ASTM D7649-10

(Test Method)Standard Test Method for Determination of Trace Carbon Dioxide, Argon, Nitrogen, Oxygen and Water in Hydrogen Fuel by Jet Pulse Injection and Gas Chromatography/Mass Spectrometer Analysis

Standard Test Method for Determination of Trace Carbon Dioxide, Argon, Nitrogen, Oxygen and Water in Hydrogen Fuel by Jet Pulse Injection and Gas Chromatography/Mass Spectrometer Analysis

SIGNIFICANCE AND USE

Low operating temperature fuel cells such as proton exchange membrane fuel cells (PEMFCs) require high purity hydrogen for maximum performance. The following are the reported effects (SAE TIR J2719) of the compounds determined by this test method.

Carbon Dioxide (CO2), acts largely as a diluent, however in the fuel cell environment CO2 can be transformed into CO.

Water (H2O), is an inert impurity, as it does not affect the function of a fuel cell stack; however, it provides a transport mechanism for water-soluble contaminants, such as Na+ or K+. In addition, it may form ice on valve internal surface at cold weather or react exothermally with metal hydride used as hydrogen fuel storage.

Inert Gases (N2 and Ar), do not normally react with a fuel cell components or fuel cell system and are considered diluents. Diluents can decrease fuel cell stack performance.

Oxygen (O2), in low concentrations is considered an inert impurity, as it does not adversely affect the function of a fuel cell stack; however, it is a safety concern for vehicle on board fuel storage as it can react violently with hydrogen to generate water and heat.

SCOPE

1.1 This test method describes a procedure primarily for the determination of carbon dioxide, argon, nitrogen, oxygen and water in high pressure fuel cell grade hydrogen by gas chromatograph/mass spectrometer (GC/MS) with injection of sample at the same pressure as sample without pressure reduction, which is called “Jet Pulse Injection”. The procedures described in this method were designed to measure carbon dioxide at 0.5micromole per mole (ppmv), Argon 1 ppmv, nitrogen 5 ppmv and oxygen 2 ppmv and water 4 ppmv.

1.2 The values stated in SI units are standard. The values stated in inch-pound units are for information only.

1.3 The mention of trade names in standard does not constitute endorsement or recommendation for use. Other manufacturers of equipment or equipment models can be used.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7649 − 10

Standard Test Method for

Determination of Trace Carbon Dioxide, Argon, Nitrogen,

Oxygen and Water in Hydrogen Fuel by Jet Pulse Injection

and Gas Chromatography/Mass Spectrometer Analysis

This standard is issued under the fixed designation D7649; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 constituent—A component (or compound) found

within a hydrogen fuel mixture.

1.1 Thistestmethoddescribesaprocedureprimarilyforthe

3.1.3 contaminant—impuritythatadverselyaffectsthecom-

determination of carbon dioxide, argon, nitrogen, oxygen and

ponents within the fuel cell system or the hydrogen storage

water in high pressure fuel cell grade hydrogen by gas

system by reacting with its components.An adverse effect can

chromatograph/mass spectrometer (GC/MS) with injection of

be reversible or irreversible.

sample at the same pressure as sample without pressure

reduction,whichiscalled“JetPulseInjection”.Theprocedures

3.1.4 dynamic calibration—calibration of an analytical sys-

described in this method were designed to measure carbon

temusingcalibrationgasstandardgeneratedbydilutingknown

dioxide at 0.5micromole per mole (ppmv), Argon 1 ppmv,

concentration compressed gas standards with hydrogen, as

nitrogen 5 ppmv and oxygen 2 ppmv and water 4 ppmv.

used in this method for carbon dioxide, argon, nitrogen and

oxygen (7.3 and 7.4).

1.2 The values stated in SI units are standard. The values

stated in inch-pound units are for information only.

3.1.5 extracted ion chromatogram (EIC)—a GC/MS chro-

matogram where a selected ion is plotted to determine the

1.3 The mention of trade names in standard does not

compound(s) of interest.

constitute endorsement or recommendation for use. Other

manufacturersofequipmentorequipmentmodelscanbeused. 3.1.6 fuel cell grade hydrogen—hydrogen satisfying the

specifications in SAE TIR J2719.

1.4 This standard does not purport to address all of the

3.1.7 hydrogen fuel—hydrogen to be tested without compo-

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- sitional change due to sample introduction, etc.

priate safety and health practices and determine the applica-

3.1.8 jet pulse injection—high pressure hydrogen fuel

bility of regulatory limitations prior to use.

sample is introduced instantaneously at the same pressure into

GC/MS.

2. Referenced Documents

3.1.9 relative humidity—ratio of actual pressure of existing

2.1 Other Standards:

water vapor to maximum possible pressure of water vapor in

SAE TIR J2719Information Report on the Development of

the atmosphere at the same temperature, expressed as a

aHydrogenQualityGuidelineforFuelCellVehiclesApril

percentage.

3.1.10 response factor (RF)—-theamountinvolume(µL)of

3. Terminology

an analyte divided by the EIC area of the analyte.

3.1 Definitions of Terms Specific to This Standard: 3.1.11 static calibration—calibration of an analytical sys-

3.1.1 absolute pressure—pressure measured with reference tem using standards in a matrix, state or manner different than

to absolute zero pressure, usually expressed as kPa, mm Hg, the samples to be analyzed, as used in this method for water

bar or psi. All the pressures mentioned in this method are concentration in hydrogen.

absolute pressure.

3.2 Acronyms:

3.2.1 FCV—fuel cell vehicle.

ThistestmethodisunderthejurisdictionofASTMCommitteeD03onGaseous

3.2.2 PEMFC—proton exchange membrane fuel cell.

Fuels and is the direct responsibility of Subcommittee D03.14 on Hydrogen and

Fuel Cells.

CurrenteditionapprovedDec.1,2010.PublishedFebruary2011.DOI:10.1520/ 4. Summary of Test Method

D7649–10.

4.1 The simultaneous analysis of carbon dioxide, argon,

AvailablefromSAEInternational(SAE),400CommonwealthDr.,Warrendale,

PA 15096-0001, http://aerospace.sae.org. nitrogen, oxygen and water at 0.5 – 5 ppmv (micromole per

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7649 − 10

mole) in hydrogen fuel samples from fueling stations is 4.4 A mass spectrometer provides sensitive and selective

challenging due to high hydrogen fuel sample pressure and detection towards carbon dioxide, argon, nitrogen, oxygen and

possible contaminations from ambient air. water.

4.2 In this method, a small stainless steel loop is initially

5. Significance and Use

pressurized with high pressure hydrogen standard or sample

5.1 Low operating temperature fuel cells such as proton

without any pressure regulation or restriction (“Sample Loop

exchange membrane fuel cells (PEMFCs) require high purity

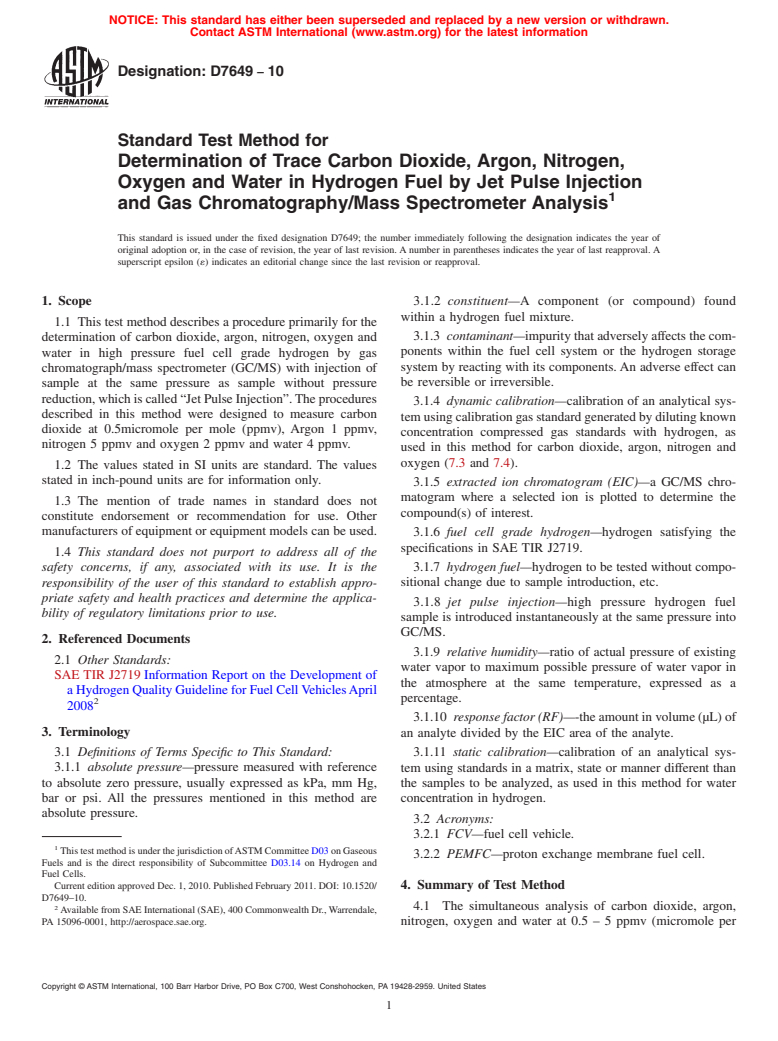

Pressurization”, Fig. 1). The hydrogen in the loop is then

hydrogen for maximum performance. The following are the

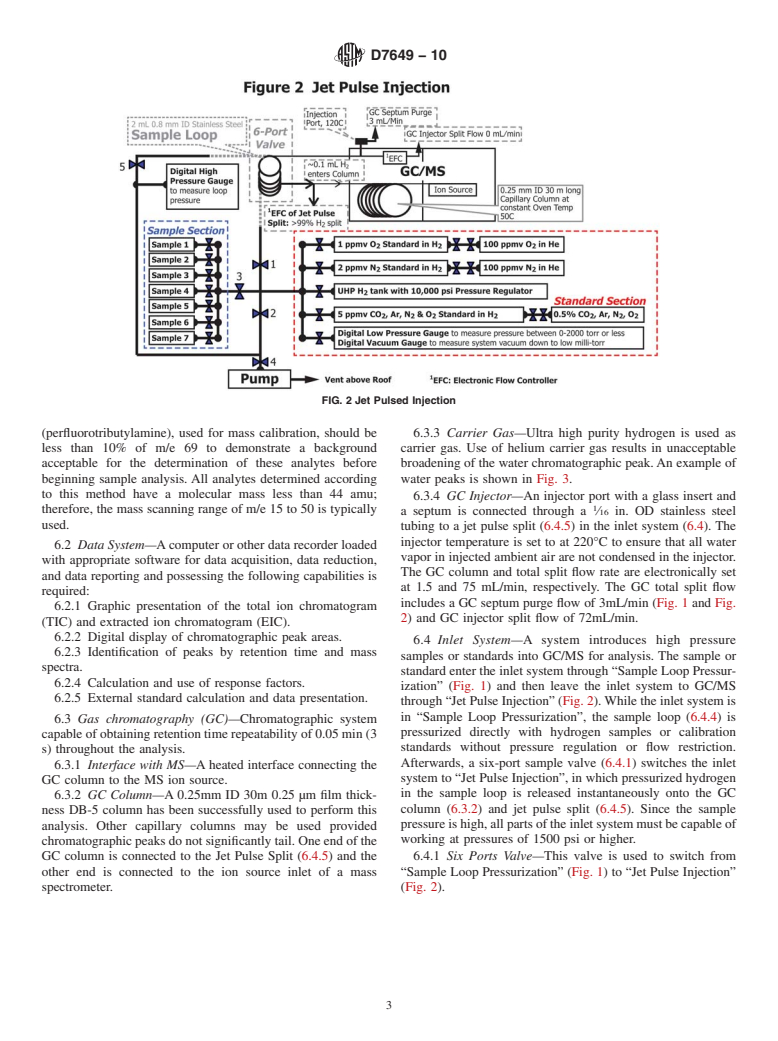

released entirely as a “jet pulse” into a T-union which splits

reported effects (SAE TIR J2719) of the compounds deter-

sample into a 0.25 µm ID 30 m long capillary column and an

mined by this test method.

electronic flow controller (EFC) used to vent excess hydrogen

to the atmosphere (“Jet Pulse Injection”, Fig. 2). Less than 1%

5.2 Carbon Dioxide (CO ), acts largely as a diluent, how-

of hydrogen enters the capillary column with the remaining

ever in the fuel cell environment CO can be transformed into

sample venting to atmosphere through EFC. As demonstrated

CO.

inAppendixX1,thehydrogenvolume“jetpulseinjected”into

5.3 Water (H O), is an inert impurity, as it does not affect

the capillary column is a constant volume and independent of

the function of a fuel cell stack; however, it provides a

thesamplelooppressurewhenthesamplelooppressureisover

transport mechanism for water-soluble contaminants, such as

90 psi. Therefore, the constant hydrogen volume from stan-

+ +

Na or K . In addition, it may form ice on valve internal

dards or samples is GC/MS analyzed in regardless of standard

surface at cold weather or react exothermally with metal

or sample pressures.

hydride used as hydrogen fuel storage.

4.3 Jet pulse injected volume into the capillary column is

5.4 Inert Gases (N and Ar), do not normally react with a

approximate 100 µL (In Appendix X1, this volume is calcu-

fuel cell components or fuel cell system and are considered

lated to be 115µL under the analytical conditions described in

diluents. Diluents can decrease fuel cell stack performance.

Appendix X1). When a 2-mL of sample loop is pressurized to

5.5 Oxygen (O ), in low concentrations is considered an

200 psi, the hydrogen in the loop is (200 psi/14.7psi)×2mL

inert impurity, as it does not adversely affect the function of a

or 27 mL. Hence, 99.5% of the hydrogen sample vents to

fuel cell stack; however, it is a safety concern for vehicle on

atmosphere. This type of “Jet Pulse Injection” has been found

board fuel storage as it can react violently with hydrogen to

acceptable for the analysis of high pressure hydrogen fuel

generate water and heat.

sample since the hydrogen volume injected is independent of

the pressures of hydrogen standards or samples. Consequently

6. Apparatus

itisunnecessarytoregulatestandardsandhydrogensamplesto

the same pressure. In addition to possible trace leaks or air 6.1 Mass Spectrometer (MS)—The MS can perform mass

trappedinside,regulatorsarenotrecommendedasmoistureon calibration with a scanning range from m/e 15 to 650. The

background peak intensities of water, nitrogen, argon, oxygen

the regulator surface can be released into the sample resulting

in a high moisture determination. and carbon dioxide in the mass spectrum of FC-43

FIG. 1 Sample Loop Pressurization

D7649 − 10

FIG. 2 Jet Pulsed Injection

(perfluorotributylamine), used for mass calibration, should be 6.3.3 Carrier Gas—Ultra high purity hydrogen is used as

less than 10% of m/e 69 to demonstrate a background carrier gas. Use of helium carrier gas results in unacceptable

acceptable for the determination of these analytes before broadening of the water chromatographic peak.An example of

beginning sample analysis. All analytes determined according water peaks is shown in Fig. 3.

to this method have a molecular mass less than 44 amu;

6.3.4 GC Injector—An injector port with a glass insert and

therefore, the mass scanning range of m/e 15 to 50 is typically

a septum is connected through a ⁄16 in. OD stainless steel

used.

tubing to a jet pulse split (6.4.5) in the inlet system (6.4). The

injector temperature is set to at 220°C to ensure that all water

6.2 Data System—Acomputer or other data recorder loaded

vapor in injected ambient air are not condensed in the injector.

with appropriate software for data acquisition, data reduction,

The GC column and total split flow rate are electronically set

and data reporting and possessing the following capabilities is

at 1.5 and 75 mL/min, respectively. The GC total split flow

required:

includes a GC septum purge flow of 3mL/min (Fig. 1 and Fig.

6.2.1 Graphic presentation of the total ion chromatogram

2) and GC injector split flow of 72mL/min.

(TIC) and extracted ion chromatogram (EIC).

6.2.2 Digital display of chromatographic peak areas.

6.4 Inlet System—A system introduces high pressure

6.2.3 Identification of peaks by retention time and mass

samples or standards into GC/MS for analysis. The sample or

spectra.

standard enter the inlet system through “Sample Loop Pressur-

6.2.4 Calculation and use of response factors.

ization” (Fig. 1) and then leave the inlet system to GC/MS

6.2.5 External standard calculation and data presentation.

through“JetPulseInjection”(Fig.2).Whiletheinletsystemis

in “Sample Loop Pressurization”, the sample loop (6.4.4)is

6.3 Gas chromatography (GC)—Chromatographic system

pressurized directly with hydrogen samples or calibration

capableofobtainingretentiontimerepeatabilityof0.05min(3

standards without pressure regulation or flow restriction.

s) throughout the analysis.

Afterwards, a six-port sample valve (6.4.1) switches the inlet

6.3.1 Interface with MS—Aheated interface connecting the

system to “Jet Pulse Injection”, in which pressurized hydrogen

GC column to the MS ion source.

in the sample loop is released instantaneously onto the GC

6.3.2 GC Column—A 0.25mm ID 30m 0.25 µm film thick-

column (6.3.2) and jet pulse split (6.4.5). Since the sample

ness DB-5 column has been successfully used to perform this

pressureishigh,allpartsoftheinletsystemmustbecapableof

analysis. Other capillary columns may be used provided

working at pressures of 1500 psi or higher.

chromatographicpeaksdonotsignificantlytail.Oneendofthe

GC column is connected to the Jet Pulse Split (6.4.5) and the 6.4.1 Six Ports Valve—This valve is used to switch from

other end is connected to the ion source inlet of a mass “Sample Loop Pressurization” (Fig. 1) to “Jet Pulse Injection”

spectrometer. (Fig. 2).

D7649 − 10

FIG. 3 m/e18 Extracted Ion Chromatogram of Sample Analysis with Co-Injection of Ambient Air

6.4.2 Samples and Calibration Standards—All calibration 6.4.5.3 Inlet of an electronic flow controller (EFC) with its

standards and samples are prepared or collected in 1800 psi outlet to ambient air. The flow rate of this EFC is always

pressure rated containers with a DOT 3A1800 label (United electronicallysetat150mL/mintoventmostoftheGCinjector

StatedDepartmentofTransportationmandatedlabel)affixedto split flow (72mL/min) during “Sample Loop Pressurization”

the outside surface. All calibration standards and samples are (Fig.1)andreleasedhydrogenfrompressurizedsampleloopin

connected to the inlet system before beginning an analytic “Jet Pulse Injection” (Fig. 2).

sequencetominimizethepotentialforairormoisturecontami- 6.4.6 Digital Vacuum Gauge—capable of measuring abso-

nation due to addition or replacement of standard or sample lute pressure at vacuum range 0 to 12,000 milli-torr (mtorr or

-3

containers. 10 torr). For the vacuum range from 0 to 1000 mtorr, the

6.4.3 Vacuum Pump—an oil vacuum pump that can pump accuracy is 6 10% or6 10 mtorr, whichever is larger.

down to 50 mtorr or less. 6.4.7 Digital Pressure Gauges—Two types of digital pres-

6.4.4 Sample Loop—stainless steel tubing with ⁄16 in. OD sure gauges are required. A pressure gauge 0 to 1000 psig is

and 2 mL inside volume. Both ends of the sample loop are used to measure sample and standard final pressure. Another

connected to a six port valve (6.4.1). digital pressure gauge in the low and narrow pressure range,

6.4.5 Jet Pulse Split—a T-union connects the following such as 0 to 2000 torr, is used to measure the pressure of pure

three portions. gases in initial standard preparation.

6.4.5.1 Six port valve (6.4.1) 6.4.8 Pressure Regulator—A 10,000 psi pressure regulator

6.4.5.2 Inlet of GC column (6.4.2) is used to reduce UHP hydrogen pressure to approximate 400

D7649 − 10

psi for calibration standard preparation. It is also used to 8. Preparation of Apparatus

pressurize the inlet system during method blank analysis, and

8.1 GC/MS—Placeinserviceinaccordancetothemanufac-

during inlet system flushing.

turer’s instructions. Perform daily mass calibration using

FC-43.As stated in 6.1, each of the peak intensities of m/e 18,

7. Reference Standards

28, 29, and 32 should be less than 10% of m/e 69 in the mass

7.1 Typical reference standards are listed in Fig. 1.Two

spectrum of FC-43 used for mass calibration. In order to

standardspreparedinheliumcontaining100ppmvO and100

achieve this condition, the GC column flow rate of GC/MS

ppmv N , are commercial available. Remaining standards

system should be set at a high flow rate, such as, 2mL/min,

listed in Fig. 1 are prepared as per below.

while the system is in standby mode to remove any air in the

7.2 0.5% CO,Ar,N and O in hydrogen—An evacuated

2 2 2 carrier gas line. In addition, when any air may be introduced

1-L cylinder is connected to four pressure-regulated com-

into the carrier gas system, such as when changing the

pressed gas cylinders containing reagent or UHP grade CO ,

2 hydrogen carrier gas tank, the GC total split flow rate is set at

Ar, N and O . The system is evacuated to less than 500 mtorr

2 2 100mL/min for an hour to rapidly remove air in the carrier gas

with all the regulators opened and the main cylinder valves

line.

closed. With the system isolated from vacuum pump, the 1-L

cylinder valve is opened and 100 torr of each target compound

9. Procedure

fromthecompressedgascylindersisexpandedintothesystem

9.1 The detailed procedures used to perform jet puls

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.