ASTM G48-99A

(Test Method)Standard Test Methods for Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys by Use of Ferric Chloride Solution

Standard Test Methods for Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys by Use of Ferric Chloride Solution

SCOPE

1.1 These test methods cover procedures for the determination of the resistance of stainless steels and related alloys to pitting and crevice corrosion (see Terminology G 15) when exposed to oxidizing chloride environments. Four procedures are described and identified as Methods A, B, C, and D.

1.1.1 Method A- Ferric chloride pitting test.

1.1.2 Method B- Ferric chloride crevice test.

1.1.3 Method C- Critical pitting temperature test.

1.1.4 Method D- Critical crevice temperature test.

1.2 Method A is designed to determine the relative pitting resistance of stainless steels and nickel-base, chromium-bearing alloys, whereas Method B can be used for determining both the pitting and crevice corrosion resistance of these alloys. Methods C and D allow for a ranking of alloys by minimum (critical) temperature to cause initiation of pitting corrosion and crevice corrosion, respectively, of stainless steels and nickel-base, chromium-bearing alloys in a standard ferritic chloride solution.

1.3 These tests may be used to determine the effects of alloying additives, heat treatment, and surface finishes on pitting and crevice corrosion resistance.

1.4 The values stated in SI units are to be regarded as the standard. Other units are given in parentheses for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: G 48 – 99a

Standard Test Methods for

Pitting and Crevice Corrosion Resistance of Stainless

Steels and Related Alloys by Use of Ferric Chloride

Solution

This standard is issued under the fixed designation G 48; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 These test methods cover procedures for the determina-

E 1338 Guide for the Identification of Metals and Alloys in

tion of the resistance of stainless steels and related alloys to

Computerized Material Property Databases

pitting and crevice corrosion (see Terminology G 15) when

G 1 Practice for Preparing, Cleaning, and Evaluating Cor-

exposed to oxidizing chloride environments. Four procedures

rosion Test Specimens

are described and identified as Methods A, B, C, and D.

G 15 Terminology Relating to Corrosion and Corrosion

1.1.1 Method A—Ferric chloride pitting test.

Testing

1.1.2 Method B—Ferric chloride crevice test.

G 46 Guide for Examination and Evaluation of Pitting

1.1.3 Method C—Critical pitting temperature test.

Corrosion

1.1.4 Method D—Critical crevice temperature test.

G 107 Guide for Formats for Collection and Compilation of

1.2 Method A is designed to determine the relative pitting

Corrosion Data for Metals for Computerized Database

resistance of stainless steels and nickel-base, chromium-

Input

bearing alloys, whereas Method B can be used for determining

both the pitting and crevice corrosion resistance of these alloys.

3. Terminology

Methods C and D allow for a ranking of alloys by minimum

3.1 Definition of Terms Specific to This Standard:

(critical) temperature to cause initiation of pitting corrosion

3.1.1 critical crevice temperature, n—the minimum tem-

and crevice corrosion, respectively, of stainless steels and

perature (°C) to produce crevice attack at least 0.025-mm

nickel-base, chromium-bearing alloys in a standard ferric

(0.001-in.) deep on the bold surface of the specimen beneath

chloride solution.

the crevice washer, edge attack ignored.

1.3 These tests may be used to determine the effects of

3.1.2 critical pitting temperature, n— the minimum tem-

alloying additives, heat treatment, and surface finishes on

perature (°C) to produce pitting attack at least 0.025-mm

pitting and crevice corrosion resistance.

(0.001-in.) deep on the bold surface of the specimen, edge

1.4 The values stated in SI units are to be regarded as the

attack ignored.

standard. Other units are given in parentheses for information

3.2 The terminology used herein, if not specifically defined

only.

otherwise, shall be in accordance with Terminology G 15.

1.5 This standard does not purport to address all of the

Definitions provided herein and not given in Terminology G 15

safety concerns, if any, associated with its use. It is the

are limited only to this standard.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Significance and Use

bility of regulatory limitations prior to use.

4.1 These test methods describe laboratory tests for com-

2. Referenced Documents paring the resistance of stainless steels and related alloys to the

initiation of pitting and crevice corrosion. The results may be

2.1 ASTM Standards:

used for ranking alloys in order of increasing resistance to

A 262 Practices for Detecting Susceptibility to Intergranu-

2 pitting and crevice corrosion initiation under the specific

lar Attack in Austenitic Stainless Steels

3 conditions of these methods. Methods A and B are designed to

D 1193 Specification for Reagent Water

cause the breakdown of Type 304 at room temperature.

4.2 The use of ferric chloride solutions is justified because it

These test methods are under the jurisdiction of ASTM Committee G-1 on

is related to, but not the same as, that within a pit or crevice site

Corrosion of Metals, and are the direct responsibility of Subcommittee G01.05 on

Laboratory Corrosion Tests.

Current edition approved Oct. 10, 1999. Published December 1999. Originally

published as G 48 – 76. Last previous edition G 48 – 99. Annual Book of ASTM Standards, Vol 14.02.

2 5

Annual Book of ASTM Standards, Vol 01.03. Annual Book of ASTM Standards, Vol 14.01.

3 6

Annual Book of ASTM Standards, Vol 11.01. Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

G48

on a ferrous alloy in chloride bearing environments (1, 2). The a bored rubber stopper. Likewise, a simple U tube condenser

presence of an inert crevice former of consistent dimension on can be fashioned.

a surface is regarded as sufficient specification of crevice

NOTE 2—The use of ground joint condensers requires that the mouth of

geometry to assess relative crevice corrosion susceptibility.

the flask have a corresponding joint.

4.3 The relative performance of alloys in ferric chloride

5.1.3.2 U Tube Condensers, fitted through holes in an

solution tests has been correlated to performance in certain real

appropriate size rubber stopper can be used in conjunction with

environments, such as natural seawater at ambient temperature

the 300-mm test tube described in 5.1.2.

(3) and strongly oxidizing, low pH, chloride containing envi-

5.1.3.3 When evaporation is not a significant problem,

ronments (4), but several exceptions have been reported (4-7).

flasks can be covered with a watch glass. Also, flasks as well

4.4 Methods A, B, C, and D can be used to rank the relative

as test tubes can be covered with loosely fitted stoppers or

resistance of stainless steels and nickel base alloys to pitting

plastic or paraffin type wraps.

and crevice corrosion in chloride-containing environments. No

statement can be made about resistance of alloys in environ-

NOTE 3—Venting must always be considered due to the possible build

up of gas pressure that may result from the corrosion process.

ments that do not contain chlorides.

4.4.1 Methods A, B, C, and D were designed to accelerate

5.1.4 Specimen Supports:

the time to initiate localized corrosion relative to most natural

5.1.4.1 One advantage of using test tubes is that specimen

environments. Consequently, the degree of corrosion damage

supports are not required. However, placement of the specimen

that occurs during testing will generally be greater than that in

does create the possible opportunity for crevice corrosion to

natural environments in any similar time period.

occur along the edge.

4.4.2 No statement regarding localized corrosion propaga-

NOTE 4—See 12.2 concerning edge attack.

tion can be made based on the results of Methods A, B, C, or

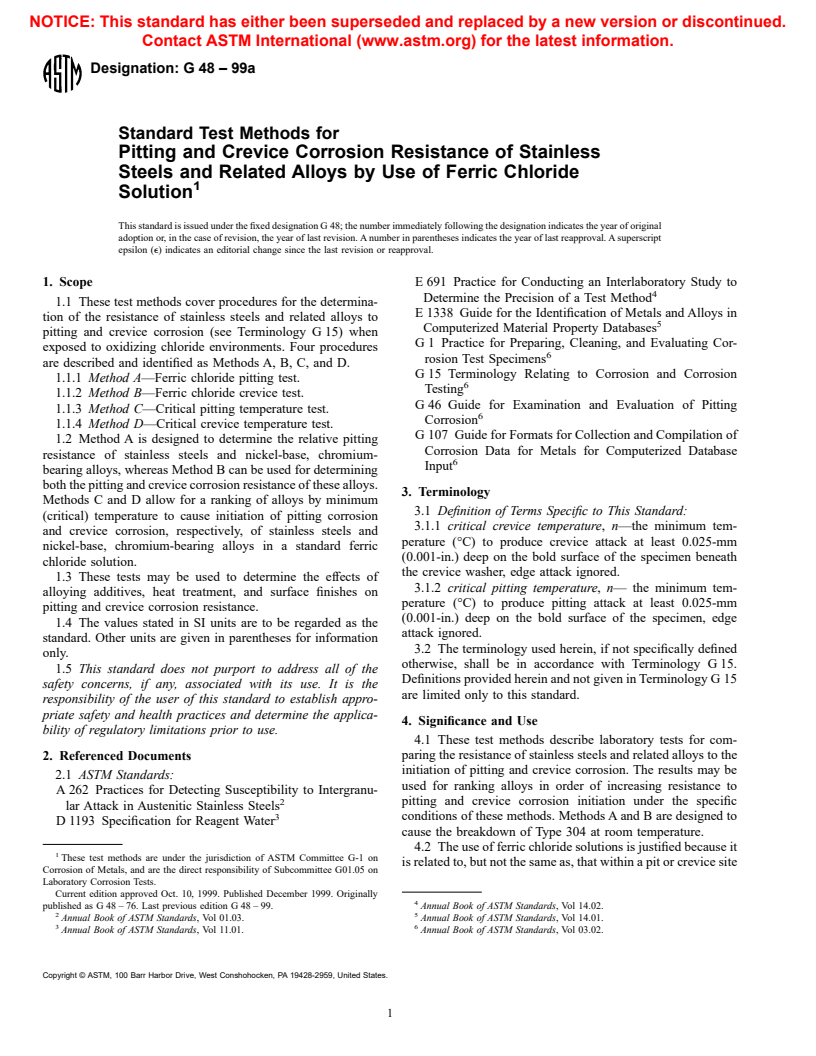

D. 5.1.4.2 When using flasks, specimens can be supported on

4.4.3 Surface preparation can significantly influence results. cradles or hooks. Cradles, such as those shown in Fig. 1,

Therefore, grinding and pickling of the specimen will mean eliminate the necessity for drilling a support hole in the test

that the results may not be representative of the conditions of specimen. While the use of hooks requires that a specimen

the actual piece from which the sample was taken. support hole be provided, the hooks, as contrasted to the cradle,

are easier to fashion. Moreover, they create only one potential

NOTE 1—Grinding or pickling on stainless steel surfaces may destroy

crevice site whereas multiple sites are possible with the cradle.

the passive layer. A 24-h air passivation after grinding or pickling is

sufficient to minimize these differences (8).

NOTE 5—A TFE-fluorocarbon cradle may be substituted for glass.

4.4.4 The procedures in Methods C and D for measuring

5.1.4.3 The use of supports for Methods B and D crevice

critical pitting corrosion temperature and critical crevice cor-

corrosion specimens is optional.

rosion temperature have no bias because the values are defined

5.2 Water or Oil Bath, constant temperature.

only in terms of these test methods.

5.2.1 For Methods A and B, the recommended test tempera-

tures are 22 6 2°C or 50 6 2°C, or both.

5. Apparatus

5.2.2 For Methods C and D, the bath shall have the

5.1 Glassware—Methods A, B, C, and D provide an option

capability of providing constant temperature between 0°C and

to use either wide mouth flasks or suitable sized test tubes.

85°C6 1°C.

Condensers are required for elevated temperature testing when

5.3 Crevice Formers—Method B:

solution evaporation may occur. Glass cradles or hooks also

5.3.1 Cylindrical TFE-fluorocarbon Blocks, two for each

may be required.

test specimen. Each block shall be 12.7-mm (0.5 in.) in

5.1.1 Flask Requirements, 1000-mL wide mouth. Tall form

diameter and 12.7-mm high, with perpendicular grooves

or Erlenmeyer flasks can be used. The mouth of the flask shall

1.6-mm (0.063 in.) wide and 1.6-mm deep cut in the top of

have a diameter of about 40 mm (1.6 in.) to allow passage of

each cylinder for retention of the O-ring or rubber bands.

the test specimen and the support.

Blocks can be machined from bar or rod stock.

5.1.2 Test Tube Requirements, the diameter of the test tube

5.3.2 Fluorinated Elastomers O-rings, or Rubber Bands,

shall also be about 40 mm (1.6 in.) in diameter. If testing

(low sulfur (0.02 % max)), two for each test specimen.

requires use of a condenser (described below), the test tube

NOTE 6—It is good practice to use all O-rings or all rubber bands in a

length shall be about 300 mm (about 12 in.); otherwise, the

given test program.

length can be about 150 to 200 mm (about 6 in. to 8 in.).

5.3.2.1 O-rings shall be 1.75 mm (0.070 in.) in cross

5.1.3 Condensers, Vents and Covers:

section; one ring with an inside diameter of about 20 mm (0.8

5.1.3.1 A variety of condensers may be used in conjunction

with the flasks described in 5.1.1. These include the cold in.) and one with an inside diameter of about 30 mm (1.1 in.).

Rubber bands shall be one No. 12 (38-mm (1.5-in.) long) and

finger-type (see, for example, Practices A 262, Practice C) or

Allihn type condensers having straight tube ends or tapered one No. 14 (51-mm (2-in.) long).

ground joints. Straight end condensers can be inserted through

NOTE 7—Rubber bands or O-rings can be boiled in water prior to use

to ensure the removal of water-soluble ingredients that might affect

corrosion.

The boldface numbers in parentheses refer to the list of references at the end of

this standard. 5.4 Crevice Formers—Method D:

G48

FIG. 1 Examples of Glass Cradles that Can Be Used to Support the Specimen

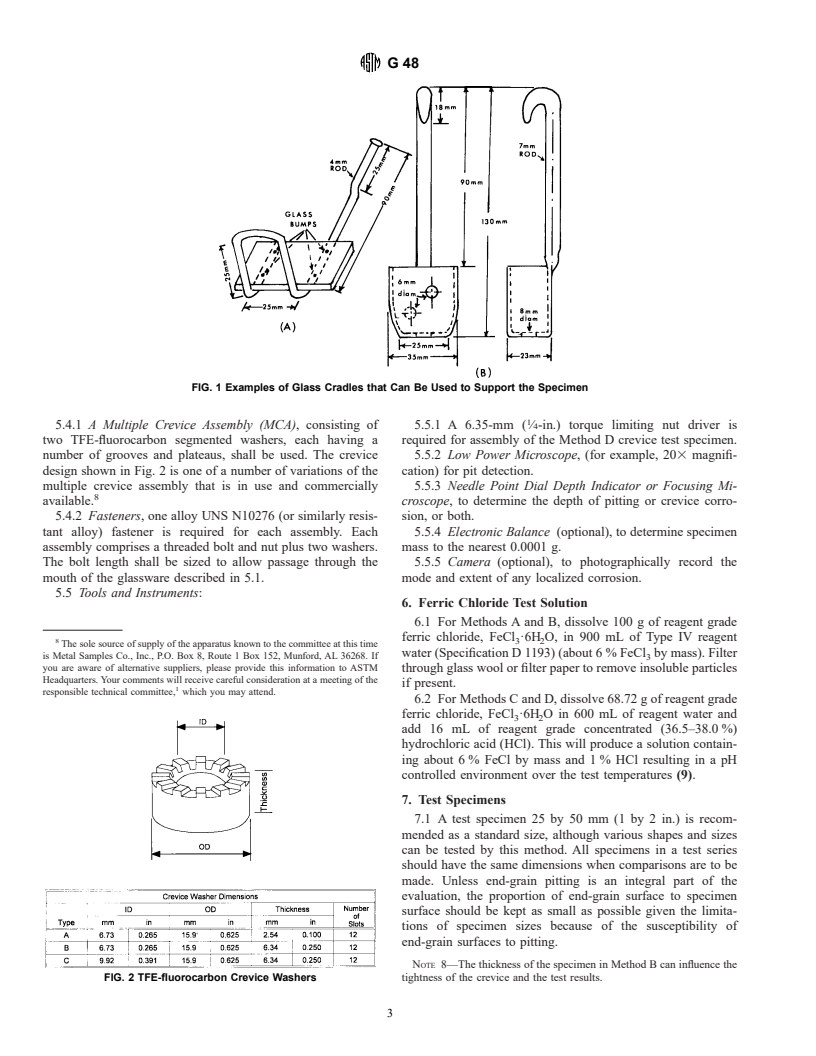

5.4.1 A Multiple Crevice Assembly (MCA), consisting of 5.5.1 A 6.35-mm ( ⁄4-in.) torque limiting nut driver is

two TFE-fluorocarbon segmented washers, each having a required for assembly of the Method D crevice test specimen.

number of grooves and plateaus, shall be used. The crevice 5.5.2 Low Power Microscope, (for example, 203 magnifi-

design shown in Fig. 2 is one of a number of variations of the cation) for pit detection.

multiple crevice assembly that is in use and commercially 5.5.3 Needle Point Dial Depth Indicator or Focusing Mi-

available. croscope, to determine the depth of pitting or crevice corro-

5.4.2 Fasteners, one alloy UNS N10276 (or similarly resis- sion, or both.

tant alloy) fastener is required for each assembly. Each 5.5.4 Electronic Balance (optional), to determine specimen

assembly comprises a threaded bolt and nut plus two washers. mass to the nearest 0.0001 g.

The bolt length shall be sized to allow passage through the 5.5.5 Camera (optional), to photographically record the

mouth of the glassware described in 5.1. mode and extent of any localized corrosion.

5.5 Tools and Instruments:

6. Ferric Chloride Test Solution

6.1 For Methods A and B, dissolve 100 g of reagent grade

ferric chloride, FeCl ·6H O, in 900 mL of Type IV reagent

3 2

The sole source of supply of the apparatus known to the committee at this time

water (Specification D 1193) (about 6 % FeCl by mass). Filter

is Metal Samples Co., Inc., P.O. Box 8, Route 1 Box 152, Munford, AL 36268. If 3

you are aware of alternative suppliers, please provide this information to ASTM through glass wool or filter paper to remove insoluble particles

Headquarters. Your comments will receive careful consideration at a meeting of the

if present.

responsible technical committee, which you may attend.

6.2 For Methods C and D, dissolve 68.72 g of reagent grade

ferric chloride, FeCl ·6H O in 600 mL of reagent water and

3 2

add 16 mL of reagent grade concentrated (36.5–38.0 %)

hydrochloric acid (HCl). This will produce a solution contain-

ing about 6 % FeCl by mass and 1 % HCl resulting in a pH

controlled environment over the test temperatures (9).

7. Test Specimens

7.1 A test specimen 25 by 50 mm (1 by 2 in.) is recom-

mended as a standard size, although various shapes and sizes

can be tested by this method. All specimens in a test series

should have the same dimensions when comparisons are to be

made. Unless end-grain pitting is an integral part of the

evaluation, the proportion of end-grain surface to specimen

surface should be kept as small as possible given the limita-

tions of specimen sizes because of the susceptibility of

end-grain surfaces to pitting.

NOTE 8—The thickness of the specimen in Method B can influence the

FIG. 2 TFE-fluorocarbon Crevice Washers tightness of the crevice and the test results.

G48

NOTE 9—End-grain attack in Methods C and D may not be as prevalent

interest. Suitable temperatures for evaluation are 22 6 2°C and

in a test in which low test temperatures are anticipated.

50 6 2°C.

9.1.2 Fasten two TFE-fluorocarbon blocks to the test speci-

7.2 When specimens are cut by shearing, the deformed

men with O-rings or a double loop of each of two rubber bands

material should be removed by machining or grinding prior to

as shown in Fig. 3. Use plastic gloves to avoid hand contact

testing unless the corrosion resistance of the sheared edges is

with metal surfaces during this operation. Use the small O-ring

being evaluated. It is good practice to remove deformed edges

or the No. 12 rubber band for the 25-mm (1-in.) dimension and

to the thickness of the material.

the large O-ring or the No. 14 rubber band for the 50-mm

7.3 For Method D a sufficient hole should be drilled and

(2-in.) dimension.

chamfered in the center of the specimen to accommodate the

9.1.3 After the test solution has reached the desired tem-

bolt and insulating sleeve used to attach the crevice device.

perature, tilt

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.