are to be regarded as the standard.

1.2.1 Exception—Alternative units provided in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

3

C709 Terminology Relating to Manufactured Carbon and Graphite (Withdrawn 2017)

D7219 Specification for Isotropic and Near-isotropic Nuclear Graphites

E94 Guide for Radiographic Examination Using Industrial Radiographic Film

E1025 Practice for Design, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI)

Used for Radiography

E1441 Guide for Computed Tomography (CT)

3. Summary of Guide

3.1 This guide describes the impact specific material properties have on the application of three nondestructive evaluation

technologies: Eddy current/electromagentic testing (ET) (surface/near surface interrogation), ultrasonic testing (UT) (volumetric

interrogation), radiographic (X-ray) testing (RT) (volumetric interrogation), to nuclear grade graphite.

4. Significance and Use

4.1 Nuclear grade graphite is a composite material made from petroleum or a coal-tar-based coke and a pitch binder.

Manufacturing graphite is an iterative process of baking and pitch impregnation of a formed billet prior to final graphitization,

which occurs at temperatures greater than 2500 °C. The impregnation and rebake step is repeated several times until the desired

product density is obtained. Integral to this process is the use of isotropic cokes and a forming process (that is, isostatically molded,

vibrationally molded, or extruded) that is intended to obtain an isotropic or near isotropic material. However, the source, size, and

blend of the starting materials as well as the forming process of the green billet will impart unique material properties as well as

variations within the final product. There will be density variations from the billet surface inward and different physical properties

with and transverse to the grain direction. Material variations are expected within individual billets as well as billet-to-billet and

1

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.F0 on Manufactured Carbon and Graphite Products.

Current edition approved Dec. 1, 2016Nov. 1, 2019. Published March 2017December 2019. Originally approved in 2016. Last previous edition approved in 2016 as

D8093 – 16. DOI: 10.1520/D8093-16.10.1520/D8093-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C70

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.