ASTM F2169-02(2008)

(Specification)Standard Specification for Resilient Stair Treads

Standard Specification for Resilient Stair Treads

ABSTRACT

This specification covers resilient stair treads made of rubber and thermoplastic vinyl for interior use. Treads covered by this specification includes the following types, class, and groups: Type TS, Type TP, Type TV, Class 1, Class 2, Group 1, and Group 2. The material requirements for the tread surface design, nosing style, and color are specified. Some typical nosing styles are illustrated. Treads shall meet the specified performance requirements for: (1) hardness, (2) molded stair tread bonding surface, (3) tread backs, (4) resistance to chemicals for short-term exposure, (5) resistance to heat, and (6) resistance to light. The prescribed dimensional requirements includes tread thickness, length, and depth. The sampling methods for the physical property tests are specified.

SCOPE

1.1 This specification covers resilient treads made of rubber and vinyl for interior use.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: F2169 – 02 (Reapproved 2008)

Standard Specification for

Resilient Stair Treads

This standard is issued under the fixed designation F2169; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This specification covers resilient treads made of rubber 3.1 Material Definitions:

and vinyl for interior use. 3.1.1 rubber, thermoplastic—The polymeric binder of this

1.2 The values stated in inch-pound units are to be regarded compound shall satisfy the definition of rubber, but remain

as the standard. The values given in parentheses are for thermoplastic, as defined in Terminology D883.

information only. 3.1.2 rubber, vulcanized thermoset—the polymeric binder

1.3 This standard does not purport to address all of the of this compound shall satisfy the definition of rubber, and

safety concerns, if any, associated with its use. It is the have been vulcanized, as defined in Terminology D1566.

responsibility of the user of this standard to establish appro- 3.1.3 vinyl, thermoplastic—The polymeric binder of this

priate safety and health practices and determine the applica- compoundshallsatisfythedefinitionofpoly(vinylchloride)in

bility of regulatory requirements prior to use. Terminology D883 and Specification D1755 but remain ther-

moplastic as defined in Terminology D883.

2. Referenced Documents

4. Classification

2.1 The following documents of the issue in effect on the

dateofthematerialpurchaseformapartofthisspecificationto 4.1 Treads covered by this specification will be of the

the extent referenced herein: following types (compositions), class, and groups, as specified.

2.2 ASTM Standards:

Type TS Rubber, Vulcanized Thermoset

Type TP Rubber, Thermoplastic

D883 Terminology Relating to Plastics

Type TV Vinyl, Thermoplastic

D1566 Terminology Relating to Rubber

Class 1 Smooth (Flat)

D1755 Specification for Poly(Vinyl Chloride) Resins Class 2 Pattern: Embossed, Grooved, or Ribbed

Group 1 Abrasive Strips: Embedded

D2240 Test Method for Rubber Property—Durometer

Group 2 Contrasting Color for Visually Impaired

Hardness

F386 Test Method for Thickness of Resilient Flooring

5. Ordering Information

Materials Having Flat Surfaces

5.1 Purchasers shall state whether this specification is to be

F925 Test Method for Resistance to Chemicals of Resilient

used, select the preferred options permitted herein, and include

Flooring

the following information in the invitation to bid or purchase

F1514 Test Method for Measuring Heat Stability of Resil-

order:

ient Flooring by Color Change

5.1.1 Title, number, and date of this specification.

F1515 Test Method for Measuring Light Stability of Resil-

5.1.2 Type, class, nosing style (see Sections 4 and 6).

ient Flooring by Color Change

5.1.3 Color (see 6.4).

2.3 ANSI Standard:

5.1.4 Quantity, in pieces, linear feet, or cartons.

ANSI/ASQC Z1.4-2003 Sampling Procedures and Tables

5.1.5 Thickness required (see 8.2).

for Inspection by Attributes

5.1.6 Length required (see 8.3).

5.1.7 Lot information, if other than as specified in ANSI/

ASQC Z1.4-2003 (see 10.1 and 11.1).

This specification is under the jurisdiction of ASTM Committee F06 on

Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80 5.1.8 Sampling, if other than as specified in ANSI/ASQC

on Specifications.

Z1.4-2003 (see 10.1).

Current edition approved March 1, 2008. Published April 2008. Originally

5.1.9 Statement requesting certification, if certification of

approved in 2002. Last previous edition approved in 2002 as F2169-02. DOI:

compliance is required (see Section 12).

10.1520/F2169-02R08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1.10 Packing requirement, if other than as specified (see

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Section 14).

Standards volume information, refer to the standard’s Document Summary page on

5.1.11 Palletization, if required.

the ASTM website.

Available from American National Standards Institute, 25 W. 43rd St., 4th

Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

F2169 – 02 (2008)

5.1.12 Markingrequired,ifotherthanspecified(seeSection

13).

5.1.13 Other requirements.

6. Materials and Manufacture

6.1 Standard Commercial Product—A tread of the same FIG. 2 Square Nose

classification shall, as a minimum, be in accordance with the

requirements of this specification and shall be the manufactur-

er’s standard commercial product. A standard commercial

product is a product that has been sold or is currently being

offered for sale on the commercial market through advertise-

ments, manufacturer’s catalogs, or brochures and represents

the latest production model.

6.2 Tread Design—The upper surface of tread shall have

one or a combination of the following:

Class 1 Smooth (Flat)

Class 2 Pattern: Embossed, Grooved, or Ribbed

Group 1 Abrasive Strips: Embedded

Group 2 Contrasting Color for Visually Impaired

6.2.1 Class 1, Smooth (Flat)—The tread surface shall be

smooth and flat.

FIG. 3 With Riser

6.2.2 Class 2, Pattern: Embossed, Grooved, or Ribbed—

When the surface is embossed, grooved or ribbed, the depth of

the design shall not be greater than 50 % of the overall 7.3 Tread Backs—Unlessotherwisespecifiedinthecontract

or order, the back or bonding surface of the rubber tread shall

thickness of the tread.

6.2.3 Group 1, Abrasive Strips (Embedded)—When speci- be sanded, buffed, roughened, ribbed/grooved, or otherwise

modified to ensure proper adhesion.

fied, one or more mineral-coated abrasive grit strips, each strip

not less than 0.030-in. (0.76 mm) thick, shall be recessed into 7.4 Resistance to Chemicals, Short-Term Exposure—When

tested in accordance with Test Method F925, the vinyl and

andadheredtothetopsurfaceofasmoothsurfacetreadportion

to form a continuous flat surface overall. Each strip shall run rubbertreadsshallhavenomorethanaslightchangeinsurface

dulling, surface attack, or staining when exposed to the

the full length of the treads and shall be parallel to the nose of

thetread.Thefrontedgeofthefirststripshallbenotmorethan following chemicals:

1 in. (25.4 mm) from the nose of the step or landing. If a White Vinegar (5 % Acetic Acid)

3 1

Rubbing Alcohol (70 % Isopropyl Alcohol)

second strip is used, it shall be ⁄4 (19 mm) to 1 ⁄2 in. (38 mm)

White Mineral Oil (Medicinal Grade)

from the first strip.

Sodium Hydroxide Solution (5 % NaOH)

6.2.4 Group 2, Contrasting Color for Visually Impaired— Hydrochloric Acid Solution (5 % HCl)

Sulfuric Acid Solution (5 % H SO )

2 4

The tread shall contain a strip of contrasting color of either the

Household Ammonia Solution (5 % NH OH)

same material or an abrasive material.

Household Bleach Solution (5.25 % NaOCl)

6.3 Nosing Style—Nosing style shall be as specified (see

Olive Oil (light)

Unleaded Gasoline (regular grade)

Figs. 1-3 for some typical styles).

Disinfectant Cleaner (5 % Phenol)

6.4 Color—According to manufacturer’s latest catalogs,

Kerosene (K1)

and actual samples. Sample color may vary with age and

NOTE 1—These basic chemicals are representative of those likely to be

storage conditions.

found in domestic, commercial, and institutional use. Many proprietary

compounds contain one or more of these basic chemicals. Should the

7. Perform

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F2169–02 Designation: F 2169 – 02 (Reapproved 2008)

Standard Specification for

Resilient Stair Treads

This standard is issued under the fixed designation F 2169; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers resilient treads made of rubber and vinyl for interior use.

1.2 Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformation

only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

requirements prior to use.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of the material purchase form a part of this specification to the

extent referenced herein:

2.2 ASTM Standards:

D883Terminology Relating to Plastics

D1566Terminology Relating to Rubber

D1755Specification on Poly (Vinyl Chloride) Resins

D2240Test Method for Rubber Property—Durometer Hardness

F386Test Method for Thickness of Resilient Flooring Having Flat Surfaces

F925Test Method for Resistance to Chemicals of Resilient Flooring

F1514Test Method for Measuring Heat Stability of Resilient Vinyl Flooring by Color Change

F1515Test Method for Measuring Light Stability of Resilient Flooring by Color Change

D 883 Terminology Relating to Plastics

D 1566 Terminology Relating to Rubber

D 1755 Specification for Poly(Vinyl Chloride) Resins

D 2240 Test Method for Rubber PropertyDurometer Hardness

F 386 Test Method for Thickness of Resilient Flooring Materials Having Flat Surfaces

F 925 Test Method for Resistance to Chemicals of Resilient Flooring

F 1514 Test Method for Measuring Heat Stability of Resilient Flooring by Color Change

F 1515 Test Method for Measuring Light Stability of Resilient Flooring by Color Change

2.3 ANSI Standard:

ANSI/ASQC Z1.4-1993ANSI/ASQC Z1.4-2003 Sampling Procedures and Tables for Inspection by Attributes

3. Terminology

3.1 Material Definitions:

3.1.1 rubber, thermoplastic—The polymeric binder of this compound shall satisfy the definition of rubber, but remain

thermoplastic, as defined in Terminology D 883.

3.1.2 rubber, vulcanized thermoset—the polymeric binder of this compound shall satisfy the definition of rubber, and have been

vulcanized, as defined in Terminology D 1566.

3.1.3 vinyl, thermoplastic—The polymeric binder of this compound shall satisfy the definition of poly (vinyl chloride) in

This specification is under the jurisdiction of ASTM Committee F06 on Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80 on

Specifications.

Current edition approved March 10, 2002. Published May 2002.

Current edition approved March 1, 2008. Published April 2008. Originally approved in 2002. Last previous edition approved in 2002 as F 2169-02.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 09.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 15.04.

Available from American National Standards Institute, 25 W. 43rd St., 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 2169 – 02 (2008)

Terminology D 883 and Specification D 1755 but remain thermoplastic as defined in Terminology D 883.

4. Classification

4.1 Treads covered by this specification will be of the following types (compositions), class, and groups, as specified.

Type TS Rubber, Vulcanized Thermoset

Type TP Rubber, Thermoplastic

Type TV Vinyl, Thermoplastic

Class 1 Smooth (Flat)

Class 2 Pattern: Embossed, Grooved, or Ribbed

Group 1 Abrasive Strips: Embedded

Group 2 Contrasting Color for Visually Impaired

5. Ordering Information

5.1 Purchasers shall state whether this specification is to be used, select the preferred options permitted herein, and include the

following information in the invitation to bid or purchase order:

5.1.1 Title, number, and date of this specification.

5.1.2 Type, class, nosing style (see Sections 4 and 6).

5.1.3 Color (see 6.4).

5.1.4 Quantity, in pieces, linear feet, or cartons.

5.1.5 Thickness required (see 8.2).

5.1.6 Length required (see 8.3).

5.1.7 Lot information, if other than as specified in ANSI/ASQC Z1.4-1993Z1.4-2003 (see 10.1 and 11.1).

5.1.8 Sampling, if other than as specified in ANSI/ASQC Z1.4-1993Z1.4-2003 (see 10.1).

5.1.9 Statement requesting certification, if certification of compliance is required (see Section 12).

5.1.10 Packing requirement, if other than as specified (see Section 14).

5.1.11 Palletization, if required.

5.1.12 Marking required, if other than specified (see Section 13).

5.1.13 Other requirements.

6. Materials and Manufacture

6.1 Standard Commercial Product—A tread of the same classification shall, as a minimum, be in accordance with the

requirements of this specification and shall be the manufacturer’s standard commercial product. A standard commercial product

is a product that has been sold or is currently being offered for sale on the commercial market through advertisements,

manufacturer’s catalogs, or brochures and represents the latest production model.

6.2 Tread Design—The upper surface of tread shall have one or a combination of the following:

Class 1 Smooth (Flat)

Class 2 Pattern: Embossed, Grooved, or Ribbed

Group 1 Abrasive Strips: Embedded

Group 2 Contrasting Color for Visually Impaired

6.2.1 Class 1, Smooth (Flat)—The tread surface shall be smooth and flat.

6.2.2 Class 2, Pattern: Embossed, Grooved, or Ribbed —When the surface is embossed, grooved or ribbed, the depth of the

design shall not be greater than 50 % of the overall thickness of the tread.

6.2.3 Group 1,Abrasive Strips (Embedded)—Whenspecified,oneormoremineral-coatedabrasivegritstrips,eachstripnotless

than 0.030-in. (0.76 mm) thick, shall be recessed into and adhered to the top surface of a smooth surface tread portion to form a

continuous flat surface overall. Each strip shall run the full length of the treads and shall be parallel to the nose of the tread. The

front edge of the first strip shall be not more than 1 in. (25.4 mm) from the nose of the step or landing. If a second strip is used,

3 1

it shall be ⁄4 (19 mm) to 1 ⁄2 in. (38 mm) from the first strip.

6.2.4 Group 2, Contrasting Color for Visually Impaired —The tread shall contain a strip of contrasting color of either the same

material or an abrasive material.

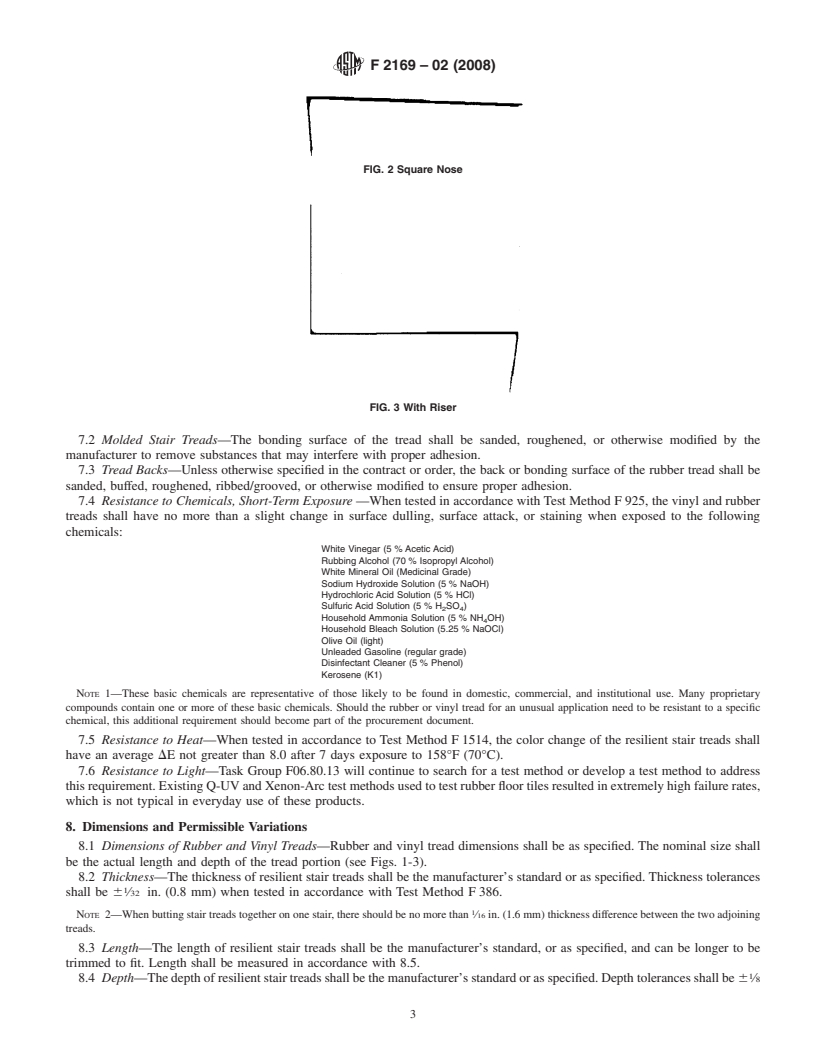

6.3 Nosing Style—Nosing style shall be as specified (see Figs. 1-3 for some typical styles).

6.4 Color—According to manufacturer’s latest catalogs, and actual samples. Sample color may vary with age and storage

conditions.

7. Performance Requirements

7.1 Hardness—Treads shall meet a Shore A Durometer reading of not less than 85 when tested according to Test Method

D 2240.

FIG. 1 Round Nose

F 2169 – 02 (2008)

FIG. 2 Square Nose

FIG. 3 With Riser

7.2 Molded Stair Treads—The bonding surface of the tread shall be sanded, roughened, or otherwise modified by the

manufacturer to remove substances that may interfere with proper adhesion.

7.3 Tread Backs—Unless otherwise specified in the contract or order, the back or bonding surface of the rubber tread shall b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.