ASTM E1813-96(2007)

(Practice)Standard Practice for Measuring and Reporting Probe Tip Shape in Scanning Probe Microscopy (Withdrawn 2016)

Standard Practice for Measuring and Reporting Probe Tip Shape in Scanning Probe Microscopy (Withdrawn 2016)

SIGNIFICANCE AND USE

The shape and orientation of the probe tip determines which information can be reliably extracted from a scan. This applies to all types of scans. For instance, in surface roughness measurement, the probe tip radius has a profound effect on the spatial frequencies that the probe can reliably measure. Consequently, in reporting data from a probe microscope, it is important to obtain and include in the report information about the shape of the probe tip.

SCOPE

1.1 This practice covers scanning probe microscopy and describes the parameters needed for probe shape and orientation.

1.2 This practice also describes a method for measuring the shape and size of a probe tip to be used in scanning probe microscopy. The method employs special sample shapes, known as probe characterizers, which can be scanned with a probe microscope to determine the dimensions of the probe. Mathematical techniques to extract the probe shape from the scans of the characterizers have been published (2-5).

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This practice covers scanning probe microscopy and describes the parameters needed for probe shape and orientation.

Formerly under the jurisdiction of Committee E42 on Surface Analysis, this practice was withdrawn in July 2016 in accordance with Section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1813 − 96(Reapproved 2007)

Standard Practice for

Measuring and Reporting Probe Tip Shape in Scanning

Probe Microscopy

This standard is issued under the fixed designation E1813; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

An image produced by a stylus scanning in close proximity to a surface is usually not an exact

replica of the surface. The data are subject to a type of distortion called dilation. The amount of

dilation depends on the shape and the orientation of the probe as well as the surface topography (1).

Analysis of the scanned probe images thus requires knowledge of the probe shape and orientation.

1. Scope 3.1.1 activelength—lengthoftheregionoftheprobetipthat

could come into contact with the sample during a scan, and is

1.1 This practice covers scanning probe microscopy and

set by the height of the tallest feature encountered, and it

describes the parameters needed for probe shape and orienta-

should be less than the probe length (see Fig. 1).

tion.

3.1.2 characterized length—the region of the probe whose

1.2 This practice also describes a method for measuring the

shape has been measured with a probe characterizer (see Fig.

shape and size of a probe tip to be used in scanning probe

1).

microscopy. The method employs special sample shapes,

known as probe characterizers, which can be scanned with a 3.1.3 concave probe—a probe that is not convex.

probe microscope to determine the dimensions of the probe.

3.1.4 convex probe—the probe is convex if for any two

Mathematical techniques to extract the probe shape from the

points in the probe, the straight line between the points lies in

scans of the characterizers have been published (2-5).

the probe.

1.3 This standard does not purport to address all of the

3.1.4.1 Discussion—Conical and cylindrical probes are

safety concerns, if any, associated with its use. It is the

convex,whileflaredprobesarenot.Minorimperfectionsinthe

responsibility of the user of this standard to establish appro-

probe, caused for instance by roughness of the probe surface,

priate safety and health practices and determine the applica-

should not be considered in determining whether a probe is

bility of regulatory limitations prior to use.

convex.

3.1.5 dilation—thedilationofaset Abyaset Bisdefinedas

2. Referenced Documents

3 follows:

2.1 ASTM Standards:

F1438TestMethodforDeterminationofSurfaceRoughness A1B 5 ¯~A1b! (1)

by Scanning Tunneling Microscopy for Gas Distribution

b{B

System Components

The image I produced by a probe tip T scanning a surface

3. Terminology

S is I = S +(−T) (6). This is the surface obtained if an in-

3.1 Definitions:

verted image of the tip is placed at all points on the surface.

The envelope produced by these inverted tip images is the

This practice is under the jurisdiction of ASTM Committee E42 on Surface image of the surface (3).

Analysis and is the direct responsibility of Subcommittee E42.14 on STM/AFM.

3.1.6 erosion—the erosion of a set A by a set B is defined as

Current edition approved June 1, 2007. Published June 2007. Originally

approved in 1996. Last previous edition approved in 2002 as E1813–96(2002). follows:

DOI: 10.1520/E1813-96R07.

A 2 B 5 ˘ A 2 b . (2)

2 ~ !

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this document.

b{B

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

An upper bound for the surface S is I−(− T), where I is

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the image and− T is an inverted image of the probe tip (5).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1813 − 96 (2007)

FIG. 1 Probe Tip Characterization

3.1.7 feedback-induced distortion—distortion of a scan

trace arising from the inability of the probe microscope

feedback to maintain close proximity between the tip and

surface, which can be caused by scanning too quickly and

changes with scan speed and scan direction.

3.1.8 flexing-induced distortion—distortion of a scan trace

arising from flexing of the probe or shank during scanning.

3.1.9 probe apex—end of the probe tip, which is farthest

from the shank.

3.1.9.1 Discussion—For some shapes, the position of the

apex is somewhat arbitrary. The apex position coincides with

the origin of the coordinate system used to describe the probe.

FIG. 2 Probe Tip Coordinates

3.1.10 probe characterizer—a structure designed to allow

extraction of the probe tip shape from a scan of the character-

izer.

3.1.11 probe flank—side of the probe in the region between

the apex and the shank.

3.1.12 probe length L—distance between the apex and the

t

shank (see Fig. 1).

3.1.13 probe shank—stiff structure supporting the probe tip.

3.1.14 probe stiffness—resistance of the probe from flexing

caused by lateral forces, expressed as a force constant (N/m)

describing the lateral flexing of the probe under an impressed

force.

3.1.15 reconstruction—an estimate of the surface topogra-

phy determined by eroding the image with the probe tip shape.

3.1.15.1 Discussion—The closeness of the approximation

depends on both probe shape and surface topography. Regions

in which the estimate is not close are known as unreconstruc-

table regions or dead zones.

4. Coordinate System

4.1 The coordinate system used to describe the probe shape

FIG. 3 Coordinates Relative to Cantilever Orientation

is shown in Fig. 2 and Fig. 3. It is a three-dimensional,

right-handed, Cartesian system with mutually orthogonal axes

x, y and z. Distance along the axes is measured in nanometers 4.2 Iftheprobeaxisistiltedrelativetothesample,Eulerian

(nm) or micrometres (µm). In many cases, these axes will be angles should be used to express the orientation of the probe.

parallel to the corresponding axes used for the sample. The z These angles are shown in Fig. 4. They may be expressed in

axis is chosen to be parallel to the axis of the probe. If the degrees. The order in which the rotations are applied is

probe is mounted on a cantilever, the orientation of the x and y important.Thefirstisaboutthe zaxisthroughtheangle φ.The

axes relative to the cantilever may be relevant because these second is about the x' axis through the angle θ. The final

cantilevers are often tilted. rotation is about the z" axis through the angle ψ. The positive

E1813 − 96 (2007)

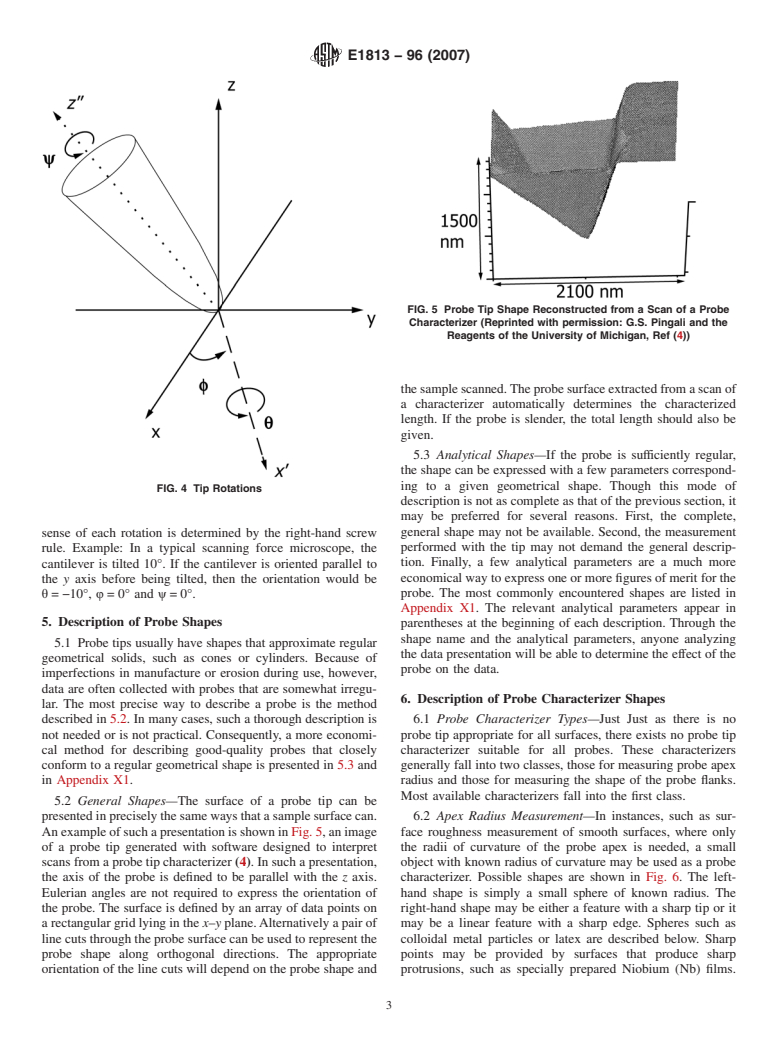

FIG. 5 Probe Tip Shape Reconstructed from a Scan of a Probe

Characterizer (Reprinted with permission: G.S. Pingali and the

Reagents of the University of Michigan, Ref (4))

thesamplescanned.Theprobesurfaceextractedfromascanof

a characterizer automatically determines the characterized

length. If the probe is slender, the total length should also be

given.

5.3 Analytical Shapes—If the probe is sufficiently regular,

the shape can be expressed with a few parameters correspond-

ing to a given geometrical shape. Though this mode of

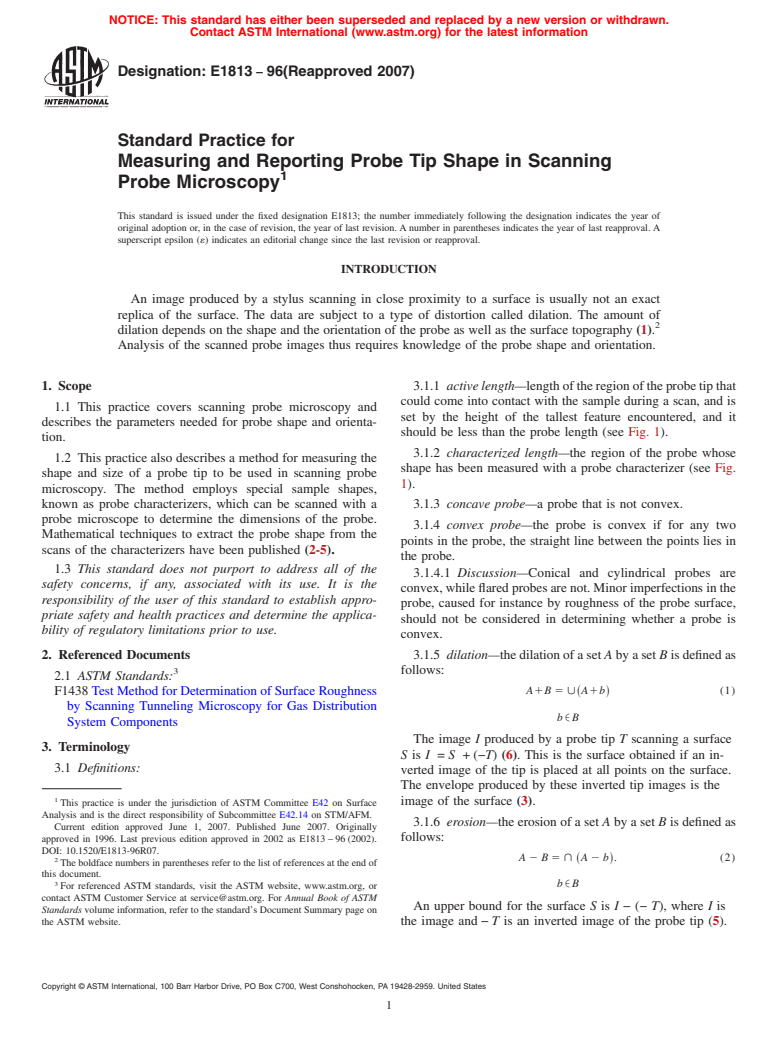

FIG. 4 Tip Rotations

descriptionisnotascompleteasthatoftheprevioussection,it

may be preferred for several reasons. First, the complete,

general shape may not be available. Second, the measurement

sense of each rotation is determined by the right-hand screw

performed with the tip may not demand the general descrip-

rule. Example: In a typical scanning force microscope, the

tion. Finally, a few analytical parameters are a much more

cantilever is tilted 10°. If the cantilever is oriented parallel to

economicalwaytoexpressoneormorefiguresofmeritforthe

the y axis before being tilted, then the orientation would be

probe. The most commonly encountered shapes are listed in

θ=−10°, φ=0° and ψ=0°.

Appendix X1. The relevant analytical parameters appear in

5. Description of Probe Shapes

parentheses at the beginning of each description. Through the

shape name and the analytical parameters, anyone analyzing

5.1 Probe tips usually have shapes that approximate regular

the data presentation will be able to determine the effect of the

geometrical solids, such as cones or cylinders. Because of

probe on the data.

imperfections in manufacture or erosion during use, however,

data are often collected with probes that are somewhat irregu-

6. Description of Probe Characterizer Shapes

lar. The most precise way to describe a probe is the method

described in 5.2. In many cases, such a thorough description is 6.1 Probe Characterizer Types—Just Just as there is no

not needed or is not practical. Consequently, a more economi- probe tip appropriate for all surfaces, there exists no probe tip

cal method for describing good-quality probes that closely characterizer suitable for all probes. These characterizers

conform to a regular geometrical shape is presented in 5.3 and generally fall into two classes, those for measuring probe apex

in Appendix X1. radius and those for measuring the shape of the probe flanks.

Most available characterizers fall into the first class.

5.2 General Shapes—The surface of a probe tip can be

presentedinpreciselythesamewaysthatasamplesurfacecan. 6.2 Apex Radius Measurement—In instances, such as sur-

AnexampleofsuchapresentationisshowninFig.5,animage face roughness measurement of smooth surfaces, where only

of a probe tip generated with software designed to interpret the radii of curvature of the probe apex is needed, a small

scansfromaprobetipcharacterizer (4).Insuchapresentation, object with known radius of curvature may be used as a probe

the axis of the probe is defined to be parallel with the z axis. characterizer. Possible shapes are shown in Fig. 6. The left-

Eulerian angles are not required to express the orientation of hand shape is simply a small sphere of known radius. The

the probe. The surface is defined by an array of data points on right-hand shape may be either a feature with a sharp tip or it

arectangulargridlyinginthe x–yplane.Alternativelyapairof may be a linear feature with a sharp edge. Spheres such as

linecutsthroughtheprobesurfacecanbeusedtorepresentthe colloidal metal particles or latex are described below. Sharp

probe shape along orthogonal directions. The appropriate points may be provided by surfaces that produce sharp

orientation of the line cuts will depend on the probe shape and protrusions, such as specially prepared Niobium (Nb) films.

E1813 − 96 (2007)

FIG. 6 Point and Edge Characterizers

Sharp linear features may be produced from crystalline sur-

faces through special etching procedures.

6.3 Probe Flank Measurement—If the characterized length

must be more than a few nanometres, then a flared

characterizer, shown in Fig. 7, should be used. Its height, H ,

c

should be greater than the height of the tallest object to be

scanned.When the characterizer is scanned with the probe, the

image will contain probe tip images, which can be extracted

with suitable software. These flared features may be either

one-dimensionallinearstructuresortwo-dimensionalplateaus.

FIG. 8 Colloidal Gold Probe Characterizer (Reprinted with per-

6.4 Embodiments of Probe Characterizers:

mission: A.T. Giberson, Ref (6))

6.4.1 Gold Colloid—Colloidal gold particles have multiple

uses as SPM imaging standard because they are

incompressible, stable monodispersive, and spherical. The 6.4.2 Strontium Titanate Crystal (SrTiO )—A high-

particles are available with three different diameters: 5.72 nm, temperature-treated(305)surfaceofSrTiO resultsinasurface

14.33 nm, and 27.96 nm. Users can choose different sizes with alternating (101) and (103) crystal planes and thus form

depending on their applications. The particles can be absorbed large terraces. As shown in Fig. 9, the surface was character-

on a substrate (such as mica) along with biomolecules. The ized by transmission electron microscopy (TEM) and revealed

uniform spherical shape of gold particles will give useful theterraceswithdefinedinclinationswithrespecttothesurface

information about the nano-geometry of the probe tip (6). Fig. plan (305) of+14° and−11.6°, respectively. Reference (7) can

8 shows anAFM image of gold colloids in distilled/deionized be used to characterize the radius of a probe apex. Fig. 10

water and adsorbed on to treated mica surface.All three sized shows a series of profiles recorded with different commercial

particles are present in the 1 by 1-µm scanned area. Image probes. The topmost profile demonstrates a Si N probe that

3 4

distortion due to tip artifacts are present as well. hasasharpprobeapex,whileProfile2and3revealatruncated

FIG. 7 Flared Probe Tip Characterizer

E1813 − 96 (2007)

FIG. 9 Transmission Electron Microscopy (TEM) Image of a (010) Cross Section Through a SrTiO Crystal (Reprinted with permission:

M. Moller, Ref (7))

Fig. 11 shows anAFM image of the Nb thin film. If the probe

apex of the AFM tip is assumed to be spherical, it is possible

to determine the radius of the probe apex from a cross section

of the AFM image. The radius of the probe apex can be

calculated to be as follows:

2 2

R 5 h 1 w/2 /2h (3)

~ ~ ! !

where

w = width of the feature, and

h = height (see Fig. 12).

FIG. 10 Two-dimensional Profiles Obtained with a Variety of

Probe Tips (Reprinted with permission: M. Moller, Ref (7))

probe apex of other Si N tips. Both an Si tip and e-beam-

3 4

deposited tip have a rounded probe apex as shown in the rest

of the profiles.

6.4.3 Polycrystalline Nb Film—An Nb thin film (8,9) de-

posited on a silicon wafer by an electron-beam evaporation

method has a dense columnar microstructure. The surface was

characterized using a field-emission SEM (FESEM) and found

to be composed of very sharp pyramidal features. These

features are sharp enough that AFM images of this surface

FIG. 11 AFM Image of an e-beam-Evaporated Nb Thin Film (Re-

correspond to images of tip, instead of the thin film surface. printed with permission: K.L. Westra, Ref (8))

E1813 − 96 (2007)

FIG. 12 A Cross Section Through the Line 1-1 in Fig. 11 (Re-

printed with permission: K.L. Westra, Ref (8))

6.4.4 Polystyrene Latex Particles—The polystyrene latex

particles (10) have uniform spherical shape with size distribu-

tions ranging from 60 to 500 nm. Using appropriate tip shape

extraction software, the geometry of the probe shape can be

extracted as with the colloidal gold. The latex particles must

adhere stably to the substrate to allow re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.