ASTM F449-16

(Practice)Standard Practice for Subsurface Installation of Corrugated Polyethylene Pipe for Agricultural Drainage or Water Table Control

Standard Practice for Subsurface Installation of Corrugated Polyethylene Pipe for Agricultural Drainage or Water Table Control

ABSTRACT

This practice covers the procedures for subsurface installation of corrugated polyethylene pipe, in accordance with the flexible conduit principles, intended for agricultural drainage or water table control. It is not however recommended for sanitary and storm sewer applications. General requirements for installation include: maximum and minimum burial depth; trench width; design of blinding, bedding, or envelope materials that are to be placed as the pipe is installed to ensure uniform continuous support; and granular or synthetic filters that are used to restrict the movement of particles into the pipe so as to maintain its hydraulic capacity. The pipe shall be aligned as smooth as possible with a curve radius larger than five times the pipe diameter while the backfill material shall be placed preferably on an angle to prevent pipe displacement or deflection. Stony trenches shall be avoided and any over-excavation or rock excavation shall be treated with proper bedding material. Factors that affect the proper handling of the pipe such as temperature; stretch caused by tension and bending forces; synthetic envelopes and filters that are subject to abrasion and tearing; and protection from fire hazards, livestock, heavy wheel traffic, and rodents or other animals shall also be considered during installation.

SCOPE

1.1 This practice is recommended for and limited to gravity flow subsurface drainage systems or water table control, but not recommended for sanitary or storm sewer applications. Procedures are outlined to minimize pipe deflection or structural damage during and after the installation process. These installation procedures are in accordance with “flexible conduit” principles.

1.2 This practice applies to all agricultural subsurface drainage or water table control installations using Specification F667, F2648, or other plastic pipe.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F449 − 16

Standard Practice for

Subsurface Installation of Corrugated Polyethylene Pipe for

1

Agricultural Drainage or Water Table Control

ThisstandardisissuedunderthefixeddesignationF449;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* and Fittings for Land Drainage Applications

1.1 This practice is recommended for and limited to gravity

3. Terminology

flow subsurface drainage systems or water table control, but

not recommended for sanitary or storm sewer applications. 3.1 Definitions are in accordance with Terminology F412

Procedures are outlined to minimize pipe deflection or struc- and abbreviations are in accordance with Terminology D1600,

tural damage during and after the installation process. These unless otherwise specified.

installation procedures are in accordance with “flexible con-

3.2 backfill—materials used to fill the trench following

duit” principles.

installation of the pipe and bedding.

1.2 This practice applies to all agricultural subsurface drain-

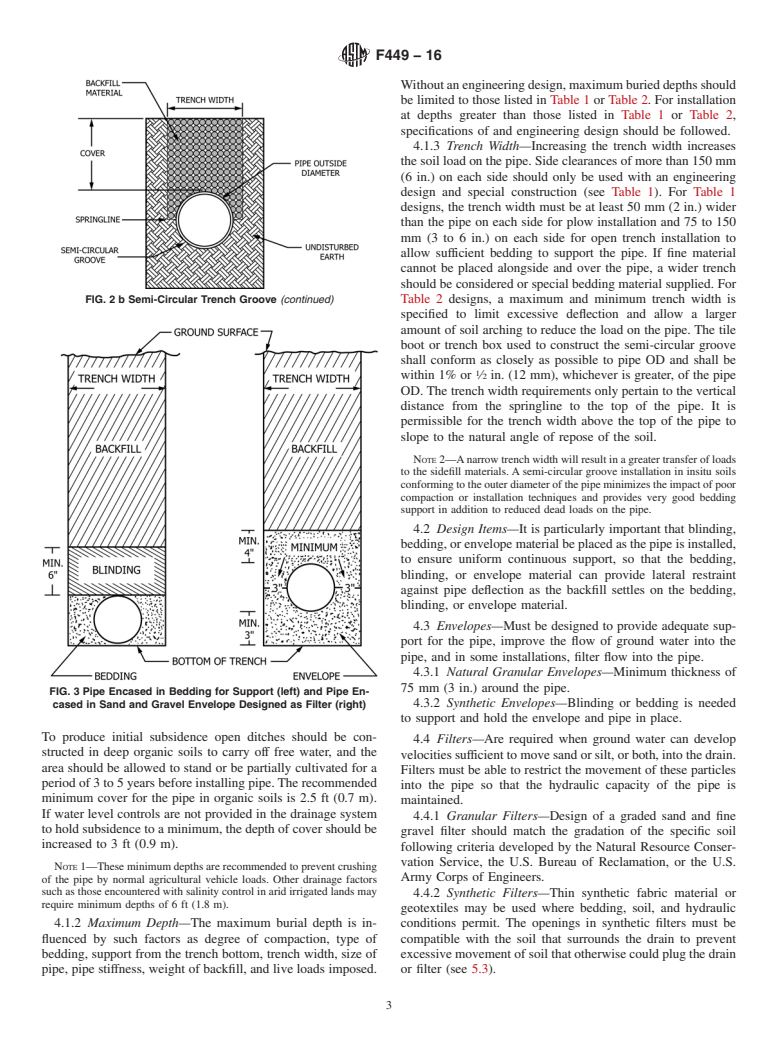

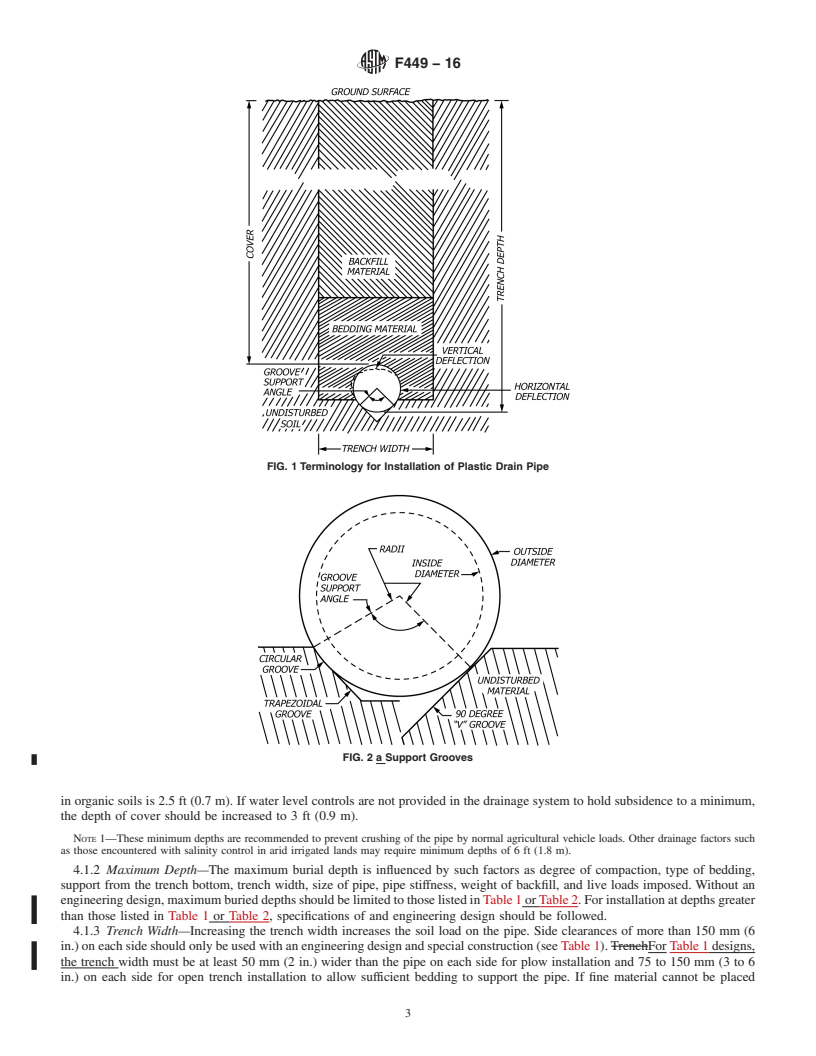

3.3 bedding—material which provides stable bottom sup-

age or water table control installations using Specification

port for the pipe including the trench bottom groove support

F667, F2648, or other plastic pipe.

angle or select material placed around the pipe, and envelope

or filter materials where used during installation.

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical 3.4 blinding—the placement of soil, bedding material over

conversions to SI units that are provided for information only

and on the sides of the pipe or envelope to ensure proper grade,

and are not considered standard. alignment, support, and protection of pipe during backfilling

and after installation.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.5 boot (also shield)—the protecting apparatus linked to

responsibility of the user of this standard to establish appro-

the rear of the installation machine in a manner which allows

priate safety and health practices and determine the applica- placement of the pipe on the trench bottom, protection of the

bility of regulatory limitations prior to use.

workman, or placement of envelope or filter material, or both.

3.6 cradle—a prefabricated rigid structure designed to pro-

2. Referenced Documents

vide trench bottom support for the pipe when soil support is

2

2.1 ASTM Standards:

inadequate.

D1600 Terminology forAbbreviatedTerms Relating to Plas-

3.7 envelope—porous material placed around the pipe to

tics

provide bedding, improve the flow of ground water into the

D2412 Test Method for Determination of External Loading

drain, or function as a filter.

Characteristics of Plastic Pipe by Parallel-Plate Loading

3.8 filter—an envelope of natural or synthetic materials

F412 Terminology Relating to Plastic Piping Systems

placed completely around a drain to permit free water move-

F667 Specification for 3 through 24 in. Corrugated Polyeth-

ment into the drain, provide stabilizing support at the soil-filter

ylene Pipe and Fittings

interface, and restrict movement of silt and sand into the drain.

F2648 Specification for 2 to 60 inch [50 to 1500 mm]

Annular Corrugated Profile Wall Polyethylene (PE) Pipe 3.9 grade—the slope of the pipe invert.

3.10 groove support angle—angle between the radii of the

1 pipe at points of contact with the formed groove of undisturbed

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land soil or a cradle.

Drainage.

3.11 mineral soils—soil containing (1) less than 30 % or-

Current edition approved Feb. 15, 2016. Published March 2016. Originally

ganicmatterbyweightprovidedthemineralfractionis60 %or

approvedin1976.Lastpreviouseditionapprovedin2014asF449 – 02(2014).DOI:

10.1520/F0449-16.

more clay, or (2) less than 20 % organic matter by weight

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

provided the mineral fraction has no clay, or (3) less than a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

proportional content of organic matter between 20 and 30 % if

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the clay content of the mineral fraction is between 0 and 60 %.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F449 − 02 (Reapproved 2014) F449 − 16

Standard Practice for

Subsurface Installation of Corrugated Polyethylene Pipe for

1

Agricultural Drainage or Water Table Control

This standard is issued under the fixed designation F449; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice is recommended for and limited to gravity flow subsurface drainage systems or water table control, but not

recommended for sanitary or storm sewer applications. Procedures are outlined to minimize pipe deflection or structural damage

during and after the installation process. These installation procedures are in accordance with “flexible conduit” principles.

1.2 This practice applies to all agricultural subsurface drainage or water table control installations using Specification

F405F667, F667F2648, or other plastic pipe.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

3

F405 Specification for Corrugated Polyethylene (PE) Pipe and Fittings (Withdrawn 2015)

F412 Terminology Relating to Plastic Piping Systems

F667 Specification for 3 through 24 in. Corrugated Polyethylene Pipe and Fittings

F2648 Specification for 2 to 60 inch [50 to 1500 mm] Annular Corrugated Profile Wall Polyethylene (PE) Pipe and Fittings for

Land Drainage Applications

3. Terminology

3.1 Definitions are in accordance with Terminology F412 and abbreviations are in accordance with Terminology D1600, unless

otherwise specified.

3.2 backfill—materials used to fill the trench following installation of the pipe and bedding.

3.3 bedding—material which provides stable bottom support for the pipe including the trench bottom groove support angle or

select material placed around the pipe, and envelope or filter materials where used during installation.

3.4 blinding—the placement of soil, bedding material over and on the sides of the pipe or envelope to ensure proper grade,

alignment, support, and protection of pipe during backfilling and after installation.

3.5 boot (also shield)—the protecting apparatus linked to the rear of the installation machine in a manner which allows

placement of the pipe on the trench bottom, protection of the workman, or placement of envelope or filter material, or both.

3.6 cradle—a prefabricated rigid structure designed to provide trench bottom support for the pipe when soil support is

inadequate.

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land Drainage.

Current edition approved March 1, 2014Feb. 15, 2016. Published September 2014March 2016. Originally approved in 1976. Last previous edition approved in 20082014

as F449 – 02(2008).(2014). DOI: 10.1520/F0449-02R14.10.1520/F0449-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F449 − 16

3.7 envelope—porous material placed around the pipe to provide bedding, improve the flow of ground water into the drain, or

function as a filter.

3.8 filter—an envelope of natural or synthetic materials placed completely around a drain to permit free water movement into

the drain, provide stabilizing support at the soil-filter interface, and restrict movement of silt and sand into the drain.

3.9 grade—the slope

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.