ASTM F3203-16

(Test Method)Standard Test Method for Determination of Gel Content of Crosslinked Polyethylene (PEX) Pipes and Tubing

Standard Test Method for Determination of Gel Content of Crosslinked Polyethylene (PEX) Pipes and Tubing

SIGNIFICANCE AND USE

5.1 Many important properties of crosslinked ethylene plastics vary with the gel content. Hence, determination of the gel content provides a basis for controlling production processes and a means of establishing the quality of finished products.

5.2 Extraction tests permit verification of the proper gel content of any given crosslinked ethylene plastic and they also permit comparison between different crosslinked ethylene plastics, including those containing fillers, provided that, for the latter, the following conditions are met:

5.2.1 The filler is not soluble in the solvent used in this method at the extraction temperature.

5.2.2 The amount of filler present in the compound either is known or can be determined.

5.2.3 Sufficient crosslinking has been achieved to prevent migration of filler during the extraction. It has been found that, at gel content above 30 %, the solvent remains clear and free of filler.

5.3 Since some oxidative degradation of the material and solvent may occur at the reflux temperature of the solvents, a suitable antioxidant is added to the solvent to inhibit such degradation.

5.4 This test method is normally used for specimens consisting of an equal representation of the entire cross section of the product, but may also be used to examine specific portions of a product for differences in extent of cross-linking when compared to either a product standard or another sample.

5.5 This test method is intended for testing crosslinked polyethylene compounds that are not hygroscopic. If compounds that are hygroscopic are tested using this method, specimen conditioning before and after extraction is required.

5.6 This standard differs from test methods Test Methods D2765, and Test Method D7567 which also describe procedures for determining the gel content of crosslinked polyethylene. It allows for the use of naphthenic blend or isoparaffin solvent as an alternative to xylenes. Xylenes are the only solvent allowed to be used for...

SCOPE

1.1 The gel content of pipe and tubing produced from crosslinked polyethylene plastics as described in Specification F876 and other pipe or tubing standards is determined by extracting with solvents such as xylenes. A test method for quantitative determination of gel content is described herein. The method is applicable to PEX pipe and tubing of all densities, including those containing fillers, and provides correction for the inert fillers present in some of those compounds.

1.2 Continuous extraction (see definition in Section 3) is used in this method to test the gel content of crosslinked polyethylene specimens. Continuous extraction when used for testing gel content has the advantages of decreased the cost of testing, increased accuracy and consistency of results, and decreased test time. This is because extraction with a pure solvent is more efficient than extraction with a partially saturated solvent.

1.3 While extraction tests may be made on articles of any shape, this test method is applicable for determining the gel content of crosslinked polyethylene pipes and tubing.

1.4 This test method makes use of xylenes or alternative solvents which have lower toxicity than xylenes. The alternative solvents are also potentially beneficial from an economic and environmental viewpoint. Xylenes are used for referee tests.

1.5 The values stated in SI units are to be regarded as standard. The inch-pound units in brackets are for information only

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F3203 − 16

Standard Test Method for

Determination of Gel Content of Crosslinked Polyethylene

1

(PEX) Pipes and Tubing

This standard is issued under the fixed designation F3203; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 The gel content of pipe and tubing produced from

D883 Terminology Relating to Plastics

crosslinked polyethylene plastics as described in Specification

D1603 Test Method for Carbon Black Content in Olefin

F876 and other pipe or tubing standards is determined by

Plastics

extracting with solvents such as xylenes. A test method for

D2765 Test Methods for Determination of Gel Content and

quantitative determination of gel content is described herein.

Swell Ratio of Crosslinked Ethylene Plastics

The method is applicable to PEX pipe and tubing of all

D7567 Test Method for Determining Gel Content in Cross-

densities, including those containing fillers, and provides

linked Ethylene Plastics Using Pressurized Liquid Extrac-

correction for the inert fillers present in some of those

3

tion (Withdrawn 2015)

compounds.

E691 Practice for Conducting an Interlaboratory Study to

1.2 Continuous extraction (see definition in Section 3)is

Determine the Precision of a Test Method

used in this method to test the gel content of crosslinked

F876 SpecificationforCrosslinkedPolyethylene(PEX)Tub-

polyethylene specimens. Continuous extraction when used for

ing

testing gel content has the advantages of decreased the cost of

4

2.2 ISO Standard:

testing, increased accuracy and consistency of results, and

ISO 10147 Pipes and Fittings Made of Crosslinked Polyeth-

decreased test time. This is because extraction with a pure

ylene (Pe-X) – Estimation of the Degree of Crosslinking

solvent is more efficient than extraction with a partially

by Determination of the Gel Content

saturated solvent.

1.3 While extraction tests may be made on articles of any

3. Terminology

shape, this test method is applicable for determining the gel

3.1 Terms as shown in Terminology D883 are applicable to

content of crosslinked polyethylene pipes and tubing.

this test method.

1.4 This test method makes use of xylenes or alternative

3.2 Definitions of Terms Specific to This Standard:

solvents which have lower toxicity than xylenes. The alterna-

3.2.1 continuous extractor, n—test apparatus for performing

tive solvents are also potentially beneficial from an economic

a continuous extraction.

and environmental viewpoint. Xylenes are used for referee

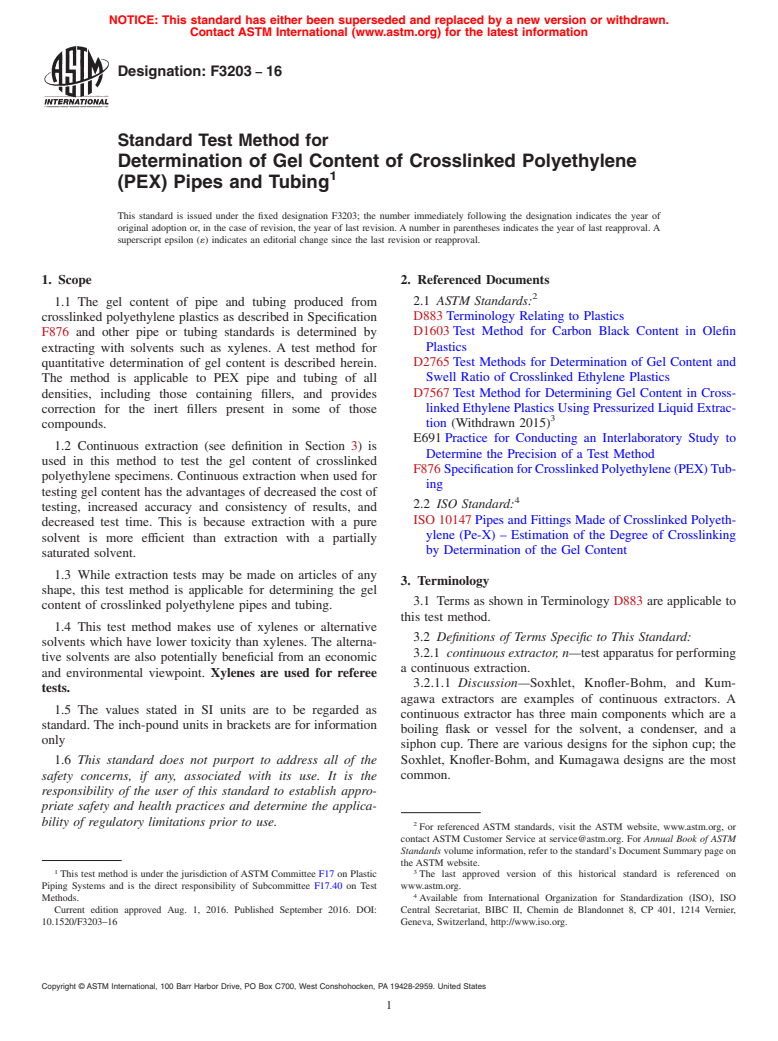

3.2.1.1 Discussion—Soxhlet, Knofler-Bohm, and Kum-

tests.

agawa extractors are examples of continuous extractors. A

1.5 The values stated in SI units are to be regarded as

continuous extractor has three main components which are a

standard. The inch-pound units in brackets are for information

boiling flask or vessel for the solvent, a condenser, and a

only

siphon cup. There are various designs for the siphon cup; the

1.6 This standard does not purport to address all of the Soxhlet, Knofler-Bohm, and Kumagawa designs are the most

common.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This test method is under the jurisdiction of ASTM Committee F17 on Plastic The last approved version of this historical standard is referenced on

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test www.astm.org.

4

Methods. Available from International Organization for Standardization (ISO), ISO

Current edition approved Aug. 1, 2016. Published September 2016. DOI: Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier,

10.1520/F3203–16 Geneva, Switzerland, http://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3203 − 16

3.2.2 continuousextraction,n—anextractionperformedina of a product for differences in extent of cross-linking when

continuous extractor where a solvent (normally xylenes) is compared to either a product standard or another sample.

heatedinavesselandboilsformingvapors,thevaporsriseand

5.5 This test method is intended for testing cross

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.