ASTM E750-98

(Practice)Standard Practice for Characterizing Acoustic Emission Instrumentation

Standard Practice for Characterizing Acoustic Emission Instrumentation

SCOPE

1.1 This practice is recommended for use in testing and measuring operating characteristics of acoustic emission electronic components or units. (See Appendix X1 for a description of components and units.) It is not intended that this practice be used for routine checks of acoustic emission instrumentation, but rather for periodic calibration or in the event of a malfunction. The sensor is not addressed in this document other than suggesting methods for standardizing system gains (equalizing them channel to channel) when sensors are present.

1.2 Where the manufacturer provides testing and measuring details in an operating and maintenance manual, the manufacturer's methods should be used in conjunction with the methods described in this practice.

1.3 Difficult or questionable instrumentation measurements should be referred to electronics engineering personnel.

1.4 The methods set forth in this practice are not intended to be either exclusive or exhaustive.

1.5 The methods (techniques) used for testing and measuring the components or units of acoustic emission instrumentation, and the results of such testing and measuring should be documented. Documentation should consist of photographs, charts or graphs, calculations, and tabulations where applicable.

1.6 AE systems that use mini or micro computers to control the collection, storage, display, and analysis of data are in common use. Features of the computer-based systems include a wide selection of measurement parameters relating to the AE event. This selection, however, is usually made after the data have been acquired. This implies that the AE signals are individually recorded for later analysis, or that all the available parameters are measured on every AE signal that exceeds the selected threshold. The latter is usually the case. The manufacturer provides a specification for each system that specifies the operating range and conditions for the system. All calibration and acceptance testing of computer-based AE systems must use the manufacturer's specification as a guide. This practice does not cover testing of the computer or computer peripherals.

1.7 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 750 – 98

Standard Practice for

Characterizing Acoustic Emission Instrumentation

This standard is issued under the fixed designation E 750; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice is recommended for use in testing and

responsibility of the user of this standard to establish appro-

measuring operating characteristics of acoustic emission elec-

priate safety and health practices and determine the applica-

tronic components or units. (See Appendix X1 for a description

bility of regulatory limitations prior to use.

of components and units.) It is not intended that this practice be

used for routine checks of acoustic emission instrumentation,

2. Referenced Documents

but rather for periodic calibration or in the event of a

2.1 ASTM Standards:

malfunction. The sensor is not addressed in this document

E 1316 Terminology for Nondestructive Examinations

other than suggesting methods for standardizing system gains

2.2 ANSI Standard:

(equalizing them channel to channel) when sensors are present.

ANSI/IEEE 100-1984 Dictionary of Electrical and Elec-

1.2 Where the manufacturer provides testing and measuring

tronic Terms

details in an operating and maintenance manual, the manufac-

2.3 Other Documents:

turer’s methods should be used in conjunction with the

Manufacturer’s Operating and Maintenance Manuals perti-

methods described in this practice.

nent to the specific instrumentation or component

1.3 Difficult or questionable instrumentation measurements

should be referred to electronics engineering personnel.

3. Terminology

1.4 The methods set forth in this practice are not intended to

3.1 Definitions—For definitions of additional terms relating

be either exclusive or exhaustive.

to acoustic emission, refer to Terminology E 1316.

1.5 The methods (techniques) used for testing and measur-

ing the components or units of acoustic emission instrumenta-

4. Apparatus

tion, and the results of such testing and measuring should be

4.1 The basic test instruments required for measuring the

documented. Documentation should consist of photographs,

operating characteristics of acoustic emission instrumentation

charts or graphs, calculations, and tabulations where appli-

include:

cable.

4.1.1 Variable Sine Wave Generator,

1.6 AE systems that use mini or micro computers to control

4.1.2 True RMS Voltmeter,

the collection, storage, display, and analysis of data are in

4.1.3 Oscilloscope,

common use. Features of the computer-based systems include

4.1.4 Variable Attenuator, graduated in decibels, and

a wide selection of measurement parameters relating to the AE

4.1.5 Tone Burst Generator.

event. This selection, however, is usually made after the data

4.2 Additional test instruments should be used for more

have been acquired. This implies that the AE signals are

specialized measurements of acoustic emission instrumenta-

individually recorded for later analysis, or that all the available

tions or components. They are as follows:

parameters are measured on every AE signal that exceeds the

4.2.1 Variable-Function Generator,

selected threshold. The latter is usually the case. The manu-

4.2.2 Time Interval Meter,

facturer provides a specification for each system that specifies

4.2.3 Frequency Meter, or Counter,

the operating range and conditions for the system. All calibra-

4.2.4 Random Noise Generator,

tion and acceptance testing of computer-based AE systems

4.2.5 Spectrum Analyzer,

must use the manufacturer’s specification as a guide. This

4.2.6 D-C Voltmeter,

practice does not cover testing of the computer or computer

4.2.7 Pulse-Modulated Signal Generator,

peripherals.

4.2.8 Variable Pulse Generator, and

This practice is under the jurisdiction of ASTM Committee E-7 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.04 on

Acoustic Emission. Annual Book of ASTM Standards, Vol 03.03.

Current edition approved May 10, 1998. Published July 1998. Originally Available from American National Standards Institute, 11 West 42nd Street,

published as E 750 – 80. Last previous edition E 750 – 88(1993)e1. 13th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E750–98

4.2.9 Phase Meter, necting cables. All measurements and tests should be docu-

4.2.10 Electronic AE Simulator. mented. The preamplifier should be terminated with the normal

4.3 An electronic AE simulator is necessary to evaluate the working load.

operation of computer-based AE instruments. A detailed ex- 5.2.2 An acceptable frequency response between cutoff

ample of the use of an electronic AE simulator is given in 5.5.3

frequencies is within 3 dB of the reference frequency. The

under dead time measurement. The instruction manual for the reference frequency is the geometric mean of the nominal

electronic AE simulator provides details on the setup and

bandwidth of the instrumentation. The mean frequency is

adjustment of the simulator. Control of pulse frequency, rise calculated as follows:

time, decay, repetition rate, and peak amplitude in the simula-

f 5 f f !2

~

tor makes it possible to simulate a wide range of AE signal M L H

conditions.

where:

f = mean frequency,

M

5. Tests and Measurements

f = nominal lower cutoff, and

L

5.1 Required Measurements:

f = nominal upper cutoff.

H

5.1.1 Tests and measurements should be performed to

5.2.3 The bandwidth should include all contiguous frequen-

determine the instrumentation bandwidth, frequency response,

cies with amplitude variations as specified by the manufacturer.

gain, noise level, threshold level, dynamic range, signal over-

Instruments that include signal processing of amplitude as a

load point, dead time, and counter accuracy.

function of frequency should have bandwidth amplitude varia-

5.1.2 Where acoustic emission test results depend upon the

tions as specified by the manufacturer.

reproduced accuracy of the temporal, spatial, or spectral

5.2.4 With the instrumentation connected as shown in Fig. 1

histories, additional measurements of instrumentation param-

and the sine wave oscillator set well within the instrumenta-

eters should be performed to determine the specific limits of

tion’s specified dynamic range, the frequency response should

instrumentation performance. Examples of such measurements

be measured between frequency limits specified in 5.2.2. The

may include amplifier slew rate, gate window width and

oscillator is maintained at a fixed amplitude and the frequency

position, and spectral analysis.

is swept through the frequency limits. The secondary amplifier,

5.1.3 Tests and measurements should be performed to

or final filter, output is monitored with an rms voltmeter. Values

determine the loss in effective sensor sensitivity resulting from

of amplitude are recorded for each of several frequencies

the capacitive loading of the cable between the preamplifier

within and beyond the nominal cutoff frequencies. The re-

and the sensor. The cable and preamplifier should be the same

corded values are plotted on chart paper. The amplitude scale

as that used for the acoustic emission tests without substitution.

may be converted to decibels. The frequency scale may be

(See also Appendix X2.)

plotted either linearly or logarithmically. Appendix X2 pro-

5.1.3.1 Important tests of a computer-based AE system

vides further discussion of wave shaping components.

include the evaluation of limits and linearity of the available

5.2.5 A spectrum analyzer may be used in conjunction with

parameters such as:

a white noise source or an oscilloscope may be used in

(a) Amplitude,

conjunction with a sweep frequency oscillator to determine

(b) Duration,

bandwidth. With a white noise source connected to the input, a

(c) Rise Time,

spectrum analyzer connected to the output will record the

(d) Energy, and

frequency response.

(e) Source Location.

5.2.6 The measured bandwidth is the difference between the

5.1.3.2 The processing speed of these data should be mea-

frequencies at which the response is 3 dB less than the response

sured as described in 5.5.3 for both single- and multiple-

at the reference frequency.

channel operation.

5.3 Gain:

5.1.3.3 The data storage capability should be tested against

5.3.1 The electronic amplification is comprised of the

the specification for single- and multiple-channel operation.

preamplifier gain, the secondary amplifier gain, and the wave

Processing speed is a function of number of channels, param-

filters insertion gains or losses. (See Appendix X2 for an

eters being measured, event duration, front-end filtering, stor-

explanation of gain measurements.)

age and display (RAM, disk, plots) and printout requirements.

5.3.2 The electronic amplification may be measured with

5.2 Frequency Response and Bandwith:

the instrumentation shown in Fig. 1. The sine wave oscillator is

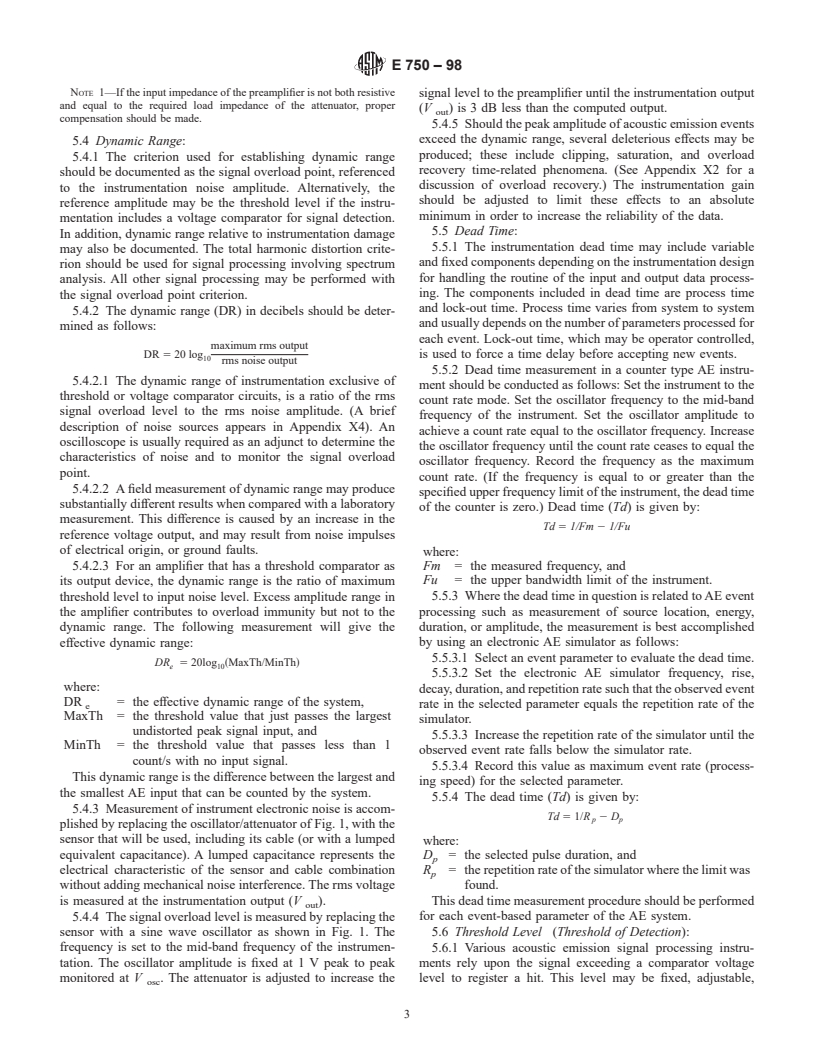

5.2.1 The instrumentation, shown in Fig. 1, includes the

set to the reference frequency. The oscillator amplitude is set

preamplifier, wave filters, secondary amplifier, and intercon-

well within the dynamic range of the instrumentation to avoid

distortion due to overload. With the voltmeter at V , oscillator

osc

amplitude is set to 1 V. The attenuator is set for a value greater

than the anticipated electronic amplification. Next, the voltme-

ter is moved to V . The attenuator is now adjusted until the

out

voltmeter again reads 1 V. The electronic amplification is equal

FIG. 1 Component Configuration Used for Testing and Measuring

to the new setting on the attenuator. A white noise generator or

the Frequency Response, Amplification, Noise, Signal Overload,

sweep generator and spectrum analyzer may be used in place of

Recovery Time, and Threshold of Acoustic Emission

Instrumentation the oscillator and RMS voltmeter.

E750–98

NOTE 1—If the input impedance of the preamplifier is not both resistive

signal level to the preamplifier until the instrumentation output

and equal to the required load impedance of the attenuator, proper

(V ) is 3 dB less than the computed output.

out

compensation should be made.

5.4.5 Should the peak amplitude of acoustic emission events

exceed the dynamic range, several deleterious effects may be

5.4 Dynamic Range:

produced; these include clipping, saturation, and overload

5.4.1 The criterion used for establishing dynamic range

recovery time-related phenomena. (See Appendix X2 for a

should be documented as the signal overload point, referenced

discussion of overload recovery.) The instrumentation gain

to the instrumentation noise amplitude. Alternatively, the

should be adjusted to limit these effects to an absolute

reference amplitude may be the threshold level if the instru-

minimum in order to increase the reliability of the data.

mentation includes a voltage comparator for signal detection.

5.5 Dead Time:

In addition, dynamic range relative to instrumentation damage

5.5.1 The instrumentation dead time may include variable

may also be documented. The total harmonic distortion crite-

and fixed components depending on the instrumentation design

rion should be used for signal processing involving spectrum

for handling the routine of the input and output data process-

analysis. All other signal processing may be performed with

ing. The components included in dead time are process time

the signal overload point criterion.

and lock-out time. Process time varies from system to system

5.4.2 The dynamic range (DR) in decibels should be deter-

and usually depends on the number of parameters processed for

mined as follows:

each event. Lock-out time, which may be operator controlled,

maximum rms output

DR 5 20 log is used to force a time delay before accepting new events.

rms noise output

5.5.2 Dead time measurement in a counter type AE instru-

5.4.2.1 The dynamic range of instrumentation exclusive of

ment should be conducted as follows: Set the instrument to the

threshold or voltage comparator circuits, is a ratio of the rms

count rate mode. Set the oscillator frequency to the mid-band

signal overload level to the rms noise amplitude. (A brief

frequency of the instrument. Set the oscillator amplitude to

description of noise sources appears in Appendix X4). An

achieve a count rate equal to the oscillator frequency. Increase

oscilloscope is usually required as an adjunct to determine the

the oscillator frequency until the count rate ceases to equal the

characteristics of noise and to monitor the signal overload

oscillator frequency. Record the frequency as the maximum

point.

count rate. (If the frequency is equal to or greater than the

5.4.2.2 A field measurement of dynamic range may produce

specified upper frequency limit of the instrument, the dead time

substantially different results when compared with a laboratory

of the counter is zero.) Dead time (Td) is given by:

measurement. This difference is caused by an increase in the

Td 5 1/Fm 2 1/Fu

reference voltage output, and may result from noise impulses

of electrical origin, or ground faults.

where:

5.4.2.3 For an amplifier that has a threshold comparator as Fm = the measured frequency, and

Fu = the upper bandwidth limit of the instrument.

its output device, the dynamic range is the ratio of maximum

threshold level to input noise level. Excess amplitude range in 5.5.3 Where the dead time in question is related to AE event

processing such as measurement of source location, energy,

the amplifier contributes to overload immunity but not to the

dynamic range. The following measurement will give the duration, or amplitude, the measurement is best accomplished

effective dynamic range: by using an electronic AE simulator as follows:

5.5.3.1 Select an event parameter to evaluate the dead time.

DR 5 20log ~MaxTh/MinTh!

e 10

5.5.3.2 Set the electronic AE simulator frequency, rise,

where:

decay, duration, and repetition rate such that the observed event

DR = the effective dynamic range of the system,

rate in the selected parameter equals the repetition rate of the

e

MaxTh = the threshold value that just passes the largest

simulator.

undistorted peak signal input, and

5.5.3.3 Increase the repetition rate of the simulator until the

MinTh = the threshold value that passes less than 1

observed event rate falls below the simulator rate.

count/s with no input signal.

5.5.3.4 Record this value as maximum event rate (process-

This dynam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.