ASTM C743-87(2018)

(Test Method)Standard Test Method for Continuity of Porcelain Enamel Coatings

Standard Test Method for Continuity of Porcelain Enamel Coatings

ABSTRACT

This test method provides for easy detection of discontinuities and areas of light coverage that are not readily seen by visual inspection on corrosion protective porcelain enamel coatings. These two issues limit the protection to the metal substrate. Apparatus includes a nondestructive coating thickness gage, either an ac or a dc high-voltage discharge test instrument with a continuously variable output voltage, and a mesh wire gauze test probe. This test uses porcelain enameled glass coating specimens of any size which should be removed from an edge or the back of a specimen and then properly conditioned as specified. If the probe is wider than the specimen, the specimen edges should be masked using electrical insulating tape.

SCOPE

1.1 Porcelain enamel coatings are applied to metals to provide protection from corrosion as well as to enhance their appearance. This test method permits the easy detection of discontinuities and areas of light coverage, not readily seen by visual inspection, which limit the protection to the substrate. Somewhat similar tests applicable to the thicker glass coatings used for chemical reaction vessels are found in Test Methods C536 and C537.

1.2 Values stated in SI units are to be regarded as the standard. Inch-pound units are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C743 − 87 (Reapproved 2018)

Standard Test Method for

Continuity of Porcelain Enamel Coatings

This standard is issued under the fixed designation C743; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test provides a means to evaluate a porcelain enamel coating for pinholes, discontinuities, and

insufficient application to better assess the ability of the coating to protect the substrate.

1. Scope 3. Terminology

1.1 Porcelain enamel coatings are applied to metals to

3.1 air-gap voltage—voltage needed to arc through a defect

provide protection from corrosion as well as to enhance their that is open to both the surface of the porcelain enamel and the

appearance. This test method permits the easy detection of

metal substrate. The length of the air gap is estimated by

discontinuities and areas of light coverage, not readily seen by measuring the enamel thickness.

visual inspection, which limit the protection to the substrate.

3.2 overvoltage—difference between an applied test voltage

Somewhat similar tests applicable to the thicker glass coatings

and the air-gap voltage for the porcelain enamel being tested.

used for chemical reaction vessels are found in Test Methods

3.3 RMS voltage—root mean square voltage, or “average”

C536 and C537.

voltage, shown on ac test meters.

1.2 Values stated in SI units are to be regarded as the

standard. Inch-pound units are provided for information only. 3.4 peak voltage—for ac meters, the voltage that will

discharge across the air gap or across a defect. The peak

1.3 This standard does not purport to address all of the

voltage is the RMS voltage multiplied by 1.414.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Apparatus

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4.1 Anondestructive coating thickness gage with a range of

1.4 This international standard was developed in accor-

at least 0 to 0.5 mm in 0.03 mm increments (0 to 20 mils in 1.0

dance with internationally recognized principles on standard-

mil increments).

ization established in the Decision on Principles for the

4.2 Either an ac or a dc high-voltage discharge test instru-

Development of International Standards, Guides and Recom-

ment with a continuously variable output voltage over the

mendations issued by the World Trade Organization Technical

range of at least 0 to 4 kV as indicated on a built-in voltmeter.

Barriers to Trade (TBT) Committee.

Theinstrumentshallbecapableofbeingsetto0.1kVandshall

have an insulated cable and probe and a means for indicating

2. Referenced Documents

(light, meter, or bell) a voltage discharge. Before use in this

2.1 ASTM Standards:

test, the high-voltage discharge test instrument shall be cali-

C536 Test Method for Continuity of Coatings in Glassed

brated in accordance with the procedure set forth in AnnexA1.

Steel Equipment by Electrical Testing

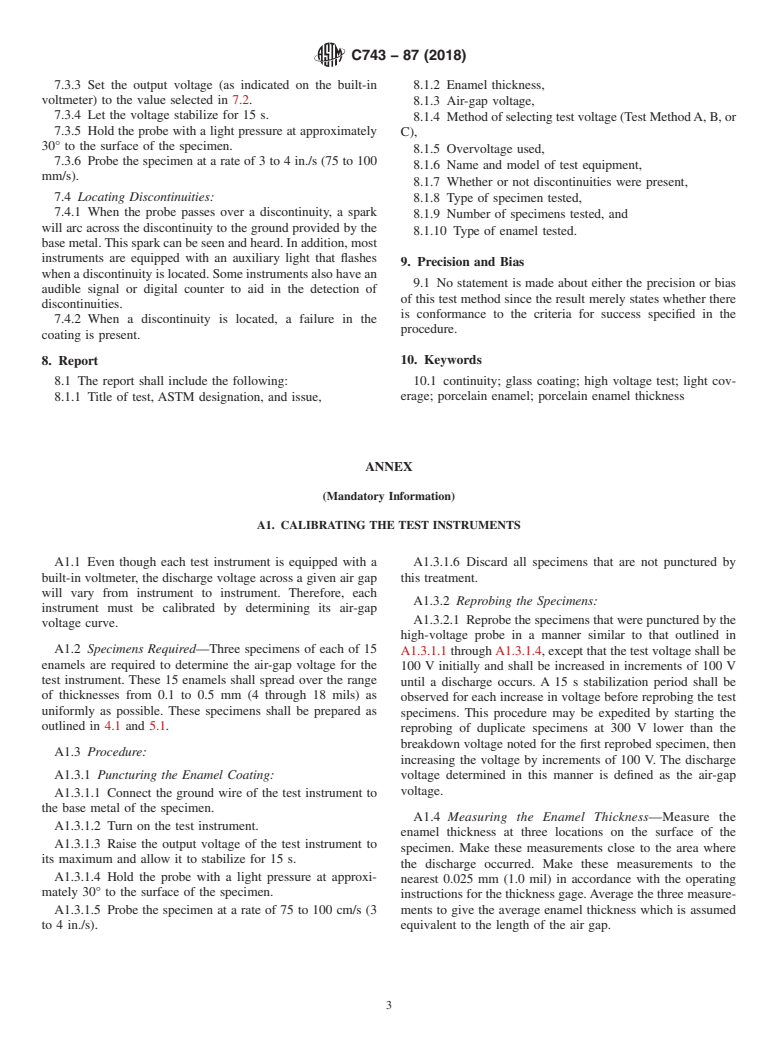

4.3 A test probe constructed of 100 mesh wire gauze as

C537 Test Method for Reliability of Glass Coatings on

Glassed Steel Reaction Equipment by High Voltage illustrated in Fig. 1.

5. Test Specimens

ThistestmethodisunderthejurisdictionofASTMCommitteeB08onMetallic

and Inorganic Coatings and is the direct responsibility of Subcommittee B08.12 on

5.1 Porcelain enameled specimens of any size may be used

Materials for Porcelain Enamel and Ceramic-Metal Systems.

in this test. The enamel shall be removed from an edge or the

Current edition approved Oct. 1, 2018. Published October 2018. Originally

ɛ1

backofthespecimentoprovideanelectricalgroundforthetest

approved in 1973. Last previous edition approved in 2014 as C743 – 87 (2014) .

DOI: 10.1520/C0743-87R18.

instrument. If the probe is wider than the specimen, the edges

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of the specimen shall be masked with electrical insulating tape

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

to prevent discharges from occurring at the edges where

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. porcelain coverage may be light.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C743 − 87 (2018)

FIG. 1 Test Probe

6. Conditioning 7.2.2.1 Determine the air-gap voltage that corresponds to

the enamel thickness from the calibration curve described in

6.1 Before testing, wash the specimens with a 1 weight %,

the annex.

solution of trisodium phosphate on a soft cellulose sponge,

7.2.2.2 Arbitrarily select the overvoltage to be used. (In-

rinse with tap water, and then rinse with distilled water. Then

creasingly smaller defects are located with this test as the

dry the specimens thoroughly in air.

overvoltage is increased. Therefore, confidence that ware

passing this test will have a long, corrosion-free service life is

7. Procedure

increased as the overvoltage is increased.)

7.1 Measuring the Enamel Thickness—Measure the enamel

7.2.2.3 Add the selected overvoltage to the air-gap voltage.

thickness at a minimum of three locations on the specimen.

This value is the test voltage.

Make these measurements to the nearest 0.03 mm (1.0 mil) in

7.2.2.4 Probe the specimen in accordance with 7.3.

accordance with the operating instructions for the thickness

gage. Use the maximum value obtained as the enamel thick- 7.2.3 Test Method C—For Compliance with a Specification

ness. —Specifications for continuity of coating will be in terms of dc

overvoltage or peak ac overvoltage (these are identical).

7.2 Selecting the Test Voltage—The test voltage to be used

Determination of the test voltage depends on whether a dc or

depends upon the purpose for conducting the test. The test can

an ac test instrument is used.

be used to determine (1) the presence of defects open to both

7.2.3.1 DC Test Instruments—Determine the test voltage in

the enamel surface and the base metal, (2) the location of areas

accordance with 7.2.2, substituting the specified overvoltage

of light coverage in addition to defects open to both the enamel

for the selected overvoltage as in 7.2.2.2 and 7.2.2.3.

surface and the base metal, or (3) compliance with a specifi-

7.2.3.2 AC Test Instruments—Divide the specified overvolt-

cation.According to the user’s purpose for con

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.