ASTM D2659-95(2005)

(Test Method)Standard Test Method for Column Crush Properties of Blown Thermoplastic Containers

Standard Test Method for Column Crush Properties of Blown Thermoplastic Containers

SIGNIFICANCE AND USE

Column crush tests provide information about the crushing properties of blown thermoplastic containers when employed under conditions approximating those under which the tests are made.

The column crush properties include the crushing yield load, deflection at crushing yield load, crushing load at failure, and apparent crushing stiffness. Blown thermoplastic containers made from materials that possess a low order of ductility may fail in crushing by brittle fracture. In such cases, the crushing yield load is equivalent to the crushing load at failure. Blown thermoplastic containers made of ductile materials may not exhibit a crushing load at failure although they will normally provide a crushing yield load value.

Column crush tests provide a standard method of obtaining data for research and development, applications, design, quality control, acceptance or rejection under specifications, and special purposes. The tests cannot be considered significant for engineering design in applications differing widely from the load - time scale of the standard test. Such applications require additional tests such as impact, creep, and fatigue.

Before proceeding with this test method, reference should be made to the specification of the material being tested. Any test specimen preparation, conditioning, dimensions, or testing parameters, or combination thereof, covered in the materials specification shall take precedence over those mentioned in this test method. If there are no material specifications, then the default conditions apply.

SCOPE

1.1 This test method covers the determination of mechanical properties of blown thermoplastic containers when loaded under columnar crush conditions at a constant rate of compressive deflection. Any container, whether blown commercially or in the laboratory, may be used as the test specimen.

1.2 The values stated in SI units are to be regarded as the standard.

Note 1—There is no similar or equivalent ISO standard.

1.3 his standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2659–95 (Reapproved 2005)

Standard Test Method for

Column Crush Properties of Blown Thermoplastic

Containers

This standard is issued under the fixed designation D2659; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

or both, of a specific container, multiple values of the crushing yield load

1. Scope

may be observed, a small deflection may occur with no increase or with

1.1 Thistestmethodcoversthedeterminationofmechanical

a decrease in the crush load, followed by resumption of the normal crush

properties of blown thermoplastic containers when loaded

load change with deflection. This phenomenon cannot be ignored in the

under columnar crush conditions at a constant rate of compres-

evaluation of the column crush properties of a blown thermoplastic

sive deflection.Any container, whether blown commercially or container, since it may be a very useful designated failure point for the

application under consideration. The load at which this abrupt change

in the laboratory, may be used as the test specimen.

occurs may be chosen as a crushing yield load for study. In such a case,

1.2 The values stated in SI units are to be regarded as the

the report of results should be accompanied by a proper description of the

standard.

crushing yield load selected.

NOTE 1—There is no known ISO equivalent to this standard.

3.1.2 crushing load at failure—the crushing load applied to

1.3 This standard does not purport to address all of the a blown thermoplastic container that produces a failure by

safety concerns, if any, associated with its use. It is the

fracture or parting of the material in any portion of said

responsibility of the user of this standard to establish appro- container. It is expressed in kilograms (or pounds).

priate safety and health practices and determine the applica-

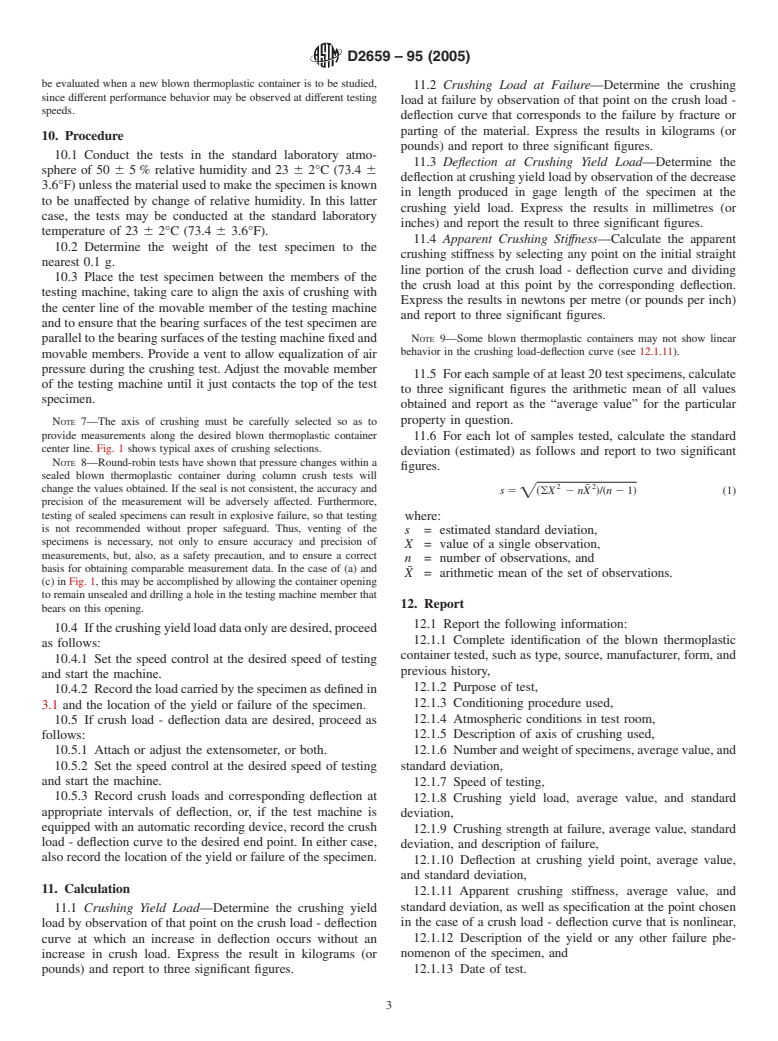

3.1.3 deflection at crushing yield load—the decrease in

bility of regulatory limitations prior to use. lengthofthecontainerspecimenproducedatthecrushingyield

load along the center line of testing (axis of crushing, see Fig.

2. Referenced Documents

1). It is expressed in millimetres (or inches).

2.1 ASTM Standards:

3.1.4 apparent crushing stiffness—the ratio of the crushing

D618 Practice for Conditioning Plastics for Testing

load to the corresponding deflection at a point on the linear

D4976 Specification for Polyethylene Plastics Molding and

portion of the crushing load deflection curve. It is expressed in

Extrusion Materials

newtons per metre (or pounds per inch).

E4 Practices for Force Verification of Testing Machines

4. Significance and Use

E83 Practice for Verification and Classification of Exten-

someter Systems

4.1 Column crush tests provide information about the crush-

ing properties of blown thermoplastic containers when em-

3. Terminology

ployed under conditions approximating those under which the

3.1 Definitions:

tests are made.

3.1.1 crushing yield load—the first load at which an in-

4.2 The column crush properties include the crushing yield

crease of deflection occurs with no increase in load in a

load, deflection at crushing yield load, crushing load at failure,

compressive crushing test. It is expressed in units of kilograms

and apparent crushing stiffness. Blown thermoplastic contain-

(or pounds) of load.

ers made from materials that possess a low order of ductility

may fail in crushing by brittle fracture. In such cases, the

NOTE 2—In some cases, usually as a result of design or styling features,

crushing yield load is equivalent to the crushing load at failure.

Blown thermoplastic containers made of ductile materials may

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

not exhibit a crushing load at failure although they will

and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting.

normally provide a crushing yield load value.

Current edition approved July 15, 2005. Published August 2005. Originally

4.3 Column crush tests provide a standard method of

approved in 1967. Last previous edition approved in 2001 as D2659 - 1995 (2001).

DOI: 10.1520/D2659-95R05.

obtaining data for research and development, applications,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

design, quality control, acceptance or rejection under specifi-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

cations, and special purposes. The tests cannot be considered

Standards volume information, refer to the standard’s Document Summary page on

significant for engineering design in applications differing

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2659–95 (2005)

free of obvious defects such as rocker bottoms or bent necks,

unless such defects constitute a variable to be studied. The

surfaces of the container that bear on the fixed and movable

members of the testing machine shall be parallel to each other.

NOTE 3—In the event that the bearing surface of the blown thermo-

plastic container deviates noticeably from the parallel relationship, the

construction and use of a suitable testing jig will be necessary. This jig

shall be attached to that crosshead member of the testing machine that

contacts the nonparallel surface of the container. Similarly, some blown

thermoplastic container designs may cause slippage on the machine

crushing surfaces. In this event, a nonslip material such as masking tape

should be applied to the slipping member of the testing machine.

7. Conditioning

7.1 Conditioning—Condition the test specimens at 23 6

2°C (73.4 6 3.6°F) and 50 6 5 % relative humidity for not less

than 40 h prior to test in accordance with Procedure A of

Practice D618, for those tests where conditioning is required.

In cases of disagreement, the tolerances shall be 61°C

FIG. 1 Typical Crushing Axes

(61.8°F) and 62 % relative humidity.

7.2 Test Conditions—Conduct tests in the standard labora-

widely from the load - time scale of the standard test. Such

tory atmosphere of 23 6 2°C (73.4 6 3.6°F) and 50 6 5%

applications require additional tests such as impact, creep, and

relative humidity, unless otherwise specified in the test meth-

fatigue.

ods. In cases of disagreement, the tolerances shall be 61°C

4.4 Before proceeding with this test method, reference

(61.8°F) and 62 % relative humidity.

shouldbemadetothespecificationofthematerialbeingtested.

Any test specimen preparation, conditioning, dimensions, or

NOTE 4—Blown thermoplastic container test specimens that are made

testing parameters, or combination thereof, covered in the of materials known to be insensitive to changes of relative humidity, may

be conditioned at the Standard LaboratoryTemperature of 23 6 2°C (73.4

materials specification shall take precedence over those men-

6 3.6°F) for a period of 24 h, unless otherwise specified.

tioned in this test method. If there are no material specifica-

tions, then the default conditions apply.

8. Number of Test Specimens

5. Apparatus

8.1 At least 20 specimens shall be tested for each sample on

5.1 Testing Machine—Any suitable testing machine capable

any given axis of crushing. If more than one axis of crushing

of control of constant-rate-of-crosshead movement and com-

is to be studied, at least 20 specimens shall be tested for each

prising essentially the following:

axis.

5.1.1 Drive Mechanism—A drive mechanism imparting the

8.2 Specimensthatfailatsomeobviousfortuitousflawshall

crosshead movable member of a uniform, controlled velocity

be discarded and retests made, unless such flaws constitute a

with respect to the fixed member, this velocity to be regulated

variable to be studied. The data should be discarded and the

as specified in Section 9.

number of rejected specimens noted.

5.1.2 Load Indicator—A load-indicating mechanism ca-

pable of showing the total crushing load carried by the test

9. Speed of Testing

specimen. The mechanism shall be essentially free from

9.1 Speed of testing shall be the relative rate of motion of

inertia-lag at the specified rate of testing and shall indicate the

the fixed and movable members of the testing machine during

crushing load with an accuracy of 61 %. The accuracy of the

the test. Rate of motion of the movable member, when the

testing machine shall be verified at least once a year, in

machineisrunningidle,maybeusedifitcanbeshownthatthe

accordance with Practices E4.

resulting speed of testing is within the limits of variation

5.2 Extensometer—A suitable instrument for determining

allowed.

the distance between the two surfaces of load application on

9.2 The speed of testing shall be constant within 610 %.

the test specimen at any time during the test. It is desirable that

9.3 The speed of testing shall be chosen in the range from

this instrument automatically record this distance, or any

12.5 mm (0.50 in.)/min to 50.0 mm (2.0 in.)/min.

change in it as a function of the c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.