ASTM B943-05

(Specification)Standard Specification for Zinc and Tin Alloy Wire Used in Thermal Spraying for Electronic Applications

Standard Specification for Zinc and Tin Alloy Wire Used in Thermal Spraying for Electronic Applications

ABSTRACT

This specification covers zinc and tin alloy wire, including zinc-aluminum, zinc-aluminum-copper, zinc-tin, zinc-tin-copper an dtin-zinc, used as thermal spray wire in the electronics industry. The wire shall conform to the required chemical composition for cadmium, zinc, tin, lead, antimony, copper, aluminum, bismuth, arsenic, iron, nickel, and magnesium. The wire shall be clean and free of corrosion, adhering foreign material, scale, seams, nicks, burrs, and other defects which would interfere with the operation of thermal spraying equipment. The wire shall uncoil readily and be free of bends or kinks that would prevent its passage through the thermal spray gun. Sampling methodology should ensure that the sample slected for testing is representative of the matreial. The diameter of the wire shall be determines at the end and the beginning of each continuous wire.

SCOPE

1.1 This specification covers zinc and tin alloy wire, including zinc-aluminum, zinc-aluminum-copper, zinc-tin, zinc-tin-copper and tin-zinc, used as thermal spray wire in the electronics industry.

1.1.1 Certain alloys specified in this standard are also used as solders for the purpose of joining together two or more metals at temperatures below their melting points, and for other purposes (as noted in Annex A1). Specification B 907 covers Zinc, Tin and Cadmium Base Alloys Used as Solders which are used primarily for the purpose of joining together two or more metals at temperatures below their melting points and for other purposes (as noted in the Annex part of Specification B 907). Specification B 833 covers Zinc and Zinc Alloy Wire for Thermal Spraying (Metallizing) used primarily for the corrosion protection of steel (as noted in the Annex part of Specification B 833).

1.1.2 Tin base alloys are included in this specification because their use in the electronics industry is similar to the use of certain zinc alloys but different than the major use of the tin and lead solder compositions specified in Specification B 32.

1.1.3 These wire alloys have a nominal liquidus temperature not exceeding 850°F (455°C).

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B943 – 05

Standard Specification for

Zinc and Tin Alloy Wire Used in Thermal Spraying for

Electronic Applications

This standard is issued under the fixed designation B943; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers zinc and tin alloy wire, includ- 2.1 ASTM Standards:

ing zinc-aluminum, zinc-aluminum-copper, zinc-tin, zinc-tin- B32 Specification for Solder Metal

copper and tin-zinc, used as thermal spray wire in the elec- B833 Specification for Zinc and Zinc Alloy Wire for Ther-

tronics industry. mal Spraying (Metallizing) for the Corrosion Protection of

1.1.1 Certain alloys specified in this standard are also used Steel

as solders for the purpose of joining together two or more B899 Terminology Relating to Non-ferrous Metals and

metalsattemperaturesbelowtheirmeltingpoints,andforother Alloys

purposes (as noted in Annex A1). Specification B907 covers B907 Specification for Zinc, Tin and Cadmium BaseAlloys

Zinc,TinandCadmiumBaseAlloysUsedasSolderswhichare Used as Solders

used primarily for the purpose of joining together two or more E29 Practice for Using Significant Digits in Test Data to

metals at temperatures below their melting points and for other Determine Conformance with Specifications

purposes (as noted in the Annex part of Specification B907). E46 Test Methods for Chemical Analysis of Lead and

Specification B833 covers Zinc and Zinc Alloy Wire for Tin-Base Solder

Thermal Spraying (Metallizing) used primarily for the corro- E47 Test Methods for Chemical Analysis of Zinc Die-

sion protection of steel (as noted in the Annex part of Casting Alloys

Specification B833). E51 Method for Spectrographic Analysis of Tin Alloys by

1.1.2 Tin base alloys are included in this specification the Powder Technique

becausetheiruseintheelectronicsindustryissimilartotheuse E87 Methods for Chemical Analysis of Lead, Tin, Anti-

of certain zinc alloys but different than the major use of the tin mony, and Their Alloys (Photometry Method)

and lead solder compositions specified in Specification B32. E527 Practice for Numbering Metals and Alloys in the

1.1.3 Thesewirealloyshaveanominalliquidustemperature Unified Numbering System (UNS)

not exceeding 850°F (455°C). E536 Test Methods for ChemicalAnalysis of Zinc and Zinc

1.2 The values stated in inch-pound units are to be regarded Alloys

as the standard. The values given in parentheses are for 2.2 Federal Standard:

information only. Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1.3 This standard does not purport to address all of the 2.3 Military Standard:

safety concerns, if any, associated with its use. It is the MIL-STD-129 Marking for Shipment and Storage

responsibility of the user of this standard to become familiar

3. Terminology

with all hazards including those identified in the appropriate

Material Safety Data Sheet (MSDS) for this product/material 3.1 Terms shall be defined in accordance with Terminology

B899.

as provided by the manufacturer, to establish appropriate

safety and health practices, and determine the applicability of

regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This specification is under the jurisdiction of ASTM Committee B02 on Standards volume information, refer to the standard’s Document Summary page on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee the ASTM website.

B02.04 on Zinc and Cadmium. Withdrawn.

Current edition approved Nov. 1, 2005. Published December 2005. DOI: Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

10.1520/B0943-05. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B943 – 05

NOTE 1—By mutual agreement between supplier and purchaser, analy-

4. Classification

sis may be required and limits established for elements or compounds not

4.1 Type Designation—The type designation uses the fol-

specified in Table 1.

lowing symbols to properly identify the material:

4.1.1 Alloy Composition—The composition is identified by 8. Dimensions and Unit Weight

a two or four-letter symbol and a number. The letters typically

8.1 The dimensions and unit weight of wire are specified in

indicate the chemical symbol for the critical element(s) in the

5.1.3 and 5.1.4. The tolerance on specified outside diameter

wire and the number indicates the nominal percentage, by

shall be 65%or 60.002 in. (0.05 mm), whichever is greater.

weight, of the primary element in the wire (see Table 1).

9. Workmanship, Finish and Appearance

5. Ordering Information

9.1 The wire shall be clean and free of corrosion, adhering

5.1 Orders for material under this specification indicate the

foreign material, scale, seams, nicks, burrs, and other defects

following information, as required, to adequately describe the

which would interfere with the operation of thermal spraying

desired material.

equipment. The wire shall uncoil readily and be free of bends

5.1.1 Type designation (see 4.1),

or kinks that would prevent its passage through the thermal

5.1.2 Detailed requirements for special forms,

spray gun.

5.1.3 Dimensions of wire (see 9.2),

9.2 The wire shall be a continuous length per spool, coil, or

5.1.4 Unit weight,

drum. Splices or welds are permitted, provided that they do not

5.1.5 Packaging (see Section 17),

interfere with the thermal spray equipment or coating process.

5.1.6 Marking (see Section 16),

9.3 The starting end of each coil shall be tagged to indicate

5.1.7 ASTM Specification number and issue, marked on (a)

winding direction and to be readily identifiable with ASTM

purchase order and (b) package or spool, and

designation.

5.1.8 Special requirements, as agreed upon between sup-

plier and purchaser. 10. Sampling

10.1 Sampling methodology should ensure that the sample

6. Materials and Manufacture

selected for testing is representative of the material. The

6.1 The producer shall have each lot of wire as uniform in

method for sampling consists of one of the following methods:

quality as practicable and of satisfactory appearance in accor-

10.1.1 Analysis may be performed on finished wire, on

dance with best industrial practices.

material selected when the wire is cast, or on samples taken

from semi-finished wire.

7. Chemical Composition

10.1.1.1 If the analysis is performed on finished wire, the

7.1 The wire shall conform to the requirements prescribed frequency of sampling for determination of chemical compo-

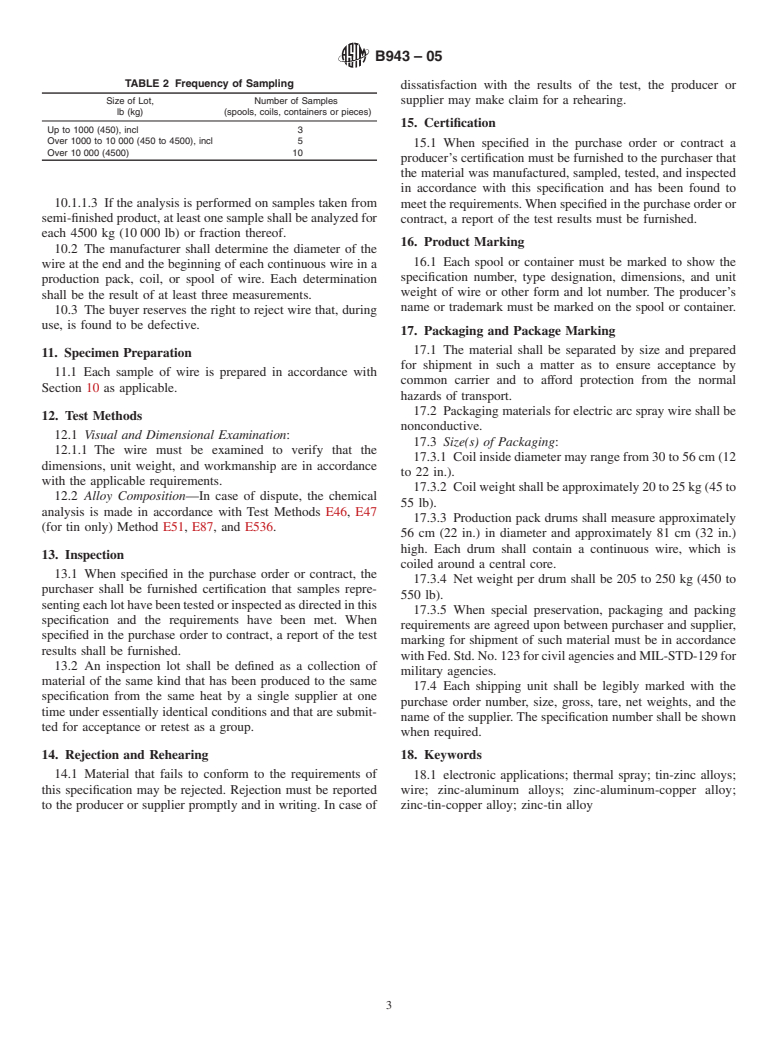

in Table 1. sition shall be in accordance withTable 2. For spools and coils,

7.2 The manufacturer shall perform chemical analyses as thesampleisobtainedbycuttingback6ft(1.8m)ofwirefrom

directed in Test Methods E536 or by other methods of at least the free end and then taking the next 6 ft for test. In other

equal accuracy to confirm that the wire conforms to the forms, an equivalent sample is selected at random from the

requirements of composition. In case of dispute, analysis by container.

Test Methods E536 shall be accepted. Analysis of alloy wires 10.1.1.2 If the analysis is performed on material selected

not covered by Test Methods E536 shall be agreed upon while the wire is being cast, at least one sample shall be

between the manufacturer and the purchaser. selected for each source of molten metal.

TABLE 1 Zinc and Zinc Alloy Wire Compositions

A,B,C

Composition % Temperature

D

FCFC UNS Cd Zn Sn Pb Sb Ag Cu Al Bi As Fe Ni Mg Solidus Liquidus

Zn 98 Z30402 0.005 REM 0.003 0.005 0.10 0.015 0.005 1.5–2.5 0.02 0.002 0.02 0.005 0.02 720 382 770 410

E

Zn 96 XXXX 0.005 REM 0.003 0.005 0.10 0.015 0.005 3.5–4.5 0.02 0.002 0.02 0.005 0.02 720 382 720 382

Zn 95 Z30502 0.005 REM 0.003 0.005 0.10 0.015 0.005 4.5–5.5 0.02 0.002 0.02 0.005 0.02 720 382 720 382

E

Zn 94 XXXX 0.005 REM 0.003 0.005 0.10 0.015 1.3–1.5 3.5–4.5 0.02 0.002 0.02 0.005 0.02 730 388 734 390

Zn 87 Z30705 0.005 REM 0.003 0.005 0.10 0.015 0.005 12.5–13.5 0.02 0.002 0.05 0.005 0.02 720 382 815 435

Zn 85 Z30702 0.005 REM 0.003 0.005 0.10 0.015 0.005 14.0–16.0 0.02 0.002 0.06 0.005 0.02 720 382 842 450

Zn/Sn 50 Z56900 0.005 REM 49.0–51.0 0.05 0.10 0.015 0.005 0.100 0.02 0.002 0.02 0.005 0.02 388 198 680 360

Zn/Sn 49 Z56930 0.005 REM 47.5–50.5 0.05 0.10 0.015 0.8–1.3 0.100 0.02 0.002 0.02 0.005 0.05 392 200 592 311

E

Sn/Zn 60 XXXX 0.005 REM 59.0–61.0 0.005 0.10 0.015 0.01 0.100 0.005 0.002 0.02 0.005 0.05 390 199 666 352

E

Sn/Zn 70 XXXX 0.005 REM 69.0–71.0 0.005 0.10 0.015 0.01 0.100 0.005 0.002 0.02 0.005 0.05 390 199 601 316

E

Sn/Zn 75 XXXX 0.004 REM 74.0–76.0 0.20 0.10 0.015 0.05 0.050 0.020 0.020 0.02 0.005 0.05 390 199 5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.