ASTM D7097-05

(Test Method)Standard Test Method for Determination of Moderately High Temperature Piston Deposits by Thermo-Oxidation Engine Oil Simulation Test-TEOST MHT

Standard Test Method for Determination of Moderately High Temperature Piston Deposits by Thermo-Oxidation Engine Oil Simulation Test-TEOST MHT

SCOPE

D

1.1 This test method covers the procedure to determine the mass of deposit formed on a specially constructed test rod exposed to repetitive passage of 8.5 g of engine oil over the rod in a thin film under oxidative and catalytic conditions at 285°C. The range of applicability of the Moderately High Temperature Thermo-Oxidation Engine Test (TEOST MHT) test method as derived from an interlaboratory study is approximately 10 to 100 mg. However, experience indicates that deposit values from 1 to 150 mg or greater may be obtained.

1.2 This test method uses a patented instrument, method and patented, numbered, and registered depositor rods traceable to the manufacturer and made specifically for the practice and precision of the test method.Note 1

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

1.3 The values stated in SI units are to be regarded as standard. Although not an SI unit, the special name, litre (L) is allowed by SI for the cubic decimetre (dm3) and the millilitre (mL) for the SI cubic centimetre (cm3).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D7097–05

Standard Test Method for

Determination of Moderately High Temperature Piston

Deposits by Thermo-Oxidation Engine Oil Simulation Test—

TEOST MHT

This standard is issued under the fixed designation D 7097; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the procedure to determine the 2.1 ASTM Standards:

mass of deposit formed on a specially constructed test rod D 4485 Specification for Performance of Engine Oils

exposedtorepetitivepassageof8.5gofengineoilovertherod D 6335 Test Method for Determination of High Tempera-

inathinfilmunderoxidativeandcatalyticconditionsat285°C. ture Deposits byThermo-Oxidation Engine Oil Simulation

The range of applicability of the Moderately HighTemperature Test

Thermo-Oxidation EngineTest (TEOSTMHT ) test method as

3. Terminology

derived from an interlaboratory study is approximately 10 to

3.1 Definitions of Terms Specific to This Standard:

100 mg. However, experience indicates that deposit values

from 1 to 150 mg or greater may be obtained. 3.1.1 bubble airflow gage, n—a precision bore glass tube

marked in tenths of a millilitre used to measure accurately the

1.2 Thistestmethodusesapatentedinstrument,methodand

patented, numbered, and registered depositor rods traceable to flow rate of air around and past the depositor rod and to

calibrate mass air flow controllers recommended for use in the

the manufacturer and made specifically for the practice and

precision of the test method. procedure.

3.1.2 depositor rod deposits, n—particulate matter formed

NOTE 1—ASTM International takes no position respecting the validity

on the depositor rod surface by oxidation of the thin film of

ofanypatentrightsassertedinconnectionwithanyitemmentionedinthis

passingoilexposedtotherodtemperatureandair,andweighed

standard. Users of this standard are expressly advised that determination

after appropriate washing and drying to obtain the net mass

of the validity of any such patent rights, and the risk of infringement of

such rights, are entirely their own responsibility. gain.

3.1.3 filter deposits, n—particulates washed from the de-

1.3 The values stated in SI units are to be regarded as

positor rod after the test and collected on a special multi-layer

standard.Although not an SI unit, the special name, litre (L) is

filter cartridge.

allowed by SI for the cubic decimetre (dm ) and the millilitre

3.1.4 MHT , n—an acronym for moderately high tempera-

(mL) for the SI cubic centimetre (cm ).

ture.

1.4 This standard does not purport to address all of the

3.1.4.1 Discussion—The TEOST MHT procedure evaluates

safety concerns, if any, associated with its use. It is the

deposit formation at temperatures that are closely related to

responsibility of the user of this standard to establish appro-

those of the piston ring zone in reciprocating engines (as

priate safety and health practices and determine the applica-

distinguished from the much higher temperatures associated

bility of regulatory limitations prior to use.

with the TEOST 33C, Test Method D 6335, procedure for

determining potential deposits in turbochargers).

3.1.5 TEOST , n—an acronym for Thermo-Oxidation En-

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

gine Oil Simulation Test.

D02.09.0G on Oxidation Testing of Engine Oils.

3.1.6 total rod deposits, n—the mass of deposits collected

Current edition approved April 1, 2005. Published May 2005.

2 on the depositor rod deposits plus any mass of deposits washed

TEOST and MHT are registered trademarks of the Tannas Co. (Reg. 2001396).

The sole source of supply of the apparatus known to the committee at this time from the depositor rod and later extracted on a filter.

is Tannas Company, 4800 James Savage Rd., Midland, MI 48642. If you are aware

3.1.7 volatilized oil, n—oil vapor coalesced on the mantle

of alternative suppliers, please provide this information to ASTM International

wall, and subsequently collected in a vial.

Headquarters.Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend.

The TEOST instrument, method and rod are patented. Interested parties are

invited to submit information regarding the identification of an alternative(s) to this For referenced ASTM standards, visit the ASTM website, www.astm.org, or

patented technology to ASTM Headquarters. Your comments will receive careful contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

consideration at a meeting of the responsible technical committee, which you may Standards volume information, refer to the standard’s Document Summary page on

attend. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7097–05

4. Summary of Test Method oil to pass into the sample flask and subsequently to the

re-circulating pump inlet tubing. (See Fig. 6.)

4.1 Deposit-forming tendencies of an engine oil under

6.1.1.5 End-cap Nuts, Four, used for compressing small

oxidative conditions are determined by circulating an oil-

O-rings around depositor rod and for positioning and sealing

catalyst mixture comprising a small sample (8.4 g) of the oil

the oil feed tube and sealing the air inlet tubing.

and a very small (0.1 g) amount of an organo-metallic catalyst.

This sample mixture is then circulated for exactly 24 h in the 6.1.1.6 Glass Mantle, the glass casing that surrounds the

TEOST MHT instrument over a special wire-wound depositor

depositor rod and diverts volatilized oil into a collecting vial.

rod heated by electrical current to a controlled temperature of (See Figs. 4-6.)

285°C at the hottest location on the rod. The depositor rod is

6.1.1.7 Mantis Clip, a wire-spring device holding the

weighed before and after the test and any deposit formation on

sampleflaskinplaceonthelowerend-cap.(SeeFig.2andFig.

the rod as well as any deposits collected from rod washings are

6.)

determined. During the test, precisely controlled and directed

6.1.1.8 Oil Feed Tube, the avenue for oil to be delivered

air is caused to bathe the oil flowing down the depositor rod

from the pump to the top of the depositor rod.

and, thereby, to provide opportunity for oxidation. Precision of

6.1.1.9 O-rings, Larger, Petroleum-resistant, create a seal

the test is strongly influenced by the care in manufacture of the

between the end-caps and glass mantle. (See Fig. 5.)

wire-wound steel depositor rods and the treatment of the

6.1.1.10 O-rings, Smaller, Petroleum- and Heat-resistant,

coating of the wound wire, the rate of air flow, and the amount

creates an air and fluid seal between depositor rod and

and degree of mixing of the catalyst.

end-caps. (See Fig. 5.)

5. Significance and Use

6.1.1.11 Pump Outlet Tubing, a flexible transparent vinyl

tube of 3.2 mm outer diameter with a flared end used to

5.1 The test method is designed to predict the deposit-

transport the oil sample from the oil pump to the oil feed tube.

forming tendencies of engine oil in the piston ring belt and

(See Fig. 6.)

upper piston crown area. Correlation has been shown between

6.1.1.12 Sample Flask, a small (~25 mL), modified form of

the TEOST MHT procedure and the TU3MH Peugeot engine

an Erlenmeyer flask with side-arm into which the catalyst and

test in deposit formation. Such deposits formed in the ring-belt

sample are first weighed, then later used to feed the sample to

area of a reciprocating engine piston can cause problems with

the circulating system. (See Fig. 2 and Fig. 6.)

engine operation and longevity. It is one of the required test

methods in Specification D 4485 to define API Category-

6.1.1.13 Stainless Steel Hex Screws and Busbar End Piece,

Identified engine oils. these secure the depositor rod to the busbars.

6.1.1.14 Thermocouples, Two, stainless steel sheathed, 1.57

6. Apparatus

mm diameter by 150 mm length. One, a J-type, is used for

6.1 TEOST MHT Instrument, with specific fittings for the

controlling the test temperature (depositor rod) while the other,

MHT procedure including parts and assemblies are as follows:

a K-type, is used to protect against an over-temperature

6.1.1 Depositor Rod Casing Assembly:

condition.

6.1.1.1 Ceramic Isolators, special non-conductive fittings

6.1.1.15 Thermocouple Lock Collar, a fitting that can be

that compress the depositor rod O-rings into the end-caps and

tightened on the thermocouple to ensure the thermocouple tip

centers the depositor rod in the end-caps to prevent leakage of

is at the correct position when placed inside the depositor rod.

oil from the lower end-cap. (See Figs. 4 and 5.)

(See Fig. 4.)

6.1.1.2 Depositor Rod, Wire-Wound, a specially patented,

6.1.1.16 Volatiles Vial Clip, the device that holds the vola-

numbered, and registered steel tube wound with pre-treated

tiles collection vial in place on the mantle. (See Fig. 4.)

steel wire. The steel tube is formed to a selected interior

6.1.2 Airflow Control Assembly, sets air flow at chosen flow

diameter to precisely contact the surface of a metal-sheathed

rate.

thermocouple.Theregistereddepositorrodsarerequiredtorun

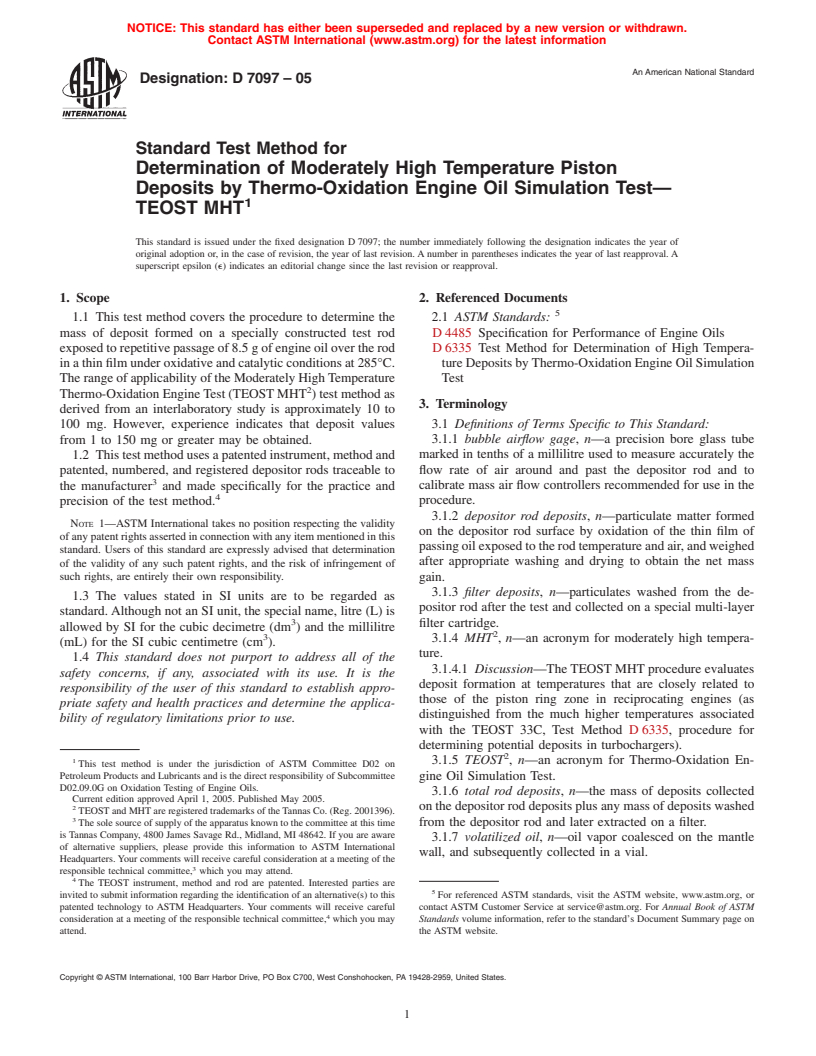

6.1.2.1 Bubble-tube Airflow Gage, a device for precisely

the TEOST MHT procedure. (See Fig. 4, Fig. 5, and Fig. 7.)

establishing the airflow rate and calibrating the flow meter

NOTE 2—Precision of the TEOST MHT procedure is highly dependent

from 1 to 30 mL/min. (See Fig. 1.)

on the uniformity of manufacture and use of patented and registered

6.1.2.2 Calibrated Flow Meter, capable of measuring ap-

depositor rods. Each depositor rod is numbered and traceable to the

proximately 1 to 20 mL/min of air and providing a continuous

manufacturer and raw steel tubing mill.

reading on airflow rate when calibrated.

6.1.1.3 End-cap, Upper, holds the upper end of the glass

6.1.2.3 Hand-held Digital Flow Meter,anoptionaldeviceto

mantleanddepositorrodinplaceandallowsairandoiltoenter

monitor air flow to or out of the mantle, capable of reading a

the deposit-forming zone separately. (See Fig. 4 and Fig. 7.)

flow rate of 10.0 6 0.1 mL/min of air.

6.1.1.4 End-cap, Lower, holds the lower end of the glass

6.1.2.4 Precision Digital Mass Flow Controller, an optional

mantleanddepositorrodinplaceandprovidesanoutletforthe

device that allows the precise control of the input air flow. (See

Fig. 1a.)

Selby,T.W.,andFlorkowski,D.F.,“TheDevelopmentoftheTEOSTProtocol

6.1.2.5 Stopwatch, reading to 1/100 s.

MHT Bench Test of Engine Oil Piston Deposit Tendency,” Supplement to the

6.1.3 Filtering Flask Assembly, provides the means for

Proceedings of the 12th Esslingen Colloquium, Esslingen, Germany, January 11-13,

2000, pp. 55-62. filtering particles washed from the depositor rod. (See Fig. 8.)

D7097–05

FIG. 1 Bubble Gage

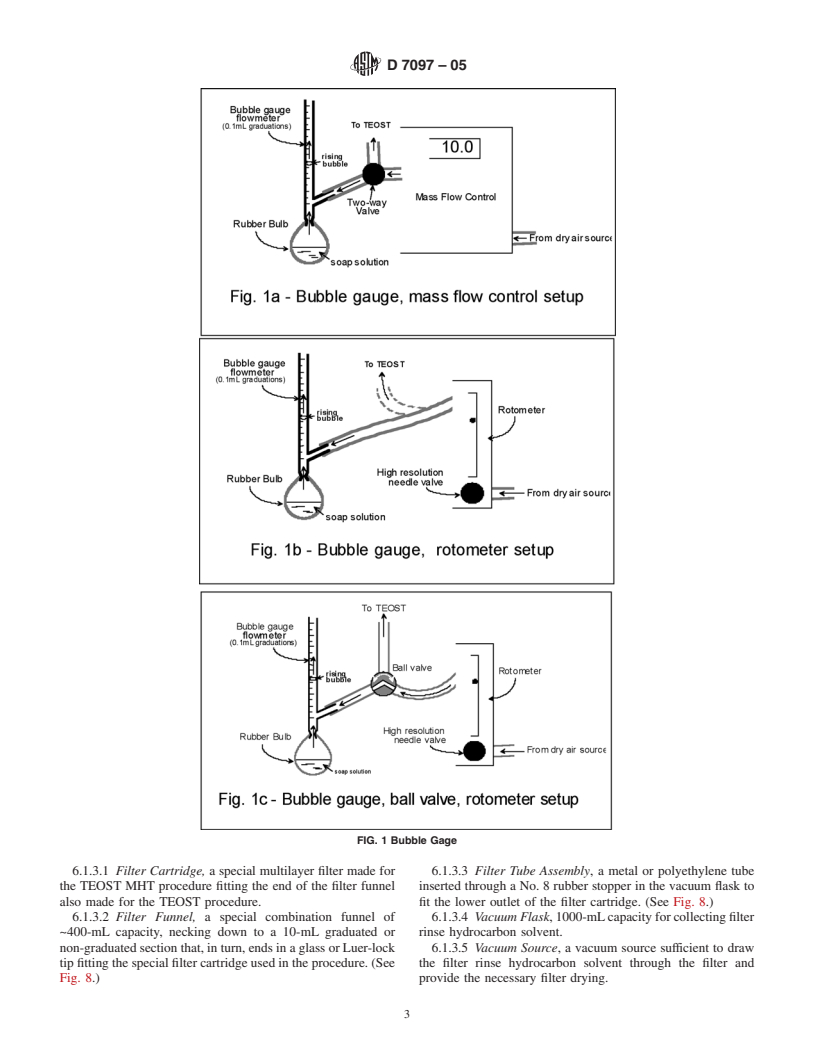

6.1.3.1 Filter Cartridge, a special multilayer filter made for 6.1.3.3 Filter Tube Assembly, a metal or polyethylene tube

the TEOST MHT procedure fitting the end of the filter funnel inserted through a No. 8 rubber stopper in the vacuum flask to

also made for the TEOST procedure. fit the lower outlet of the filter cartridge. (See Fig. 8.)

6.1.3.2 Filter Funnel, a special combination funnel of 6.1.3.4 VacuumFlask,1000-mLcapacityforcollectingfilter

~400-mL capacity, necking down to a 10-mL graduated or rinse hydrocarbon solvent.

non-graduated section that, in turn, ends in a glass or Luer-lock 6.1.3.5 Vacuum Source, a vacuum source sufficient to draw

tip fitting the special filter cartridge used in the procedure. (See the filter rinse hydrocarbon solvent through the filter and

Fig. 8.) provide the necessary filter drying.

D7097–05

warm to room temperature before opening to eliminate con-

densation). Temporary sealed storage, up to four weeks, may

be at room temperature.

7.6 Certified Reference Oils, certified low deposit fluid

(LDF, about 10 to 15 mg), medium deposit fluid (MDF, about

40 to 50 mg), and high deposit fluid (HDF, about 70 to 90 mg).

7.7 Combination Pump Calibration and Temperature Con-

trol Thermocouple Depth Setting Oil, TPC-1, a highly

deposit-resistant oil used in setting pump calibration and

FIG. 2 Sample Flask with Stirring Bar and Mantis Clip

temperature control calibration without forming significant

deposits on the depositor rod during these calibrations.

6.1.3.6 Wire Rod, stainless steel, 1 to 1.5 mm diameter, 300

7.8 Varnish Cleaning Liquid, used in cleaning varnish from

to 350 mm length, for dislodging any deposits trapped in the

mantle, end-caps, and other components of the equipment after

narrow portion of the filter funnel just above the filter.

test. Other glass cleaners with varnish removing capabilities

6.2 Ancillary Equipment, needed or helpful:

also may be used.

6.2.1 Balance, capable of weighing deposits to the nearest

0.1 mg with a minimum capacity of 100 g.

8. Programming the Apparatus

6.2.2 Catalyst Syringe, a syringe of 100 µL capacity, for

8.1 PID (proportional, integral, and derivative) Settings for

carefully metering the catalyst being weighed into the sample

Temperature Control—Adjustthethermocouplesensitivityand

flask.

response values (PID settings) to have the minimum excursion

6.2.3 Oil Sample Transfer Pipettes, disposable glass or

from the temperature value desired during operation. See

plastic pipettes or droppers.

Instrument Manual for recommended settings and adjustment

6.2.4 Oil Extraction Test Tubes, three, 120-mm tall, made of

technique.

glass or hydrocarbon solvent-resistant plastic.

8.2 Temperature Controller Setting—Set the temperature

6.2.5 Temperature Recorder, an optional device for tracking

control program to maintain 285°C for 24-h according to the

the temperature of the upper depositor rod thermocouple over

instructions in the Instrument Manual.

the 24-h period of the test.

8.3 If using a strip chart recorder, turn on the strip chart, set

6.2.6 Thermocouple Depth Insertion Gage, an optional

the chart speed to 10 mm/h, but do not lower the pen(s) or turn

measurement device fabricated for simple setting and checking

on the chart drive at this time.

thermocouple insertion depth, using a millimetre graduation

8.4 If using other means of continuously recording tempera-

scale.

tures, prepare these for receiving information.

6.2.7 Vials and Caps, a vial and matching cap of 10 mL or

more in volume with an 11.5 mm diameter mouth a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.