ASTM C1695-10(2015)

(Specification)Standard Specification for Fabrication of Flexible Removable and Reusable Blanket Insulation for Hot Service

Standard Specification for Fabrication of Flexible Removable and Reusable Blanket Insulation for Hot Service

ABSTRACT

This specification details the minimum property, design and construction requirements for flexible removable and reusable blanket insulation for hot service of above ambient temperatures. Insulation must be one of the following flexible fibrous materials acceptable for the maximum temperature of service: high temperature fiber blanket of any type or grade; needled glass fiber mechanically bonded felt; and mineral fiber blanket of the type suitable for the application. The material for the outer jacket liner and straps, where used, shall either be plain woven glass fiber fabric or that which has been treated with a water resistant compound such as silicone or fluorocarbon, and conforms with the following requirements: minimum weight; breaking strength; tear strength; burst strength; abrasion resistance; color; temperature resistance; and flame resistance.

SCOPE

1.1 This specification covers the minimum requirements for materials and fabrication of flexible removable and reusable blanket insulation for hot service, from above ambient temperatures to 1000°F (538°C).

1.2 This specification separately addresses both outdoor and indoor applications.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1695 −10 (Reapproved 2015)

Standard Specification for

Fabrication of Flexible Removable and Reusable Blanket

Insulation for Hot Service

This standard is issued under the fixed designation C1695; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C1263 Test Method for Thermal Integrity of Flexible Water

Vapor Retarders

1.1 This specification covers the minimum requirements for

D3389 Test Method for Coated FabricsAbrasion Resistance

materials and fabrication of flexible removable and reusable

(Rotary Platform Abrader)

blanket insulation for hot service, from above ambient tem-

D3776/D3776M Test Methods for Mass Per Unit Area

peratures to 1000°F (538°C).

(Weight) of Fabric

1.2 This specification separately addresses both outdoor and

D3786/D3786M Test Method for Bursting Strength of Tex-

indoor applications.

tile Fabrics—Diaphragm Bursting StrengthTester Method

1.3 The values stated in inch-pound units are to be regarded D5034 TestMethodforBreakingStrengthandElongationof

Textile Fabrics (Grab Test)

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only D5035 Test Method for Breaking Force and Elongation of

Textile Fabrics (Strip Method)

and are not considered standard.

D5189 Test Method for Temperature Corresponding To

1.4 This standard does not purport to address all of the

Vapor-Liquid Ratio Of 20 For Gasoline And Gasoline-

safety concerns, if any, associated with its use. It is the

Oxgenate Blends (Bomb Method) (Withdrawn 1993)

responsibility of the user of this standard to establish appro-

D5587 Test Method for Tearing Strength of Fabrics by

priate safety and health practices and determine the applica-

Trapezoid Procedure

bility of regulatory limitations prior to use.

D6413/D6413M Test Method for Flame Resistance of Tex-

tiles (Vertical Test)

2. Referenced Documents

2.2 Other Standards:

2.1 ASTM Standards:

R

3E Plus Insulation Thickness Computer Program North

C168 Terminology Relating to Thermal Insulation

American Insulation Manufacturers Association

C553 Specification for Mineral Fiber Blanket Thermal Insu-

(NAIMA)

lation for Commercial and Industrial Applications

MIL-C-20079H Military Specification Cloth, Glass; Tape,

C680 Practice for Estimate of the Heat Gain or Loss and the

Textile Glass and Thread, Glass and Wire Reinforced

Surface Temperatures of Insulated Flat, Cylindrical, and

Glass

Spherical Systems by Use of Computer Programs

C892 Specification for High-Temperature Fiber Blanket

3. Terminology

Thermal Insulation

C1086 Specification for Glass Fiber Mechanically Bonded 3.1 General—Definitions included in Terminology C168

shall apply to the terms used in this specification.

Felt Thermal Insulation

C1129 Practice for Estimation of Heat Savings by Adding

3.2 Definitions of Terms Specific to This Standard:

Thermal Insulation to Bare Valves and Flanges

3.2.1 coated fabric, n—Awoven fabric coated with a rubber

or plastic compound such that the woven fabric material itself

is not exposed to the environment.

This specification is under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.40 on

Insulation Systems.

Current edition approved Sept. 1, 2015. Published October 2015. Originally The last approved version of this historical standard is referenced on

approved in 2009. Last previous edition approved in 2010 as C1695-10. DOI: www.astm.org.

10.1520/C1695-10R15. Available from North American Insulation Manufacturers Association

For referenced ASTM standards, visit the ASTM website, www.astm.org, or (NAIMA), 11 Canal Center Plaza, Suite 103, Alexandria, VA 22314, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.naima.org.

Standards volume information, refer to the standard’s Document Summary page on Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

the ASTM website. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1695−10 (2015)

3.2.2 D-ring, n—a section of heavy wire which forms a Mineral Fiber Blanket, per Specification C553, of the Type

complete loop in either a rectangular shape or the shape of the suitable for the application.

capital letter “D”, that is used in removable insulation blankets

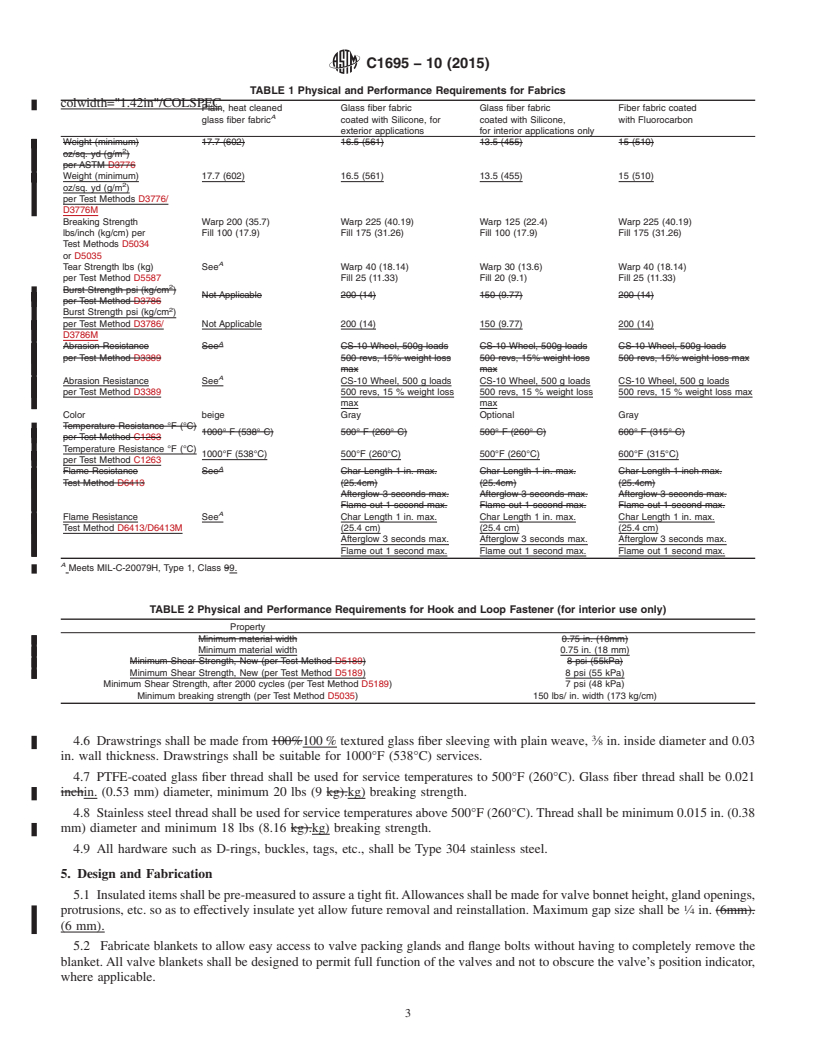

4.2 Material for the outer jacket liner and straps, where

for attaching a fabric strap that secures the blanket around a

used,shallbewovenglassfibercloththathasbeentreatedwith

pipe component or piece of equipment.

a water resistant compound, such as silicone or fluorocarbon,

3.2.3 hook and loop fastener, n—a woven molded fabric

thatissuitableforbothinteriorandexterioruse,andhavingthe

material that has small hooks on one part and small loops on

properties as shown in Table 1.

the other such that, when pressed together, they adhere to one

4.3 Material for the inner jacket shall be the same as for the

another and further, requiring a significant force to separate on

outer jacket for surface temperatures less than 500°F

another.

(260°F°C).

3.2.4 lacing anchor, n—a metal disk, located on the outside

4.3.1 For surfaces from 501°F (261°C) to 1000°F (538°C)

of an insulation blanket, that is secured to a pin that passes

where leaks of process fluids are not expected, the inner layer

through the blanket; the assembly is used to wrap tire wire

and gussets shall be one of the following:

around so as to secure an insulation blanket around a pipe

4.3.1.1 a plain, heat cleaned, glass fiber fabric,

component or piece of equipment.

4.3.1.2 a Type 304 stainless steel wire knitted mesh made

3.2.5 lacing hook, n—a metal hook that is located on the

from 0.008 in. (0.20 mm) diameter wire with nominal 6 to 8

outside surface of an insulation blanket and that is secured

openings per in.

through the blanket; tie wire is wrapped around it so as to

4.3.2 For surfaces from 501°F (261°C) to 1000°F (538°C)

secure an insulation blanket around a pipe component or piece

where leaks of process fluids are expected, such as flange pairs

of equipment.

and valves, the inner layer and gussets shall be as specified in

3.2.6 removable and reusable blanket insulation, n—An

4.3.1 and 4.3.1.1 above but also with Type 304 stainless steel

insulation blanket, encased in woven fabric and/or woven wire

foil that has a minimum thickness of 0.001 in. (0.025 mm).

mesh, that has attachment mechanisms designed to allow the

This foil shall be placed between the insulation material and

assembly to be installed, then later removed and reinstalled,

the outer fabric or wire mesh.

without using any new insulation or fabric materials.

4.4 Lacing hooks and lacing anchors shall be made of 12

Gauge, Type 304 stainless steel.

4. Materials

4.5 Tie-Down Straps:

4.1 Insulation shall be of a flexible fibrous material accept-

able for the maximum temperature of the application. Accept- 4.5.1 Outdoor Applications—These tie-down straps shall be

able materials must be one of the following: constructed of one of the following three types of material: (1)

High Temperature Fiber Blanket per Specification C892, any the same material as the outer jacket, (2) a woven glass fiber

Type or Grade fabric, or (3) a tape of suitable thickness with the same coating

Needled Glass Fiber Mechanically Bonded Felt per Specifica- as the outer jacket material. If the same material as the outer

tion C1086 jacket is used, then a double thickness is required with an edge

TABLE 1 Physical and Performance Requirements for Fabrics

Plain, heat cleaned Glass fiber fabric Glass fiber fabric Fiber fabric coated

A

glass fiber fabric coated with Silicone, for coated with Silicone, with Fluorocarbon

exterior applications for interior applications only

Weight (minimum) 17.7 (602) 16.5 (561) 13.5 (455) 15 (510)

oz/sq. yd (g/m )

per Test Methods D3776/

D3776M

Breaking Strength Warp 200 (35.7) Warp 225 (40.19) Warp 125 (22.4) Warp 225 (40.19)

lbs/inch (kg/cm) per Fill 100 (17.9) Fill 175 (31.26) Fill 100 (17.9) Fill 175 (31.26)

Test Methods D5034

or D5035

A

Tear Strength lbs (kg) See Warp 40 (18.14) Warp 30 (13.6) Warp 40 (18.14)

per Test Method D5587 Fill 25 (11.33) Fill 20 (9.1) Fill 25 (11.33)

Burst Strength psi (kg/cm )

per Test Method D3786/ Not Applicable 200 (14) 150 (9.77) 200 (14)

D3786M

A

Abrasion Resistance See CS-10 Wheel, 500 g loads CS-10 Wheel, 500 g loads CS-10 Wheel, 500 g loads

per Test Method D3389 500 revs, 15 % weight loss 500 revs, 15 % weight loss 500 revs, 15 % weight loss max

max max

Color beige Gray Optional Gray

Temperature Resistance °F (°C)

1000°F (538°C) 500°F (260°C) 500°F (260°C) 600°F (315°C)

per Test Method C1263

A

Flame Resistance See Char Length 1 in. max. Char Length 1 in. max. Char Length 1 in. max.

Test Method D6413/D6413M (25.4 cm) (25.4 cm) (25.4 cm)

Afterglow 3 seconds max. Afterglow 3 seconds max. Afterglow 3 seconds max.

Flame out 1 second max. Flame out 1 second max. Flame out 1 second max.

A

Meets MIL-C-20079H, Type 1, Class 9.

C1695−10 (2015)

trimsewninplacealongbothedges.Edgetrimshallbeapplied 5.7 Any single blanket or blanket piece shall not exceed 45

to prevent exposed fabric edges. Ends of the straps shall be lbs (20.4 kg). Blankets with a finished weight of 45 lbs (20.4

1 1

turned under ⁄4 (6.35 mm) to ⁄2 (13 mm) inch and double- kg) or less shall be fabricated in one piece.

stitched to prevent unraveling.

4.5.2 Indoor Applications Only—These tie-down straps 6. Construction

shall be constructed either of the same materials as for Outdoor

6.1 Outdoor Applications:

Applications, specified in 4.5.1, or of a hook and loop fastener

6.1.1 All fabric seams shall be either sewn or held together

material with a maximum use temperature of 220°F (104°C).

with 16 gauge type 304 stainless steel hog ring staples on 1 to

Minimum width of the hook and loop fastener material shall be

3 in. (25 to 75 mm) center

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1695 − 10 C1695 − 10 (Reapproved 2015)

Standard Specification for

Fabrication of Flexible Removable and Reusable Blanket

Insulation for Hot Service

This standard is issued under the fixed designation C1695; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the minimum requirements for materials and fabrication of flexible removable and reusable blanket

insulation for hot service, from above ambient temperatures to 1000°F (538°C).

1.2 This specification separately addresses both outdoor and indoor applications.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C168 Terminology Relating to Thermal Insulation

C553 Specification for Mineral Fiber Blanket Thermal Insulation for Commercial and Industrial Applications

C680 Practice for Estimate of the Heat Gain or Loss and the Surface Temperatures of Insulated Flat, Cylindrical, and Spherical

Systems by Use of Computer Programs

C892 Specification for High-Temperature Fiber Blanket Thermal Insulation

C1086 Specification for Glass Fiber Mechanically Bonded Felt Thermal Insulation

C1129 Practice for Estimation of Heat Savings by Adding Thermal Insulation to Bare Valves and Flanges

C1263 Test Method for Thermal Integrity of Flexible Water Vapor Retarders

D3389 Test Method for Coated Fabrics Abrasion Resistance (Rotary Platform Abrader)

D3776D3776/D3776M Test Methods for Mass Per Unit Area (Weight) of Fabric

D3786D3786/D3786M Test Method for Bursting Strength of Textile Fabrics—Diaphragm Bursting Strength Tester Method

D5034 Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

D5035 Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method)

D5189 Test Method for Temperature Corresponding To Vapor-Liquid Ratio Of 20 For Gasoline And Gasoline-Oxgenate Blends

(Bomb Method) (Withdrawn 1993)

D5587 Test Method for Tearing Strength of Fabrics by Trapezoid Procedure

D6413D6413/D6413M Test Method for Flame Resistance of Textiles (Vertical Test)

2.2 Other Standards:

R 4

3E Plus Insulation Thickness Computer Program North American Insulation Manufacturers Association (NAIMA)

MIL-C-20079H Military Specification Cloth, Glass; Tape, Textile Glass and Thread, Glass and Wire Reinforced Glass

This specification is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.40 on Insulation

Systems.

Current edition approved May 1, 2010Sept. 1, 2015. Published June 2010October 2015. Originally approved in 2009. Last previous edition approved in 20092010 as

C1695–09.C1695-10. DOI: 10.1520/C1695-10.10.1520/C1695-10R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Available from North American Insulation Manufacturers Association (NAIMA), 4411 Canal Center Plaza, Suite 310103, Alexandria, VA 22314, http://www.naima.org

http://www.naima.org.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, DLA Document Services, Building 4/D, 700 Robbins Ave., Philadelphia, PA

19111-5098, http://www.dodssp.daps.mil.19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1695 − 10 (2015)

3. Terminology

3.1 General—Definitions included in Terminology C168 shall apply to the terms used in this specification.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 removable and reusable blanket insulation, n—An insulation blanket, encased in woven fabric and / or woven wire mesh,

that has attachment mechanisms designed to allow the assembly to be installed, then later removed and reinstalled, without using

any new insulation or fabric materials.

3.2.1 coated fabric, n—A woven fabric coated with a rubber or plastic compound such that the woven fabric material itself is

not exposed to the environment.

3.2.2 D-ring, n—a section of heavy wire which forms a complete loop in either a rectangular shape or the shape of the capital

letter “D”, that is used in removable insulation blankets for attaching a fabric strap that secures the blanket around a pipe

component or piece of equipment.

3.2.3 hook and loop fastener, n—a woven molded fabric material that has small hooks on one part and small loops on the other

such that, when pressed together, they adhere to one another and further, requiring a significant force to separate on another.

3.2.4 lacing hook, n—a metal hook that is located on the outside surface of an insulation blanket and that is secured through

the blanket; tie wire is wrapped around it so as to secure an insulation blanket around a pipe component or piece of equipment.

3.2.4 lacing anchor, n—a metal disk, located on the outside of an insulation blanket, that is secured to a pin that passes through

the blanket; the assembly is used to wrap tire wire around so as to secure an insulation blanket around a pipe component or piece

of equipment.

3.2.5 D-ring,lacing hook, n—a section of heavy wire which forms a complete loop in either a rectangular shape or the shape

of the capital letter “D”, that is used in removable insulation blankets for attaching a fabric strap that secures the metal hook that

is located on the outside surface of an insulation blanket and that is secured through the blanket; tie wire is wrapped around it so

as to secure an insulation blanket around a pipe component or piece of equipment.

3.2.6 removable and reusable blanket insulation, n—An insulation blanket, encased in woven fabric and/or woven wire mesh,

that has attachment mechanisms designed to allow the assembly to be installed, then later removed and reinstalled, without using

any new insulation or fabric materials.

4. Materials

4.1 Insulation shall be of a flexible fibrous material acceptable for the maximum temperature of the application. Acceptable

materials must be one of the following:

High Temperature Fiber Blanket per Specification C892, any Type or Grade

Needled Glass Fiber Mechanically Bonded Felt per Specification C1086

Mineral Fiber Blanket, per Specification C553, of the Type suitable for the application.

4.2 Material for the outer jacket liner and straps, where used, shall be woven glass fiber cloth that has been treated with a water

resistant compound, such as silicone or fluorocarbon, that is suitable for both interior and exterior use, and having the properties

as shown in Table 1.

4.3 Material for the inner jacket shall be the same as for the outer jacket for surface temperatures less than 500°F (260°F°C).

4.3.1 For surfaces from 501°F (261°C) to 1000°F (538°C) where leaks of process fluids are not expected, the inner layer and

gussets shall be one of the following:

4.3.1.1 a plain, heat cleaned, glass fiber fabric,

4.3.1.2 a Type 304 stainless steel wire knitted mesh made from 0.008 inchin. (0.20 mm) diameter wire with nominal 6 to 8

openings per in.

4.3.2 For surfaces from 501°F (261°C) to 1000°F (538°C) where leaks of process fluids are expected, such as flange pairs and

valves, the inner layer and gussets shall be as specified in 4.3.1 and 4.3.1.1 above but also with Type 304 stainless steel foil that

has a minimum thickness of 0.001 in. (0.025 mm). This foil shall be placed between the insulation material and the outer fabric

or wire mesh.

4.4 Lacing hooks and lacing anchors shall be made of 12 Gauge, Type 304 stainless steel.

4.5 Tie-Down Straps:

4.5.1 Outdoor Applications—These tie-down straps shall be constructed of one of the following three types of material: (1) the

same material as the outer jacket, (2) a woven glass fiber fabric, or (3) a tape of suitable thickness with the same coating as the

outer jacket material. If the same material as the outer jacket is used, then a double thickness is required with an edge trim sewn

in place along both edges. Edge trim shall be applied to prevent exposed fabric edges. Ends of the straps shall be turned under ⁄4

(6.35mm) (6.35 mm) to ⁄2 (13mm) (13 mm) inch and double-stitched to prevent unraveling.

4.5.2 Indoor Applications only—Only—These tie-down straps shall be constructed either of the same materials as for Outdoor

Applications, specified in 4.5.1, or of a hook and loop fastener material with a maximum use temperature of 220°F (104°C).

Minimum width of the hook and loop fastener material shall be 0.75 in. (19 mm).

C1695 − 10 (2015)

TABLE 1 Physical and Performance Requirements for Fabrics

colwidth="1.42in"/COLSPEC

Plain, heat cleaned Glass fiber fabric Glass fiber fabric Fiber fabric coated

A

glass fiber fabric coated with Silicone, for coated with Silicone, with Fluorocarbon

exterior applications for interior applications only

Weight (minimum) 17.7 (602) 16.5 (561) 13.5 (455) 15 (510)

oz/sq. yd (g/m )

per ASTM D3776

Weight (minimum) 17.7 (602) 16.5 (561) 13.5 (455) 15 (510)

oz/sq. yd (g/m )

per Test Methods D3776/

D3776M

Breaking Strength Warp 200 (35.7) Warp 225 (40.19) Warp 125 (22.4) Warp 225 (40.19)

lbs/inch (kg/cm) per Fill 100 (17.9) Fill 175 (31.26) Fill 100 (17.9) Fill 175 (31.26)

Test Methods D5034

or D5035

A

Tear Strength lbs (kg) See Warp 40 (18.14) Warp 30 (13.6) Warp 40 (18.14)

per Test Method D5587 Fill 25 (11.33) Fill 20 (9.1) Fill 25 (11.33)

Burst Strength psi (kg/cm )

Not Applicable 200 (14) 150 (9.77) 200 (14)

per Test Method D3786

Burst Strength psi (kg/cm )

per Test Method D3786/ Not Applicable 200 (14) 150 (9.77) 200 (14)

D3786M

A

Abrasion Resistance See CS-10 Wheel, 500g loads CS-10 Wheel, 500g loads CS-10 Wheel, 500g loads

per Test Method D3389 500 revs, 15% weight loss 500 revs, 15% weight loss 500 revs, 15% weight loss max

max max

A

Abrasion Resistance See CS-10 Wheel, 500 g loads CS-10 Wheel, 500 g loads CS-10 Wheel, 500 g loads

per Test Method D3389 500 revs, 15 % weight loss 500 revs, 15 % weight loss 500 revs, 15 % weight loss max

max max

Color beige Gray Optional Gray

Temperature Resistance °F (°C)

1000° F (538° C) 500° F (260° C) 500° F (260° C) 600° F (315° C)

per Test Method C1263

Temperature Resistance °F (°C)

1000°F (538°C) 500°F (260°C) 500°F (260°C) 600°F (315°C)

per Test Method C1263

A

Flame Resistance See Char Length 1 in. max. Char Length 1 in. max. Char Length 1 inch max.

Test Method D6413 (25.4cm) (25.4cm) (25.4cm)

Afterglow 3 seconds max. Afterglow 3 seconds max. Afterglow 3 seconds max.

Flame out 1 second max. Flame out 1 second max. Flame out 1 second max.

A

Flame Resistance See Char Length 1 in. max. Char Length 1 in. max. Char Length 1 in. max.

Test Method D6413/D6413M (25.4 cm) (25.4 cm) (25.4 cm)

Afterglow 3 seconds max. Afterglow 3 seconds max. Afterglow 3 seconds max.

Flame out 1 second max. Flame out 1 second max. Flame out 1 second max.

A

Meets MIL-C-20079H, Type 1, Class 99.

TABLE 2 Physical and Performance Requirements for Hook and Loop Fastener (for interior use only)

Property

Minimum material width 0.75 in. (18mm)

Minimum material width 0.75 in. (18 mm)

Minimum Shear Strength, New (per Test Method D5189) 8 psi (55kPa)

Minimum Shear Strength, New (per Test Method D5189) 8 psi (55 kPa)

Minimum Shear Strength, after 2000 cycles (per Test Method D5189) 7 psi (48 kPa)

Minimum breaking strength (per Test Method D5035) 150 lbs/ in. width (173 kg/cm)

4.6 Drawstrings shall be made from 100%100 % textured glass fiber sleeving with plain weave, ⁄8 in. inside diameter and 0.03

in. wall thickness. Drawstrings shall be suitable for 1000°F (538°C) services.

4.7 PTFE-coated glass fiber thread shall be used for service temperatures to 500°F (260°C). Glass fiber thread shall be 0.021

inchin. (0.53 mm) diameter, minimum 20 lbs (9 kg).kg) breaking strength.

4.8 Stainless steel thread shall be used for service temperatures above 500°F (260°C). Thread shall be minimum 0.015 in. (0.38

mm) diameter and minimum 18 lbs (8.16 kg).kg) breaking strength.

4.9 All hardware such as D-rings, buckles, tags, etc., shall be Type 304 stainless steel.

5. Design and Fabrication

5.1 Insulated items shall be pre-measured to assure a tight fit. Allowances shall be made for valve bonnet height, gland openings,

protrusions, etc. so as to effectively insulate yet allow future removal and reinstallation. Maximum gap size shall be ⁄4 in. (6mm).

(6 mm).

5.2 Fabricate blankets to allow easy access to valve packing glands and flange bolts without having to completely remove the

blanket. All valve blankets shall be designed to permit full function of the valves and not to obscure the valve’s position indicator,

where applicable.

C1695 − 10 (2015)

5.3 For applications where leaks are expected, any leak from the packing gland or flanges must be channeled out of the blanket

to prevent soaking the insulation.

5.4 Force-folding or bending of blankets is not allowed.

5.5 Blankets shall be fabricated with a minimum 2 in. (50 mm) of overlap at the end flap to overlap the adjacent insulation.

5.6 Blankets shall be fabricated with parting faces at the blanket low point to facilitate drainage, if possible. Otherwise, a

drainage grommet shall be installed at the blanket low point.

5.7 Any single blanket or blanket piece shall not exceed 45 lbs (20.4 kg). Blankets with a finished weight of 45 lbs (20.4 kg)

or less shall be fabricated in one piece.

6. Construction

6.1 Outdoor Applications:

6.1.1 All fabric seams shall be either sewn or held together with 16 gauge type 304 stainless steel hog ring staples on 1”1 to

3” 3 in. (25 to 75 mm) centers. Machine stitchin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.