ASTM F2592-06

(Test Method)Standard Test Method for Measuring the Force-Displacement of a Membrane Switch

Standard Test Method for Measuring the Force-Displacement of a Membrane Switch

SCOPE

1.1 This test method covers the measurement of force displacement characteristics of a membrane switch.

1.2 Hysteresis (force-displacement) curve can be used in the determination of Actuation Force, Displacement, Contact Force, Restoration Force, and Tactile Response Slope.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2592–06

Standard Test Method for

Measuring the Force-Displacement of a Membrane Switch

This standard is issued under the fixed designation F 2592; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.11 Fmin—an applied force, minimum force seen be-

tween Fmax and point at which probe movement ceases.

1.1 This test method covers the measurement of force

2.1.11.1 Discussion—Fmax can equal Fmin.

displacement characteristics of a membrane switch.

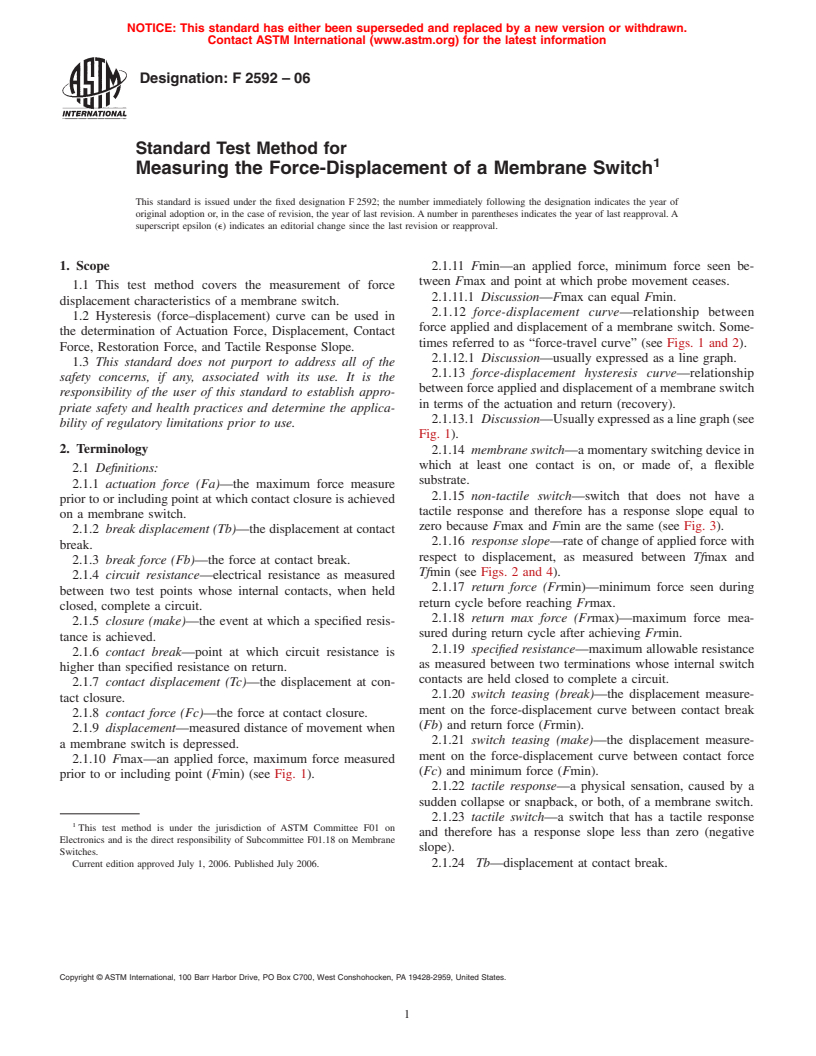

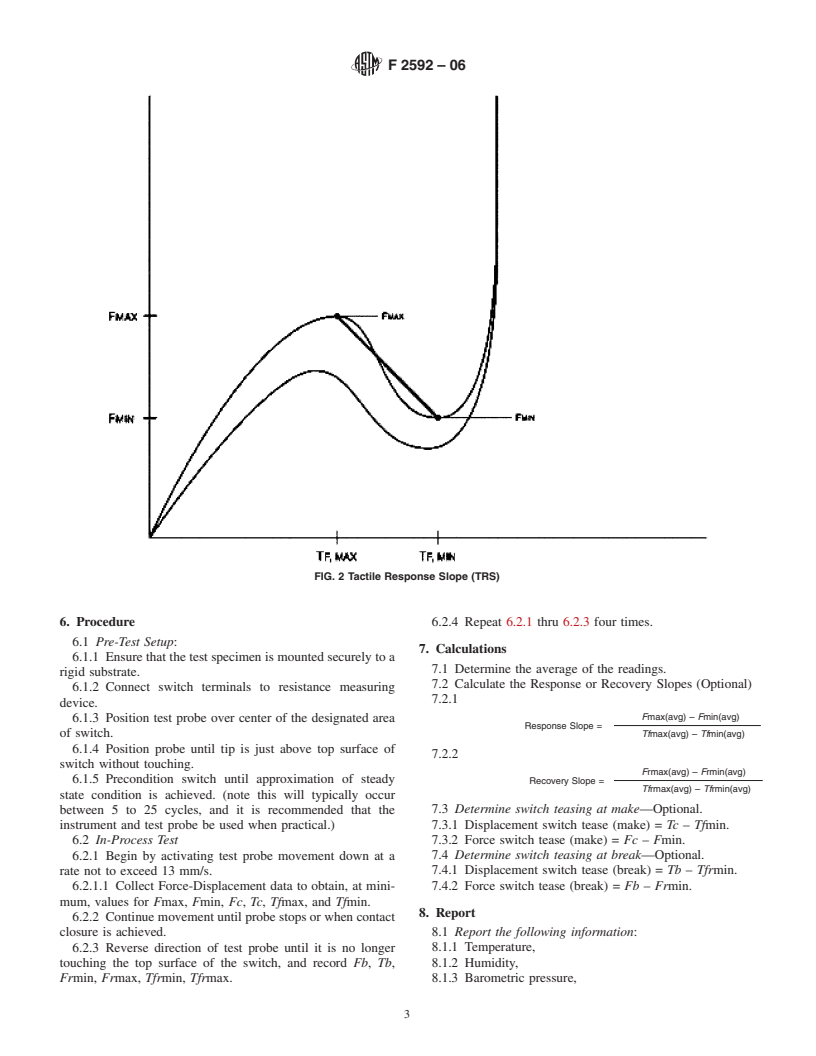

2.1.12 force-displacement curve—relationship between

1.2 Hysteresis (force–displacement) curve can be used in

force applied and displacement of a membrane switch. Some-

the determination of Actuation Force, Displacement, Contact

times referred to as “force-travel curve” (see Figs. 1 and 2).

Force, Restoration Force, and Tactile Response Slope.

2.1.12.1 Discussion—usually expressed as a line graph.

1.3 This standard does not purport to address all of the

2.1.13 force-displacement hysteresis curve—relationship

safety concerns, if any, associated with its use. It is the

between force applied and displacement of a membrane switch

responsibility of the user of this standard to establish appro-

in terms of the actuation and return (recovery).

priate safety and health practices and determine the applica-

2.1.13.1 Discussion—Usually expressed as a line graph (see

bility of regulatory limitations prior to use.

Fig. 1).

2. Terminology

2.1.14 membrane switch—a momentary switching device in

which at least one contact is on, or made of, a flexible

2.1 Definitions:

substrate.

2.1.1 actuation force (Fa)—the maximum force measure

2.1.15 non-tactile switch—switch that does not have a

prior to or including point at which contact closure is achieved

tactile response and therefore has a response slope equal to

on a membrane switch.

zero because Fmax and Fmin are the same (see Fig. 3).

2.1.2 break displacement (Tb)—the displacement at contact

2.1.16 response slope—rate of change of applied force with

break.

respect to displacement, as measured between Tfmax and

2.1.3 break force (Fb)—the force at contact break.

Tfmin (see Figs. 2 and 4).

2.1.4 circuit resistance—electrical resistance as measured

2.1.17 return force (Frmin)—minimum force seen during

between two test points whose internal contacts, when held

return cycle before reaching Frmax.

closed, complete a circuit.

2.1.18 return max force (Frmax)—maximum force mea-

2.1.5 closure (make)—the event at which a specified resis-

sured during return cycle after achieving Frmin.

tance is achieved.

2.1.19 specified resistance—maximum allowable resistance

2.1.6 contact break—point at which circuit resistance is

as measured between two terminations whose internal switch

higher than specified resistance on return.

contacts are held closed to complete a circuit.

2.1.7 contact displacement (Tc)—the displacement at con-

2.1.20 switch teasing (break)—the displacement measure-

tact closure.

ment on the force-displacement curve between contact break

2.1.8 contact force (Fc)—the force at contact closure.

(Fb) and return force (Frmin).

2.1.9 displacement—measured distance of movement when

2.1.21 switch teasing (make)—the displacement measure-

a membrane switch is depressed.

ment on the force-displacement curve between contact force

2.1.10 Fmax—an applied force, maximum force measured

(Fc) and minimum force (Fmin).

prior to or including point (Fmin) (see Fig. 1).

2.1.22 tactile response—a physical sensation, caused by a

sudden collapse or snapback, or both, of a membrane switch.

2.1.23 tactile switch—a switch that has a tactile response

This test method is under the jurisdiction of ASTM Committee F01 on

and therefore has a response slope less than zero (negative

Electronics and is the direct responsibility of Subcommittee F01.18 on Membrane

slope).

Switches.

Current edition approved July 1, 2006. Published July 2006. 2.1.24 Tb—displacement at contact break.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2592–06

NOTE—Area between forward and return curves is the difference in work by the tactile mechanism showing hysterisis in the tactile system.

FIG. 1 Force Displacement Hysterisis Loop

2.1.25 Tfmax—Displacement at Fmax. 4. Interferences

2.1.26 Tfmin—Displacement at Fmin.

4.1 Results compared between a manual system and auto-

mated system can be significant based on the response time of

2.1.27 Tfrmax—displacement at Frmax.

operator and the equipment.

2.1.28 Tfrmin—displacement at Frmin.

4.2 Theswitchsampleshouldbemountedonarigidsupport

in order to get a more accurate representation of the force and

3. Significance and Use

displacement (travel).

3.1 The force and displacement values when converted to a

slope are useful in quantifying the differences in tactile

5. Apparatus

response among membrane switches.

5.1 Test Probe, made of non-elastic material with a circular

3.2 Specified resistance is useful to manufacturers and users

flat tip with

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.