ASTM D5056-02

(Test Method)Standard Test Method for Trace Metals in Petroleum Coke by Atomic Absorption

Standard Test Method for Trace Metals in Petroleum Coke by Atomic Absorption

SCOPE

1.1 This test method covers the analysis for the commonly determined trace metals (aluminum, calcium, iron, nickel, silicon, sodium, and vanadium) in laboratory analysis samples of raw and calcined petroleum coke by atomic absorption spectroscopy.

1.2 The elemental concentration ranges for which this test method is applicable and the limits of detection of this test method are listed in Table 1.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For hazard statements, see Sections 8-10.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D5056–02

Standard Test Method for

1

Trace Metals in Petroleum Coke by Atomic Absorption

This standard is issued under the fixed designation D 5056; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

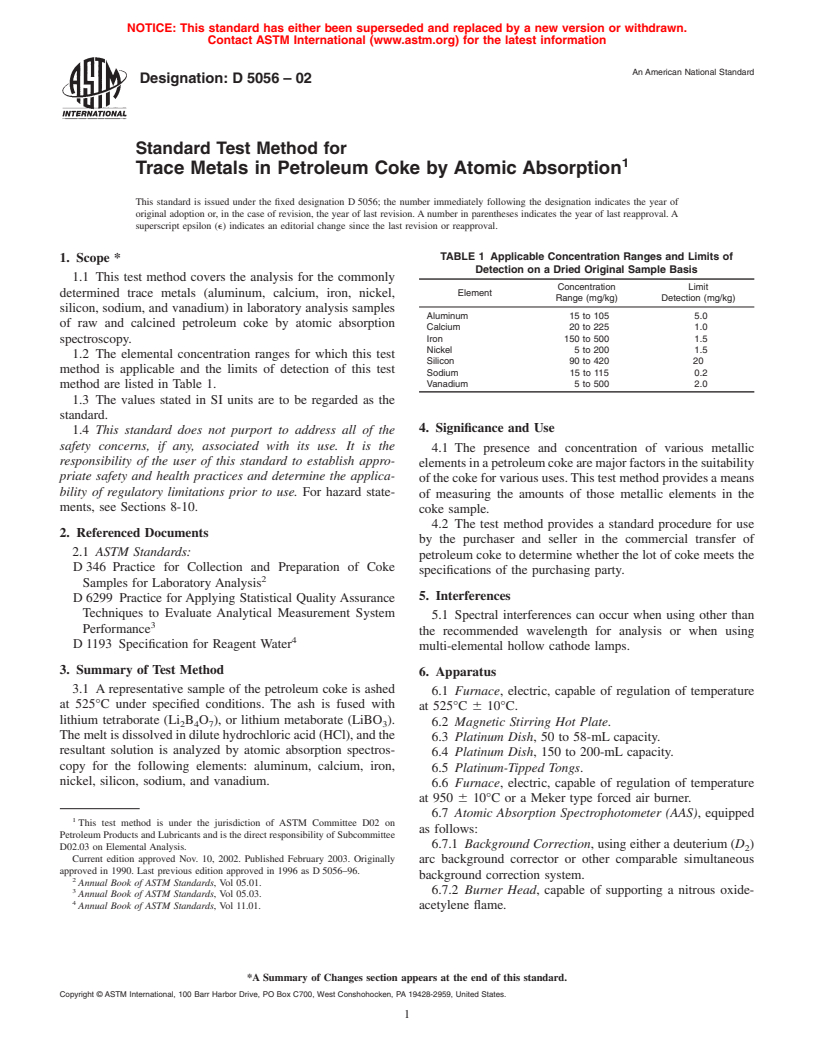

TABLE 1 Applicable Concentration Ranges and Limits of

1. Scope *

Detection on a Dried Original Sample Basis

1.1 This test method covers the analysis for the commonly

Concentration Limit

Element

determined trace metals (aluminum, calcium, iron, nickel,

Range (mg/kg) Detection (mg/kg)

silicon, sodium, and vanadium) in laboratory analysis samples

Aluminum 15 to 105 5.0

of raw and calcined petroleum coke by atomic absorption

Calcium 20 to 225 1.0

spectroscopy. Iron 150 to 500 1.5

Nickel 5 to 200 1.5

1.2 The elemental concentration ranges for which this test

Silicon 90 to 420 20

method is applicable and the limits of detection of this test

Sodium 15 to 115 0.2

Vanadium 5 to 500 2.0

method are listed in Table 1.

1.3 The values stated in SI units are to be regarded as the

standard.

4. Significance and Use

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.1 The presence and concentration of various metallic

responsibility of the user of this standard to establish appro-

elementsinapetroleumcokearemajorfactorsinthesuitability

priate safety and health practices and determine the applica-

ofthecokeforvarioususes.Thistestmethodprovidesameans

bility of regulatory limitations prior to use. For hazard state-

of measuring the amounts of those metallic elements in the

ments, see Sections 8-10.

coke sample.

4.2 The test method provides a standard procedure for use

2. Referenced Documents

by the purchaser and seller in the commercial transfer of

2.1 ASTM Standards:

petroleum coke to determine whether the lot of coke meets the

D 346 Practice for Collection and Preparation of Coke

specifications of the purchasing party.

2

Samples for Laboratory Analysis

5. Interferences

D 6299 Practice for Applying Statistical Quality Assurance

Techniques to Evaluate Analytical Measurement System

5.1 Spectral interferences can occur when using other than

3

Performance

the recommended wavelength for analysis or when using

4

D 1193 Specification for Reagent Water

multi-elemental hollow cathode lamps.

3. Summary of Test Method

6. Apparatus

3.1 A representative sample of the petroleum coke is ashed

6.1 Furnace, electric, capable of regulation of temperature

at 525°C under specified conditions. The ash is fused with

at 525°C 6 10°C.

lithium tetraborate (Li B O ), or lithium metaborate (LiBO ).

6.2 Magnetic Stirring Hot Plate.

2 4 7 3

Themeltisdissolvedindilutehydrochloricacid(HCl),andthe

6.3 Platinum Dish, 50 to 58-mL capacity.

resultant solution is analyzed by atomic absorption spectros-

6.4 Platinum Dish, 150 to 200-mL capacity.

copy for the following elements: aluminum, calcium, iron,

6.5 Platinum-Tipped Tongs.

nickel, silicon, sodium, and vanadium.

6.6 Furnace, electric, capable of regulation of temperature

at 950 6 10°C or a Meker type forced air burner.

6.7 Atomic Absorption Spectrophotometer (AAS), equipped

1

This test method is under the jurisdiction of ASTM Committee D02 on

as follows:

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

6.7.1 Background Correction, using either a deuterium (D )

D02.03 on Elemental Analysis.

2

Current edition approved Nov. 10, 2002. Published February 2003. Originally

arc background corrector or other comparable simultaneous

approved in 1990. Last previous edition approved in 1996 as D 5056–96.

background correction system.

2

Annual Book of ASTM Standards, Vol 05.01.

3 6.7.2 Burner Head, capable of supporting a nitrous oxide-

Annual Book of ASTM Standards, Vol 05.03.

4

acetylene flame.

Annual Book of ASTM Standards, Vol 11.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

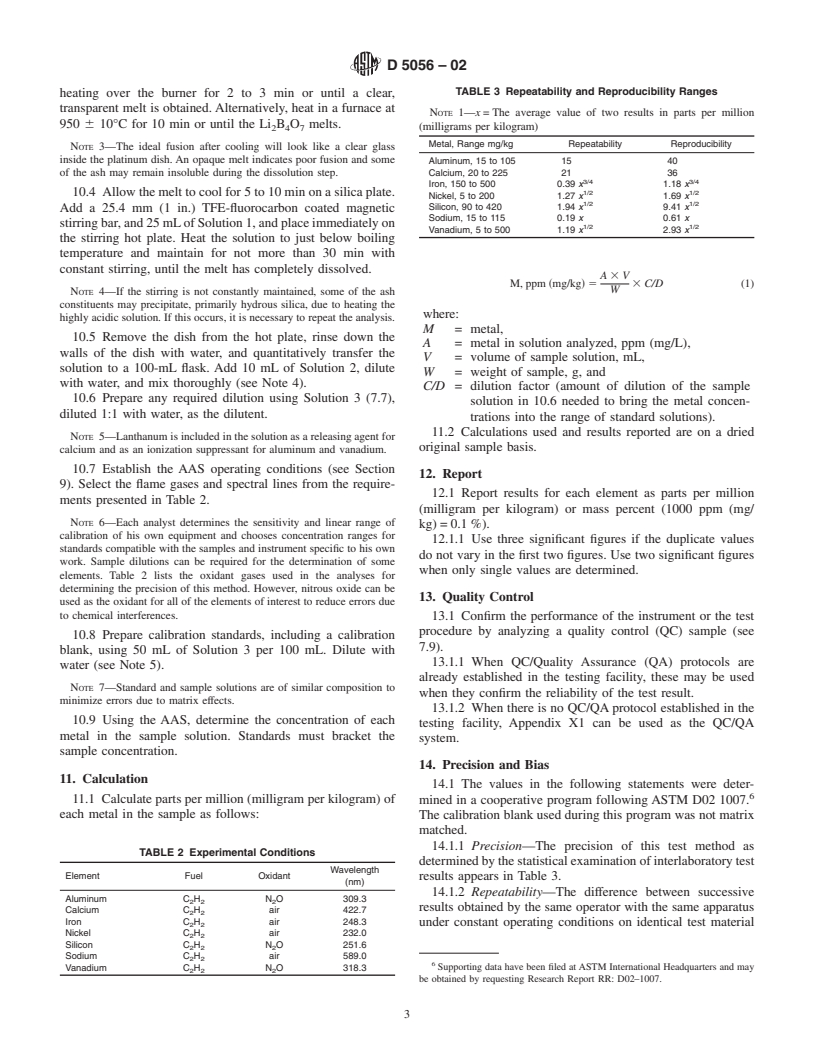

D5056–02

6.7.3 Burner Head, single or multiple-slot, capable of sup- <1.0 to 50 ppm (mg/L). Working standards containing alumi-

porting an air-acetylene flame. num, calcium, iron, nickel, silicon, sodium, and vanadium in

6.7.4 Hollow Cathode Lamps, one for each of the elements concentration ranges below 10 ppm (mg/kg) are to be prepared

to be analyzed: aluminum, calcium, iron, nickel, silicon, daily to ensure stability.

sodium, and vanadium. 7.9 Quality Control (QC) Samples, preferably are portions

of one or mor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.