ASTM D7450-08

(Specification)Standard Specification for Performance of Rear Axle Gear Lubricants Intended for API Category GL-5 Service

Standard Specification for Performance of Rear Axle Gear Lubricants Intended for API Category GL-5 Service

SCOPE

1.1 This specification covers test methods and acceptance criteria for determining the acceptability of gear oils for applications which specify a lubricant meeting the performance requirements of API Category GL-5 service. Lubricants which meet these performance requirements are typically intended for use in automotive axles, particularly those containing hypoid gears, operating under various combinations of high-speed/shock-load and low-speed/high-torque conditions.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7450 −08

StandardSpecification for

Performance of Rear Axle Gear Lubricants Intended for API

Category GL-5 Service

This standard is issued under the fixed designation D7450; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Military Standards:

MIL-L-2105C Lubricating Oil, Gear, Multipurpose

1.1 This specification covers test methods and acceptance

MIL-L-2105D Lubricating Oil, Gear, Multipurpose

criteria for determining the acceptability of gear oils for

MIL-PRF-2105E Lubricating Oil, Gear, Multipurpose

applicationswhichspecifyalubricantmeetingtheperformance

2.3 ASTM Test Monitoring Center Documents:

requirements ofAPI Category GL-5 service. Lubricants which

meettheseperformancerequirementsaretypicallyintendedfor L-42 Test Procedure

use in automotive axles, particularly those containing hypoid

2.4 SAE Documents:

gears, operating under various combinations of high-speed/

J306 Automotive Gear Lubricant Viscosity Classification

shock-load and low-speed/high-torque conditions.

J2360 Lubricating Oil, Gear Multipurpose (Metric) Military

Use

1.2 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

3. Terminology

conversions to SI units that are provided for information only

and are not considered standard.

3.1 Definitions:

1.3 This standard does not purport to address all of the 3.1.1 ridging, n—on ring and pinion gears, an alteration of

the tooth surface to give a series of parallel raised and polished

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- ridges running diagonally in the direction of sliding motion,

eitherpartiallyorcompletelyacrossthetoothsurfacesofgears.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. D6121

3.1.2 rippling, n—on ring and pinion gears, an alteration of

2. Referenced Documents

the tooth surface to give an appearance of a more or less

2.1 ASTM Standards:

regular pattern resembling ripples on water or fish scales.

D130 Test Method for Corrosiveness to Copper from Petro-

D6121

leum Products by Copper Strip Test

3.1.3 pitting, n—on ring and pinion gears, small irregular

D892 Test Method for Foaming Characteristics of Lubricat-

cavities in the tooth surface, resulting from the breaking out of

ing Oils

small areas of surface metal. D6121

D5704 Test Method for Evaluation of the Thermal and

3.1.4 spalling, n—on ring and pinion gears, the breaking

Oxidative Stability of Lubricating Oils Used for Manual

out of flakes of irregular area of the tooth surface, a condition

Transmissions and Final Drive Axles

more extensive than pitting. D6121

D6121 Test Method for Evaluation of Load-Carrying Capac-

3.1.5 scoring, n—on ring and pinion gears, the rapid

ity of Lubricants Under Conditions of Low Speed and

removal of metal from the tooth surfaces caused by the tearing

High Torque Used for Final Hypoid Drive Axles

out of small contacting particles that have welded together as

D7038 Test Method for Evaluation of Moisture Corrosion

a result of metal-to-metal contact. The scored surface is

Resistance of Automotive Gear Lubricants

characterized by a matte or dull finish. D6121

This specification is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.B0 on Automotive Lubricants. Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Current edition approved May 1, 2008. Published June 2008. DOI: 10.1520/ Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

D7450-08. www.dodssp.daps.mil.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from ASTM Test Monitoring Center, 6555 Penn Avenue, Pittsburgh,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM PA 15206–4489, Attn: Administrator.

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7450−08

TABLE 1 API Category GL-5 Tests and Acceptance Criteria

Test Item Minimum Maximum

A,B

L-42 .

%Scoring, Pinion

Equal to or better (lower) than

Drive Side

the mean scoring value of the

Coast Side

passing reference oil test results

%Scoring, Ring

used to calibrate the stand

Drive Side

Coast Side

Test Method D6121 (formerly L-37) using non-lubrited

B,C

hardware

Ridging, ASTM merit rating 8 .

Rippling, ASTM merit rating 8 .

Wear, ASTM merit rating 5 .

Pitting/Spalling, ASTM merit rating 9.3 .

Scoring, ASTM merit rating 10 .

D

Test Method D7038 (formerly L-33-1)

Final rust merit rating 9.0

E

Test Method D5704 (formerly L-60-1) or L-60

Viscosity Increase, percent … 100

Pentane Insolubles, wt percent … 3.0

Toluene Insolubles, wt percent … 2.0

Test Method D892, tendency

Sequence I, mL . 20

Sequence II, mL . 50

Sequence III, mL . 20

F

Test Method D130

ASTM rating . 3

A

The latest version of this test can be obtained from the ASTM Test Monitoring Center. The Canadian version of the L-42 test follows the procedure of the L-42 test with

the modifications detailed in Annex A1, Table A1.1 of the L-42 test procedure.

B

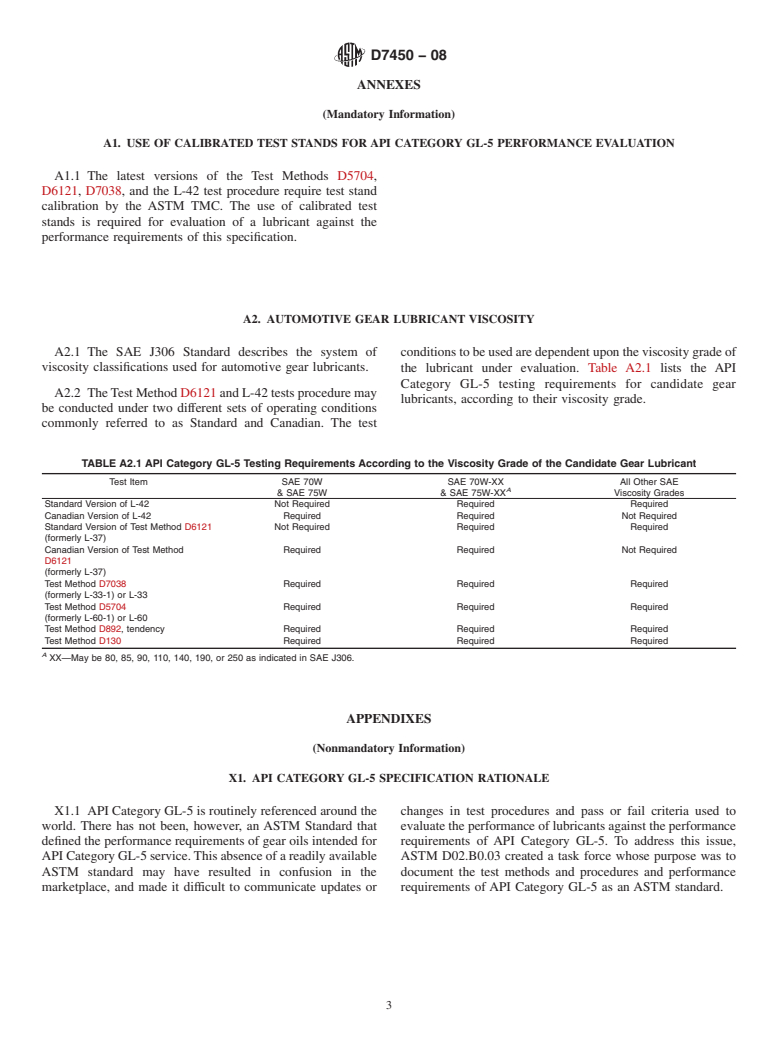

This test may be conducted under two different sets of operating conditions, commonly referred to as Standard and Canadian. The test conditions to be used are

dependant upon the viscosity grade of the lubricant under evaluation. Please see A2.2 and Table A2.1 for details as to which version of this test should be used in the

evaluation of a specific lubricant.

C

The Canadian version of the Test Method D6121 test follows the procedure of the Test Method D6121 test with the modifications detailed in Test Method D6121, Annex

A6.2, Table A6.1.

D

Candidate fluids tested previous to the development of the Test Method D7038 pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.