ASTM B541-95

(Specification)Standard Specification for Gold Electrical Contact Alloy

Standard Specification for Gold Electrical Contact Alloy

SCOPE

1.1 This specification covers a gold-rich, age-hardenable alloy in rod, wire, and strip form applicable to electrical contacts.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units may be approximate.

1.3 The following precautionary statement pertains to the test method portion only, Section 7, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: B 541 – 95

Standard Specification for

1

Gold Electrical Contact Alloy

This standard is issued under the fixed designation B 541; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ε) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

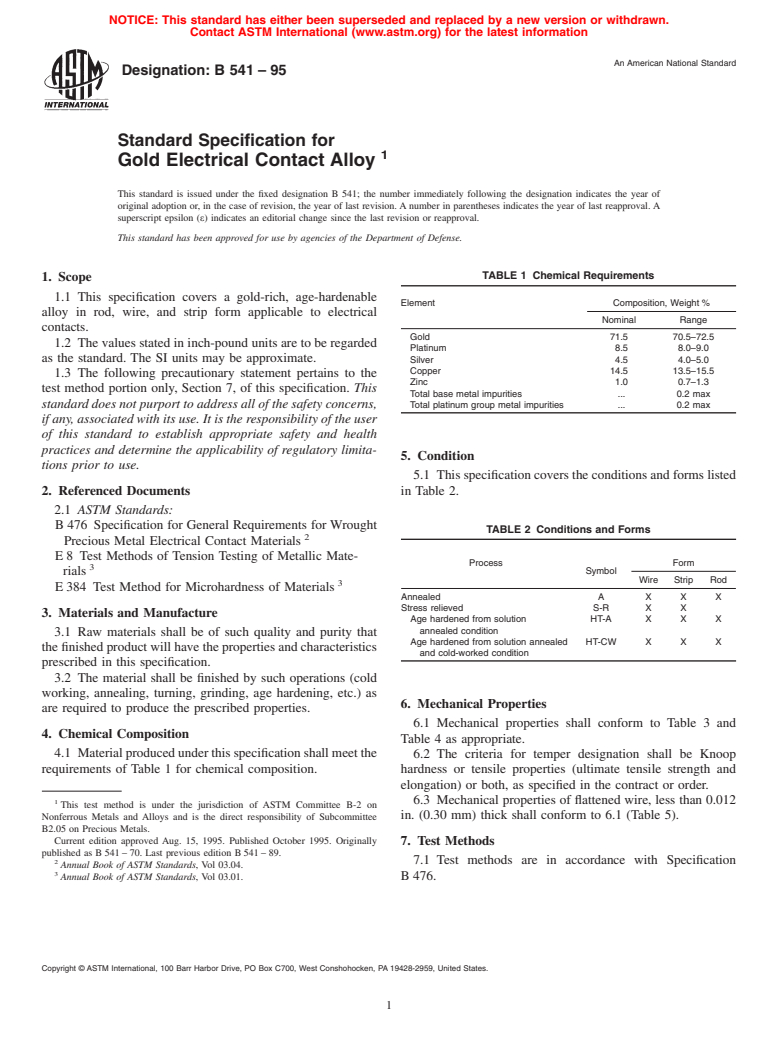

TABLE 1 Chemical Requirements

1. Scope

1.1 This specification covers a gold-rich, age-hardenable

Element Composition, Weight %

alloy in rod, wire, and strip form applicable to electrical

Nominal Range

contacts.

Gold 71.5 70.5–72.5

1.2 The values stated in inch-pound units are to be regarded

Platinum 8.5 8.0–9.0

as the standard. The SI units may be approximate.

Silver 4.5 4.0–5.0

Copper 14.5 13.5–15.5

1.3 The following precautionary statement pertains to the

Zinc 1.0 0.7–1.3

test method portion only, Section 7, of this specification. This

Total base metal impurities . 0.2 max

standard does not purport to address all of the safety concerns, Total platinum group metal impurities . 0.2 max

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

5. Condition

tions prior to use.

5.1 This specification covers the conditions and forms listed

2. Referenced Documents in Table 2.

2.1 ASTM Standards:

B 476 Specification for General Requirements for Wrought

TABLE 2 Conditions and Forms

2

Precious Metal Electrical Contact Materials

E 8 Test Methods of Tension Testing of Metallic Mate-

Process Form

3

rials Symbol

Wire Strip Rod

3

E 384 Test Method for Microhardness of Materials

Annealed A X X X

Stress relieved S-R X X

3. Materials and Manufacture

Age hardened from solution HT-A XXX

annealed condition

3.1 Raw materials shall be of such quality and purity that

Age hardened from solution annealed HT-CW XXX

the finished product will have the properties and characteristics

and cold-worked condition

prescribed in this specification.

3.2 The material shall be finished by such operations (cold

working, annealing, turning, grinding, age hardening, etc.) as

6. Mechanical Properties

are required to produce the prescribed properties.

6.1 Mechanical properties shall conform to Table 3 and

4. Chemical Composition

Table 4 as appropriate.

4.1 Materialproducedunderthisspecificationshallmeetthe

6.2 The criteria for temper designation shall be Knoop

requirements of Table 1 for chemical composition. hardness or tensile properties (ultimate tensile strength and

elongation) or both, as specified in the contract or order.

1 6.3 Mechanical properties of flattened wire, less than 0.012

This test method is under the jurisdiction of ASTM Committee B-2 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee in. (0.30 mm) thick shall conform to 6.1 (Table 5).

B2.05 on Precious Metals.

Current edition approved Aug. 15, 1995. Published October 1995. Originally

7. Test Methods

published as B 541 – 70. Last previous edition B 541 – 89.

2 7.1 Test methods are in accordance with Specification

Annual Book of ASTM Standards, Vol 03.04.

3

Annual Book of ASTM Standards, Vol 03.01. B 476.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 541–95

A

TABLE 3 Mechanical Properties of Wire (0.004 to 0.020-in. (0.12 to 0.5-mm) diameter)

Property Condition

A S-R HT-A HT-CW

Tensile strength, ksi 85–110 130–170 130–165 150–200

Tensile strength, MPa 590–760 900–1170 900–1140 1030–1380

Elongation, % in 5 in. or 125 mm 20 min 5–15 7–14 2–10

B

Hardness, Knoop, HK 180–240 270–340 280–350 310–380

100

B

Hardness, Vickers HV 180–250 270–340 285–360 290–370

100

A

See 6.2.

B

See 7.3.

A

TABLE 4 Mechanical Properties of Wire (0.021 to 0.080-in. (0.51 to 0.200-mm) diameter)

Property Condition

A S-R HT-A HT-CW

Tensile strength, ksi 80–110 130–170 130–160 145–195

Tensile strength, MPa 550–760 900–1170 900–1100 1000–1340

Elongation, % in 2 in. or 50 mm 16 min 4–14 5–14 2–10

B

Hardness, Knoop HK 180–240 270–340 270–340 290–370

100

B

Hardness, Vickers HV 180–250 270–340 285–360 290–370

100

A

See 6.2.

B

See 7.3.

A

TABLE 5 Mechanical Properties of Strip (0.003 to 0.020-in. (0.12 to 0.5-mm) thick)

Property Condition

A S-R HT-A HT-CW

Tensile strength, ksi 85–115 125–165 125–155 140–180

Tensile strength, MPa 590–790 860–1140 860–1070 970–1240

Elongation, % in 2 in. or 50 mm 12 min 3–16 3–12 2–10

B

Hardness, Knoop, HK 200–250 270–340 270–340 290–370

100

B

Hardness, Vickers HV 180–250 270–340 275–350 285–365

100

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.