ASTM B987/B987M-20

(Specification)Standard Specification for Carbon Fiber Thermoset Polymer Matrix Composite Core (CFC) for use in Overhead Electrical Conductors

Standard Specification for Carbon Fiber Thermoset Polymer Matrix Composite Core (CFC) for use in Overhead Electrical Conductors

ABSTRACT

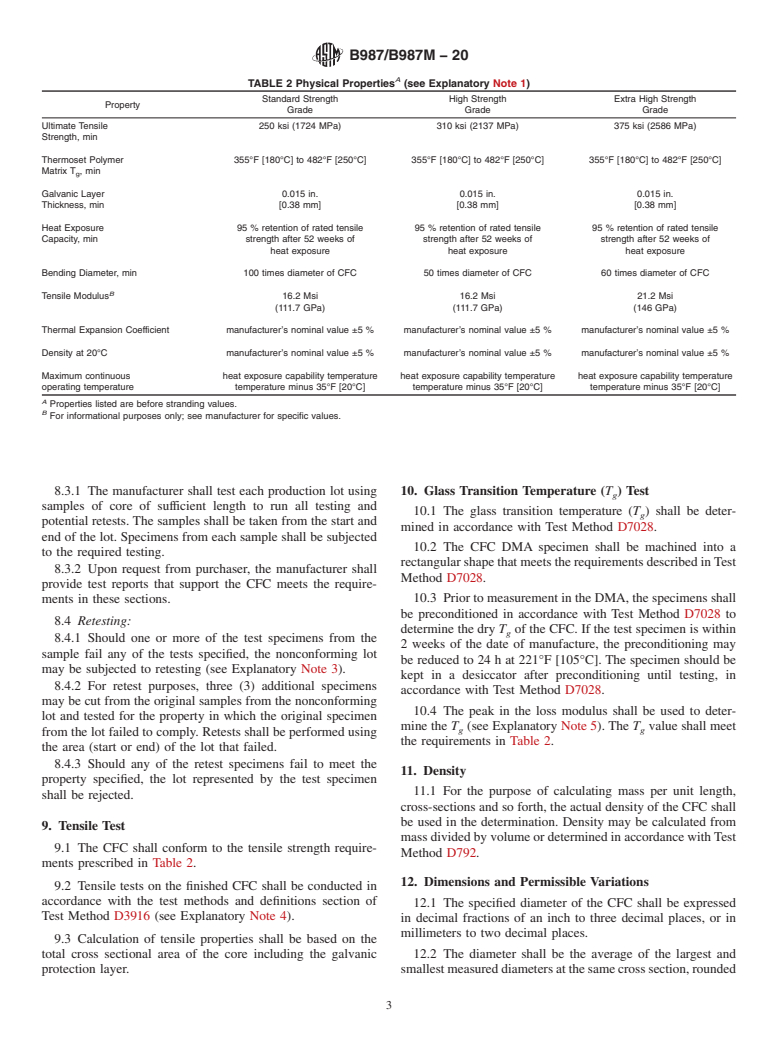

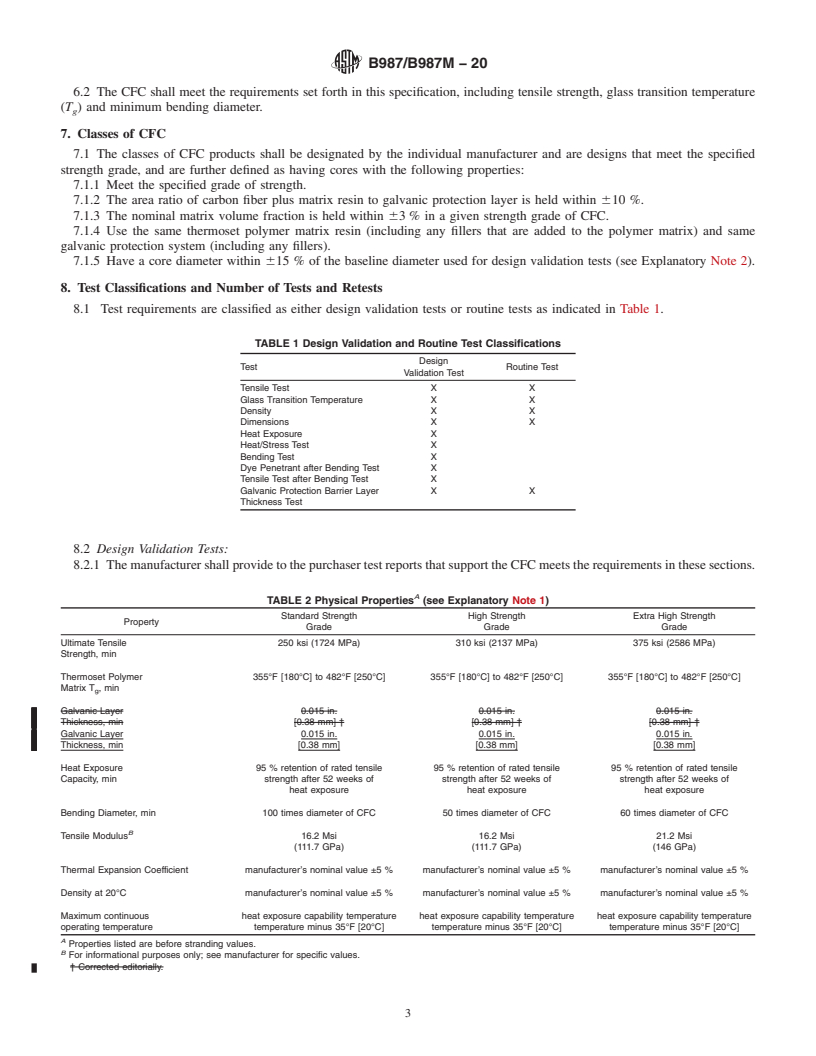

This specification covers carbon fiber composite core/thermoset (CFCC/TS) matrix for use in reinforcing or supporting overhead electrical conductors. It provides requirements for CFCC/TS materials and manufacture, including tensile strength, glass transition temperature, and minimum bending diameter. This specification also applies to classes of CFCC/TS, test classifications and number of tests and retests, actual density of the CFCC/TS, minimum thickness of the galvanic protection barrier layer, joints, workmanship, finish and appearance, inspection, certification, and packaging and package material. The tests covered by this specification are: tensile test and glass transition temperature test, bending test, dye penetrant testing after bending test, tensile test after bending test, heat exposure test, and heat/stress test.

SCOPE

1.1 This specification covers carbon fiber reinforced thermoset matrix composite core strength members for use in reinforcing or supporting overhead electrical conductors.

1.2 This specification covers carbon fiber core diameters from 0.180 to 0.500 in. [4.57 to 12.7 mm], inclusive.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B987/B987M −20

Standard Specification for

Carbon Fiber Thermoset Polymer Matrix Composite Core

1

(CFC) for use in Overhead Electrical Conductors

This standard is issued under the fixed designation B987/B987M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3916 Test Method for Tensile Properties of Pultruded

Glass-Fiber-Reinforced Plastic Rod

1.1 This specification covers carbon fiber reinforced ther-

D5117 Test Method for Dye Penetration of Solid Fiberglass

moset matrix composite core strength members for use in

Reinforced Pultruded Stock

reinforcing or supporting overhead electrical conductors.

D5423 Specification for Forced-Convection Laboratory Ov-

1.2 This specification covers carbon fiber core diameters

ens for Evaluation of Electrical Insulation

from 0.180 to 0.500 in. [4.57 to 12.7 mm], inclusive.

D7028 TestMethodforGlassTransitionTemperature(DMA

Tg) of Polymer Matrix Composites by Dynamic Mechani-

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in cal Analysis (DMA)

E29 Practice for Using Significant Digits in Test Data to

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining Determine Conformance with Specifications

values from the two systems may result in non-conformance

3. Terminology

with the standard.

3.1 Definitions of Terms Specific to This Standard:

1.4 This standard does not purport to address all of the

3.1.1 CFC (carbon fiber composite core/thermoset matrix),

safety concerns, if any, associated with its use. It is the

n—consisting of continuous carbon fiber tows held together by

responsibility of the user of this standard to establish appro-

a polymer matrix where the polymer is specifically a thermo-

priate safety, health, and environmental practices and deter-

setting polymer. The carbon fiber composite core is protected

mine the applicability of regulatory limitations prior to use.

with a galvanic protection barrier layer.

1.5 This international standard was developed in accor-

3.1.2 core, n—see CFC.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 3.1.3 design validation tests, n—the purpose of these tests is

Development of International Standards, Guides and Recom- to verify the suitability of the CFC design, materials, and

mendations issued by the World Trade Organization Technical method of manufacturing to meet the requirements in this

Barriers to Trade (TBT) Committee. specification. To ensure compliance with this specification,

these tests shall be performed on composite core samples at the

2. Referenced Documents

time of manufacture and be repeated whenever the design,

manufacturing method or the materials have changed. The

2.1 The following documents of the issue in effect on date

results of design validation tests are to be recorded and are

of material purchase form a part of this specification to the

considered valid for the whole class of CFC.

extent referenced herein.

2 3.1.4 DMA (dynamic mechanical analyzer), n—a device

2.2 ASTM Standards:

that measures the T of a polymer matrix or composite by

g

D792 Test Methods for Density and Specific Gravity (Rela-

subjecting the sample to an oscillating stress while heating the

tive Density) of Plastics by Displacement

specimen at a given heating rate.

3.1.5 galvanic protection barrier layer, n—anon-conductive

1

layer that prevents the carbon fiber of the composite core from

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on

making contact with the aluminum strands used in the conduc-

Conductors of Light Metals.

tor.

Current edition approved Aug. 1, 2020. Published August 2020. Originally

ɛ1

3.1.6 glass transition temperature (T ), n—a temperature

approved in 2014. Last previous edition approved in 2017 as B987/B987M – 17 .

g

DOI: 10.1520/B0987_B0987M-20.

where the polymer matrix properties transition from a hard,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

glassystatetoarubberystate.Thistemperatureisdefinedtobe

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the temperature at which a curve defined by plotting loss

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: B987/B987M − 17 B987/B987M − 20

Standard Specification for

Carbon Fiber Thermoset Polymer Matrix Composite Core

1

(CFC) for use in Overhead Electrical Conductors

This standard is issued under the fixed designation B987/B987M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Table 2 was corrected editorially in November 2017.

1. Scope

1.1 This specification covers carbon fiber reinforced thermoset matrix composite core strength members for use in reinforcing

or supporting overhead electrical conductors.

1.2 This specification covers carbon fiber core diameters from 0.180 to 0.500 in. [4.57 to 12.7 mm], inclusive.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein.

2

2.2 ASTM Standards:

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D3916 Test Method for Tensile Properties of Pultruded Glass-Fiber-Reinforced Plastic Rod

D5117 Test Method for Dye Penetration of Solid Fiberglass Reinforced Pultruded Stock

D5423 Specification for Forced-Convection Laboratory Ovens for Evaluation of Electrical Insulation

D7028 Test Method for Glass Transition Temperature (DMA Tg) of Polymer Matrix Composites by Dynamic Mechanical

Analysis (DMA)

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 CFC (carbon fiber composite core/thermoset matrix), n—consisting of continuous carbon fiber tows held together by a

polymer matrix where the polymer is specifically a thermosetting polymer. The carbon fiber composite core is protected with a

galvanic protection barrier layer.

3.1.2 core, n—see CFC.

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on Conductors

of Light Metals.

Current edition approved Feb. 1, 2017Aug. 1, 2020. Published March 2017August 2020. Originally approved in 2014. Last previous edition approved in 20142017 as

ɛ1

B987/B987MB987/B987M – 17 – 14. DOI: 10.1520/B0987/B0987M-17E01. DOI: 10.1520/B0987_B0987M-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B987/B987M − 20

3.1.3 design validation tests, n—the purpose of these tests is to verify the suitability of the CFC design, materials, and method

of manufacturing to meet the requirements in this specification. To ensure compliance with this specification, these tests shall be

performed on composite core samples at the time of manufacture and be repeated whenever the design, manufacturing method or

the materials have changed. The results of design validation tests are to be recorded and are considered valid for the whole class

of CFC.

3.1.4 DMA (dynamic mechanical analyzer), n—a device that measures the T of a polymer matrix or composite by subjecting

g

the sample to an oscillating stress while heating

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.