ASTM C657-19

(Test Method)Standard Test Method for D-C Volume Resistivity of Glass

Standard Test Method for D-C Volume Resistivity of Glass

SIGNIFICANCE AND USE

4.1 This experimental procedure yields meaningful data for the dc volume resistivity of glass. It is designed to minimize space charge, buildup polarization effects, and surface conductances. The temperature range is limited to room temperature to the annealing point of the specimen glass.

SCOPE

1.1 This test method covers the determination of the dc volume resistivity of a smooth, preferably polished, glass by measuring the resistance to passage of a small amount of direct current through the glass at a voltage high enough to assure adequate sensitivity. This current must be measured under steady-state conditions that is neither a charging current nor a space-charge, buildup polarization current.

1.2 This test method is intended for the determination of resistivities less than 1016 Ω·cm in the temperature range from 25 °C to the annealing point of the glass.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 5.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C657 − 19

Standard Test Method for

1

D-C Volume Resistivity of Glass

This standard is issued under the fixed designation C657; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope Materials at Elevated Temperatures (Withdrawn 2001)

1.1 This test method covers the determination of the dc

3. Summary of Test Method

volume resistivity of a smooth, preferably polished, glass by

3.1 The dc volume resistance is measured in accordance

measuring the resistance to passage of a small amount of direct

with Test Methods D257, with the specimen located in a

current through the glass at a voltage high enough to assure

heating chamber with adequate temperature control, electrical

adequate sensitivity. This current must be measured under

shielding and insulation of the sample leads as described in

steady-state conditions that is neither a charging current nor a

Test Method D1829.

space-charge, buildup polarization current.

1.2 This test method is intended for the determination of

4. Significance and Use

16

resistivities less than 10 Ω·cm in the temperature range from

4.1 This experimental procedure yields meaningful data for

25 °C to the annealing point of the glass.

the dc volume resistivity of glass. It is designed to minimize

1.3 This standard does not purport to address all of the space charge, buildup polarization effects, and surface conduc-

safety concerns, if any, associated with its use. It is the tances. The temperature range is limited to room temperature

responsibility of the user of this standard to establish appro- to the annealing point of the specimen glass.

priate safety, health, and environmental practices and deter-

5. Cautions

mine the applicability of regulatory limitations prior to use.

For specific hazard statements, see Section 5.

5.1 Thermal emfs should be avoided. Connections involv-

1.4 This international standard was developed in accor- ing dissimilar metals can cause measurement difficulties. Even

dance with internationally recognized principles on standard- copper-copper oxide junctions can produce high thermal emfs.

ization established in the Decision on Principles for the Clean, similar metals should be used for electrical junctions.

Development of International Standards, Guides and Recom-

Platinum is recommended. Welded or crimped connections

mendations issued by the World Trade Organization Technical rather than soldered joints avoid difficulties. Specimen elec-

Barriers to Trade (TBT) Committee.

trodes shall have sufficient cross section for adequate electrical

conductance.

2. Referenced Documents

6. Apparatus

2

2.1 ASTM Standards:

6.1 Resistance-Measuring Devices, and the possible prob-

D257 Test Methods for DC Resistance or Conductance of

lems associated with them are discussed thoroughly in Section

Insulating Materials

7 and Appendixes X1 and X3 of Test Methods D257. Further

D374/D374M Test Methods for Thickness of Solid Electri-

discussion of electrometer circuitry is covered in AnnexA1 to

cal Insulation

this test method.

D1711 Terminology Relating to Electrical Insulation

D1829 Test Method for Electrical Resistance of Ceramic

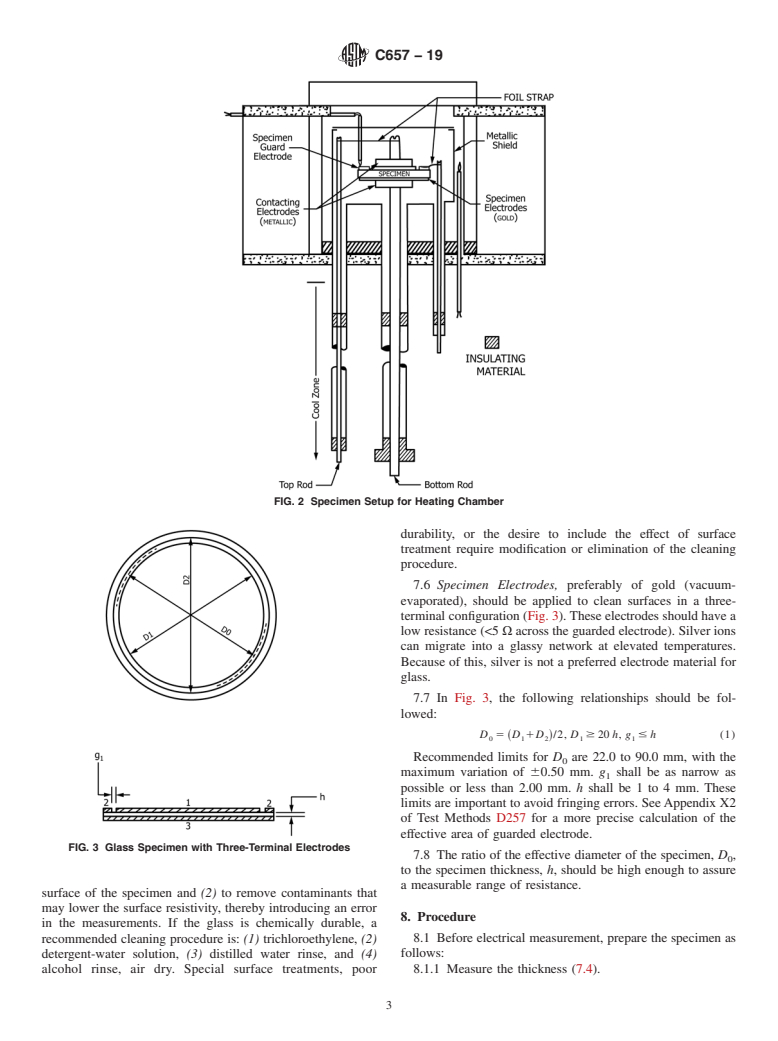

6.2 Heating Chamber (Fig. 1)—For heating the specimen, a

suitable electric furnace shall be used. The construction of the

furnace shall be such that the specimen is subjected to a

uniform heat application with a minimum of temperature

1

This test method is under the jurisdiction of ASTM Committee C14 on Glass

fluctuation. An adequate muffle should be provided to shield

and Glass Products and is the direct responsibility of Subcommittee C14.04 on

Physical and Mechanical Properties.

the specimen from direct radiation by the heating elements.

Current edition approved Nov. 1, 2019. Published December 2019. Originally

This may be made of a ceramic such as aluminum oxide or

approved in 1970. Last previous edition approved in 2013 as C657 – 93 (2013).

equivalent. A grounded metallic shield shall also be provided

DOI: 10.1520/C0657-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

----------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C657 − 93 (Reapproved 2013) C657 − 19

Standard Test Method for

1

D-C Volume Resistivity of Glass

This standard is issued under the fixed designation C657; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the dc volume resistivity of a smooth, preferably polished, glass by measuring

the resistance to passage of a small amount of direct current through the glass at a voltage high enough to assure adequate

sensitivity. This current must be measured under steady-state conditions that is neither a charging current nor a space-charge,

buildup polarization current.

16

1.2 This test method is intended for the determination of resistivities less than 10 Ω·cm in the temperature range from

25°C25 °C to the annealing point of the glass.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For specific hazard statements, see Section 5.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D257 Test Methods for DC Resistance or Conductance of Insulating Materials

D374 Test Methods for Thickness of Solid Electrical Insulation (Metric) D0374_D0374M

D1711 Terminology Relating to Electrical Insulation

3

D1829 Test Method for Electrical Resistance of Ceramic Materials at Elevated Temperatures (Withdrawn 2001)

3. Summary of Test Method

3.1 The dc volume resistance is measured in accordance with Test Methods D257, with the specimen located in a heating

chamber with adequate temperature control, electrical shielding and insulation of the sample leads as described in Test Method

D1829.

4. Significance and Use

4.1 This experimental procedure yields meaningful data for the dc volume resistivity of glass. It is designed to minimize space

charge, buildup polarization effects, and surface conductances. The temperature range is limited to room temperature to the

annealing point of the specimen glass.

5. Cautions

5.1 Thermal emfs should be avoided. Connections involving dissimilar metals can cause measurement difficulties. Even

copper-copper oxide junctions can produce high thermal emfs. Clean, similar metals should be used for electrical junctions.

Platinum is recommended. Welded or crimped connections rather than soldered joints avoid difficulties. Specimen electrodes shall

have sufficient cross section for adequate electrical conductance.

1

This test method is under the jurisdiction of ASTM Committee C14 on Glass and Glass Products and is the direct responsibility of Subcommittee C14.04 on Physical

and Mechanical Properties.

Current edition approved Oct. 1, 2013Nov. 1, 2019. Published October 2013December 2019. Originally approved in 1970. Last previous edition approved in 20082013

as C657 – 93 (2008).(2013). DOI: 10.1520/C0657-93R13.10.1520/C0657-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C657 − 19

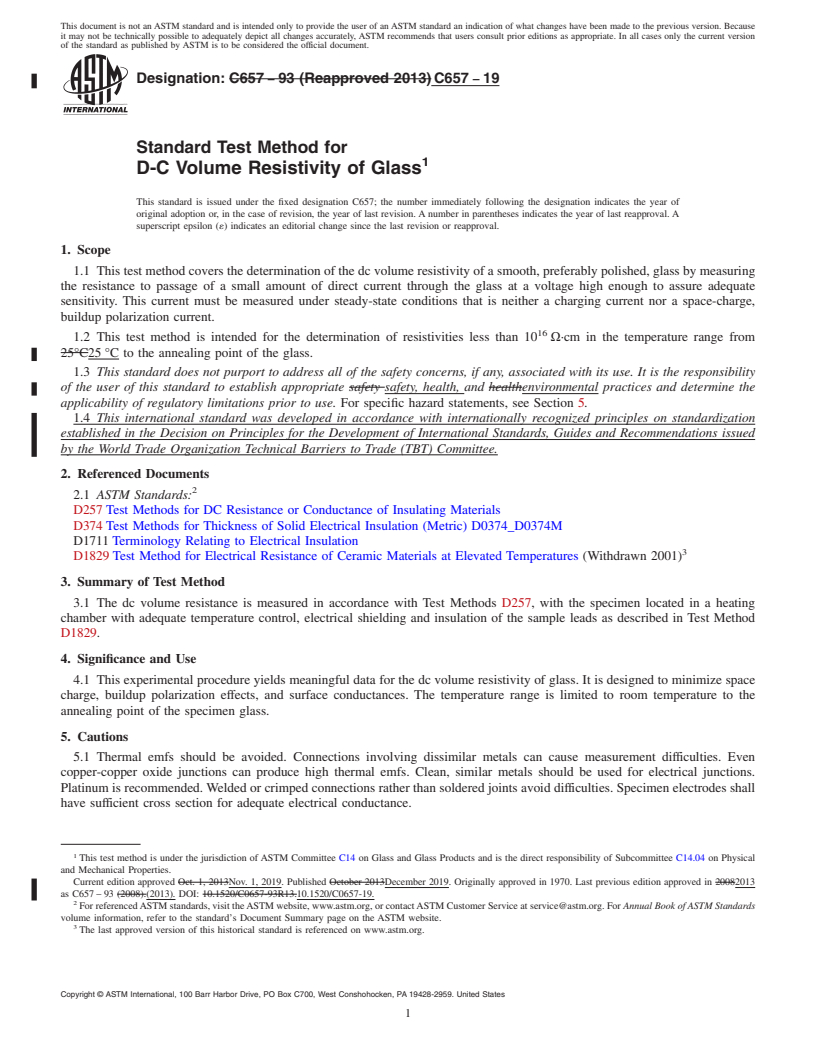

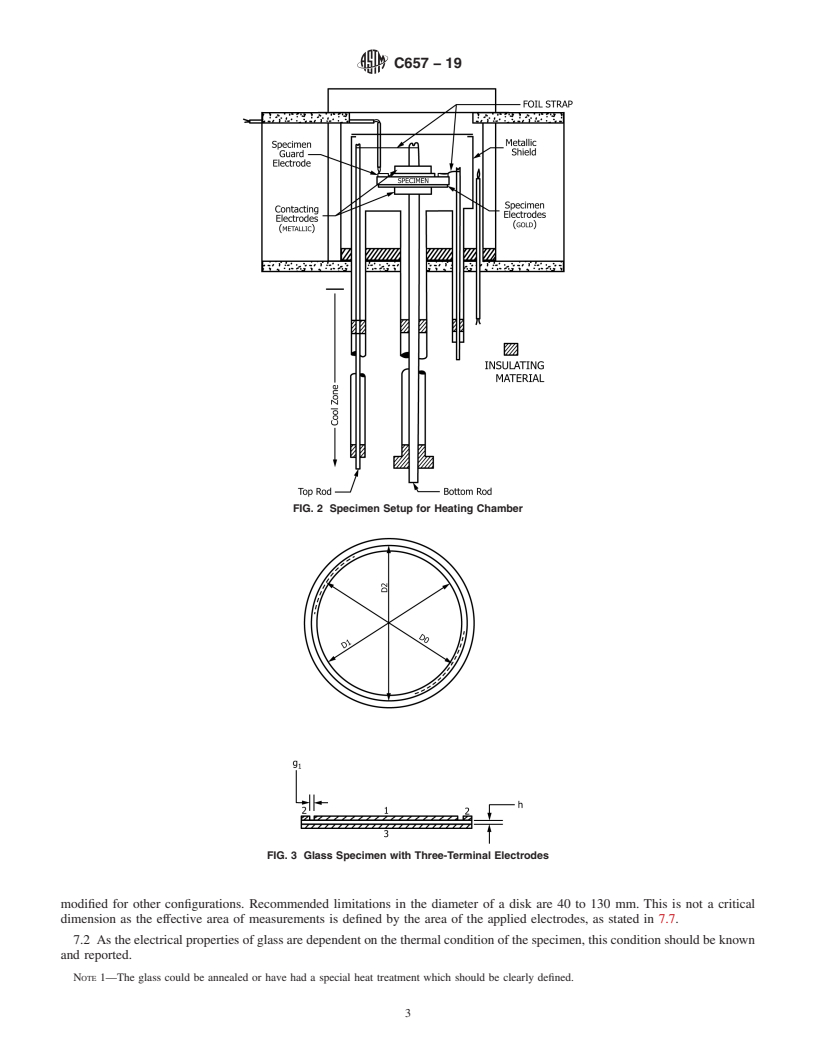

NOTE 1—Heating elements attached to fused alumina core—covered with baked-on refractory cement.

FIG. 1 Heating Chamber

6. Apparatus

6.1 Resistance-Measuring Devices, and the possible problems associated with them are discussed thoroughly in Section 97 and

Appendixes A1X1 and A3X3 of Test Methods D257. Further discussion of electrometer circuitry is covered in Annex A1 to this

test method.

6.2 Heating Chamber (Fig. 1)—For heating the specimen, a suitable electric

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.