ASTM E803-91(2002)

(Test Method)Standard Test Method for Determining the L/D Ratio of Neutron Radiography Beams

Standard Test Method for Determining the L/D Ratio of Neutron Radiography Beams

SIGNIFICANCE AND USE

The quality of a neutron radiographic image is dependent upon many factors. The L/D ratio is one of those factors and constitutes a numerical definition of the geometry of the neutron beam. The L/D ratio required for a specific neutron radiographic examination is dependent upon the thickness of the specimen and the physical characteristics of the particular element of interest. Use of this test method allows the radiographer and the user to determine and periodically check the effective collimation ratio.

SCOPE

1.1 This method defines an empirical technique for the measurement of the effective collimation ratio, L/D , of neutron radiography beams. The technique is based upon analysis of a neutron radiographic image and is independent of measurements and calculations based on physical dimensions of the collimator system. The values derived by this technique should be more accurate than those based on physical measurements, particularly for poorly defined apertures.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 803 – 91 (Reapproved 2002)

Standard Test Method for

Determining the L/D Ratio of Neutron Radiography Beams

This standard is issued under the fixed designation E 803; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope and constitutes a numerical definition of the geometry of the

neutron beam. The L/D ratio required for a specific neutron

1.1 This test method defines an empirical technique for the

radiographic examination is dependent upon the thickness of

measurement of the effective collimation ratio, L/D, of neutron

the specimen and the physical characteristics of the particular

radiography beams. The technique is based upon analysis of a

element of interest. Use of this test method allows the

neutron radiographic image and is independent of measure-

radiographer and the user to determine and periodically check

ments and calculations based on physical dimensions of the

the effective collimation ratio.

collimator system.The values derived by this technique should

be more accurate than those based on physical measurements,

5. Apparatus

particularly for poorly defined apertures.

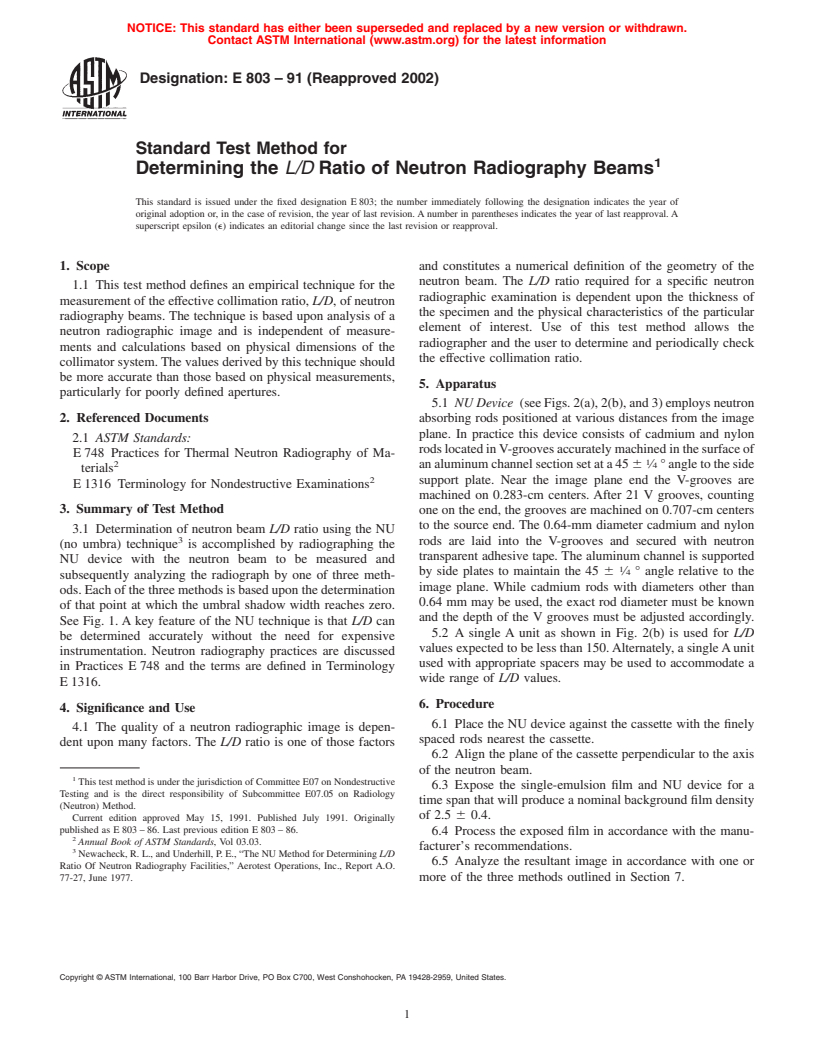

5.1 NU Device (seeFigs.2(a),2(b),and3)employsneutron

2. Referenced Documents absorbing rods positioned at various distances from the image

plane. In practice this device consists of cadmium and nylon

2.1 ASTM Standards:

rodslocatedinV-groovesaccuratelymachinedinthesurfaceof

E 748 Practices for Thermal Neutron Radiography of Ma-

analuminumchannelsectionsetata45 6 ⁄4°angletotheside

terials

support plate. Near the image plane end the V-grooves are

E 1316 Terminology for Nondestructive Examinations

machined on 0.283-cm centers. After 21 V grooves, counting

3. Summary of Test Method one on the end, the grooves are machined on 0.707-cm centers

to the source end. The 0.64-mm diameter cadmium and nylon

3.1 Determination of neutron beam L/D ratio using the NU

rods are laid into the V-grooves and secured with neutron

(no umbra) technique is accomplished by radiographing the

transparent adhesive tape. The aluminum channel is supported

NU device with the neutron beam to be measured and

by side plates to maintain the 45 6 ⁄4 ° angle relative to the

subsequently analyzing the radiograph by one of three meth-

image plane. While cadmium rods with diameters other than

ods. Each of the three methods is based upon the determination

0.64 mm may be used, the exact rod diameter must be known

of that point at which the umbral shadow width reaches zero.

and the depth of the V grooves must be adjusted accordingly.

See Fig. 1. A key feature of the NU technique is that L/D can

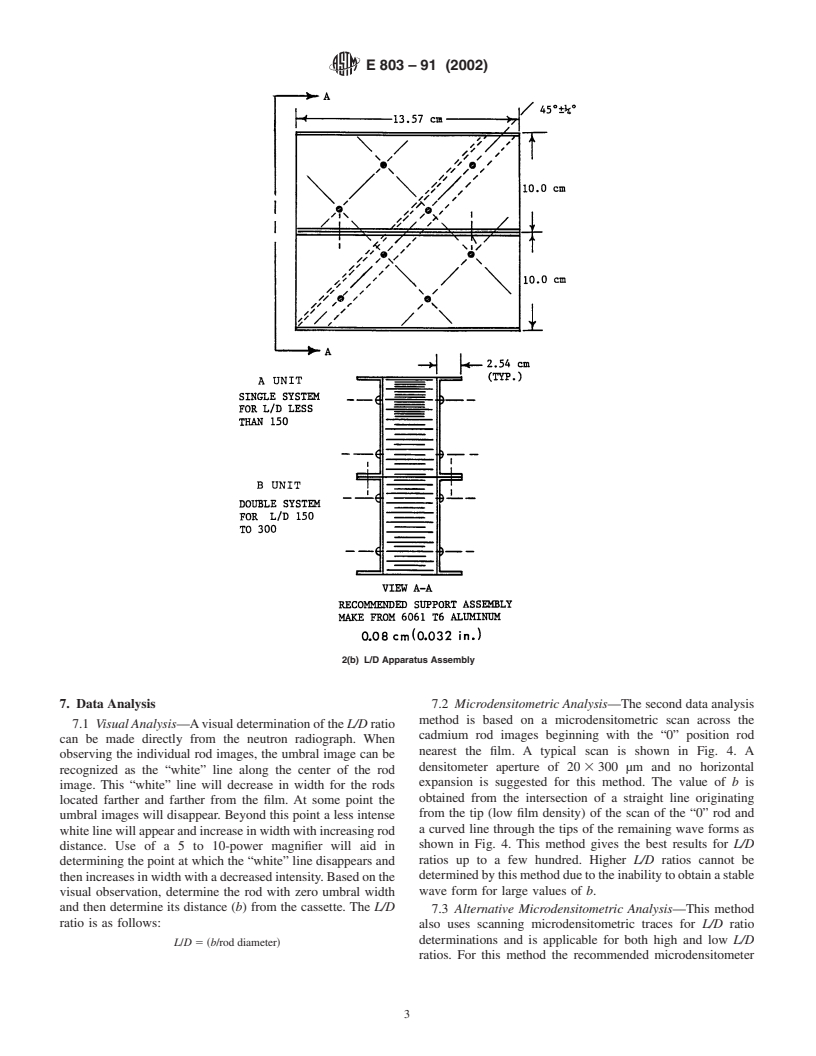

5.2 A single A unit as shown in Fig. 2(b) is used for L/D

be determined accurately without the need for expensive

values expected to be less than 150.Alternately, a singleAunit

instrumentation. Neutron radiography practices are discussed

used with appropriate spacers may be used to accommodate a

in Practices E 748 and the terms are defined in Terminology

wide range of L/D values.

E 1316.

6. Procedure

4. Significance and Use

6.1 Place the NU device against the cassette with the finely

4.1 The quality of a neutron radiographic image is depen-

spaced rods nearest the cassette.

dent upon many factors. The L/D ratio is one of those factors

6.2 Align the plane of the cassette perpendicular to the axis

of the neutron beam.

This test method is under the jurisdiction of Committee E07 on Nondestructive

6.3 Expose the single-emulsion film and NU device for a

Testing and is the direct responsibility of Subcommittee E07.05 on Radiology

time span that will produce a nominal background film density

(Neutron) Method.

of 2.5 6 0.4.

Current edition approved May 15, 1991. Published July 1991. Originally

published as E 803 – 86. Last previous edition E 803 – 86.

6.4 Process the exposed film in accordance with the manu-

Annual Book of ASTM Standards, Vol 03.03.

facturer’s recommendations.

Newacheck, R. L., and Underhill, P. E., “The NU Method for Determining L/D

6.5 Analyze the resultant image in accordance with one or

Ratio Of Neutron Radiography Facilities,” Aerotest Operations, Inc., Report A.O.

77-27, June 1977. more of the three methods outlined in Section 7.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 803 – 91 (2002)

FIG. 1 Diagram of Zero Umbra Image Configuration

NOTE 1—Rods at “A” positions are 1 cm each side of center line (22 ea.)

NOTE 2—Rods at “B” positions are 2 cm each side of center line (9 ea.)

NOTE 3—Rods at “C” positions are 2.5 cm each side of center line (1 ea.)

NOTE 4—All dimensions from base line to reduce accumulative errors

NOTE 5—Rod arrangement shown for single system device. For an add-on device, to form a double system, extend the 11 spaces for 7.78 cm to 19

spaces for 13.43 cm and eliminate the close spacing (20 for 5.65 cm)

NOTE 6—Rods held tightly in position with one layer of transparent tape

2(a) Support Channel Subassembly with Rod Spacing

E 803 – 91 (2002)

2(b) L/D Apparatus Assembly

7. Data Analysis 7.2 Microdensitometric Analysis—The second data analysis

method is based on a microdensitometric scan across the

7.1 Visual Analysis—Avisualdeterminationofthe L/Dratio

cadmium rod images beginning with the “0” position rod

can be made directly from the neutron radiograph. When

nearest the film. A typical scan is shown in Fig. 4. A

observing the individual rod images, the umbral image can be

densitometer aperture of 20 3 300 µm and no horizontal

recognized as the “white” line along the center of the rod

expansion is suggested for this method. The value of b is

image. This “white” line will decrease in width for the rods

obtained from the intersection of a straight line originating

located farther and farther from the film. At some point the

from the tip (low film density) of the scan of the “0” rod and

umbral images will disappear. Beyond this point a less intense

a curved line through the tips of the remaining wave forms as

whitelinewillappearandincreaseinwidthwithincreasingrod

shown in Fig. 4. This method gives the best results for L/D

distance. Use of a 5 to 10-power magnifier will aid in

ratios up to a few hundred. Higher L/D ratios cannot be

determining the point at which the “white” line disappears and

determinedbythismethodduetotheinabilitytoobtainastable

thenincreasesinwidthwithadecreasedintensity.Basedonthe

visual observation, determine the rod with zero umbral width wave form for large values of b.

and then determine its distance (b) from the cassette. The L/D

7.3 Alternative Microdensitometric Analysis—This method

ratio is as follows:

also uses scanning microdensitometric traces for L/D ratio

determinations and is applicable for both high and low L/D

L/D5~b/rod diameter!

ratios. For this method the recommended microdensitometer

E 803 – 91 (2002)

FIG. 3 NU Device Pictorials

settings are: 20 3 300-µm aperture and 503 (or more) chart

where:

recording expansion. These settings will produce individual

U = umbral width of a rod near the image plane,

wave forms as shown in Fig. 5. At least two wave forms must

U = umbral image width of a rod near the d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.