ASTM D4727/D4727M-98

(Specification)Standard Specification for Corrugated and Solid Fiberboard Sheet Stock (Container Grade) and Cut Shapes

Standard Specification for Corrugated and Solid Fiberboard Sheet Stock (Container Grade) and Cut Shapes

SCOPE

1.1 This specification covers fiberboard primarily used for the fabrication of boxes and interior details such as pads, sleeves, liners, partitions, die-cut sheets, etc.

1.2 The performance of fiberboard boxes is largely dependent on the paper components from which they are fabricated and, in the case of corrugated boxes, on the flute structure as well. Therefore, a variety of grades reflecting varied performance levels are specified.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. See Practice E380 for conversion of units.

1.4 The following safety hazards caveat pertains only to the test portion, Sections 8 and 9, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4727/D4727M – 98

Standard Specification for

Corrugated and Solid Fiberboard Sheet Stock (Container

Grade) and Cut Shapes

This standard is issued under the fixed designation D 4727/D4727M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 3951 Practice for Commercial Packaging

D 3953 Specification for Strapping, Flat Steel and Seals

1.1 This specification covers fiberboard primarily used for

D 4169 Practice for Performance Testing of Shipping Con-

the fabrication of boxes and interior details such as pads,

tainers and Systems

sleeves, liners, partitions, die-cut sheets, etc.

D 4675 Guide for Selection and Use of Flat Strapping

1.2 The performance of fiberboard boxes is largely depen-

Materials

dent on the paper components from which they are fabricated

D 5118/D 5118M Practice for Fabrication of Fiberboard

and, in the case of corrugated boxes, on the flute structure as

Shipping Boxes

well. Therefore, a variety of grades reflecting varied perfor-

D 5168 Practice for Fabrication and Closure of Triple Wall

mance levels are specified.

Corrugated Fiberboard Containers

1.3 The values stated in either inch-pound units or SI units

D 5639/D5639M Practice for Selection of Corrugated Fi-

are to be regarded separately as standard. Within the text, the

berboard Materials and Box Construction Based on Per-

SI units are shown in brackets. The values stated in each

formance Requirements

system are not exact equivalents; therefore, each system must

E 162 Test Method for Surface Flammability of Materials

be used independently of the other. Combining values from the

Using a Radiant Heat Energy Source

two systems may result in non-conformance with the standard.

E 380 Practice for the Use of the International System of

See Practice E 380 for conversion of units.

Units (SI) (The Modernized Metric System)

1.4 The following safety hazards caveat pertains only to the

E 662 Test Method for Specific Optical Density of Smoke

test portion, Sections 8 and 9, of this specification: This

Generated by Solid Materials

standard does not purport to address all of the safety concerns,

2.2 TAPPI Standards:

if any, associated with its use. It is the responsibility of the user

T 410 Weight per Unit Area (Basis Weight or Substance)

of this standard to establish appropriate safety and health

T 411 Thickness (Caliper) of Paper and Paperboard

practices and determine the applicability of regulatory limita-

T 441 Water Absorptiveness of Sized (Non-Bibulous) Paper

tions prior to use.

and Paperboard (Cobb Test)

2. Referenced Documents T 803 Puncture and Stiffness Test of Container Board

T 810 Bursting Strength of Corrugated and Solid Fiber-

2.1 ASTM Standards:

board

D 585 Practice for Sampling and Accepting a Single Lot of

T 811 Edge Crush Test

Paper, Paperboard, Fiberboard and Related Product

T 812 Ply Separation of Solid and Corrugated Fiberboard

D 685 Practice for Conditioning Paper and Paper Products

(Wet)

for Testing

2.3 Other Standards:

D 996 Terminology of Packaging and Distribution Environ-

National Motor Freight Classification

ments

D 3950 Specification for Strapping, Nonmetallic (and Join-

ing Methods)

Annual Book of ASTM Standards, Vol 04.07.

Annual Book of ASTM Standards, Vol 14.02.

Available from the Technical Association of the Pulp and Paper Industry

This specification is under the jurisdiction of ASTM Committee D-10 on

(TAPPI), P.O. Box 105113, Atlanta, GA 30348.

Packaging and is the direct responsibility of Subcommittee D10.27 on Paper and

National Motor Freight Classification is available from National Motor Freight

Paperboard.

Traffic Assoc., Inc., 2200 Mill Road, Alexandria, VA 22314.

Current edition approved April 10, 1998. Published December 1998. Originally

published as D 4727 – 87. Last previous edition D 4727/D 4727M – 96.

Annual Book of ASTM Standards, Vol 15.09.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4727/D4727M – 98

Uniform Freight Classification 5.1.5 Flute design of type corrugated fiberboard; variety SW

ISO 535 Paper and Board—Determination of Water and DW (see 6.2.1 and section 6.2.1.1),

Absorbtion—Cobb Method

5.1.6 Mill run or trimmed sheets,

5.1.7 Dimensional direction of flutes of type CF, fiberboard,

3. Terminology

5.1.8 Packing and marking requirements (see S3 and S4),

3.1 General definitions for packaging and distribution envi-

and

ronments are found in Terminology D 996.

5.1.9 Palletization requirements (see S3.1.1.1).

4. Classification

6. Materials and Manufacture

4.1 Type—Corrugated fiberboard (CF).

4.1.1 Classes—Domestic and domestic/fire retardant (D/

MATERIALS

FR).

4.1.1.1 Variety—Singlewall (SW).

(a) (a) Grades—125, 150, 175, 200, 275, and 350.

6.1 Paperboard Components:

4.1.1.2 Variety—Doublewall (DW).

6.1.1 Facings and Outer Plies—The facings of corrugated

(a) (a) Grades—200, 275, 350, 500 and 600.

fiberboard and the plies of solid fiberboard shall have bending

4.1.1.3 Variety—Triplewall (TW).

qualities to satisfy the requirements of 7.6. The paperboard

(a) (a) Grade—1100.

components of weather-resistant class material shall be treated

4.1.2 Classes—Weather-resistant and weather-resistant/fire

with a suitable wet strength resin to make them water resistant.

retardant (WR/FR).

Similarly, the paperboard components of fire retardant class

4.1.2.1 Variety—Singlewall (SW).

material shall be treated to make them fire retardant to meet the

(a) (a) Grades—V3c, W5c and W6c.

requirements of 7.7.1 and 7.7.2.

4.1.2.2 Variety—Doublewall (DW).

6.1.1.1 Outer Facing of Corrugated Fiberboard, Water- and

(a) (a) Grade—V11c, V13c and V15c.

Water Vapor Resistant Class—One outer facing of this material

4.1.2.3 Variety—Triplewall.

shall be a composite sheet comprised of one ply of sized, wet

(a) (a) Grade—1100.

strength kraft linerboard laminated to a ply of linerboard

4.1.3 Classes—Water and water-vapor resistant (WWVR)

2 2

conforming to 6.1.1 with a minimum of 6 lb/1000 ft [29 g/m ]

and water and water-vapor resistant/fire retardant (WWVR/

of polyethylene. The sized ply shall be on the exterior side of

FR).

the facing, with the unsized linerboard next to the corrugated

4.1.3.1 Variety—Singlewall (SW).

medium. At the supplier’s option, both plies of linerboard may

(a) (a) Grades—V3c WWVR, W5c WWVR.

of a sized wet strength material.

4.1.3.2 Variety—Doublewall (DW).

6.1.1.2 Facing and Outer Plies Pertaining to Hazardous

(a) (a) Grades—V11c WWVR and V13c WWVR.

Materials Packaging—The facings of corrugated fiberboard

4.2 Type—Solid Fiberboard (SF).

and the plies of solid fiberboard shall have water resistance

4.2.1 Class—Domestic (D).

qualities to satisfy the following requirement from ISO 535:

4.2.1.1 Grades—125, 175, 200, 275, 350, 500 and 600.

(a) Water resistance of the outer surface shall be such that

4.2.2 Class—Weather-resistant.

the increase in mass, as determined in a test carried out over a

4.2.2.1 Grades— V2s, V3s, V4s, W5s and W6s.

period of 30 min by the Cobb test method of determining water

absorbtion, is not greater than 155 g/m .

5. Ordering Information

6.1.2 Corrugated Medium—The corrugating medium of

5.1 Purchasers should select the preferred options permitted

corrugated fiberboard shall be made from any suitable fibers.

herein, and include the following information in procurement

6.2 Adhesives:

documents:

5.1.1 Title, number and date of this specification,

6.2.1 Domestic and Domestic/Fire Retardant Classes—The

5.1.2 Type, class, variety and grade (see 4.1 and 7.1), adhesive used in the construction of the domestic/fire retardant

5.1.3 Size of sheet, pad, etc. (see 7.3.1.4),

class of fiberboard should be that which is commercially used

5.1.4 Center line of score to center line of score or sheet by the industry, and shall enable the end item to meet the

edge (see 7.3.1.4),

strength requirements specified herein.

6.2.2 Weather-Resistant and Weather-Resistant/Fire Retar-

dant Classes—The adhesive used in the construction of

weather-resistant fiberboard shall be water-resistant to the

Uniform Freight Classification is available from Rail Publication Service, 151

Ellis St. N.E., Suite 260, Atlanta, GA 30335–6021.

extent that the end item will meet the requirements of this

Available from the American National Standards Institute (ANSI), 105–111

specification (see 7.4).

South State Street, Hackensack, NJ 07601.

6.2.3 Water and Water Vapor-Resistant and Water and

Grade numbers for single and double wall corrugated varieties and solid fiber

types refer to the bursting strength in lb/in. as determined by TAPPI T 810.

Water Vapor-Resistant/Fire Retardant Classes—The adhesives

Grade number for triplewall refers to the dry puncture resistance in units as

used shall enable the combined board to meet the requirements

determined by TAPPI T803.

of 7.4. Paragraph 7.4 also applies to the polyethylene liner-

Available from Standardization Documents Order Desk, Bldg. 4 Section D,

700 Robbins Ave., Philadelphia, PA 19111–5094, Attn: NPODS. board bonds in the laminated facings.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4727/D4727M – 98

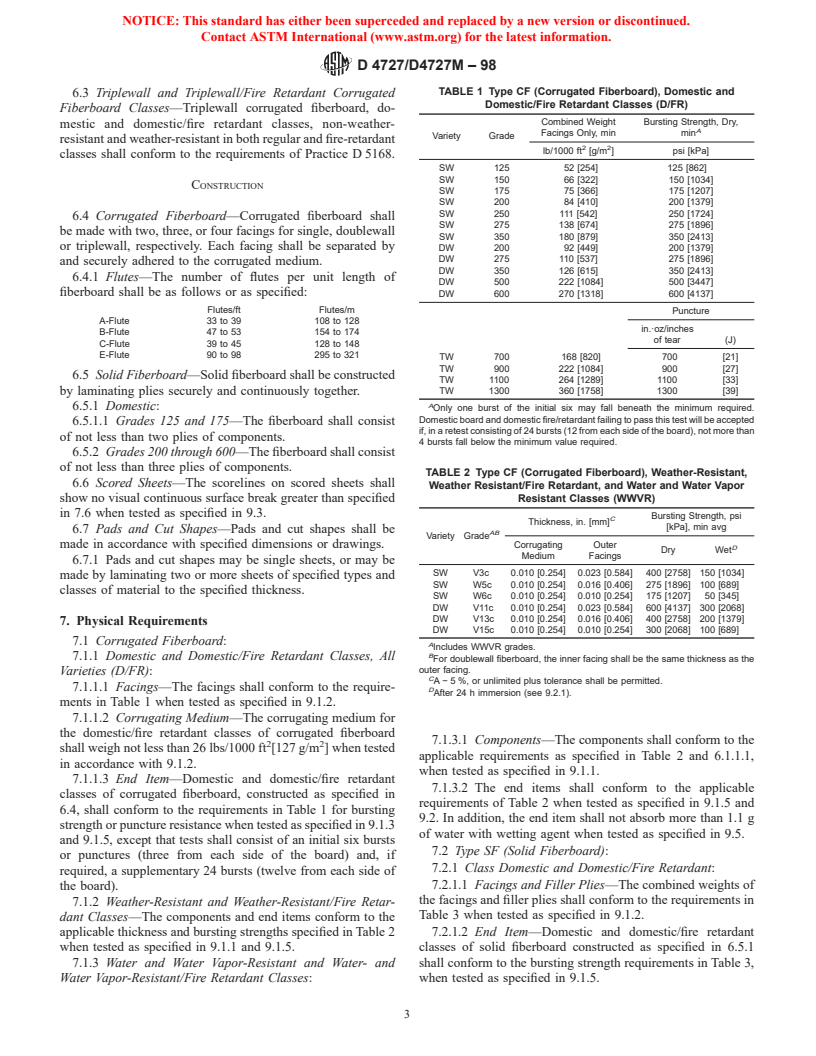

TABLE 1 Type CF (Corrugated Fiberboard), Domestic and

6.3 Triplewall and Triplewall/Fire Retardant Corrugated

Domestic/Fire Retardant Classes (D/FR)

Fiberboard Classes—Triplewall corrugated fiberboard, do-

Combined Weight Bursting Strength, Dry,

mestic and domestic/fire retardant classes, non-weather-

A

Facings Only, min min

Variety Grade

resistant and weather-resistant in both regular and fire-retardant

2 2

lb/1000 ft [g/m ] psi [kPa]

classes shall conform to the requirements of Practice D 5168.

SW 125 52 [254] 125 [862]

SW 150 66 [322] 150 [1034]

CONSTRUCTION

SW 175 75 [366] 175 [1207]

SW 200 84 [410] 200 [1379]

SW 250 111 [542] 250 [1724]

6.4 Corrugated Fiberboard—Corrugated fiberboard shall

SW 275 138 [674] 275 [1896]

be made with two, three, or four facings for single, doublewall

SW 350 180 [879] 350 [2413]

or triplewall, respectively. Each facing shall be separated by

DW 200 92 [449] 200 [1379]

DW 275 110 [537] 275 [1896]

and securely adhered to the corrugated medium.

DW 350 126 [615] 350 [2413]

6.4.1 Flutes—The number of flutes per unit length of

DW 500 222 [1084] 500 [3447]

fiberboard shall be as follows or as specified: DW 600 270 [1318] 600 [4137]

Flutes/ft Flutes/m

Puncture

A-Flute 33 to 39 108 to 128

in.·oz/inches

B-Flute 47 to 53 154 to 174

of tear (J)

C-Flute 39 to 45 128 to 148

E-Flute 90 to 98 295 to 321

TW 700 168 [820] 700 [21]

TW 900 222 [1084] 900 [27]

6.5 Solid Fiberboard—Solid fiberboard shall be constructed

TW 1100 264 [1289] 1100 [33]

by laminating plies securely and continuously together. TW 1300 360 [1758] 1300 [39]

A

6.5.1 Domestic:

Only one burst of the initial six may fall beneath the minimum required.

Domestic board and domestic fire/retardant failing to pass this test will be accepted

6.5.1.1 Grades 125 and 175—The fiberboard shall consist

if, in a retest consisting of 24 bursts (12 from each side of the board), not more than

of not less than two plies of components.

4 bursts fall below the minimum value required.

6.5.2 Grades 200 through 600—The fiberboard shall consist

of not less than three plies of components.

TABLE 2 Type CF (Corrugated Fiberboard), Weather-Resistant,

6.6 Scored Sheets—The scorelines on scored sheets shall

Weather Resistant/Fire Retardant, and Water and Water Vapor

show no visual continuous surface break greater than specified Resistant Classes (WWVR)

in 7.6 when tested as specified in 9.3.

Bursting Strength, psi

C

Thickness, in. [mm]

[kPa], min avg

6.7 Pads and Cut Shapes—Pads and cut shapes shall be

AB

Variety Grade

Corrugating Outer

made in accordance with specified dimensions or drawings.

D

Dry Wet

Medium Facings

6.7.1 Pads and cut shapes may be single sheets, or may be

SW V3c 0.010 [0.254] 0.023 [0.584] 400 [2758] 150 [1034]

made by laminating two or more sheets of specified types and

SW W5c 0.010 [0.254] 0.016 [0.406] 275 [1896] 100 [689]

classes of material to the specified thickness.

SW W6c 0.010 [0.254] 0.010 [0.254] 175 [1207] 50 [345]

DW V11c 0.010 [0.254] 0.023 [0.584] 600 [4137] 300 [2068]

DW V13c 0.010 [0.254] 0.016 [0.406] 400 [2758] 200 [1379]

7. Physical Requirements

DW V15c 0.010 [0.254] 0.010 [0.254] 300 [2068] 100 [689]

7.1 Corrugated Fiberboard:

A

Includes WWVR grades.

B

7.1.1 Domestic and Domestic/Fire Retardant Classes, All

For doublewall fiberboard, the inner facing shall be the same thickness as the

outer facing.

Varieties (D/FR):

C

A−5%, or unlimited plus tolerance shall be permitted.

7.1.1.1 Facings—The facings shall conform to the require- D

After 24 h immersion (see 9.2.1).

ments in Table 1 when tested as specified in 9.1.2.

7.1.1.2 Corrugating Medium—The corrugating medium for

the domestic/fire retardant classes of corrugated fiberboard

7.1.3.1 Components—The components shall conform to the

2 2

shall weigh not less than 26 lbs/1000 ft [127 g/m ] when tested

applicable requirements as specified in Table 2 and 6.1.1.1,

in accordance with 9.1.2.

when tested as specified in 9.1.1.

7.1.1.3 End Item—Domestic and domestic/fire retardant

7.1.3.2 The end items shall conform to the applicable

classes of corrugated fiberboard, constructed as specified in

requirements of Table 2 when tested as specified in 9.1.5 and

6.4, shall conform to the requirements in Table 1 for bursting

9.2. In addition, the end item shall not absorb more than 1.1 g

strength or puncture resistance when tested as specified in 9.1.3

of water with wetting agent when tested as specified in 9.5.

and 9.1.5, except that tests shall consist of an initial six bursts

7.2 Type SF (Solid Fiberboard):

or punctures (three from each side of the board) and, if

7.2.1 Class Domestic and Domestic/Fire Retardant:

required, a supplementary 24 bursts (twelve from each side of

7.2.1.1 Facings and Filler Plies—The combined weights of

the board).

the facings and filler plies shall conform to the requirements in

7.1.2 Weather-Resistant and Weather-Resistant/Fire Retar-

Table 3 when tested as specified in 9.1.2.

dant Classes—The components and end items conform to the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.