ASTM D6417-99

(Test Method)Standard Test Method for Estimation of Engine Oil Volatility by Capillary Gas Chromatography

Standard Test Method for Estimation of Engine Oil Volatility by Capillary Gas Chromatography

SCOPE

1.1 This test method covers an estimation of the amount of engine oil volatilized at 371°C (700°F).

1.1.1 This test method can also be used to estimate the amount of oil volatilized at any temperature between 126 and 371°C, if so desired.

1.2 This test method is limited to samples having an initial boiling point (IBP) greater than 126°C (259°F) or the first calibration point and to samples containing lubricant base oils with end points less than 615°C (1139°F) or the last n-paraffins in the calibration mixture. By using some instruments and columns, it is possible to extend the useful range of the test method.

1.3 This test method uses the principles of simulated distilation methodology.

1.4 This test method may be applied to both lubricant oil base stocks and finished lubricants containing additive packages. These additive packages generally contain high molecular weight, non-volatile components that do not elute from the chromatographic column under the test conditions. The calculation procedure used in this test method assumes that all of the sample elutes from the column and is detected with uniform response. This assumption is not true for samples with non-volatile additives, and the results might be biased high relative to Test Method D 5480, which uses an internal standard to account for the uneluted material. For this reason, results by this test method are reported as area percent of oil.

1.5 The values stated in SI units are to be regarded as the standard. The values stated in inch-pound units are provided for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6417 – 99

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Estimation of Engine Oil Volatility by Capillary Gas

Chromatography

This standard is issued under the fixed designation D 6417; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Petroleum Fractions by Gas Chromatography

D 4626 Practice for Calculation of Gas Chromatographic

1.1 This test method covers an estimation of the amount of

Response Factors

engine oil volatilized at 371°C (700°F).

D 5480 Test Method for Motor Oil Volatility by Gas Chro-

1.1.1 This test method can also be used to estimate the

matography

amount of oil volatilized at any temperature between 126 and

D 5800 Test Method for Evaporation Loss of Lubricating

371°C, if so desired.

Oils by the Noack Method

1.2 This test method is limited to samples having an initial

E 355 Practice for Gas Chromatographic Terms and Rela-

boiling point (IBP) greater than 126°C (259°F) or the first

tionships

calibration point and to samples containing lubricant base oils

E 594 Practice for Testing Flame Ionization Detectors Used

with end points less than 615°C (1139°F) or the last n-paraffins

in Gas Chromatography

in the calibration mixture. By using some instruments and

E 1510 Practice for Installing Fused Silica Open Tubular

columns, it is possible to extend the useful range of the test

Capillary Columns in Gas Chromatographs

method.

2.2 DIN Standard:

1.3 This test method uses the principles of simulated distil-

DIN 51.581 Noack Evaporative Test

lation methodology.

1.4 This test method may be applied to both lubricant oil

3. Terminology

base stocks and finished lubricants containing additive pack-

3.1 Definitions—This test method makes reference to many

ages. These additive packages generally contain high molecu-

common gas chromatographic procedures, terms, and relation-

lar weight, non-volatile components that do not elute from the

ships. Detailed definitions of these can be found in Practices

chromatographic column under the test conditions. The calcu-

E 355, E 594, and E 1510.

lation procedure used in this test method assumes that all of the

3.2 Definitions of Terms Specific to This Standard:

sample elutes from the column and is detected with uniform

3.2.1 area slice—the area resulting from the integration of

response. This assumption is not true for samples with non-

the chromatographic detector signal within a specified reten-

volatile additives, and the results might be biased high relative

tion time interval. In area slice mode (see 6.5.2), peak detection

to Test Method D 5480, which uses an internal standard to

parameters are bypassed and the detector signal integral is

account for the uneluted material. For this reason, results by

recorded as area slices of consecutive, fixed duration time

this test method are reported as area percent of oil.

intervals.

1.5 The values stated in SI units are to be regarded as

3.2.2 corrected area slice—an area slice corrected for base-

standard. The values stated in inch-pound units are provided

line offset by subtraction of the exactly corresponding area

for information only.

slice in a previously recorded blank (nonsample) analysis.

1.6 This standard does not purport to address all of the

3.2.3 cumulative corrected area—the accumulated sum of

safety concerns, if any, associated with its use. It is the

corrected area slices from the beginning of the analysis through

responsibility of the user of this standard to establish appro-

a given retention time (RT), ignoring any nonsample area (for

priate safety and health practices and determine the applica-

example, solvent).

bility of regulatory limitations prior to use.

3.2.4 slice rate—the time interval used to integrate the

2. Referenced Documents continuous (analog) chromatographic detector response during

an analysis. The slice rate is expressed in hertz (for example,

2.1 ASTM Standards:

integrations or slices per second).

D 2887 Test Method for Boiling Range Distribution of

Annual Book of ASTM Standards, Vol 05.02.

This test method is under the jurisdiction of ASTM Committee D-2 on

Annual Book of ASTM Standards, Vol 05.03.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

Annual Book of ASTM Standards, Vol 14.02.

D02.04 on Hydrocarbon Analysis.

Published by Deutsches Institut für Normunge and available from Beuth

Current edition approved April 10, 1999. Published June 1999.

Verlag, GmbH, Burgqrafenstrasse 6, 1000 Berlin 30, Germany.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6417

3.2.5 slice time—the cumulative slice rate (analysis time) 6. Apparatus

associated with each area slice throughout the chromatographic

6.1 Chromatograph—The gas chromatographic system

analysis. The slice time is the time at the end of each

used must have the following performance characteristics:

contiguous area slice.

6.1.1 Column Oven, capable of sustained and linear pro-

3.2.6 total sample area—the cumulative corrected area

grammed temperature operation from near ambient (for ex-

from the initial point to the final area point.

ample, 35 to 50°C) up to 400°C.

3.3 Abbreviation—A common way to abbreviate hydrocar-

6.1.2 Column Temperature Programmer—The chromato-

bon compounds is to designate the number of carbon atoms in

graph must be capable of linear programmed temperature

the compound. A prefix is used to indicate the carbon chain

operation up to 400°C at selectable linear rates up to 20°C/min.

form while a subscript suffix denotes the number of carbon

The programming rate must be sufficiently reproducible to

atoms (for example, normal decane n-C ; iso-tetradecane 5

obtain the RT repeatability of 0.1 min (6 s) for each component

i-C ).

in the calibration mixture described in 7.6.

6.1.3 Detector—This test method requires a FID. The de-

4. Summary of Test Method

tector must meet or exceed the following specifications as

4.1 A nonpolar open tubular (capillary) gas chromato-

detailed in Practice E 594.

graphic column is used to elute the hydrocarbon components of 6.1.3.1 Operating Temperature, up to 400°C.

the sample in order of increasing boiling point.

6.1.3.2 Sensitivity, >0.005 coulombs/ g carbon.

−11

4.2 A sample aliquot is diluted with a viscosity reducing

6.1.3.3 Minimum Detectability,1 3 10 g carbon / s.

solvent and introduced into the chromatographic system. At

6.1.3.4 Linear Range,10 .

least one laboratory analyzed samples using neat injection

6.1.3.5 Connection of the column to the detector must be

without solvent dilution. The precision of the method was

such that no temperature below the column temperature exists.

calculated on diluted samples. If a laboratory chooses to use

Refer to Practice E 1510 for proper installation and condition-

neat injection, it should first confirm that it is obtaining similar

ing of the capillary column.

results. Sample vaporization is provided by separate heating of

6.1.4 Sample Inlet System—Any sample inlet system ca-

the point of injection or in conjunction with column oven

pable of meeting the performance specification in 7.6 may be

heating.

used. Programmed temperature vaporization (PTV) and pro-

4.3 The column oven temperature is raised at a reproducible

grammable cool on-column injection systems have been used

linear rate to effect separation of the hydrocarbon components

successfully.

in order of increasing boiling point. The elution of sample

6.2 Microsyringe—A microsyringe with a 23 gage, or

components is quantitatively determined by a flame ionization

smaller, stainless steel needle is used for on-column sample

detector (FID). The detector signal integral is recorded as area

introduction. Syringes of 0.1 μL to 10 μL capacity have been

slices for consecutive RT intervals during the analysis.

used.

4.4 RTs of known hydrocarbons spanning the scope of the

6.2.1 Automatic syringe injection is recommended to

test method (C -C ) are determined and correlated to their

8 60 achieve best precision.

boiling point temperatures. The RT at 371°C (700°F) is

6.3 Column—This test method is limited to the use of

calculated using linear regression, utilizing the calibration

nonpolar wall coated open tubular (WCOT) columns of high

developed from the n-paraffins. The cumulative corrected area

thermal stability. Glass, fused silica, and stainless steel col-

of the sample determined to the 371°C RT is used to calculate

umns with a 0.53-mm diameter have been successfully used.

the percentage of oil volatilized at 371°C.

Cross-linked or bonded methyl silicone liquid phases with film

thickness from 0.10 to 1.0 μm have been used. The column

5. Significance and Use

length and liquid phase film thickness must allow the elution of

5.1 The determination of engine oil volatility at at least C60 n-paraffin (boiling point 5 615°C). The column

and conditions must provide separation of typical petroleum

371°C(700°F) is a requirement in some lubricant specifica-

tions. hydrocarbons in order of increasing boiling point and meet the

column resolution requirements of 8.2.1.

5.2 This test method is intended as an alternative to Test

6.4 Carrier Gas Flow/Pressure Control—The optimum car-

Methods D 5800 and D 5480 and the Noack method for the

determination of engine oil volatility (see DIN 51.581). The rier gas flow for the column and chromatographic system

should be used. It is recommended that the system be equipped

data obtained from this test method are not directly equivalent

to Test Method D 5800. The calculated results of the oil with a constant pressure/constant flow device capable of

maintaining the carrier gas at a constant flow rate throughout

volatility estimation by this test method can be biased by the

presence of additives (polymeric materials), which may not the temperature program.

completely elute from the gas chromatographic column, or by 6.5 Data Acquisition System:

heavier base oils not completely eluting from the column. The 6.5.1 Recorder—A 0 to 1 mV range recording potentiom-

results of this test method may also not correlate with other oil eter, or equivalent, with a full-scale response time of 2 s, or

volatility methods for nonhydrocarbon synthetic oils. less, may be used to provide a graphical display.

5.3 This test method can be used on lubricant products not 6.5.2 Integrator—Means must be provided for determining

within the scope of other test methods using simulated distil- the accumulated area under the chromatogram. This can be

lation methodologies, such as Test Method D 2887. done by means of an electronic integrator or computer based

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6417

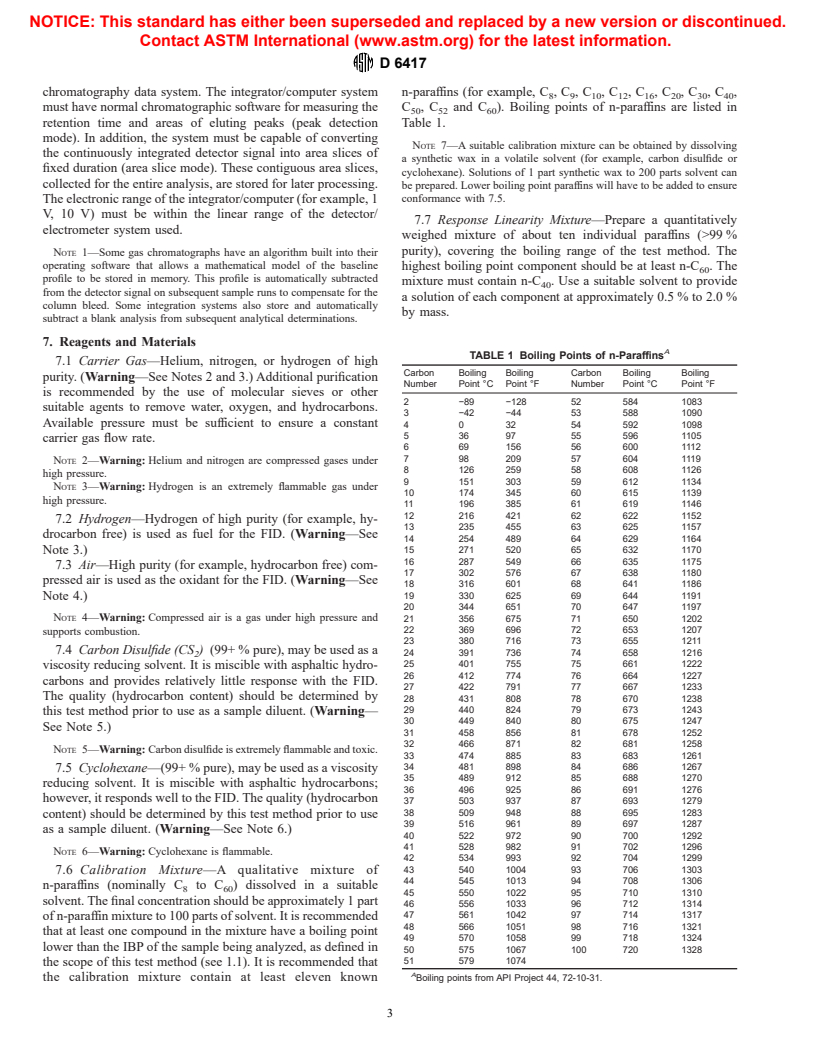

chromatography data system. The integrator/computer system n-paraffins (for example, C ,C ,C ,C ,C ,C ,C ,C ,

8 9 10 12 16 20 30 40

must have normal chromatographic software for measuring the C ,C and C ). Boiling points of n-paraffins are listed in

50 52 60

retention time and areas of eluting peaks (peak detection Table 1.

mode). In addition, the system must be capable of converting

NOTE 7—A suitable calibration mixture can be obtained by dissolving

the continuously integrated detector signal into area slices of

a synthetic wax in a volatile solvent (for example, carbon disulfide or

fixed duration (area slice mode). These contiguous area slices,

cyclohexane). Solutions of 1 part synthetic wax to 200 parts solvent can

collected for the entire analysis, are stored for later processing.

be prepared. Lower boiling point paraffins will have to be added to ensure

conformance with 7.5.

The electronic range of the integrator/computer (for example, 1

V, 10 V) must be within the linear range of the detector/

7.7 Response Linearity Mixture—Prepare a quantitatively

electrometer system used.

weighed mixture of about ten individual paraffins (>99 %

NOTE 1—Some gas chromatographs have an algorithm built into their purity), covering the boiling range of the test method. The

operating software that allows a mathematical model of the baseline

highest boiling point component should be at least n-C . The

profile to be stored in memory. This profile is automatically subtracted

mixture must contain n-C . Use a suitable solvent to provide

from the detector signal on subsequent sample runs to compensate for the

a solution of each component at approximately 0.5 % to 2.0 %

column bleed. Some integration systems also store and automatically

by mass.

subtract a blank analysis from subsequent analytical determinations.

7. Reagents and Materials

A

TABLE 1 Boiling Points of n-Paraffins

7.1 Carrier Gas—Helium, nitrogen, or hydrogen of high

Carbon Boiling Boiling Carbon Boiling Boiling

purity. (Warning—See Notes 2 and 3.) Additional purification

Number Point °C Point °F Number Point °C Point °F

is recommended by the use of molecular sieves or other

2 −89 −128 52 584 1083

suitable agents to remove water, oxygen, and hydrocarbons.

3 −42 −44 53 588 1090

Available pressure must be sufficient to ensure a constant

4 0 32 54 592 1098

5 36 97 55 596 1105

carrier gas flow rate.

6 69 156 56 600 1112

7 98 209 57 604 1119

NOTE 2—Warning: Helium and nitrogen are compressed gases under

8 126 259 58 608 1126

high pressure.

9 151 303 59 612 1134

NOTE 3—Warning: Hydrogen is an extremely flammable gas under

10 174 345 60 615 1139

high pressure.

11 196 385 61 619 1146

12 216 421 62 622 1152

7.2 Hydrogen—Hydrogen of high purity (for example, hy-

13 235 455 63 625 1157

drocarbon free) is used as fuel for the FID. (Warning—See

14 254 489 64 629 1164

15 271 520 65 632 1170

Note 3.)

16 287 549 66 635 1175

7.3 Air—High purity (for example, hydrocarbon free) com-

17 302 576 67 638 1180

pressed air is used as the oxidant for the FID. (Warning—See

18 316 601 68 641 1186

Note 4.) 19 330 625 69 644 1191

20 344 651 70 647 1197

NOTE 4—Warning: Compressed air is a gas under high pressure and 21 356 675 71 650 1202

22 369 696 72 653 1207

supports combustion.

23 380 716 73 655 1211

7.4 Carbon Disulfide (CS ) (99+ % pure), may be used as a

24 391 736 74 658 1216

25 401 755 75 661 1222

viscosity reducing solvent. It is miscible with asphaltic hydro-

26 412 774 76 664 1227

carbons and provides relatively littl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.