ASTM F1563-23

(Specification)Standard Specification for Tools to Squeeze-off Polyethylene (PE) Gas Pipe or Tubing

Standard Specification for Tools to Squeeze-off Polyethylene (PE) Gas Pipe or Tubing

ABSTRACT

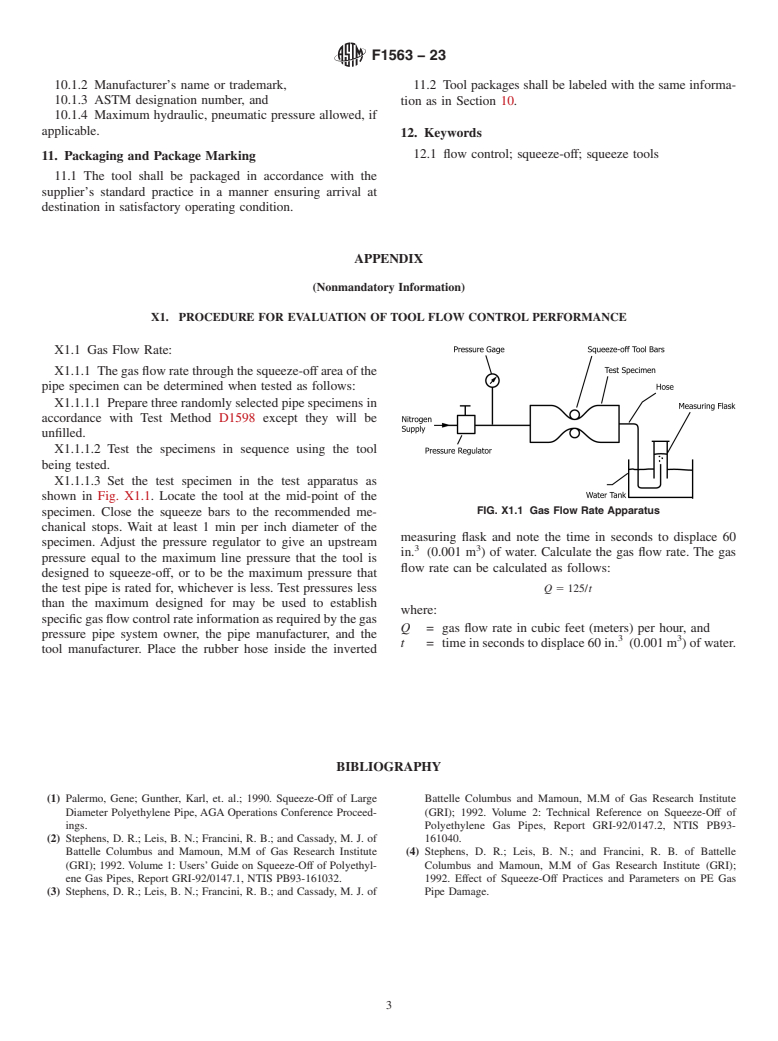

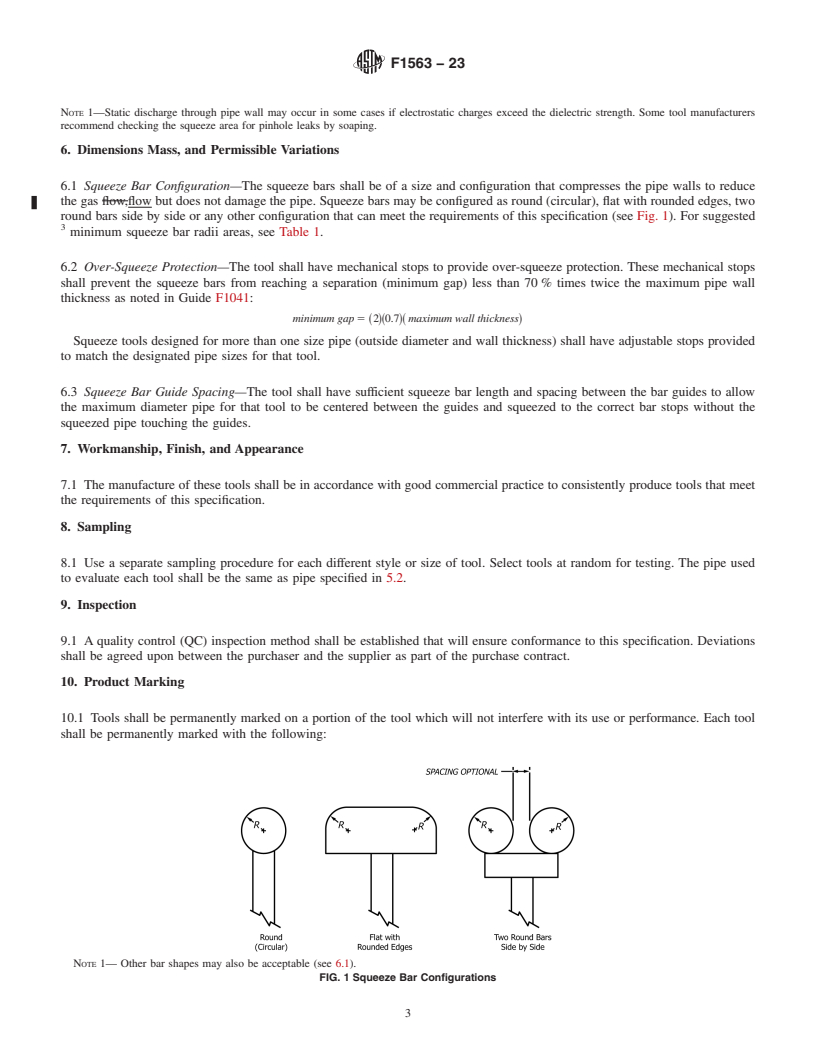

This specification covers the physical requirements for tools used to squeeze-off polyethylene gas pipe and tubing. The squeeze bars shall be of a size and configuration that compresses the pipe walls to reduce the gas flow, but does not damage the pipe and may be configured as round (circular), flat with rounded edges, two round bars side by side, or any other configuration. The tool shall have the following requirements: mechanical, hydraulic, or pneumatic force mechanisms; resistance to damage or deformation; release protection; release rate; flow control; and grounding. It shall also have sufficient squeeze bar length and spacing to allow the maximum diameter pipe to be centered between the guides and mechanical stops to provide protection for over squeezing.

SCOPE

1.1 This specification covers the physical requirements for tools used to squeeze-off polyethylene (PE) pipe and tubing. It is limited to squeeze-off procedures set forth by the pipe manufacturer as referred to in Specification D2513 for gas pressure pipe systems.

1.2 Nothing in this specification shall be construed as recommending practices or systems at variances with governing codes and project specifications.

1.3 Where applicable in this specification, “pipe” shall mean “pipe and tubing,” and “tool” shall mean “squeeze-off tool.”

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The following safety hazards caveat pertains only to the test methods portions, Section 5 and Appendix X1 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1563 − 23 An American National Standard

Standard Specification for

1

Tools to Squeeze-off Polyethylene (PE) Gas Pipe or Tubing

This standard is issued under the fixed designation F1563; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1600 Terminology for Abbreviated Terms Relating to Plas-

tics

1.1 This specification covers the physical requirements for

D2513 Specification for Polyethylene (PE) Gas Pressure

tools used to squeeze-off polyethylene (PE) pipe and tubing. It

Pipe, Tubing, and Fittings

is limited to squeeze-off procedures set forth by the pipe

F412 Terminology Relating to Plastic Piping Systems

manufacturer as referred to in Specification D2513 for gas

F1041 Guide for Squeeze-Off of Polyolefin Gas Pressure

pressure pipe systems.

Pipe and Tubing

1.2 Nothing in this specification shall be construed as

3. Terminology

recommending practices or systems at variances with govern-

ing codes and project specifications.

3.1 General—Definitions are in accordance with Terminol-

ogy F412, unless otherwise specified. Abbreviations are in

1.3 Where applicable in this specification, “pipe” shall

accordance with Terminology D1600, unless otherwise speci-

mean “pipe and tubing,” and “tool” shall mean “squeeze-off

fied.

tool.”

3.2 Definitions of Terms Specific to This Standard:

1.4 The values stated in inch-pound units are to be regarded

3.2.1 squeeze-off—a technique used to control the flow of

as standard. The values given in parentheses are mathematical

gas through a pipe by the compressing action of a mechanical,

conversions to SI units that are provided for information only

hydraulic or pneumatic device. Squeeze-off may be used, as

and are not considered standard.

recommended by the tool or pipe manufacturer, to reduce the

1.5 The following safety hazards caveat pertains only to the

flow of gas to an acceptable rate. Under certain conditions

test methods portions, Section 5 and Appendix X1 of this

complete stoppage of flow may be obtained.

specification: This standard does not purport to address all of

the safety concerns, if any, associated with its use. It is the

4. Materials and Manufacture

responsibility of the user of this standard to establish appro-

4.1 Tools shall be manufactured from materials that have

priate safety, health, and environmental practices and deter-

the structural properties to meet the requirements of this

mine the applicability of regulatory limitations prior to use.

specification.

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

5. Other Requirements

ization established in the Decision on Principles for the

5.1 Force Mechanism—The force mechanism (mechanical,

Development of International Standards, Guides and Recom-

hydraulic or pneumatic) shall provide a force of at least 1.25

mendations issued by the World Trade Organization Technical

times the force required to squeeze-off the most rigid pipe size

Barriers to Trade (TBT) Committee.

within the squeeze parameters recommended by the manufac-

turer of the tool. The most rigid pipe is a function of pipe

2. Referenced Documents

diameter, wall thickness, pipe material and temperature. The

2

2.1 ASTM Standards:

tool manufacturer determines which pipe products his tool is

D1598 Test Method for Time-to-Failure of Plastic Pipe

suitable for. Power tools such as impact wrenches or pneumatic

Under Constant Internal Pressure

motored torque multipliers shall not be used.

5.2 Tool Strength—A tool shall not be structurally damaged

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic

or functionally affected when tested as follows:

Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas.

5.2.1 Measure the load (P) required to squeeze-off the most

Current edition approved Nov. 1, 2023. Published November 2023. Originally

rigid pipe (largest size, thickest wall, highest density, lowest

approved in 1993. Last previous edition approved in 2019 as F1563-01(2019). DOI:

10.1520/F1563-23.

temperature) within the range of the tool.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2.2 Prepare a pipe specimen from this pipe. The specimen

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

length shall be no less than five times the nominal outside

Standards volume information, refer to the standard’s Document Summary page on

the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1563 − 01 (Reapproved 2019) F1563 − 23 An American National Standard

Standard Specification for

1

Tools to Squeeze-off Polyethylene (PE) Gas Pipe or Tubing

This standard is issued under the fixed designation F1563; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the physical requirements for tools used to squeeze-off polyethylene (PE) pipe and tubing. It is

limited to squeeze-off procedures set forth by the pipe manufacturer as referred to in Specification D2513 for gas pressure pipe

systems.

1.2 Nothing in this specification shall be construed as recommending practices or systems at variances with governing codes and

project specifications.

1.3 Where applicable in this specification, “pipe” shall mean “pipe and tubing,” and “tool” shall mean “squeeze-off tool.”

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 The following safety hazards caveat pertains only to the test methods portions, Section 5 and Appendix X1 of this

specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D638 Test Method for Tensile Properties of Plastics

D1598 Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2513 Specification for Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings

F412 Terminology Relating to Plastic Piping Systems

F1041 Guide for Squeeze-Off of Polyolefin Gas Pressure Pipe and Tubing

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas.

Current edition approved Aug. 1, 2019Nov. 1, 2023. Published November 2019November 2023. Originally approved in 1993. Last previous edition approved in 20112019

as F1563-01(2011).F1563-01(2019). DOI: 10.1520/F1563-01R19.10.1520/F1563-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1563 − 23

3. Terminology

3.1 General—Definitions are in accordance with Terminology F412, unless otherwise specified. Abbreviations are in accordance

with Terminology D1600, unless otherwise specified.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 squeeze-off—a technique used to control the flow of gas through a pipe by the compressing action of a mechanical, hydraulic

or pneumatic device. Squeeze-off may be used, as recommended by the tool or pipe manufacturer, to reduce the flow of gas to an

acceptable rate. Under certain conditions complete stoppage of flow may be obtained.

4. Materials and Manufacture

4.1 Tools shall be manufactured from materials that have the structural properties to meet the requirements of this specification.

5. Other Requirements

5.1 Force Mechanism—The force mechanism (mechanical, hydraulic or pneumatic) shall provide a force of at least 1.25 times the

force required to squeeze-off the most rigid pipe size within the squeeze parameters recommended by the manufacturer of the tool.

The most rigid pipe is a function of pipe diameter, wall thickness, pipe material and temperature. The tool manufacturer determines

which pipe products his tool is suitable for. Power tools such as impact wrenches or pn

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.