ASTM D1838-12a

(Test Method)Standard Test Method for Copper Strip Corrosion by Liquefied Petroleum (LP) Gases

Standard Test Method for Copper Strip Corrosion by Liquefied Petroleum (LP) Gases

SIGNIFICANCE AND USE

5.1 Copper corrosion limits provide assurance that difficulties will not be experienced in deterioration of the copper and copper-alloy fittings and connections that are commonly used in many types of utilization, storage, and transportation equipment.

SCOPE

1.1 This test method covers the detection of the presence of components in liquefied petroleum gases which can be corrosive to copper. Note 1—For an equivalent copper strip test applicable to less volatile petroleum products, see Test Method D130.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 7.1, 10.3.1, and Annex A1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1838 −12a

StandardTest Method for

1

Copper Strip Corrosion by Liquefied Petroleum (LP) Gases

This standard is issued under the fixed designation D1838; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.1.2 FEPA—FederationofEuropeanProducersAssociation

1.1 This test method covers the detection of the presence of

4. Summary of Test Method

components in liquefied petroleum gases which can be corro-

4.1 A polished copper strip is immersed in approximately

sive to copper.

100 mL of the sample and exposed at a temperature of 37.8°C

NOTE 1—For an equivalent copper strip test applicable to less volatile

(100°F) for1hina cylinder of suitable working pressure. At

petroleum products, see Test Method D130.

the end of this period, the copper strip is removed and rated as

1.2 The values stated in SI units are to be regarded as

one of the four classifications of the ASTM Copper Strip

standard. The values given in parentheses are for information

Corrosion Standard (ADJD0130).

only.

1.3 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

5.1 Copper corrosion limits provide assurance that difficul-

responsibility of the user of this standard to establish appro-

ties will not be experienced in deterioration of the copper and

priate safety and health practices and determine the applica-

copper-alloy fittings and connections that are commonly used

bility of regulatory limitations prior to use. For specific

in many types of utilization, storage, and transportation equip-

warning statements, see 7.1, 10.3.1, and Annex A1.

ment.

2. Referenced Documents

6. Apparatus

2

2.1 ASTM Standards:

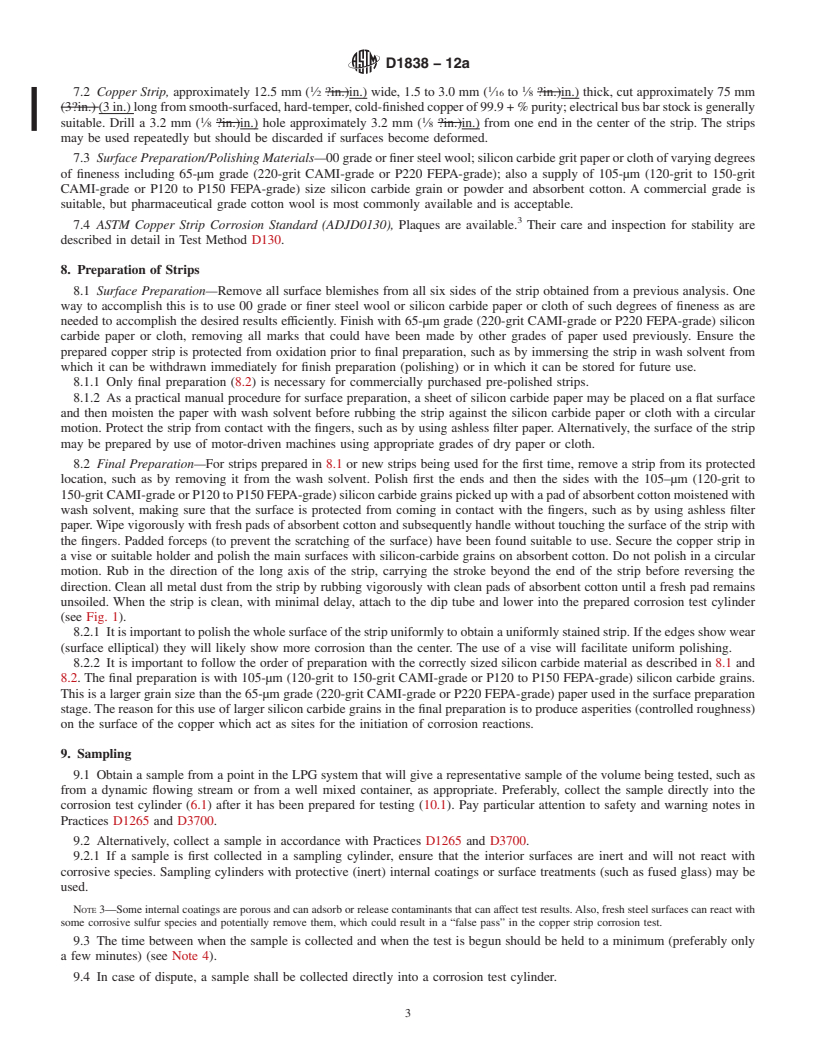

6.1 Corrosion Test Cylinder, constructed of stainless steel

D130 Test Method for Corrosiveness to Copper from Petro-

with an O-ring removable top closure according to the dimen-

leum Products by Copper Strip Test

sions given in Fig. 1. Provide a flexible inert hose, such as one

D1265 Practice for Sampling Liquefied Petroleum (LP)

composed of aluminum or stainless steel, which permits

Gases, Manual Method

inverting the test cylinder as required in the procedure (see

D3700 Practice for Obtaining LPG Samples Using a Float-

Note 2). The whole assembly, including the corrosion test

ing Piston Cylinder

cylinder, shall be constructed to withstand a minimum hydro-

2.2 ASTM Adjuncts:

static test pressure of 6900 kPa (1000 psig). No leak shall be

ADJD0130, ASTM Copper Strip Corrosion Standard for

discernible when tested at 3450 kPa (500 psig) with gas.

3

Petroleum

1

NOTE 2—Swivel connections with an adapter to fit a 6.4 mm ( ⁄4 in.)

pipe may be used.

3. Terminology

6.1.1 The assembly shall be tested for compliance with the

3.1 Abbreviations:

minimum pressure rating of 6900 kPa (1000 psig) by hydro-

3.1.1 CAMI—Coated Abrasives Manufacturers Institute

static testing, or alternative testing protocol acceptable to the

local authority having jurisdiction, prior to first use.Additional

testing can be required by the local authority having jurisdic-

1

This test method is under the jurisdiction of ASTM Committee D02 on

tion.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.H0 on Liquefied Petroleum Gas.

6.1.2 The assembly shall be verified for gas tightness by

Current edition approved Dec. 1, 2012. Published March 2013. Originally

leaktestingataminimumof3450kPa(500psig)withinertgas

approved in 1961. Last previous edition approved in 2012 as D1838–12. DOI:

prior to first use, whenever pressure-containing components of

10.1520/D1838-12A.

2

the assembly are replaced, or otherwise on an annual basis.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1.3 Note the presence and length (about 60 mm) of the

Standards volume information, refer to the standard’s Document Summary page on

outage tube shown in Fig. 1, to provide adequate ullage for

the ASTM website.

3

safety.Asafety pressure relief device may also be incorporated

Available from ASTM International Headquarters. Order Adjunct No.

ADJD0130. into the design of the corrosion test cylinder, if desired. If a

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1838−12a

in.) from one end in the center of the strip. The strips may be

used repeatedly but should be discarded if surfaces become

deforme

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1838 − 12 D1838 − 12a

Standard Test Method for

1

Copper Strip Corrosion by Liquefied Petroleum (LP) Gases

This standard is issued under the fixed designation D1838; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the detection of the presence of components in liquefied petroleum gases which can be corrosive

to copper.

NOTE 1—For an equivalent copper strip test applicable to less volatile petroleum products, see Test Method D130.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific warning statements, see 7.1, 10.3.1, and Annex A1.

2. Referenced Documents

2

2.1 ASTM Standards:

D130 Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test

D1265 Practice for Sampling Liquefied Petroleum (LP) Gases, Manual Method

D3700 Practice for Obtaining LPG Samples Using a Floating Piston Cylinder

2.2 ASTM Adjuncts:

3

ADJD0130, ASTM Copper Strip Corrosion Standard for Petroleum

3. Terminology

3.1 Abbreviations:

3.1.1 CAMI—Coated Abrasives Manufacturers Institute

3.1.2 FEPA—Federation of European Producers Association

4. Summary of Test Method

4.1 A polished copper strip is immersed in approximately 100 mL of the sample and exposed at a temperature of 37.8°C (100°F)

for 1 h in a cylinder of suitable working pressure. At the end of this period, the copper strip is removed and rated as one of the

four classifications of the ASTM Copper Strip Corrosion Standard (ADJD0130).

5. Significance and Use

5.1 Copper corrosion limits provide assurance that difficulties will not be experienced in deterioration of the copper and

copper-alloy fittings and connections that are commonly used in many types of utilization, storage, and transportation equipment.

6. Apparatus

6.1 Corrosion Test Cylinder, constructed of stainless steel with an O-ring removable top closure according to the dimensions

given in Fig. 1. Provide a flexible inert hose, such as one composed of aluminum or stainless steel, which permits inverting the

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.H0 on

Liquefied Petroleum Gas.

Current edition approved Nov. 1, 2012Dec. 1, 2012. Published December 2012March 2013. Originally approved in 1961. Last previous edition approved in 20112012 as

D1838–11.–12. DOI: 10.1520/D1838-12.10.1520/D1838-12A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from ASTM International Headquarters. Order Adjunct No. ADJD0130.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1838 − 12a

Metric Equivalents

?in. mm in. mm

in. mm in. mm

1

⁄8 3.2 3 76

1

⁄8 3.2 3 76

1

⁄4 6.4 6 152

1

⁄4 6.4 6 152

1

1 ⁄2 38.1

FIG. 1 Copper Strip Corrosion Test Cylinder

test cylinder as required in the procedure (see Note 2). The whole assembly, including the corrosion test cylinder, shall be

constructed to withstand a minimum hydrostatic test pressure of 6900 kPa (1000 psig). No leak shall be discernible when tested

at 3450 kPa (500 psig) with gas.

1

NOTE 2—Swivel connections with an adapter to fit a 6.4 mm ( ⁄4 in.) pipe may be used.

6.1.1 The assembly shall be tested for compliance with the minimum pressure rating of 6900 kPa (1000 psig) by hydrostatic

testing, or alternative testing protocol acceptable to the local authority having jurisdiction, prior to first use. Additional testing can

be required by the local authority having jurisdiction.

6.1.2 The assembly shall be verified for gas tightness by leak testing at a minimum of 3450 kPa (500 psig) with

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.