ASTM D7386-16

(Practice)Standard Practice for Performance Testing of Packages for Single Parcel Delivery Systems

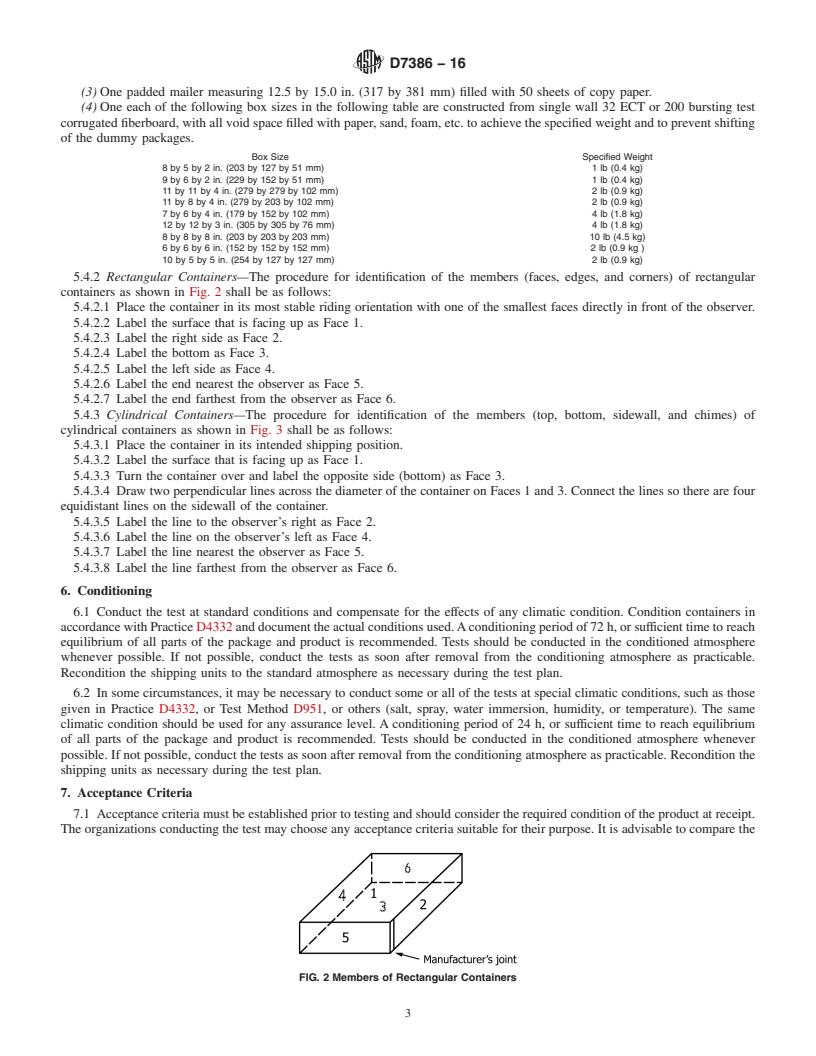

Standard Practice for Performance Testing of Packages for Single Parcel Delivery Systems

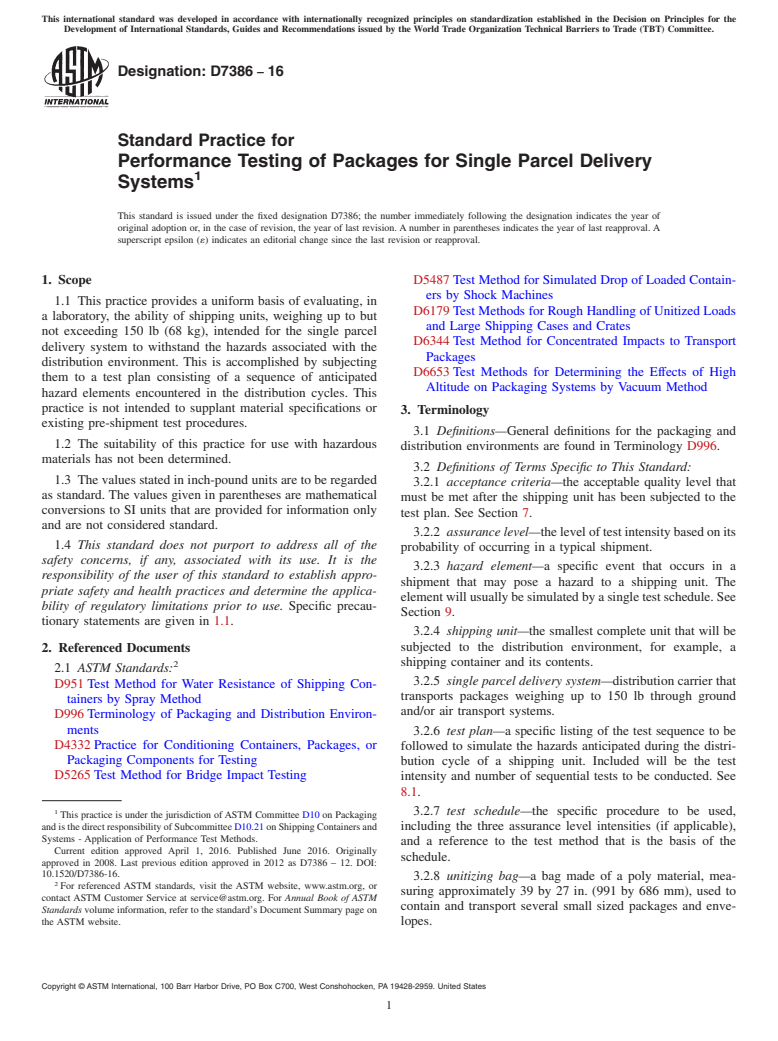

SIGNIFICANCE AND USE

4.1 This practice provides a guide for the evaluation of shipping units in accordance with a uniform system, using established test methods at levels representative of those occurring in actual distribution. The recommended test levels are based on available information on the shipping and handling environment, and current industry/government practice and experience. The tests should be performed sequentially on the same containers in the order given. For use as a performance test, this practice requires that the shipping unit tested remain unopened until the sequence of tests are completed. If used for other purposes, such as package development, it may be useful to open and inspect shipping units at various times throughout the sequence. This may, however, prohibit evaluating the influence of the container closure on container performance.

SCOPE

1.1 This practice provides a uniform basis of evaluating, in a laboratory, the ability of shipping units, weighing up to but not exceeding 150 lb (68 kg), intended for the single parcel delivery system to withstand the hazards associated with the distribution environment. This is accomplished by subjecting them to a test plan consisting of a sequence of anticipated hazard elements encountered in the distribution cycles. This practice is not intended to supplant material specifications or existing pre-shipment test procedures.

1.2 The suitability of this practice for use with hazardous materials has not been determined.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 1.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7386 − 16

Standard Practice for

Performance Testing of Packages for Single Parcel Delivery

1

Systems

This standard is issued under the fixed designation D7386; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D5487Test Method for Simulated Drop of Loaded Contain-

ers by Shock Machines

1.1 This practice provides a uniform basis of evaluating, in

D6179Test Methods for Rough Handling of Unitized Loads

a laboratory, the ability of shipping units, weighing up to but

and Large Shipping Cases and Crates

not exceeding 150 lb (68 kg), intended for the single parcel

D6344Test Method for Concentrated Impacts to Transport

delivery system to withstand the hazards associated with the

Packages

distribution environment. This is accomplished by subjecting

D6653Test Methods for Determining the Effects of High

them to a test plan consisting of a sequence of anticipated

Altitude on Packaging Systems by Vacuum Method

hazard elements encountered in the distribution cycles. This

practice is not intended to supplant material specifications or

3. Terminology

existing pre-shipment test procedures.

3.1 Definitions—General definitions for the packaging and

1.2 The suitability of this practice for use with hazardous

distribution environments are found in Terminology D996.

materials has not been determined.

3.2 Definitions of Terms Specific to This Standard:

1.3 The values stated in inch-pound units are to be regarded

3.2.1 acceptance criteria—the acceptable quality level that

as standard. The values given in parentheses are mathematical

must be met after the shipping unit has been subjected to the

conversions to SI units that are provided for information only

test plan. See Section 7.

and are not considered standard.

3.2.2 assurance level—theleveloftestintensitybasedonits

1.4 This standard does not purport to address all of the

probability of occurring in a typical shipment.

safety concerns, if any, associated with its use. It is the

3.2.3 hazard element—a specific event that occurs in a

responsibility of the user of this standard to establish appro-

shipment that may pose a hazard to a shipping unit. The

priate safety and health practices and determine the applica-

elementwillusuallybesimulatedbyasingletestschedule.See

bility of regulatory limitations prior to use. Specific precau-

Section 9.

tionary statements are given in 1.1.

3.2.4 shipping unit—the smallest complete unit that will be

subjected to the distribution environment, for example, a

2. Referenced Documents

shipping container and its contents.

2

2.1 ASTM Standards:

3.2.5 single parcel delivery system—distribution carrier that

D951Test Method for Water Resistance of Shipping Con-

transports packages weighing up to 150 lb through ground

tainers by Spray Method

and/or air transport systems.

D996Terminology of Packaging and Distribution Environ-

ments

3.2.6 test plan—a specific listing of the test sequence to be

D4332Practice for Conditioning Containers, Packages, or followed to simulate the hazards anticipated during the distri-

Packaging Components for Testing

bution cycle of a shipping unit. Included will be the test

D5265Test Method for Bridge Impact Testing intensity and number of sequential tests to be conducted. See

8.1.

1 3.2.7 test schedule—the specific procedure to be used,

This practice is under the jurisdiction ofASTM Committee D10 on Packaging

andisthedirectresponsibilityofSubcommitteeD10.21onShippingContainersand

including the three assurance level intensities (if applicable),

Systems - Application of Performance Test Methods.

and a reference to the test method that is the basis of the

Current edition approved April 1, 2016. Published June 2016. Originally

schedule.

approved in 2008. Last previous edition approved in 2012 as D7386 – 12. DOI:

10.1520/D7386-16.

3.2.8 unitizing bag—a bag made of a poly material, mea-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

suring approximately 39 by 27 in. (991 by 686 mm), used to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

contain and transport several small sized packages and enve-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. lopes.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7386 − 16

4. Significance and Use

4.1 T

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7386 − 12 D7386 − 16

Standard Practice for

Performance Testing of Packages for Single Parcel Delivery

1

Systems

This standard is issued under the fixed designation D7386; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice provides a uniform basis of evaluating, in a laboratory, the ability of shipping units, weighing up to but not

exceeding 150 lb (68 kg), intended for the single parcel delivery system to withstand the hazards associated with the distribution

environment. This is accomplished by subjecting them to a test plan consisting of a sequence of anticipated hazard elements

encountered in the distribution cycles. This practice is not intended to supplant material specifications or existing pre-shipment test

procedures.

1.2 The suitability of this practice for use with hazardous materials has not been determined.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific precautionary statements are given in 1.1.

2. Referenced Documents

2

2.1 ASTM Standards:

D951 Test Method for Water Resistance of Shipping Containers by Spray Method

D996 Terminology of Packaging and Distribution Environments

D4332 Practice for Conditioning Containers, Packages, or Packaging Components for Testing

D5265 Test Method for Bridge Impact Testing

D5487 Test Method for Simulated Drop of Loaded Containers by Shock Machines

D6179 Test Methods for Rough Handling of Unitized Loads and Large Shipping Cases and Crates

D6344 Test Method for Concentrated Impacts to Transport Packages

D6653 Test Methods for Determining the Effects of High Altitude on Packaging Systems by Vacuum Method

3. Terminology

3.1 Definitions—General definitions for the packaging and distribution environments are found in Terminology D996.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 acceptance criteria—the acceptable quality level that must be met after the shipping unit has been subjected to the test

plan. See Section 7.

3.2.2 assurance level—the level of test intensity based on its probability of occurring in a typical shipment.

3.2.3 hazard element—a specific event that occurs in a shipment that may pose a hazard to a shipping unit. The element will

usually be simulated by a single test schedule. See Section 9.

3.2.4 shipping unit—the smallest complete unit that will be subjected to the distribution environment, for example, a shipping

container and its contents.

1

This practice is under the jurisdiction of ASTM Committee D10 on Packaging and is the direct responsibility of Subcommittee D10.21 on Shipping Containers and

Systems - Application of Performance Test Methods.

Current edition approved April 1, 2012April 1, 2016. Published May 2012June 2016. Originally approved in 2008. Last previous edition approved in 20082012 as D7386

– 08.12. DOI: 10.1520/D7386-12.10.1520/D7386-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7386 − 16

3.2.5 single parcel delivery system—distribution carrier that transports packages weighing up to 150 lb through ground and/or

air transport systems.

3.2.6 test plan—a specific listing of the test sequence to be followed to simulate the hazards anticipated during the distribution

cycle of a shipping unit. Included will be the test intensity and number of sequential tests to be conducted. See 8.1.

3.2.7 test schedule—the specific procedure to be used, including the three assurance level intensities (if applicable), and a

reference to the test method that is the basis of the schedule.

3.2.8 u

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.