ASTM F1900-98

(Test Method)Standard Test Method for Water Resistance of Footwear Using a Walking Step Simulator

Standard Test Method for Water Resistance of Footwear Using a Walking Step Simulator

SCOPE

1.1 This test method describes a method of measuring the water resistance of footwear.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1900 – 98

Standard Test Method for

Water Resistance of Footwear Using a Walking Step

1,2

Simulator

This standard is issued under the fixed designation F 1900; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope correlation between this test and footwear performance in the

field or footwear performance in the SATRA Trough-Water

1.1 This test method describes a method of measuring the

Penetration Test has not been fully determined.

water resistance of footwear.

1.2 This standard does not purport to address all of the

4. Apparatus

safety concerns, if any, associated with its use. It is the

4.1 Mechanism, such as the one shown in Fig. 1, that

responsibility of the user of this standard to establish appro-

approximates the movements and forces involved in human

priate safety and health practices and determine the applica-

walking motion. The important features of the walking motion

bility of regulatory limitations prior to use.

produced by the mechanism are defined as follows:

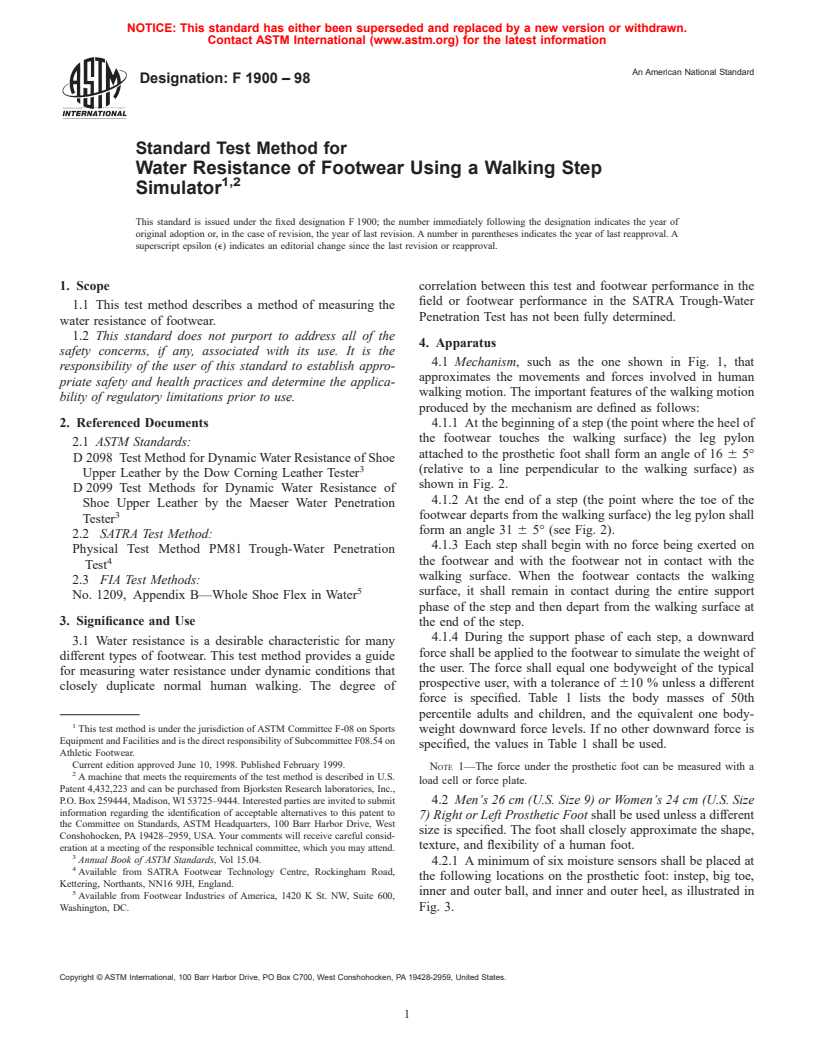

2. Referenced Documents 4.1.1 At the beginning of a step (the point where the heel of

the footwear touches the walking surface) the leg pylon

2.1 ASTM Standards:

attached to the prosthetic foot shall form an angle of 16 6 5°

D 2098 Test Method for Dynamic Water Resistance of Shoe

(relative to a line perpendicular to the walking surface) as

Upper Leather by the Dow Corning Leather Tester

shown in Fig. 2.

D 2099 Test Methods for Dynamic Water Resistance of

4.1.2 At the end of a step (the point where the toe of the

Shoe Upper Leather by the Maeser Water Penetration

footwear departs from the walking surface) the leg pylon shall

Tester

form an angle 31 6 5° (see Fig. 2).

2.2 SATRA Test Method:

4.1.3 Each step shall begin with no force being exerted on

Physical Test Method PM81 Trough-Water Penetration

the footwear and with the footwear not in contact with the

Test

walking surface. When the footwear contacts the walking

2.3 FIA Test Methods:

surface, it shall remain in contact during the entire support

No. 1209, Appendix B—Whole Shoe Flex in Water

phase of the step and then depart from the walking surface at

3. Significance and Use

the end of the step.

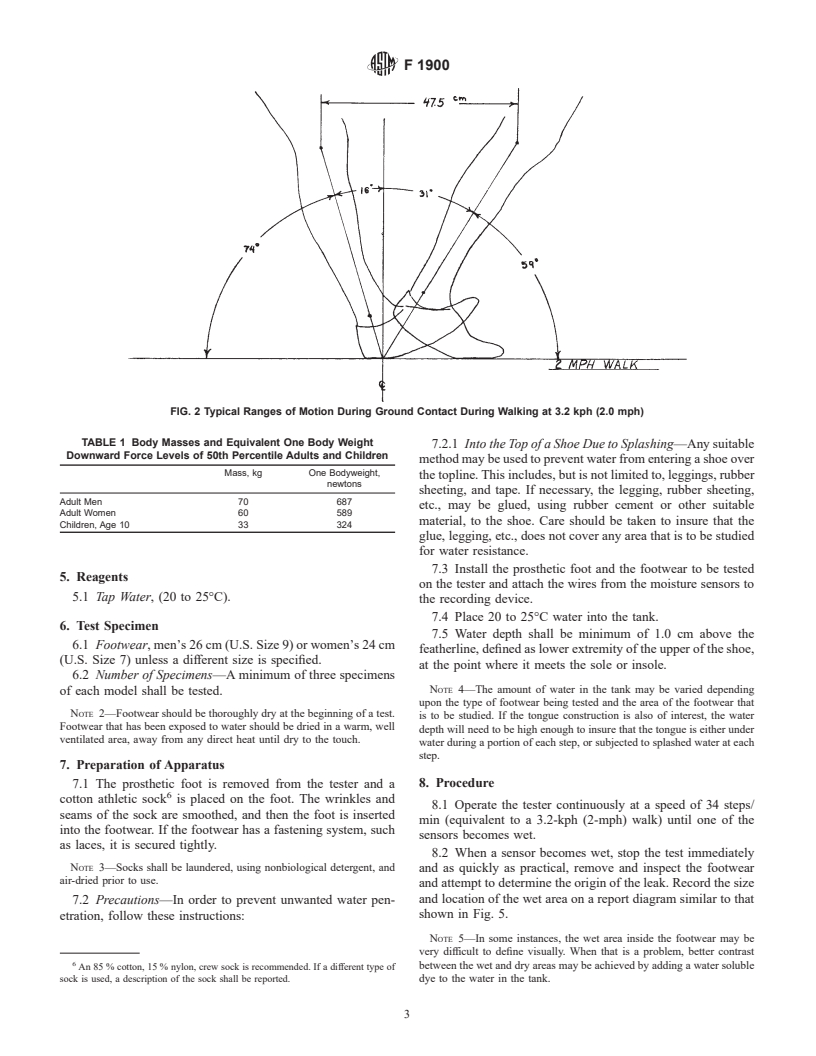

4.1.4 During the support phase of each step, a downward

3.1 Water resistance is a desirable characteristic for many

force shall be applied to the footwear to simulate the weight of

different types of footwear. This test method provides a guide

the user. The force shall equal one bodyweight of the typical

for measuring water resistance under dynamic conditions that

prospective user, with a tolerance of 610 % unless a different

closely duplicate normal human walking. The degree of

force is specified. Table 1 lists the body masses of 50th

percentile adults and children, and the equivalent one body-

This test method is under the jurisdiction of ASTM Committee F-08 on Sports

weight downward force levels. If no other downward force is

Equipment and Facilities and is the direct responsibility of Subcommittee F08.54 on

specified, the values in Table 1 shall be used.

Athletic Footwear.

Current edition approved June 10, 1998. Published February 1999.

NOTE 1—The force under the prosthetic foot can be measured with a

A machine that meets the requirements of the test method is described in U.S.

load cell or force plate.

Patent 4,432,223 and can be purchased from Bjorksten Research laboratories, Inc.,

P.O. Box 259444, Madison, WI 53725–9444. Interested parties are invited to submit 4.2 Men’s 26 cm (U.S. Size 9) or Women’s 24 cm (U.S. Size

information regarding the identification of acceptable alternatives to this patent to

7) Right or Left Prosthetic Foot shall be used unless a different

the Committee on Standards, ASTM Headquarters, 100 Barr Harbor Drive, West

size is specified. The foot shall closely approximate the shape,

Conshohocken, PA 19428–2959, USA. Your comments will receive careful consid-

texture, and flexibility of a human foot.

eration at a meeting of the responsible technical committee, which you may attend.

Annual Book of ASTM Standards, Vol 15.04.

4.2.1 A minimum of six moisture sensors shall be placed at

Available from SATRA Footwear Technology Centre, Rockingham Road,

the following locations on the prosthetic foot: instep, big toe,

Kettering, Northants, NN16 9JH, England.

5 inner and outer ball, and inner and outer heel, as illustrated in

Available from Footwear Industries of America, 1420 K St. NW, Suite 600,

Fig. 3.

Washington, DC.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1900

(1) Prosthetic foot with moisture sensors

(2) Water tank

(3) Motor with speed control

(4) Mechanism for producing back and forth motion

(5) Cam to control location of knee

(6) Cam to control location of ankle

(7) Slide mechanism

(8) Air cylinder to lower the foot at the beginning of each step and raise it again at the completion of each

step

FIG. 1 Footwear Tester

4.2.2 The moisture sensors shall determine the presence of opening in the front, that is covered by transparent material, to

water. A circuit diagram for a sensor that has proven to be

permit observation of the footwear during the test.

suitable for this application is shown in Fig. 4.

4.4 Recording Device, that counts the number of steps

4.3 Water Tank, made of stainless steel (or other corrosion

(cycles) that the footwear is subjected to, monitors the moisture

resistant material). The tank shall be large enough so that the

sensors, and records the number of steps that have been

upper portion of a shoe or boot does not come in contact with

accomplished when the sensors become “wet.”

the tank at any time during the test. The tank should have an

F 1900

FIG. 2 Typical Ranges of Moti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.