ASTM E795-00

(Practice)Standard Practices for Mounting Test Specimens During Sound Absorption Tests

Standard Practices for Mounting Test Specimens During Sound Absorption Tests

SCOPE

1.1 These practices cover test specimen mountings to be used during sound absorption tests performed in accordance with Test Method C423.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E795–00

Standard Practices for

Mounting Test Specimens During Sound Absorption Tests

This standard is issued under the fixed designation E 795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope the room construction requirements of Test Method C 423.In

most cases, the surface will be the floor of the reverberation

1.1 These practices cover test specimen mountings to be

room.

used during sound absorption tests performed in accordance

with Test Method C 423.

4. Significance and Use

1.2 The values stated in SI units are to be regarded as the

4.1 The sound absorption of a material that covers a flat

standard. The values given in parentheses are for information

surface depends not only on the physical properties of the

only.

material but also on the way in which the material is mounted

2. Referenced Documents over the surface.The mountings specified in these practices are

intended to simulate in the laboratory conditions that exist in

2.1 ASTM Standards:

normal use.

C 423 Test Method for Sound Absorption and Sound Ab-

4.2 Some of the specified mountings require special fixtures

sorption Coefficients by the Reverberation Room Method

or minor deviations from normal practice. These fixtures or

C 634 Terminology Relating to Environmental Acoustics

deviations are to be used only during laboratory tests and

2.2 ISO Standard:

should not be specified for practical installations. They are

ISO 354 Measurement of SoundAbsorption in a Reverbera-

noted in the specifications for the mountings in question by the

tion Room

phrase “for laboratory testing only.”

3. Terminology

4.3 Test reports may refer to these mountings by type

designation instead of providing a detailed description of the

3.1 Definitions of Terms Specific to This Standard:

mounting used.

3.1.1 Except as noted in 4.2, the terms used in these

practices are defined in Terminology C 634.

5. Classification

3.2 The following terms have the meaning noted for these

5.1 The mountings are designated as follows:

practices only:

5.1.1 Type A Mounting—Test specimen laid directly against

3.2.1 sound-absorbing units — consists of test specimens

the test surface (described in detail in Section 6).

that are in direct contact with or suspended from ceilings,

5.1.2 Type B Mounting—Test specimen cemented to gyp-

walls, or other room surfaces. Sound-absorbing units include,

sum board and laid directly against the test surface (described

but are not limited to, baffles, draperies, space absorbers,

in detail in Section 7).

volume absorbers (bass traps), and other three-dimensional

5.1.3 Type C Mounting—Test specimen comprising sound-

objects.

absorptive material behind a perforated, expanded, open facing

3.2.2 test surface—any hard surface over which the test

or other porous material (described in detail in Section 8).

specimen or test specimen mounting is placed for testing in

5.1.4 Type D Mounting—Test specimen mounted on wood

accordance with Test Method C 423. The surface shall satisfy

furring strips (described in detail in Section 9).

5.1.5 Type E Mounting—Test specimen mounted with an air

space behind it (described in detail in Section 10).

These practices are under the jurisdiction of ASTM Committee E-33 on

5.1.6 Type G Mounting—Test specimen is a drapery, win-

Environmental Acoustics and are the direct responsibility of Subcommittee E33.01

dow shade, or blind hung parallel to the test surface (described

on Sound Absorption.

Current edition approved May 10, 2000. Published August 2000. Originally

in detail in Section 11).

published as E 795 – 81. Last previous edition E 795 – 93.

5.1.7 Type H Mounting—Test specimen is a drapery sus-

Annual Book of ASTM Standards, Vol 04.06.

pended away from any vertical surface (described in detail in

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036. Section 12).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E795–00

5.1.8 Type I Mounting—The specimen is a spray- or trowel- between the bottom of the frame and the test surface shall be

applied material on an acoustically hard substrate (described in sealed with duct tape or caulking.

detail in Section 13).

NOTE 1—The Type A mounting is intended to simulate normal use

5.1.9 Type J Mounting—The specimen is a sound-absorbing

where a product, such as carpet, wall panels, or ceiling tile is either laid

unit or set of sound-absorbing units (described in detail in

directly on the floor or attached to a wall or ceiling with adhesive or

Section 14). mechanical fasteners. Panels or tile may be arranged in a pattern that

simulates their actual installation, but the arrangement shall be explicitly

5.1.10 Type K Mounting—Test specimen is an office screen

noted and described in the report.

(described in detail in Section 15).

5.1.11 Type L Mounting—This mounting is for use with

7. Type B Mounting

concrete blocks or block-like specimens that are normally

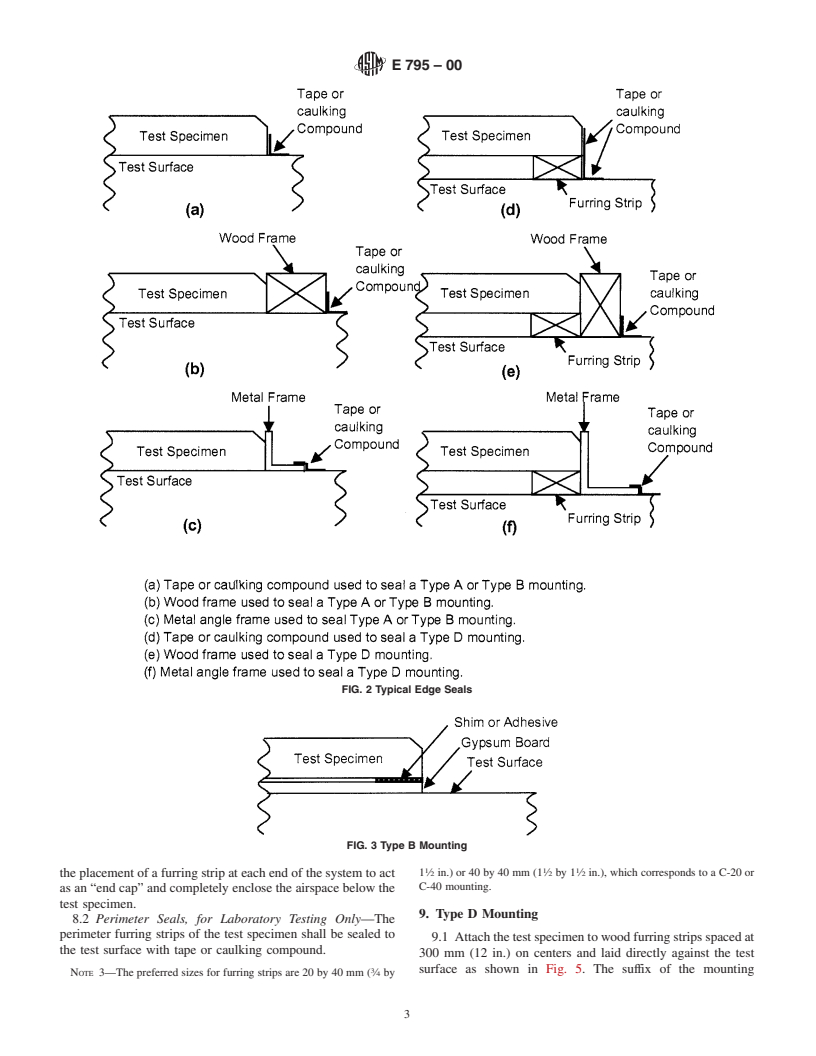

7.1 Adhere the test specimen to gypsum board laid directly

assembled using mortar (described in detail in Section 16).

against the test surface as shown in Fig. 3. The thickness of the

5.2 Type C, D, E, and G mountings are further designated

gypsum board is not critical.

by a numerical suffix which indicates the distance (in millime-

7.2 Apply the adhesive in accordance with the manufactur-

tres) from the specimen to the test surface rounded to the

er’sinstructions.Iftherearenospecificinstructions,applyfour

nearest integral multiple of 5 mm. For example, a Type E-400

daubs of adhesive to the back of each piece of the test

mounting is a plenum mounting in which the face of the test

specimen.

specimen is 400 mm (15 ⁄4 in.) away from the test surface. The

7.3 For Laboratory Testing Only—Place 3 by 25 by 25-mm

distances specified by the suffixes are as follows:

( ⁄8 by 1 by 1-in.) hardboard shims between the test specimen

5.2.1 For a Type C Mounting—The thickness of the furring

and the gypsum board at the four corners of each piece of test

strips.

specimen.

5.2.2 For a Type D Mounting—The thickness of the furring

7.4 Perimeter Seals, for Laboratory Testing Only—Seal the

strips.

perimeter edges of the test specimen by one of the following

5.2.3 For a Type E Mounting—The distance from the

methods:

exposed face of the test specimen to the test surface.

7.4.1 Cover with tape, caulking compound, or a similar

5.2.4 For a Type G Mounting—The distance from the

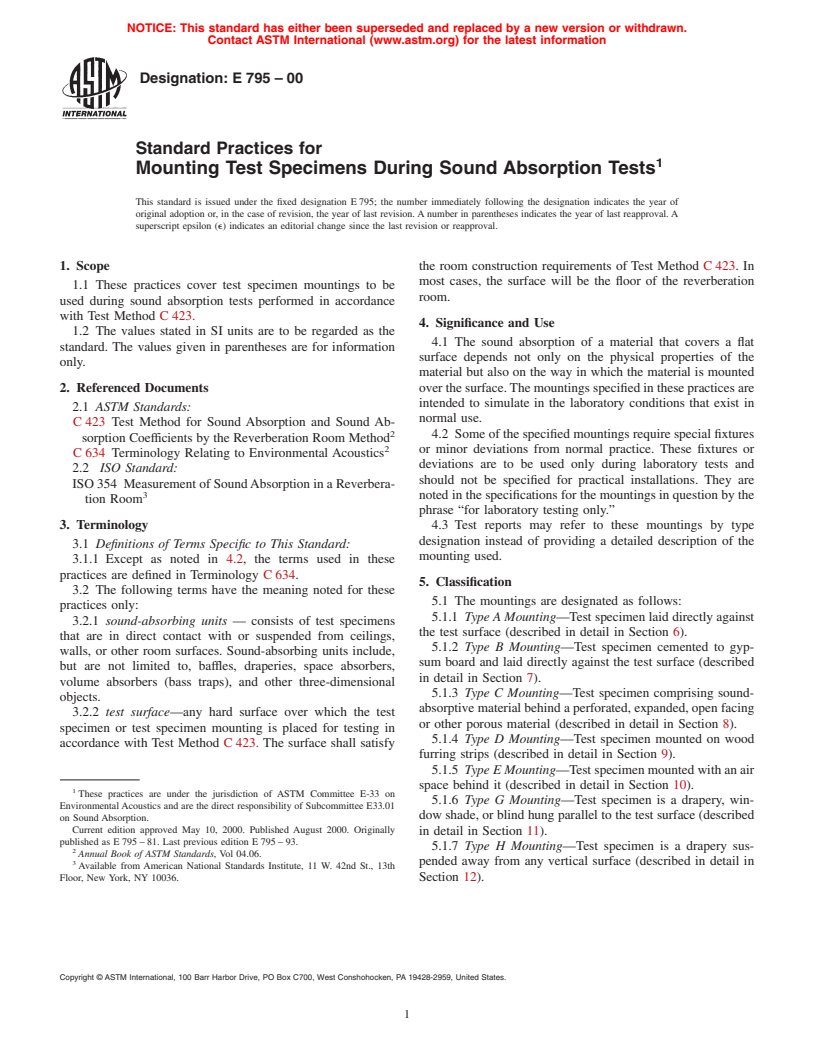

product as shown in Fig. 2.

centerline of the hangers to the test surface.

7.4.2 Cover with a wood or metal frame so that the top

surface of the frame is flush with the front face of the test

6. Type A Mounting

specimen as shown in Fig. 2. Minimize air spaces between the

6.1 Lay the test specimen directly against the test surface as

frame and the perimeter edge of the test specimen. Air gaps

shown in Fig. 1.

between the bottom of the frame and the test surface shall be

6.2 Do not use an adhesive that is likely to leave a thin air

sealed with duct tape or caulking.

space behind the test specimen. However, mechanical fasten-

ers, carpet tape, or contact cement may be used to hold the

NOTE 2—The Type B mounting is intended to simulate acoustical

ceiling tiles or other sound-absorptive products adhered to a hard surface

specimen against a vertical or overhead surface or to keep the

with an adhesive. In normal use, this method of application leaves a thin

specimen in contact with the floor.

air space between the product and the surface to which it is adhered. The

6.3 Iftwoormorepiecesofmaterial(orseparatepanels)are

3-mm ( ⁄8-in.) thick hardboard shims are used to control the depth of the

butted together to form the test specimen, it may be advisable

air space during laboratory tests and should not be included in a normal

to cover the joints between adjacent pieces with tape, caulking

installation.

compound, or other material that is not sound absorptive. If the

8. Type C Mounting

joints are sealed in this manner, the test report shall describe

the method of sealing. 8.1 The test specimen shall comprise sound-absorptive ma-

6.4 Perimeter Seals for Laboratory Testing Only—If the terial behind a perforated, expanded, open facing, or other

perimeter edges of the test specimen are not exposed in normal porous material attached to wood furring strips spaced 600 mm

use, seal them by one of the following two methods: (24 in.) on centers and laid directly against the test surface as

6.4.1 Cover with tape, caulking compound, or a similar shown in Fig. 4. The suffix of the mounting designation shall

product as shown in Fig. 2.

be the actual thickness of the furring strips rounded to the

6.4.2 Cover with a wood or metal frame so that the top nearest integral multiple of 5 mm.

surface of the frame is flush with the front face of the test

8.1.1 The length of the furring strips described in 8.1 shall

specimen as shown in Fig. 2. Minimize air spaces between the be shorter than the length of the test specimen by an amount

frame and the perimeter edge of the test specimen. Air gaps

equal to twice the width of the furring strips. This will allow

FIG. 1 Type A Mounting

E795–00

FIG. 2 Typical Edge Seals

FIG. 3 Type B Mounting

1 1 1

1 ⁄2 in.) or 40 by 40 mm (1 ⁄2 by 1 ⁄2 in.), which corresponds to a C-20 or

the placement of a furring strip at each end of the system to act

C-40 mounting.

as an “end cap” and completely enclose the airspace below the

test specimen.

9. Type D Mounting

8.2 Perimeter Seals, for Laboratory Testing Only—The

perimeter furring strips of the test specimen shall be sealed to

9.1 Attachthetestspecimentowoodfurringstripsspacedat

the test surface with tape or caulking compound.

300 mm (12 in.) on centers and laid directly against the test

3 surface as shown in Fig. 5. The suffix of the mounting

NOTE 3—The preferred sizes for furring strips are 20 by 40 mm ( ⁄4 by

E795–00

FIG. 4 Type C Mounting

FIG. 5 Type D Mounting

designation shall be the actual thickness of the furring strips frame and the perimeter edge of the test specimen. Air gaps

rounded to the nearest integral multiple of 5 mm. between the bottom of the frame and the test surface shall be

9.1.1 The length of the furring strips described in 9.1 shall sealed with duct tape or caulking.

be shorter than the length of the test specimen by an amount

3 1

NOTE 4—Thepreferredsizeforfurringstripsis20by40mm( ⁄4by1 ⁄2

equal to twice the width of the furring strips. This will allow

in.). This is a D-20 mounting.

the placement of a furring strip at each end of the system to act

as an “end cap” and completely enclose the airspace below the

10. Type E Mounting

test specimen.

10.1 Mount the test specimen in a fixture that supports the

9.2 Perimeter Seals, for Laboratory Testing Only—Seal the

exposed face of the specimen at a designated distance from the

perimeter edges of the test specimen by one of the following

test surface as shown in Fig. 6. The suffix of the mounting

methods:

designation shall be the distance between the exposed face of

9.2.1 Cover with tape, caulking compound, or a similar

the specimen and the test surface rounded to the nearest

product as shown in Fig. 2.

integral multiple of 5 mm.

9.2.2 Cover with a wood or metal frame so that the top

surface of the frame is flush with the front face of the test 10.2 Mounting Fixture for Laboratory Testing Only—The

specimen as shown in Fig. 2. Minimize air spaces between the mounting fixture shall satisfy the following requirements:

FIG. 6 Type E Mounting

E795–00

10.2.1 The mounting fixture, test specimen, and test surface 11.2 Attach the hangers to a solid beam or plank that is

shall enclose an air space that has no interior partitions. butted against the test surface as shown in Fig. 7. The beam or

10.2.2 The joint between the fixture and the test surface plank should prevent sound waves from passing over the top of

shall be sealed to prevent air leaks between the enclosed space the test specimen, into or out of the space behind it.

and the outside.

NOTE 8—The preferred distance between the centerline of the hangers

10.2.3 The fixture shall include a rigid grid system that

and the test surface is 75 mm (3 in.). If another distance is used, it should

supports the exposed face of the test specimen at the required

be an integral multiple of 25 mm.

distance from the test surface. The distance from the exposed

face of the test specimen (excluding decorative features) to the

12. Type H Mounting

test surface shall not vary by more than 5 mm (0.20 in.), across

12.1 The test specimen shall be a drapery. The distance

the entire face of the specimen.

between the suspended drapery and any vertical surface,

10.2.4 The fixture shall seal the perimeter edges of the test

rotating vane, or diffuser panel shall be consistent with the

specimen, and the top surface of the fixture shall be flush with

requirements of Test Method C 423. The drapery shall not be

the front face of the test specimen as shown in Fig. 6.

parallel to any wall as shown in Fig. 8.

10.2.5 The mounting fixture shall be made of a sturdy

material, such as 20-mm ( ⁄4-in.) thick plywood or 3-mm NOTE 9—Type H mountings are intended to simulate draperies used as

sound-absorbing units.

( ⁄8-in.) thick aluminum.

10.2.6 If a grid system is placed between the panels, on the

13. Type I Mounting

exposed side of the specimen, the grid size and arrangement

shall be noted in the report. 13.1 Spray or trowel the material to be tested on to a

substrate that satisfies the following conditions:

NOTE 5—Type E mountings are intended to simulate a suspended

13.1.1 The substrate shall be no more than 25 mm (1 in.)

ceiling with an open plenum above it.

thick.

NOTE 6—When there is good reason to test on aType E mounting other

than Type E-400, a mounting whose suffix is an integral multiple of 25 is

13.1.2 The sound absorption coefficients of the substrate

preferred (for example, E-375, E-425, and so forth).

shall be less than 0.05 in each frequency band when tested on

NOTE 7—It has been found that if a gasket is used between the test

a Type A mounting in accordance with Test Method C 423.

fixture and the test surface, placing the gasket so that it is flush with the

13.1.3 The substrate shall not cup or wrap after the material

exterior surface of the test fixture will minimized the variability in results.

has been applied.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.