ASTM F894-13

(Specification)Standard Specification for Polyethylene (PE) Large Diameter Profile Wall Sewer and Drain Pipe

Standard Specification for Polyethylene (PE) Large Diameter Profile Wall Sewer and Drain Pipe

ABSTRACT

This specification covers requirements and test methods for materials, dimensions, workmanship, ring stiffness, flattening, joint systems, and a form of marking for polyethylene (PE) pipe of profile wall construction and with bell and spigot, heat fusion, extrusion welded or electrofusion joints for use in gravity flow applications, such as for sewers and drains. The PE profile wall pipe products cover six standard ring stiffness constant (RSC) classifications, namely 40, 63, 100, and 160, 250 and 400. These are referred to as RSC 40, RSC 63, RSC 100, RSC 160, RSC 250 and RSC 400. Referee testing, ring stiffness constant testing, flattening test, and joint tightness test shall be performed to meet the requirements prescribed.

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, ring stiffness, flattening, joint systems, and a form of marking for large diameter, 10 to 120 in. (250 to 3050 mm), inside diameter based polyethylene (PE) pipe of profile wall construction and with bell and spigot, heat fusion, extrusion welded or elctrofusion joints for use in gravity flow applications, such as for sewers and drains. Note 1—Pipe produced to this specification should be installed in accordance with Practice D2321 and with the manufacturer's recommendations.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F894 −13 An American National Standard

Standard Specification for

Polyethylene (PE) Large Diameter Profile Wall Sewer and

1

Drain Pipe

ThisstandardisissuedunderthefixeddesignationF894;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* tic Pipe for Sewers and Other Gravity-Flow Applications

D2412Test Method for Determination of External Loading

1.1 This specification covers requirements and test methods

Characteristics of Plastic Pipe by Parallel-Plate Loading

for materials, dimensions, workmanship, ring stiffness,

D2837Test Method for Obtaining Hydrostatic Design Basis

flattening, joint systems, and a form of marking for large

forThermoplasticPipeMaterialsorPressureDesignBasis

diameter, 10 to 132 in. (250 to 3355 mm), inside diameter

for Thermoplastic Pipe Products

based polyethylene (PE) pipe of profile wall construction and

D3212Specification for Joints for Drain and Sewer Plastic

with bell and spigot, heat fusion, extrusion welded or elctro-

Pipes Using Flexible Elastomeric Seals

fusion joints for use in gravity flow applications, such as for

D3350Specification for Polyethylene Plastics Pipe and Fit-

sewers and drains.

tings Materials

NOTE 1—Pipe produced to this specification should be installed in

F412Terminology Relating to Plastic Piping Systems

accordance with Practice D2321 and with the manufacturer’s recommen-

F477Specification for Elastomeric Seals (Gaskets) for Join-

dations.

ing Plastic Pipe

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

F585Guide for Insertion of Flexible Polyethylene Pipe Into

as standard. The values given in parentheses are mathematical

Existing Sewers

conversions to SI units that are provided for information only

F1290PracticeforElectrofusionJoiningPolyolefinPipeand

and are not considered standard.

Fittings

1.3 The following safety hazards caveat pertains only to the F2620PracticeforHeatFusionJoiningofPolyethylenePipe

test method portion, Section 8, of this specification: This

and Fittings

standard does not purport to address all of the safety concerns,

2.2 Federal Standard:

3

if any, associated with its use. It is the responsibility of the user

Fed. Std. No. 123Marking for Shipment (Civil Agencies)

of this standard to establish appropriate safety and health

2.3 Military Standard:

practices and determine the applicability of regulatory limita- 3

MIL-STD-129Marking for Shipment and Storage

tions prior to use.

3. Terminology

2. Referenced Documents

3.1 Definitions—Definitions are in accordance with Termi-

2

2.1 ASTM Standards:

nology F412 and abbreviations are in accordance with Termi-

D618Practice for Conditioning Plastics for Testing

nologyD1600,unlessotherwisespecified.Theabbreviationfor

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

polyethylene is PE.

tics

3.2 Definitions of Terms Specific to This Standard:

D2122Test Method for Determining Dimensions of Ther-

3.2.1 closed profile (CP)—a profile wall pipe wall construc-

moplastic Pipe and Fittings

tion that presents essentially smooth internal and external

D2321PracticeforUndergroundInstallationofThermoplas-

surfaces.

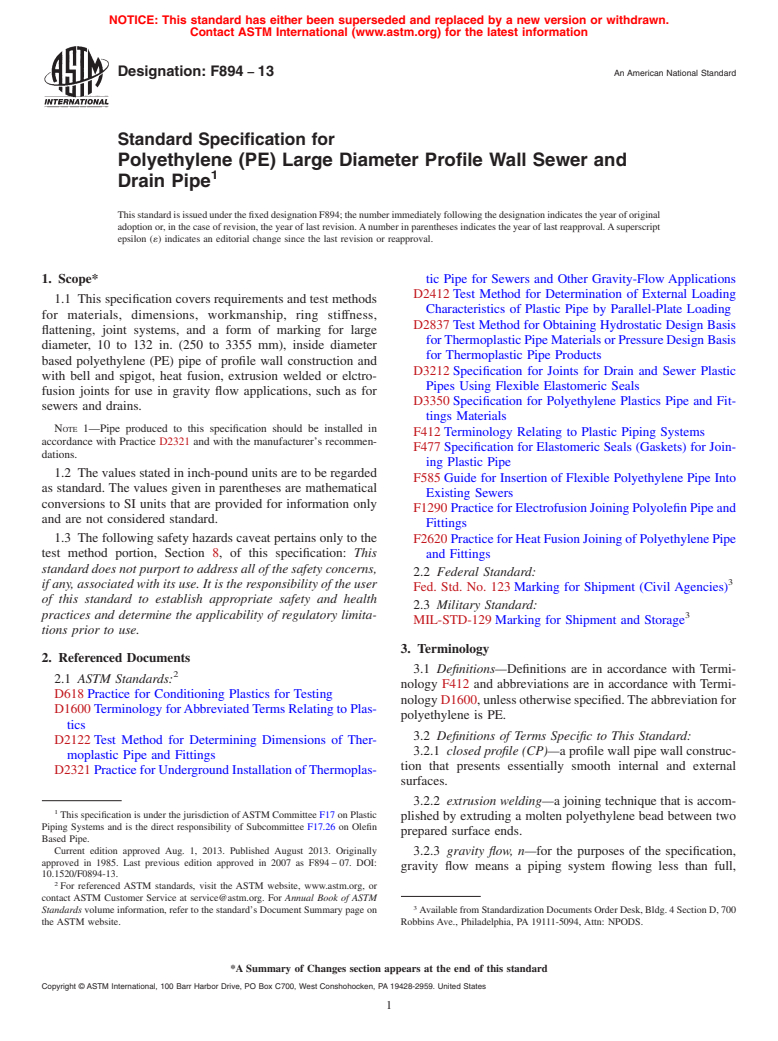

3.2.2 extrusion welding—a joining technique that is accom-

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

plished by extruding a molten polyethylene bead between two

Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin

prepared surface ends.

Based Pipe.

Current edition approved Aug. 1, 2013. Published August 2013. Originally

3.2.3 gravity flow, n—for the purposes of the specification,

approved in 1985. Last previous edition approved in 2007 as F894–07. DOI:

gravity flow means a piping system flowing less than full,

10.1520/F0894-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F894−13

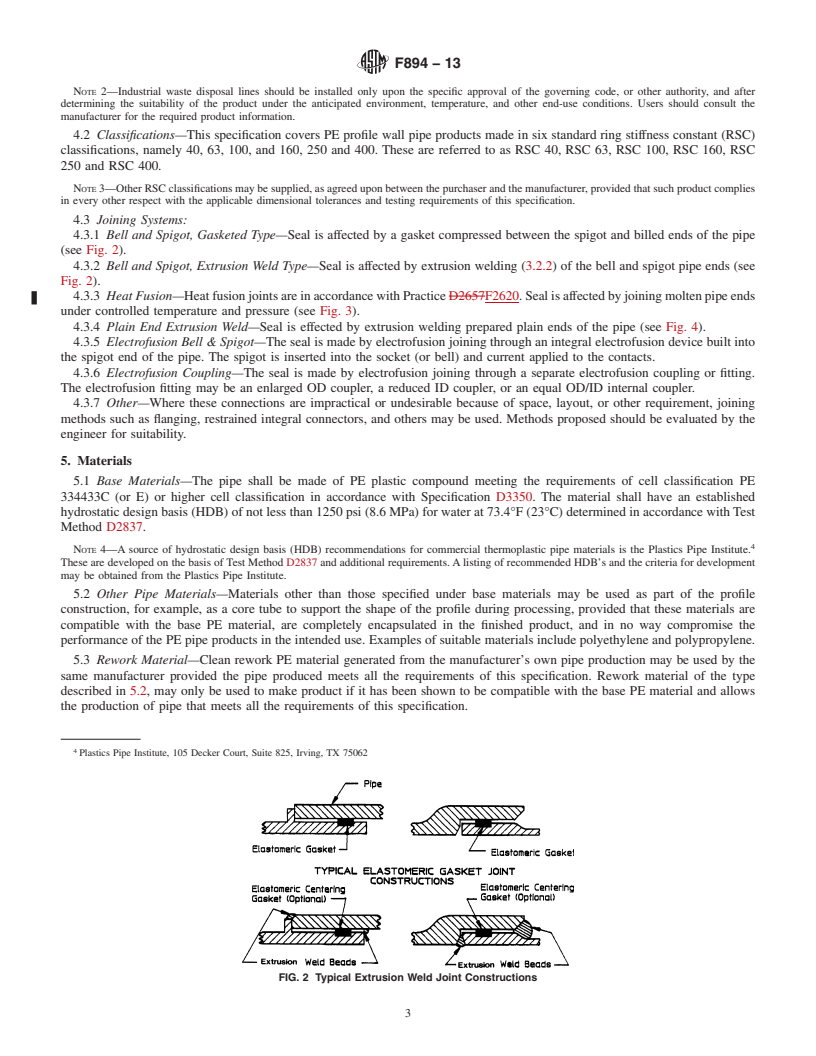

except during storms or high flow conditions when the system 4. Classifications and Uses

maybecomesurchargedinwhichcase,thesystemissubjectto

4.1 Uses—The requirements of this specification are in-

temporary internal hydrostatic pressure that is limited to joint

tended to provide pipe suitable for underground or overground

capabilities.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F894 − 07 F894 − 13 An American National Standard

Standard Specification for

Polyethylene (PE) Large Diameter Profile Wall Sewer and

1

Drain Pipe

This standard is issued under the fixed designation F894; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, ring stiffness, flattening,

joint systems, and a form of marking for large diameter, 10 to 120132 in. (250 to 30503355 mm), inside diameter based

polyethylene (PE) pipe of profile wall construction and with bell and spigot, heat fusion, extrusion welded or elctrofusion joints

for use in gravity flow applications, such as for sewers and drains.

NOTE 1—Pipe produced to this specification should be installed in accordance with Practice D2321 and with the manufacturer’s recommendations.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only. only and are not considered standard.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 8, of this specification:This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2321 Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

D2657 Practice for Heat Fusion Joining of Polyolefin Pipe and Fittings

D2837 Test Method for Obtaining Hydrostatic Design Basis for Thermoplastic Pipe Materials or Pressure Design Basis for

Thermoplastic Pipe Products

D3212 Specification for Joints for Drain and Sewer Plastic Pipes Using Flexible Elastomeric Seals

D3350 Specification for Polyethylene Plastics Pipe and Fittings Materials

F412 Terminology Relating to Plastic Piping Systems

F477 Specification for Elastomeric Seals (Gaskets) for Joining Plastic Pipe

F585 Practice for Insertion of Flexible Polyethylene Pipe Into Existing Sewers

F1290 Practice for Electrofusion Joining Polyolefin Pipe and Fittings

F2620 Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings

2.2 Federal Standard:

3

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

2.3 Military Standard:

3

MIL-STD-129 Marking for Shipment and Storage

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin Based

Pipe.

Current edition approved Feb. 1, 2007Aug. 1, 2013. Published February 2007August 2013. Originally approved in 1985. Last previous edition approved in 20062007 as

F894 – 06.F894 – 07. DOI: 10.1520/F0894-07.10.1520/F0894-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F894 − 13

3. Terminology

3.1 Definitions—Definitions are in accordance with Terminology F412 and abbreviations are in accordance with Terminology

D1600, unless otherwise specified. The abbreviation for polyethylene is PE.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 closed profile (CP)—a profile wall pipe wall construction that presents essentially smooth internal and external surfaces.

3.2.2 extrusion welding—a joining technique that is ac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.