ASTM C158-23

(Test Method)Standard Test Methods for Strength of Glass by Flexure (Determination of Modulus of Rupture)

Standard Test Methods for Strength of Glass by Flexure (Determination of Modulus of Rupture)

SIGNIFICANCE AND USE

4.1 For the purpose of this test, glasses and glass-ceramics are considered brittle (perfectly elastic) and to have the property that fracture normally occurs at the surface of the test specimen from the principal tensile stress. The flexural strength is considered a valid measure of the tensile strength subject to the considerations that follow.

4.2 The flexural strength for a group of test specimens is influenced by variables associated with the test procedure. Such factors are specified in the test procedure or required to be stated in the report. These include but are not limited to the rate of stressing, the test environment, and the area of the specimen subjected to stress.

4.2.1 In addition, the variables having the greatest effect on the flexural strength value for a group of test specimens are the condition of the surfaces and glass quality near the surfaces in regard to the number and severity of stress-concentrating discontinuities or flaws, and the degree of prestress existing in the specimens. Each of these can represent an inherent part of the strength characteristic being determined or can be a random interfering factor in the measurement.

4.2.2 Test Method A is designed to include the condition of the surface of the specimen as a factor in the measured strength. Therefore, subjecting a fixed and significant area of the surface to the maximum tensile stress is desirable. Since the number and severity of surface flaws in glass are primarily determined by manufacturing and handling processes, this test method is limited to products from which specimens of suitable size can be obtained with minimal dependence of measured strength upon specimen preparation techniques. This test method is therefore designated as a test for flexural strength of flat glass.

4.2.3 Test Method B describes a general procedure for test, applicable to specimens of rectangular or elliptical cross section. This test method is based on the assumption that a comparative ...

SCOPE

1.1 These test methods cover the determination of the flexural strength (the modulus of rupture in bending) of glass and glass-ceramics.

1.2 These test methods are applicable to annealed and prestressed glasses and glass-ceramics available in varied forms. Alternative test methods are described; the test method used shall be determined by the purpose of the test and geometric characteristics of specimens representative of the material.

1.2.1 Test Method A is a test for flexural strength of flat glass.

1.2.2 Test Method B is a comparative test for flexural strength of glass and glass-ceramics.

1.3 The test methods appear in the following order:

Sections

Test Method A

7 to 10

Test Method B

11 to 16

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C158 − 23

Standard Test Methods for

Strength of Glass by Flexure (Determination of Modulus of

1

Rupture)

This standard is issued under the fixed designation C158; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 These test methods cover the determination of the

C148 Test Methods for Polariscopic Examination of Glass

flexural strength (the modulus of rupture in bending) of glass

Containers

and glass-ceramics.

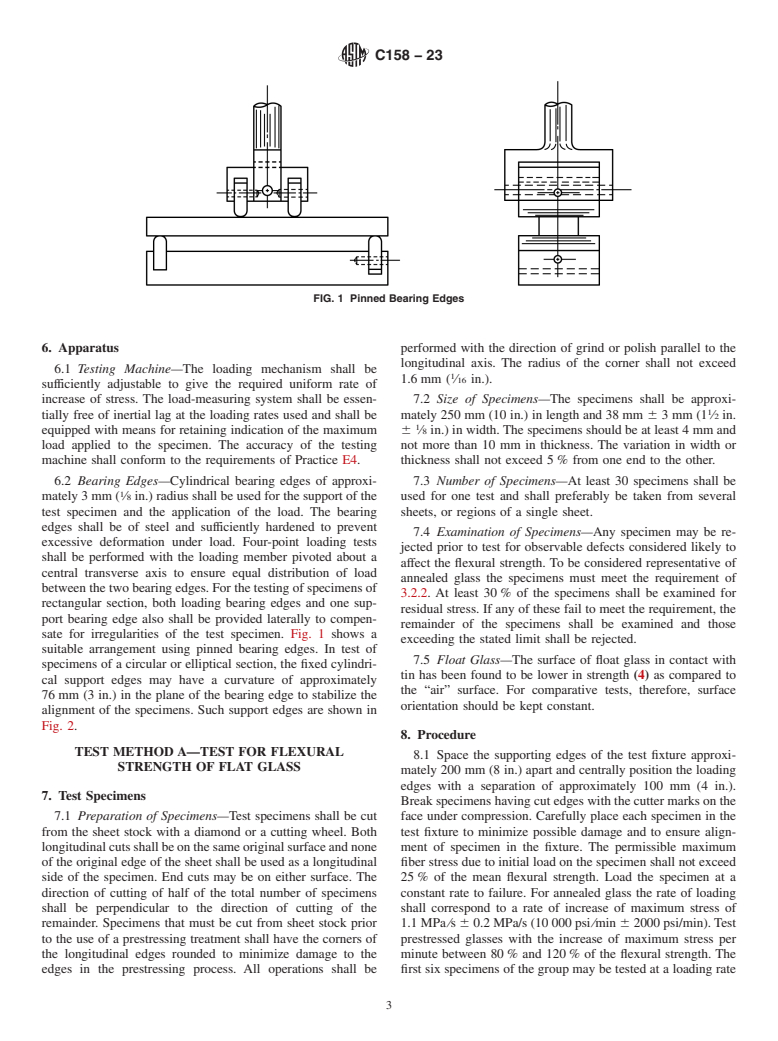

E4 Practices for Force Calibration and Verification of Test-

1.2 These test methods are applicable to annealed and

ing Machines

prestressed glasses and glass-ceramics available in varied

SI10-02 IEEE/ASTM SI 10 American National Standard for

forms. Alternative test methods are described; the test method

Use of the International System of Units (SI): The Modern

used shall be determined by the purpose of the test and

Metric System

geometric characteristics of specimens representative of the

3. Terminology

material.

1.2.1 Test Method A is a test for flexural strength of flat

3.1 Definitions:

glass.

3.1.1 glass-ceramics—solid materials, predominantly crys-

talline in nature, formed by the controlled crystallization of

1.2.2 Test Method B is a comparative test for flexural

glasses.

strength of glass and glass-ceramics.

3.1.2 flexural strength—the value of maximum tensile stress

1.3 The test methods appear in the following order:

in the extreme fiber of a beam loaded to failure in bending.

Sections

Test Method A 7 to 10 3.1.3 prestressed—material in which a significant and con-

Test Method B 11 to 16

trolled degree of compressive stress has been deliberately

1.4 This standard does not purport to address all of the produced in the surfaces.

safety concerns, if any, associated with its use. It is the

3.1.4 standard laboratory atmosphere—an atmosphere hav-

responsibility of the user of this standard to establish appro-

ing a temperature of 23 °C 6 2 °C and a relative humidity of

priate safety, health, and environmental practices and deter-

40 % 6 10 %.

mine the applicability of regulatory limitations prior to use.

3.2 Definitions of Terms Specific to This Standard:

1.5 This international standard was developed in accor-

3.2.1 abraded—describes a test specimen that has at least a

dance with internationally recognized principles on standard-

portion of the area of maximum surface tensile stress during

ization established in the Decision on Principles for the

testing subjected to an operationally defined procedure for

Development of International Standards, Guides and Recom-

mechanical abrasion. The severity and uniformity of abrasion

mendations issued by the World Trade Organization Technical

should be sufficient to ensure origin of failure substantially in

Barriers to Trade (TBT) Committee.

the region of maximum stress.

3.2.2 annealed glass—describes a specimen that shall not

have a temper or degree of residual stress resulting from prior

1

These test methods are under the jurisdiction of ASTM Committee C14 on

Glass and Glass Products and are the direct responsibility of Subcommittee C14.04

2

on Physical and Mechanical Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2023. Published November 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1940. Last previous edition approved in 2017 as C158 – 02 (2017). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/C0158-23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C158 − 23

thermal treatment in excess of the following limits when ration is necessary to obtain comparable strength values. The

measured polarimetrically (see Annex A1): use of a controlled abrasion of the specimen as a final

3.2.2.1 Specimens of rectangular section shall not have a normalizing procedure is recommended for such comparative

tensile stress at the midplane of more than 1.4 MPa (200 psi) tests.

nor more than 2.8 MPa (400 psi) compression at the surface.

4.2.4 A comparative abraded strength, determined as sug-

3.2.2.2 Specimens in rod form may be examined by viewing

gested in Test Met

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C158 − 02 (Reapproved 2017) C158 − 23

Standard Test Methods for

Strength of Glass by Flexure (Determination of Modulus of

1

Rupture)

This standard is issued under the fixed designation C158; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods cover the determination of the flexural strength (the modulus of rupture in bendingbending) of glass and

glass-ceramics.

1.2 These test methods are applicable to annealed and prestressed glasses and glass-ceramics available in varied forms. Alternative

test methods are described; the test method used shall be determined by the purpose of the test and geometric characteristics of

specimens representative of the material.

1.2.1 Test Method A is a test for modulus of rupture flexural strength of flat glass.

1.2.2 Test Method B is a comparative test for modulus of rupture flexural strength of glass and glass-ceramics.

1.3 The test methods appear in the following order:

Sections

Test Method A 6 to 9

Test Method A 7 to 10

Test Method B 10 to 15

Test Method B 11 to 16

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. Specific hazard statements are given in Section 10 and A1.5, A2.3.3, A2.4.3 and A2.5.3.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C148 Test Methods for Polariscopic Examination of Glass Containers

E4 Practices for Force Calibration and Verification of Testing Machines

1

These test methods are under the jurisdiction of ASTM Committee C14 on Glass and Glass Products and are the direct responsibility of Subcommittee C14.04 on Physical

and Mechanical Properties.

Current edition approved Nov. 1, 2017Nov. 1, 2023. Published November 2017November 2023. Originally approved in 1940. Last previous edition approved in 20122017

as C158 – 02 (2012).(2017). DOI: 10.1520/C0158-02R17.10.1520/C0158-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C158 − 23

SI10-02 IEEE/ASTM SI 10 American National Standard for Use of the International System of Units (SI): The Modern Metric

System

3. Terminology

3.1 Definitions:

3.1.1 glass-ceramics—solid materials, predominantly crystalline in nature, formed by the controlled crystallization of glasses.

3.1.2 modulus of rupture in bending—flexural strength—the value of maximum tensile or compressive stress (whichever causes

failure) stress in the extreme fiber of a beam loaded to failure in bending computed from the flexure formula: bending.

M c

S 5 (1)

b

I

where:

M = maximum bending moment, computed from the maximum load and the original moment arm,

c = initial distance from the neutral axis to the extreme fiber where failure occurs, and

I = initial moment of inertia of the cross section about the neutral axis.

3.1.3 prestressed—material in which a significant and controlled degree of compressive stress has been deliberately produced in

the surfaces.

3.1.4 standard laboratory atmosphere—an atmosphere having a temperature of 23 6 2°C23 °C 6 2 °C and a relative humidity

of 4040 % 6 10 %.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 abraded—describes a test specimen that has at least a portion of the area of maximum surface tensile stress during testing

subjected to an operationally defined procedure for mechanical abrasion. The severity and uniformity of abrasion should be

sufficient to ensure origin of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.