ASTM C363/C363M-16

(Test Method)Standard Test Method for Node Tensile Strength of Honeycomb Core Materials

Standard Test Method for Node Tensile Strength of Honeycomb Core Materials

SIGNIFICANCE AND USE

5.1 The honeycomb tensile-node bond strength is a fundamental property than can be used in determining whether honeycomb cores can be handled during cutting, machining and forming without the nodes breaking. The tensile-node bond strength is the tensile stress that causes failure of the honeycomb by rupture of the bond between the nodes. It is usually a peeling-type failure.

5.2 This test method provides a standard method of obtaining tensile-node bond strength data for quality control, acceptance specification testing, and research and development.

SCOPE

1.1 This test method covers the determination of the tensile-node bond strength of honeycomb core materials.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C363/C363M − 16

Standard Test Method for

Node Tensile Strength of Honeycomb Core Materials

This standard is issued under the fixed designation C363/C363M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope relating to sandwich constructions. Terminology D883 defines

terms relating to plastics. Terminology E6 defines terms

1.1 This test method covers the determination of the tensile-

relating to mechanical testing. Terminology E456 and Practice

node bond strength of honeycomb core materials.

E177 define terms relating to statistics. In the event of a

1.2 The values stated in either SI units or inch-pound units

conflict between terms, Terminology D3878 shall have prece-

are to be regarded separately as standard. The values stated in

dence over the other Terminologies.

each system may not be exact equivalents; therefore, each

3.2 Symbols:

system shall be used independently of the other. Combining

3.2.1 σ—tensile node strength, MPa [psi].

values from the two systems may result in non-conformance

with the standard. 3.2.2 P—ultimate tensile force, N [lb].

1.3 This standard does not purport to address all of the 3.2.3 b—initial width of specimen, mm [in.].

safety concerns, if any, associated with its use. It is the

3.2.4 t—thickness of specimen, mm [in.].

responsibility of the user of this standard to establish appro-

3.2.5 x¯—sample mean (average).

priate safety and health practices and determine the applica-

3.2.6 S —sample standard deviation.

bility of regulatory limitations prior to use.

n−1

3.2.7 CV—sample coefficient of variation (in percent).

2. Referenced Documents

3.2.8 n—number of specimens.

2.1 ASTM Standards:

3.2.9 x —measured or derived property.

D883 Terminology Relating to Plastics 1

D3878 Terminology for Composite Materials

4. Summary of Test Method

D5229/D5229M Test Method for MoistureAbsorption Prop-

erties and Equilibrium Conditioning of Polymer Matrix

4.1 This test method consists of subjecting a honeycomb

Composite Materials

construction to a uniaxial tensile force parallel to the plane of

E4 Practices for Force Verification of Testing Machines

the honeycomb. The force is transmitted to the honeycomb

E6 Terminology Relating to Methods of Mechanical Testing

through pins, which are placed in cell rows on the top and

E122 Practice for Calculating Sample Size to Estimate,With

bottom portions of one specimen.

Specified Precision, the Average for a Characteristic of a

4.2 The only acceptable failure mode for tensile-node bond

Lot or Process

strength is the tensile failure of the node-to-node honeycomb

E177 Practice for Use of the Terms Precision and Bias in

bond within the body of the honeycomb specimen. Failure of

ASTM Test Methods

the honeycomb material at the loading pin location is not a

E456 Terminology Relating to Quality and Statistics

valid failure mode.

3. Terminology

5. Significance and Use

3.1 Definitions—Terminology D3878 defines terms relating

to high-modulus fibers and their composites, as well as terms 5.1 The honeycomb tensile-node bond strength is a funda-

mental property than can be used in determining whether

honeycomb cores can be handled during cutting, machining

This test method is under the jurisdiction of ASTM Committee D30 on

and forming without the nodes breaking. The tensile-node

Composite Materials and is the direct responsibility of Subcommittee D30.09 on

Sandwich Construction.

bond strength is the tensile stress that causes failure of the

Current edition approved April 1, 2016. Published April 2016. Originally

honeycomb by rupture of the bond between the nodes. It is

approvedin1955.Lastpreviouseditionapprovedin2015asC363 – 09(2015).DOI:

usually a peeling-type failure.

10.1520/C0363_C0363M-16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2 This test method provides a standard method of obtain-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ing tensile-node bond strength data for quality control, accep-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tance specification testing, and research and development.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C363/C363M − 16

6. Interferences

6.1 System Alignment—Excessive bending will cause pre-

mature failure. Every effort should be made to eliminate excess

bending from the test system. Bending may occur as a result of

misaligned grips, poor specimen preparation, or poor align-

ment of the loading fixture.

6.2 Geometry—Specific geometric factors that affect the

tensile-node bond strength include cell geometry, cell size, cell

wall thickness and, specimen dimensions (length, width and

thickness).

6.3 Environment—Resultsareaffectedbytheenvironmental

conditions under which the tests are conducted. Specimens

tested in various environments can exhibit significant differ-

ences in both strength behavior and failure mode. Critical

environments must be assessed independently.

7. Apparatus

7.1 Testing Machine—The testing machine shall be in ac-

cordance with Practices E4 and shall satisfy the following

requirements:

7.1.1 Testing Machine Configuration—The testing machine

shall have both an essentially stationary head and a movable

head.

7.1.2 Drive Mechanism—The testing machine drive mecha-

nism shall be capable of imparting to the movable head a

controlled velocity with respect to the stationary head. The

velocity of the movable head shall be capable of being

regulated in accordance with 11.3.

7.1.3 Force Indicator—The testing machine load-sensing

device shall be capable of indicating the total force being

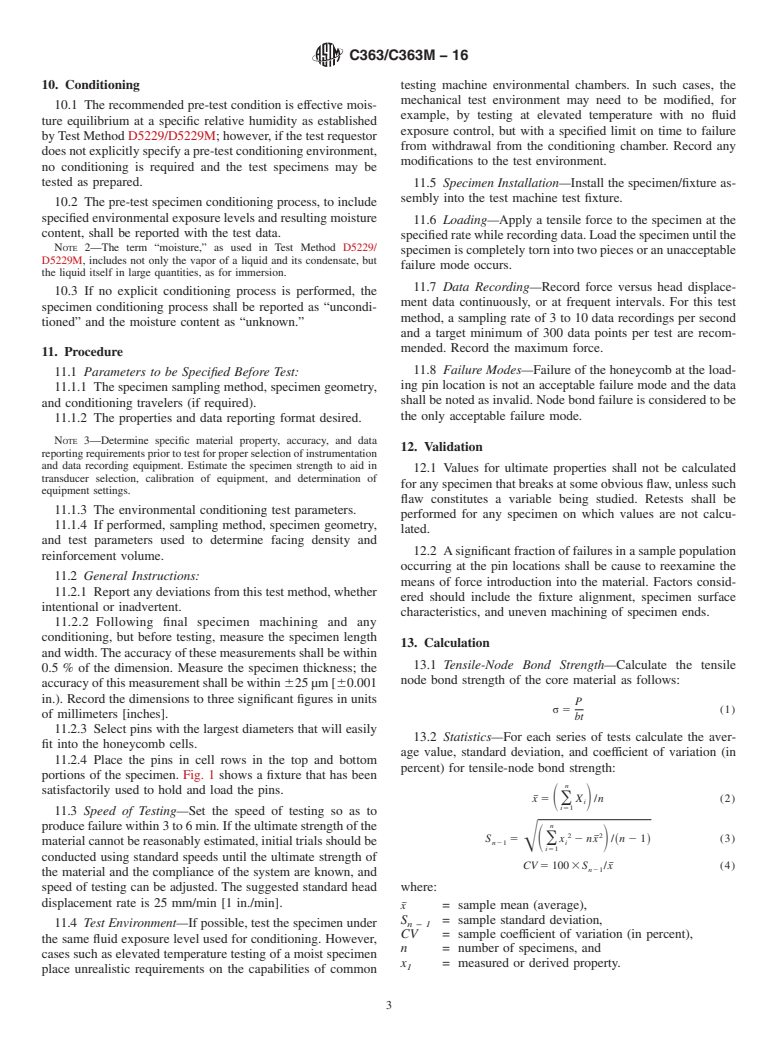

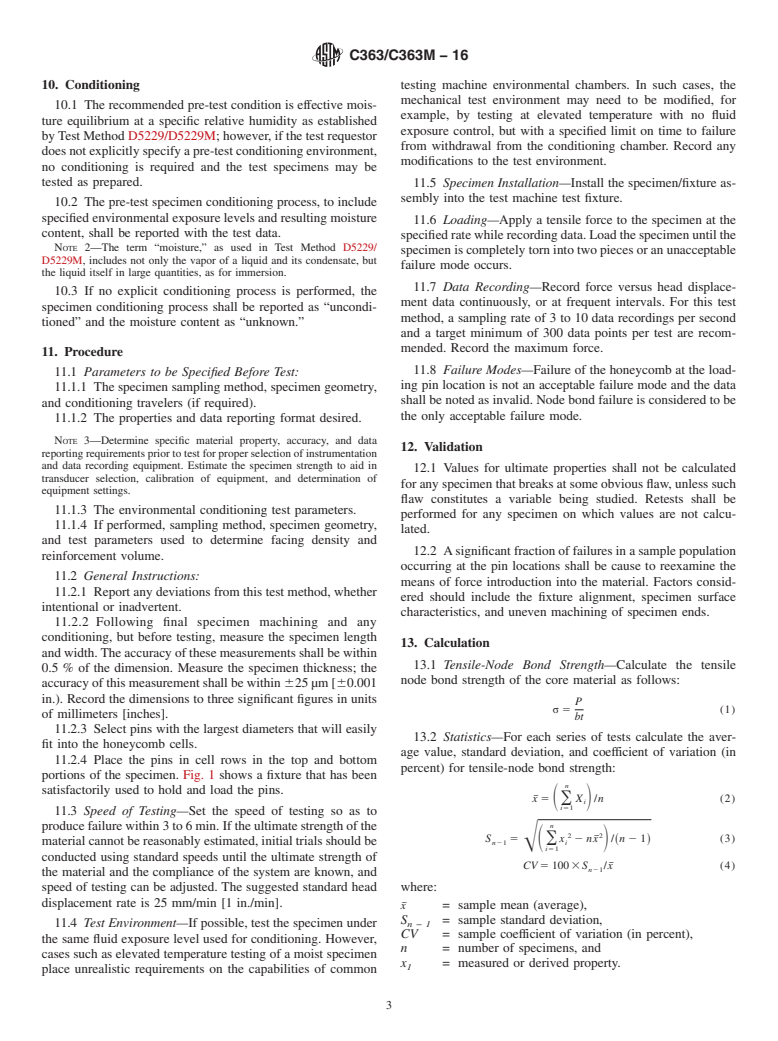

FIG. 1 Honeycomb Core Tensile-Node Bond Strength Test Setup

carried by the test specimen. This device shall be essentially

free from inertia lag at the specified rate of testing and shall

indicate the force with an accuracy over the force range(s) of

length of 260 [10 in.] with a minimum test section outside the

interest of within 61 % of the indicated value.

grips of 200 mm [8 in.]. The standard thickness of the core

7.2 Grips—Refer to Fig. 1 for an example grip configura-

slice shall be 12 6 1 mm [0.500 6 0.04 in.] for nonmetallic

tion.

cores and 16 6 1 mm [0.625 6 0.04 in.] for metallic cores.

Nonstandard thicknesses are within the scope of this test

7.3 Calipers—The caliper(s) shall use a flat anvil interface

method provided the actual thickness value is reported. Non-

tomeasurespecimenlength,widthandthickness.Theaccuracy

standard thickness specimens shall have uniform thickness

of the instruments shall be suitable for reading to within1%of

within 61mm[60.04 in.].

the sample width and thickness. For typical specimen

NOTE 1—The standard thickness values listed above are based on

geometries, an instrument with an accuracy of 625 µm

historical values for metallic and nonmetallic core thicknesses used for

[60.001 in.] is desirable for both thickness and width mea-

qualification and allowable test programs.

surements.

8.3 Specimen Preparation and Machining—Specimens

8. Sampling and Test Specimens

shall be cut such that the number of cells along the width is

constant along the specimen length. The length being defined

8.1 Sampling—The number of test specimens and the

as the specimen dimension parallel to the application of the

method of their selection depend on the purpose of the

force, Fig. 1. The specimen width shall be parallel to the node

particular test under consideration, and no general rule can be

bond areas.

given to cover all cases. However, when specimens are to be

used for acceptance tests, at least five specimens shall be

8.4 Labeling—Label the test specimens so that they will be

tested, and these specimens shall be selected from that portion

distinct from each other and traceable back to the panel of

of the material which appears to have a maximum of distorted

origin, and will neither influence the test nor be affected by it.

cellsormisalignmentofbondareas.Forstatisticallysignificant

data, consult the procedures outlined in Practice E122. Report 9. Calibration

the method of sampling.

9.1 The accuracy of all measuring equipment shall have

8.2 Geometry—The test specimens shall be 130 65mm[5 certified calibrations that are current at the time of the use of

6 0.2 in.] wide. The test specimens shall have a minimum the equipment.

C363/C363M − 16

10. Conditioning testing machine environmental chambers. In such cases, th

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C363/C363M − 09 (Reapproved 2015) C363/C363M − 16

Standard Test Method for

Node Tensile Strength of Honeycomb Core Materials

This standard is issued under the fixed designation C363/C363M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the tensile-node bond strength of honeycomb core materials.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C274 Terminology of Structural Sandwich Constructions (Withdrawn 2016)

D883 Terminology Relating to Plastics

D3878 Terminology for Composite Materials

D5229/D5229M Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite

Materials

E4 Practices for Force Verification of Testing Machines

E6 Terminology Relating to Methods of Mechanical Testing

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E456 Terminology Relating to Quality and Statistics

E1309 Guide for Identification of Fiber-Reinforced Polymer-Matrix Composite Materials in Databases (Withdrawn 2015)

E1434 Guide for Recording Mechanical Test Data of Fiber-Reinforced Composite Materials in Databases (Withdrawn 2015)

E1471 Guide for Identification of Fibers, Fillers, and Core Materials in Computerized Material Property Databases (Withdrawn

2015)

3. Terminology

3.1 Definitions—Terminology D3878 defines terms relating to high-modulus fibers and their composites.

Terminologycomposites, as C274 defineswell as terms relating to structural sandwich constructions. Terminology D883 defines

terms relating to plastics. Terminology E6 defines terms relating to mechanical testing. Terminology E456 and Practice E177 define

terms relating to statistics. In the event of a conflict between terms, Terminology D3878 shall have precedence over the other

Terminologies.

3.2 Symbols:

3.2.1 σ—tensile node strength, MPa [psi].

3.2.2 P—ultimate tensile force, N [lb].

3.2.3 b—initial width of specimen, mm [in.].

This test method is under the jurisdiction of ASTM Committee D30 on Composite Materials and is the direct responsibility of Subcommittee D30.09 on Sandwich

Construction.

Current edition approved July 1, 2015April 1, 2016. Published August 2015April 2016. Originally approved in 1955. Last previous edition approved in 20092015 as

C363 – 09.C363 – 09(2015). DOI: 10.1520/C0363_C0363M-09R15.10.1520/C0363_C0363M-16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C363/C363M − 16

3.2.4 t—thickness of specimen, mm [in.].

3.2.5 x¯—sample mean (average).

3.2.6 S —sample standard deviation.

n − 1

3.2.7 CV—sample coefficient of variation (in percent).

3.2.8 n—number of specimens.

3.2.9 x —measured or derived property.

4. Summary of Test Method

4.1 This test method consists of subjecting a honeycomb construction to a uniaxial tensile force parallel to the plane of the

honeycomb. The force is transmitted to the honeycomb through pins, which are placed in cell rows on the top and bottom portions

of one specimen.

4.2 The only acceptable failure mode for tensile-node bond strength is the tensile failure of the node-to-node honeycomb bond

within the body of the honeycomb specimen. Failure of the honeycomb material at the loading pin location is not a valid failure

mode.

5. Significance and Use

5.1 The honeycomb tensile-node bond strength is a fundamental property than can be used in determining whether honeycomb

cores can be handled during cutting, machining and forming without the nodes breaking. The tensile-node bond strength is the

tensile stress that causes failure of the honeycomb by rupture of the bond between the nodes. It is usually a peeling-type failure.

5.2 This test method provides a standard method of obtaining tensile-node bond strength data for quality control, acceptance

specification testing, and research and development.

6. Interferences

6.1 System Alignment—Excessive bending will cause premature failure. Every effort should be made to eliminate excess

bending from the test system. Bending may occur as a result of misaligned grips, poor specimen preparation, or poor alignment

of the loading fixture.

6.2 Geometry—Specific geometric factors that affect the tensile-node bond strength include cell geometry, cell size, cell wall

thickness and, specimen dimensions (length, width and thickness).

6.3 Environment—Results are affected by the environmental conditions under which the tests are conducted. Specimens tested

in various environments can exhibit significant differences in both strength behavior and failure mode. Critical environments must

be assessed independently.

7. Apparatus

7.1 Testing Machine—The testing machine shall be in accordance with Practices E4 and shall satisfy the following

requirements:

7.1.1 Testing Machine Configuration—The testing machine shall have both an essentially stationary head and a movable head.

7.1.2 Drive Mechanism—The testing machine drive mechanism shall be capable of imparting to the movable head a controlled

velocity with respect to the stationary head. The velocity of the movable head shall be capable of being regulated in accordance

with 11.3.

7.1.3 Force Indicator—The testing machine load-sensing device shall be capable of indicating the total force being carried by

the test specimen. This device shall be essentially free from inertia lag at the specified rate of testing and shall indicate the force

with an accuracy over the force range(s) of interest of within 61 % of the indicated value.

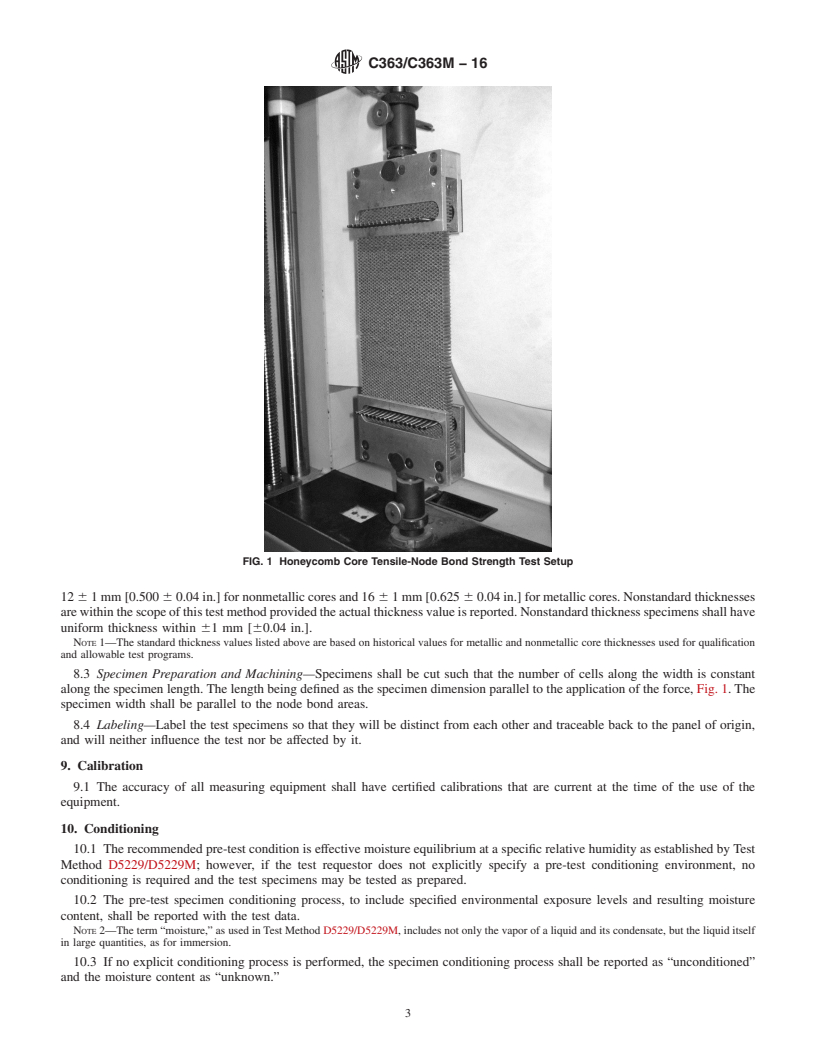

7.2 Grips—Refer to Fig. 1 for an example grip configuration.

7.3 Calipers—The caliper(s) shall use a flat anvil interface to measure specimen length, width and thickness. The accuracy of

the instruments shall be suitable for reading to within 1 % of the sample width and thickness. For typical specimen geometries,

an instrument with an accuracy of 625 μm [60.001 in.] is desirable for both thickness and width measurements.

8. Sampling and Test Specimens

8.1 Sampling—The number of test specimens and the method of their selection depend on the purpose of the particular test

under consideration, and no general rule can be given to cover all cases. However, when specimens are to be used for acceptance

tests, at least five specimens shall be tested, and these specimens shall be selected from that portion of the material which appears

to have a maximum of distorted cells or misalignment of bond areas. For statistically significant data, consult the procedures

outlined in Practice E122. Report the method of sampling.

8.2 Geometry—The test specimens shall be 130 6 5 mm [5 6 0.2 in.] wide. The test specimens shall have a minimum length

of 260 [10 in.] with a minimum test section outside the grips of 200 mm [8 in.]. The standard thickness of the core slice shall be

C363/C363M − 16

FIG. 1 Honeycomb Core Tensile-Node Bond Strength Test Setup

12 6 1 mm [0.500 6 0.04 in.] for nonmetallic cores and 16 6 1 mm [0.625 6 0.04 in.] for metallic cores. Nonstandard thicknesses

are within the scope of this test method provided the actual thickness value is reported. Nonstandard thickness specimens shall have

uniform thickness within 61 mm [60.04 in.].

NOTE 1—The standard thickness values listed above are based on historical values for metallic and nonmetallic core thicknesses used for qualification

and allowable test programs.

8.3 Specimen Preparation and Machining—Specimens shall be cut such that the number of cells along the width is constant

along the specimen length. The length being defined as the specimen dimension parallel to the application of the force, Fig. 1. The

specimen width shall be parallel to the node bond areas.

8.4 Labeling—Label the test specimens so that they will be distinct from each other and traceable back to the panel of origin,

and will neither influence the test nor be affected by it.

9. Calibration

9.1 The accuracy of all measuring equipment shall have certified calibra

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C363/C363M − 16

Standard Test Method for

Node Tensile Strength of Honeycomb Core Materials

This standard is issued under the fixed designation C363/C363M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope relating to sandwich constructions. Terminology D883 defines

terms relating to plastics. Terminology E6 defines terms

1.1 This test method covers the determination of the tensile-

relating to mechanical testing. Terminology E456 and Practice

node bond strength of honeycomb core materials.

E177 define terms relating to statistics. In the event of a

1.2 The values stated in either SI units or inch-pound units

conflict between terms, Terminology D3878 shall have prece-

are to be regarded separately as standard. The values stated in

dence over the other Terminologies.

each system may not be exact equivalents; therefore, each

3.2 Symbols:

system shall be used independently of the other. Combining

3.2.1 σ—tensile node strength, MPa [psi].

values from the two systems may result in non-conformance

with the standard. 3.2.2 P—ultimate tensile force, N [lb].

1.3 This standard does not purport to address all of the 3.2.3 b—initial width of specimen, mm [in.].

safety concerns, if any, associated with its use. It is the

3.2.4 t—thickness of specimen, mm [in.].

responsibility of the user of this standard to establish appro-

3.2.5 x¯—sample mean (average).

priate safety and health practices and determine the applica-

3.2.6 S —sample standard deviation.

bility of regulatory limitations prior to use. n − 1

3.2.7 CV—sample coefficient of variation (in percent).

2. Referenced Documents

3.2.8 n—number of specimens.

2.1 ASTM Standards:

3.2.9 x —measured or derived property.

D883 Terminology Relating to Plastics

D3878 Terminology for Composite Materials

4. Summary of Test Method

D5229/D5229M Test Method for Moisture Absorption Prop-

erties and Equilibrium Conditioning of Polymer Matrix

4.1 This test method consists of subjecting a honeycomb

Composite Materials

construction to a uniaxial tensile force parallel to the plane of

E4 Practices for Force Verification of Testing Machines

the honeycomb. The force is transmitted to the honeycomb

E6 Terminology Relating to Methods of Mechanical Testing

through pins, which are placed in cell rows on the top and

E122 Practice for Calculating Sample Size to Estimate, With

bottom portions of one specimen.

Specified Precision, the Average for a Characteristic of a

4.2 The only acceptable failure mode for tensile-node bond

Lot or Process

strength is the tensile failure of the node-to-node honeycomb

E177 Practice for Use of the Terms Precision and Bias in

bond within the body of the honeycomb specimen. Failure of

ASTM Test Methods

the honeycomb material at the loading pin location is not a

E456 Terminology Relating to Quality and Statistics

valid failure mode.

3. Terminology

5. Significance and Use

3.1 Definitions—Terminology D3878 defines terms relating

5.1 The honeycomb tensile-node bond strength is a funda-

to high-modulus fibers and their composites, as well as terms

mental property than can be used in determining whether

honeycomb cores can be handled during cutting, machining

This test method is under the jurisdiction of ASTM Committee D30 on

and forming without the nodes breaking. The tensile-node

Composite Materials and is the direct responsibility of Subcommittee D30.09 on

Sandwich Construction.

bond strength is the tensile stress that causes failure of the

Current edition approved April 1, 2016. Published April 2016. Originally

honeycomb by rupture of the bond between the nodes. It is

approved in 1955. Last previous edition approved in 2015 as C363 – 09(2015). DOI:

usually a peeling-type failure.

10.1520/C0363_C0363M-16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2 This test method provides a standard method of obtain-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ing tensile-node bond strength data for quality control, accep-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tance specification testing, and research and development.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C363/C363M − 16

6. Interferences

6.1 System Alignment—Excessive bending will cause pre-

mature failure. Every effort should be made to eliminate excess

bending from the test system. Bending may occur as a result of

misaligned grips, poor specimen preparation, or poor align-

ment of the loading fixture.

6.2 Geometry—Specific geometric factors that affect the

tensile-node bond strength include cell geometry, cell size, cell

wall thickness and, specimen dimensions (length, width and

thickness).

6.3 Environment—Results are affected by the environmental

conditions under which the tests are conducted. Specimens

tested in various environments can exhibit significant differ-

ences in both strength behavior and failure mode. Critical

environments must be assessed independently.

7. Apparatus

7.1 Testing Machine—The testing machine shall be in ac-

cordance with Practices E4 and shall satisfy the following

requirements:

7.1.1 Testing Machine Configuration—The testing machine

shall have both an essentially stationary head and a movable

head.

7.1.2 Drive Mechanism—The testing machine drive mecha-

nism shall be capable of imparting to the movable head a

controlled velocity with respect to the stationary head. The

velocity of the movable head shall be capable of being

regulated in accordance with 11.3.

7.1.3 Force Indicator—The testing machine load-sensing

device shall be capable of indicating the total force being

FIG. 1 Honeycomb Core Tensile-Node Bond Strength Test Setup

carried by the test specimen. This device shall be essentially

free from inertia lag at the specified rate of testing and shall

indicate the force with an accuracy over the force range(s) of

length of 260 [10 in.] with a minimum test section outside the

interest of within 61 % of the indicated value.

grips of 200 mm [8 in.]. The standard thickness of the core

7.2 Grips—Refer to Fig. 1 for an example grip configura-

slice shall be 12 6 1 mm [0.500 6 0.04 in.] for nonmetallic

tion.

cores and 16 6 1 mm [0.625 6 0.04 in.] for metallic cores.

Nonstandard thicknesses are within the scope of this test

7.3 Calipers—The caliper(s) shall use a flat anvil interface

method provided the actual thickness value is reported. Non-

to measure specimen length, width and thickness. The accuracy

standard thickness specimens shall have uniform thickness

of the instruments shall be suitable for reading to within 1 % of

within 61 mm [60.04 in.].

the sample width and thickness. For typical specimen

NOTE 1—The standard thickness values listed above are based on

geometries, an instrument with an accuracy of 625 µm

historical values for metallic and nonmetallic core thicknesses used for

[60.001 in.] is desirable for both thickness and width mea-

qualification and allowable test programs.

surements.

8.3 Specimen Preparation and Machining—Specimens

8. Sampling and Test Specimens

shall be cut such that the number of cells along the width is

constant along the specimen length. The length being defined

8.1 Sampling—The number of test specimens and the

as the specimen dimension parallel to the application of the

method of their selection depend on the purpose of the

force, Fig. 1. The specimen width shall be parallel to the node

particular test under consideration, and no general rule can be

bond areas.

given to cover all cases. However, when specimens are to be

used for acceptance tests, at least five specimens shall be

8.4 Labeling—Label the test specimens so that they will be

tested, and these specimens shall be selected from that portion

distinct from each other and traceable back to the panel of

of the material which appears to have a maximum of distorted

origin, and will neither influence the test nor be affected by it.

cells or misalignment of bond areas. For statistically significant

data, consult the procedures outlined in Practice E122. Report 9. Calibration

the method of sampling.

9.1 The accuracy of all measuring equipment shall have

8.2 Geometry—The test specimens shall be 130 6 5 mm [5 certified calibrations that are current at the time of the use of

6 0.2 in.] wide. The test specimens shall have a minimum the equipment.

C363/C363M − 16

10. Conditioning testing machine environmental chambers. In such cases, the

mechanical test environment may need to be modified, for

10.1 The recommended pre-test conditi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.