ASTM D7215-22

(Test Method)Standard Test Method for Calculated Flash Point from Simulated Distillation Analysis of Distillate Fuels

Standard Test Method for Calculated Flash Point from Simulated Distillation Analysis of Distillate Fuels

SIGNIFICANCE AND USE

4.1 The flash point temperature is one measure of the tendency of the test specimen to form a flammable mixture with air under controlled laboratory conditions. It is only one of a number of properties that must be considered in assessing the overall flammability hazard of a material.

4.2 Flash point is used in shipping and safety regulations to define flammable and combustible materials. Consult the particular regulation involved for precise definitions of these classifications.

4.3 Flash point can indicate the possible presence of highly volatile and flammable materials in a relatively non-volatile or non-flammable material.

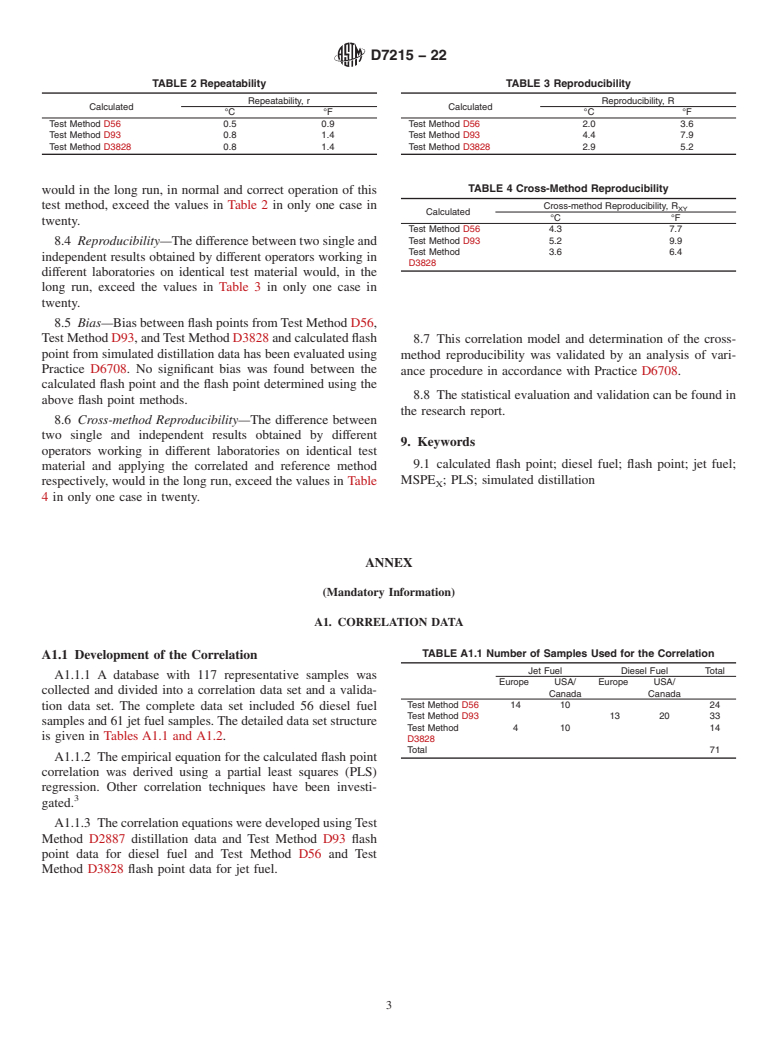

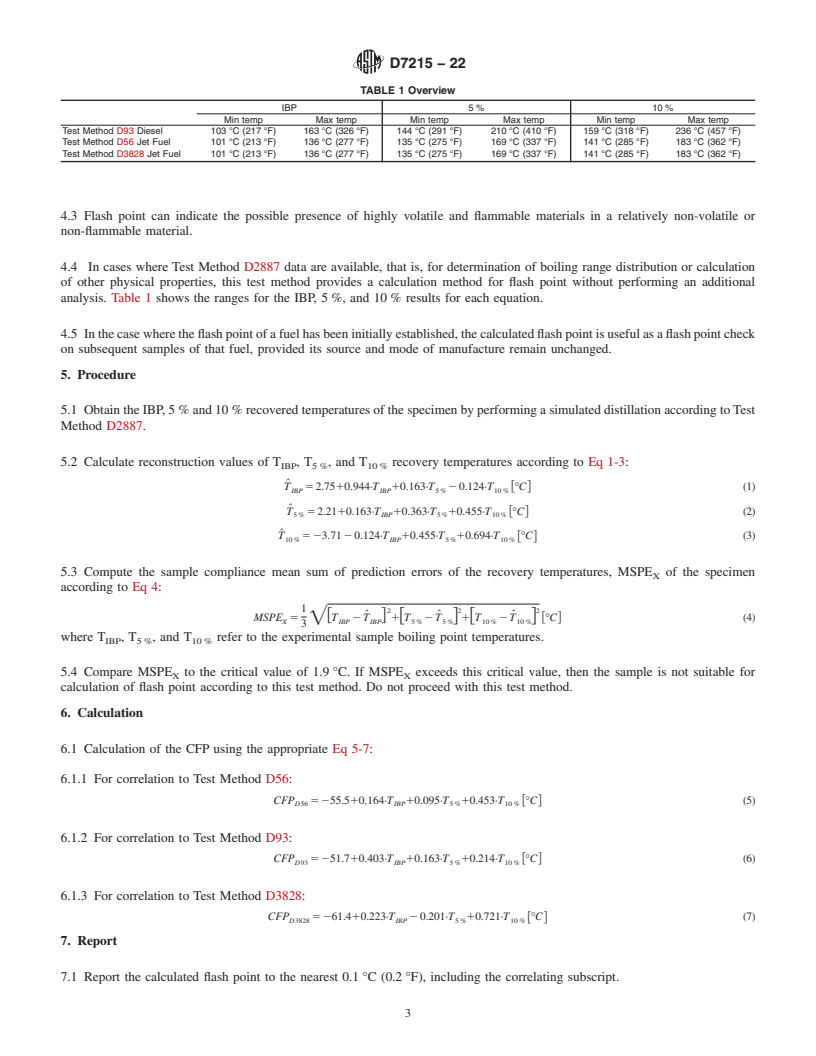

4.4 In cases where Test Method D2887 data are available, that is, for determination of boiling range distribution or calculation of other physical properties, this test method provides a calculation method for flash point without performing an additional analysis. Table 1 shows the ranges for the IBP, 5 %, and 10 % results for each equation.

4.5 In the case where the flash point of a fuel has been initially established, the calculated flash point is useful as a flash point check on subsequent samples of that fuel, provided its source and mode of manufacture remain unchanged.

SCOPE

1.1 This test method covers the calculated flash point formula, which represents a means for directly estimating the flash point temperature of distillate fuels from Test Method D2887 data. The value computed from the equation is termed the “calculated flash point.” The calculated flash point formula is applicable to diesel fuel samples based on a correlation to Test Method D93 over the range from 47 °C to 99 °C, and to jet fuel samples based on a correlation to Test Method D56 and Test Method D3828 over the range from 35 °C to 67 °C.

1.2 The calculated flash point formula is valid for diesel and jet fuels with an IBP between 90 °C and 162 °C (194 °F and 324 °F), Test Method D2887 5 % recovery temperature between 136 °C and 207 °C (277 °F and 405 °F), and Test Method D2887 10 % recovery temperature between 142 °C and 222 °C (288 °F and 432 °F). For each flash point test method (Test Method D56, Test Method D93, and Test Method D3828) a separate equation has been established. See 4.4 for a detailed overview of the simulated distillation IBP, 5 %, and 10 % ranges per equation.

1.3 A calculated diagnostic parameter, not exceeding a given threshold value, is a prerequisite for acceptance of the calculated flash point.

1.4 The diagnostic parameter MSPEX (Mean Summed Prediction Error) checks the sample compliance, based on reconstruction of TIBP, T5 %, and T10 % of the sample, via a calculation procedure. A value for MSPEX not exceeding the threshold level of 1.9 °C is a prerequisite for accepting the calculated flash point, CFP.

Note 1: It is important to note that calculated flash point results, at this time, are not recognized by regulatory organizations in verifying conformance to applicable regulations.

Note 2: The calculated flash point derived from simulated distillation data depends upon the accuracy of determination of the IBP temperature and the 5 % and 10 % recovery temperatures.

Note 3: If the user's specification requires a defined flash point test method other than this test method, neither this test method nor any other test method should be substituted for the prescribed test method without obtaining comparative data and an agreement from the specifier.

1.5 The values stated in SI units are to be regarded as the standard.

1.5.1 Exception—The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in acc...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7215 − 22

Standard Test Method for

Calculated Flash Point from Simulated Distillation Analysis

1

of Distillate Fuels

This standard is issued under the fixed designation D7215; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

method other than this test method, neither this test method nor any other

1. Scope*

test method should be substituted for the prescribed test method without

1.1 This test method covers the calculated flash point

obtaining comparative data and an agreement from the specifier.

formula, which represents a means for directly estimating the

1.5 The values stated in SI units are to be regarded as the

flash point temperature of distillate fuels from Test Method

standard.

D2887 data. The value computed from the equation is termed

1.5.1 Exception—The values given in parentheses are for

the “calculated flash point.” The calculated flash point formula

information only.

is applicable to diesel fuel samples based on a correlation to

1.6 This standard does not purport to address all of the

TestMethodD93overtherangefrom47 °Cto99 °C,andtojet

safety concerns, if any, associated with its use. It is the

fuel samples based on a correlation to Test Method D56 and

responsibility of the user of this standard to establish appro-

Test Method D3828 over the range from 35 °C to 67 °C.

priate safety, health, and environmental practices and deter-

1.2 The calculated flash point formula is valid for diesel and

mine the applicability of regulatory limitations prior to use.

jet fuels with an IBP between 90 °C and 162 °C (194 °F and

1.7 This international standard was developed in accor-

324 °F), Test Method D2887 5 % recovery temperature be-

dance with internationally recognized principles on standard-

tween 136 °C and 207 °C (277 °F and 405 °F), and Test

ization established in the Decision on Principles for the

Method D2887 10 % recovery temperature between 142 °C

Development of International Standards, Guides and Recom-

and 222 °C (288 °F and 432 °F). For each flash point test

mendations issued by the World Trade Organization Technical

method (Test Method D56,Test Method D93, andTest Method

Barriers to Trade (TBT) Committee.

D3828) a separate equation has been established. See 4.4 for a

detailed overview of the simulated distillation IBP, 5 %, and

2. Referenced Documents

10 % ranges per equation.

2

2.1 ASTM Standards:

1.3 A calculated diagnostic parameter, not exceeding a

D56 Test Method for Flash Point by Tag Closed Cup Tester

given threshold value, is a prerequisite for acceptance of the

D93 Test Methods for Flash Point by Pensky-Martens

calculated flash point.

Closed Cup Tester

D975 Specification for Diesel Fuel

1.4 The diagnostic parameter MSPE (Mean Summed

X

D1655 Specification for Aviation Turbine Fuels

Prediction Error) checks the sample compliance, based on

D2887 Test Method for Boiling Range Distribution of Pe-

reconstruction of T ,T , and T of the sample, via a

IBP 5% 10 %

troleum Fractions by Gas Chromatography

calculation procedure. A value for MSPE not exceeding the

X

D3828 Test Methods for Flash Point by Small Scale Closed

threshold level of 1.9 °C is a prerequisite for accepting the

Cup Tester

calculated flash point, CFP.

D4175 Terminology Relating to Petroleum Products, Liquid

NOTE1—Itisimportanttonotethatcalculatedflashpointresults,atthis

time, are not recognized by regulatory organizations in verifying confor- Fuels, and Lubricants

mance to applicable regulations.

D6708 Practice for Statistical Assessment and Improvement

NOTE 2—The calculated flash point derived from simulated distillation

of Expected Agreement Between Two Test Methods that

data depends upon the accuracy of determination of the IBP temperature

Purport to Measure the Same Property of a Material

and the 5 % and 10 % recovery temperatures.

NOTE 3—If the user’s specification requires a defined flash point test

3. Terminology

3.1 Definitions:

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

2

Subcommittee D02.04.0K on Correlative Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2022. Published November 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2008. Last previous edition approved in 2016 as D7215 – 16. DOI: Standards volume information, refer to th

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7215 − 16 D7215 − 22

Standard Test Method for

Calculated Flash Point from Simulated Distillation Analysis

1

of Distillate Fuels

This standard is issued under the fixed designation D7215; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the calculated flash point formula, which represents a means for directly estimating the flash point

temperature of distillate fuels from Test Method D2887 data. The value computed from the equation is termed the “calculated flash

point.” The calculated flash point formula is applicable to diesel fuel samples based on a correlation to Test Method D93 over the

range from 47 °C to 99 °C, and to jet fuel samples based on a correlation to Test Method D56 and Test Method D3828 over the

range from 35 °C to 67 °C.

1.2 The calculated flash point formula is valid for diesel and jet fuels with an IBP between 90 °C and 162 °C (194 °F and 324 °F),

Test Method D2887 5 % recovery temperature between 136 °C and 207 °C (277 °F and 405 °F), and Test Method D2887 10 %

recovery temperature between 142 °C and 222 °C (288 °F and 432 °F). For each flash point test method (Test Method D56, Test

Method D93, and Test Method D3828) a separate equation has been established. See 4.4 for a detailed overview of the simulated

distillation IBP, 5 %, and 10 % ranges per equation.

1.3 A calculated diagnostic parameter, not exceeding a given threshold value, is a prerequisite for acceptance of the calculated

flash point.

1.4 The diagnostic parameter MSPE (Mean Summed Prediction Error) checks the sample compliance, based on reconstruction

X

of T , T , and T of the sample, via a calculation procedure. A value for MSPE not exceeding the threshold level of 1.9 °C

IBP 5 % 10 % X

is a prerequisite for accepting the calculated flash point, CFP.

NOTE 1—It is important to note that calculated flash point results, at this time, are not recognized by regulatory organizations in verifying conformance

to applicable regulations.

NOTE 2—The calculated flash point derived from simulated distillation data depends upon the accuracy of determination of the IBP temperature and the

5 % and 10 % recovery temperatures.

NOTE 3—If the user’s specification requires a defined flash point test method other than this test method, neither this test method nor any other test method

should be substituted for the prescribed test method without obtaining comparative data and an agreement from the specifier.

1.5 The values stated in SI units are to be regarded as the standard.

1.5.1 Exception—The values given in parentheses are for information only.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.04.0K on Correlative Methods.

Current edition approved July 1, 2016Nov. 1, 2022. Published July 2016November 2022. Originally approved in 2008. Last previous edition approved in 20132016 as

D7215 – 08 (2013).D7215 – 16. DOI: 10.1520/D7215-16.10.1520/D7215-22.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7215 − 22

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D56 Test Method for Flash Point by Tag Closed Cup Tester

D93 Test Methods for Flash Point by Pensky-Martens Closed Cup Tester

D975 Specification for Diesel Fuel

D1655 Specification for Aviation Turbine Fuels

D2887 Test Method for Boiling Range Distribution of Petroleum Fractions by Gas Chromatography

D3828 Test Methods for Flash Point by Sm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.